Global Mercury Project

Environmental Assessment in

two Small Scale Gold Mining

Areas in Indonesia

Biogeochemical Aspects

Saulo Rodrigues-Filho et al. (2004)

Country Task Force Meeting

Global Mercury Project GEF-UNDP-UNIDO

Dec 14th to 15th 2004, Jakarta, Indonesia

Project Staff

UNIDO Project Coordination Unit

University of Munich

Christian Beinhoff Chief Technical

Institute of Forensic

Advisor

Medicine

Pablo Huidobro Project Manager

Stephan Boese O“Reilly

Marcello Veiga Small Scale Mining

Stefan Maydl

Expert

Alexandra Dittmann

CETEM Centre for Mineral Technology Sven Illig

Saulo Rodrigues Filho Team Leader

Gustav Drash

Roberto Villas Bōas

Zuleica C. Castilhos

UNIDO OFFICE JAKARTA

Ronaldo L. C. dos Santos

Mr. Masayoshi Matsushita

Allegra Viviane Yallouz

Country Focal Point

Bernhard Peregovich

Mr. Thamrin Sihite

Silvia Egler

Assistant of Country

Flavia M. F. Nascimento

Focal Point

Luiz Roberto Pedroso

Ms. Selinawati

OUTLINE

· Objetives

· Materials and Methods

· Description of the study areas

· Mining and Processing Techniques

· Results of the Environmental Assessment

· Conclusions and Recommendations

OBJECTIVES

· Conduct an assessment

of the

magnitude of mercury contamination in

two study areas affected by gold mining

areas in Indonesia;

· Provide technical support for

intervention measures;

OBJECTIVES (cont.)

· investigation of existing geochemical

sources of Hg, also prior to the

establishment of a mining activity

(background);

· evaluation of Hg bioavailability and

mobility through characterization of

hydrochemistry, geochemistry,

mineralogy and bioindicators.

MATERIALS AND METHODS

· 768 samples split into 420 biological

indicators as fish, plants and shells, and 348

inorganic indicators, as sediments, soils and

water;

· Total suspended solids (TSS) and water play

a pivotal role in assessing mercury mobility

and the nature of pollution;

· Mercury transported either in solution or

onto suspended particles may settle forming

mercury sinks;

MATERIALS AND METHODS

· It was sought the collection of naturally

settled TSS samples where favorable

hydrodynamic conditions were found;

· Preparation of sediment, soil and tailing

samples consisted of wet sieving (< 74 µm)

and drying at 40 °C;

· After removing the individual axial muscle

(fillet) of fish, each sample was placed in

polyethylene bags and ice boxes, and frozen

after reaching hotel facilities.

MATERIALS AND METHODS

· Analytical method for total Hg follows

methodology developed by Akagi and

Nishimura (1991). acid digestion followed by

reduction to elemental mercury, aeration and

measurement by cold vapor atomic

absorption spectrometry;

· AAS with pyrolisis used in the field

(LUMEX)

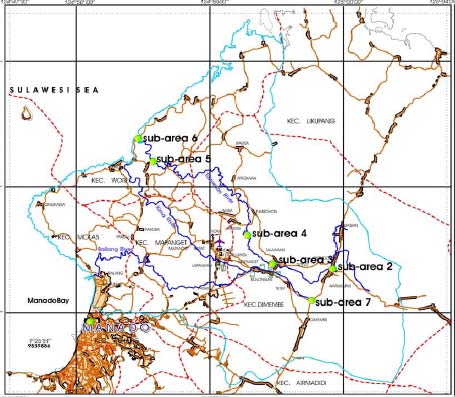

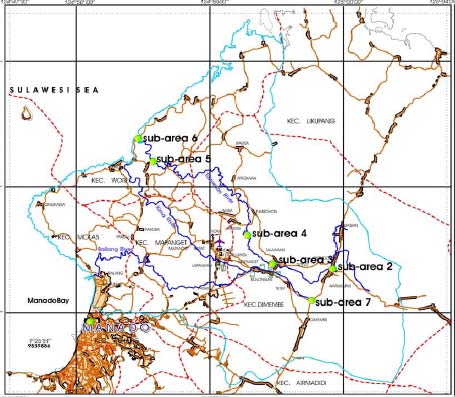

North Sulawesi - Indonesia

North Sulawesi Indonesia

Sampling Campaign September 2003

· 157 fish samples

· 149 inorganic samples (soils, sedi-

ments and water)

· 57 bioindicators other than fish (plants,

roots, mussels and corals)

· 250 human samples (blood, hair and

urine)

· Total of 613 samples

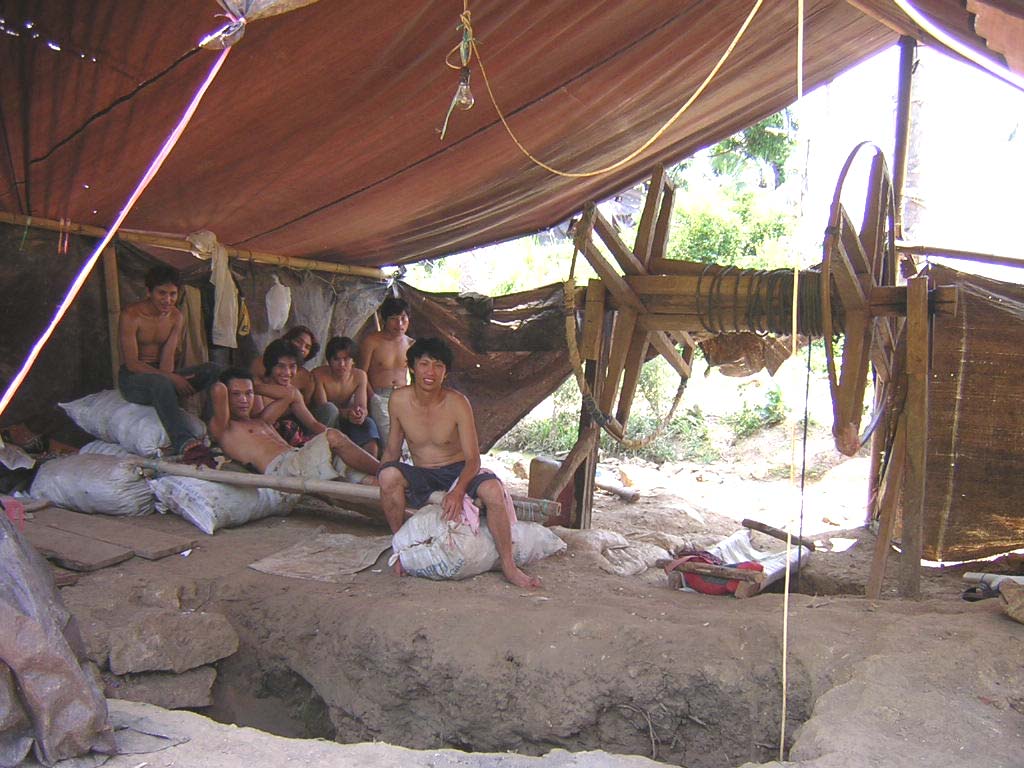

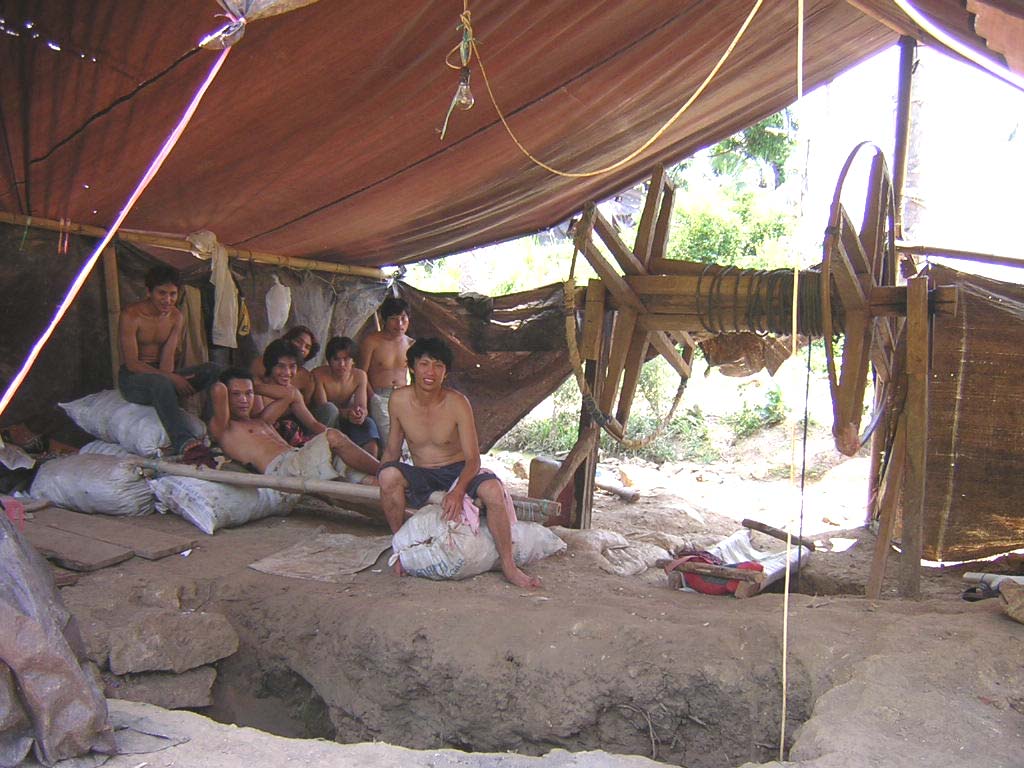

Tatelu-Manado-North Sulawesi

Mining area hills, shafts and

coconuts plantation

Tatelu-Manado-North Sulawesi

· Shaft and manual elevator

· Very young miners, estimated 1000 to

1500 ones

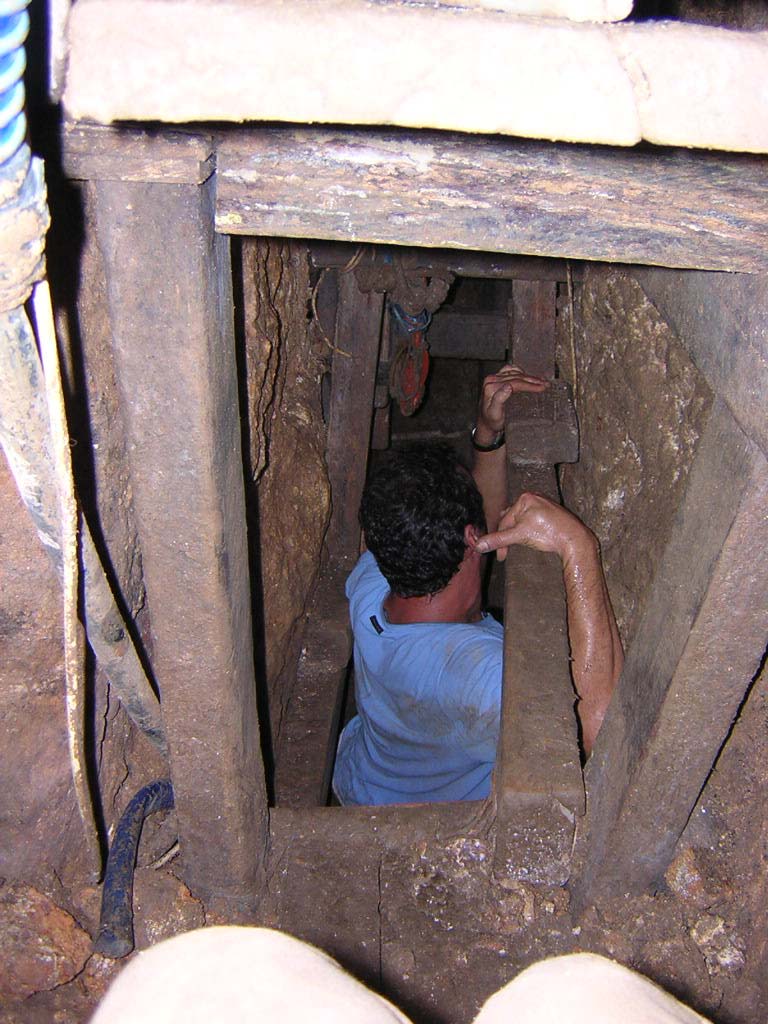

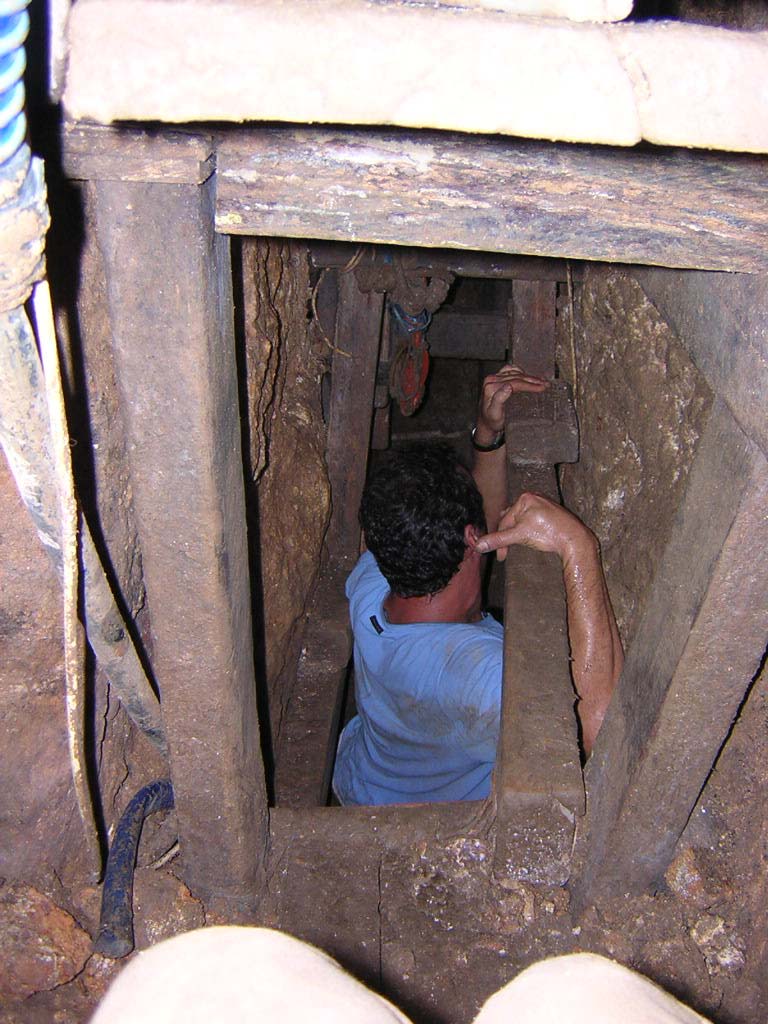

Hard Rock Mining

· inside a narrow shaft

50-70 cm wide

· pushing 30 kg ore

sacks from 30 m of

depth to the surface

· primary gold ore

· quartz veins in

volcanic rocks

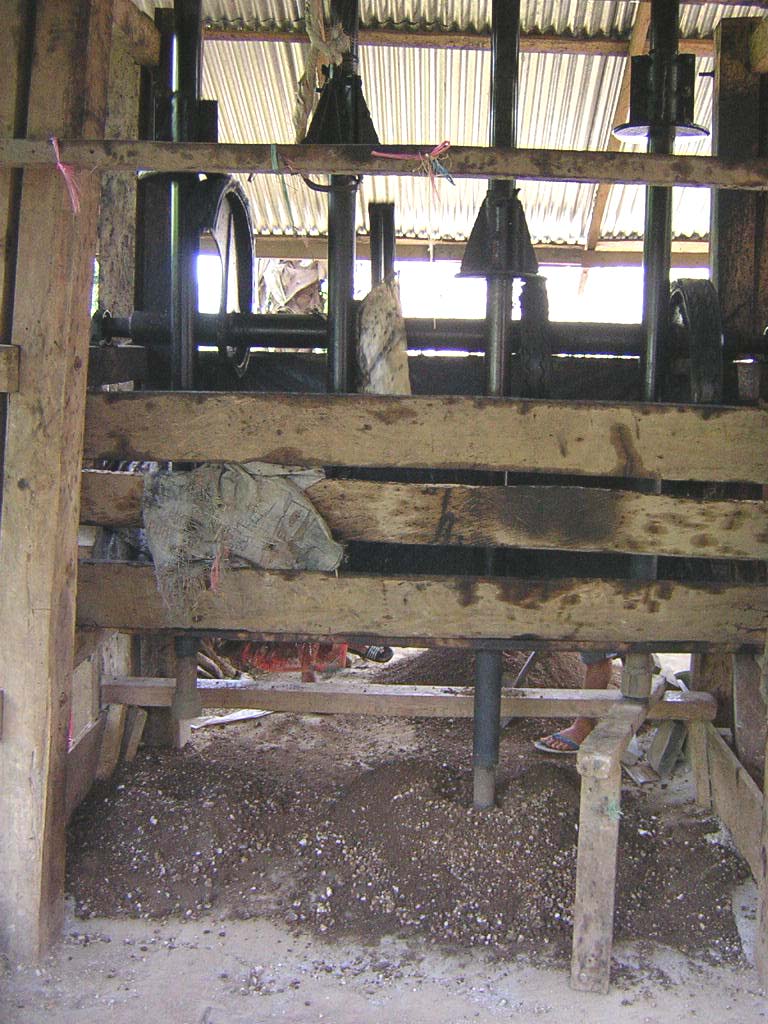

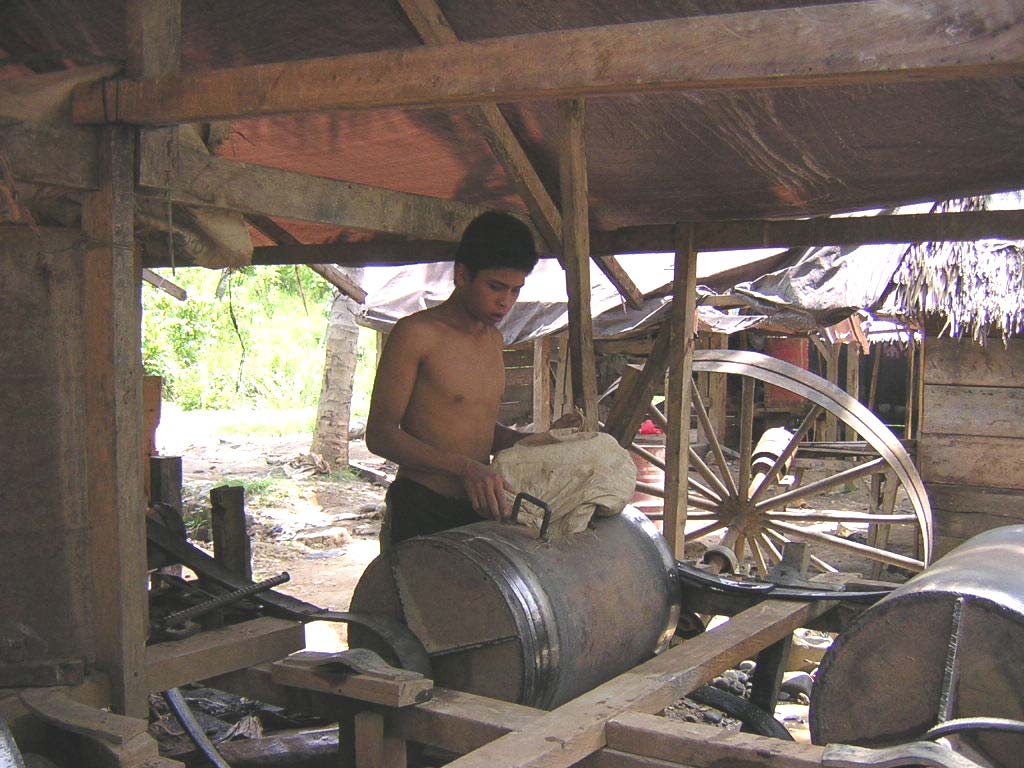

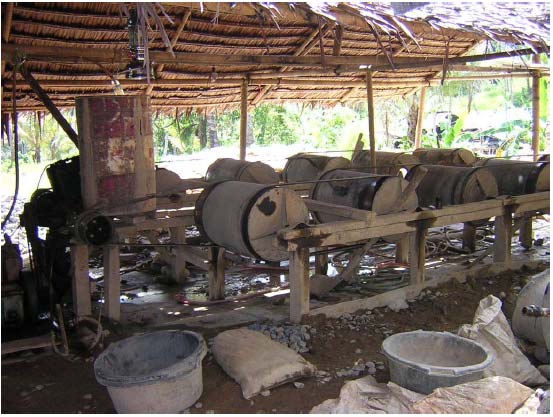

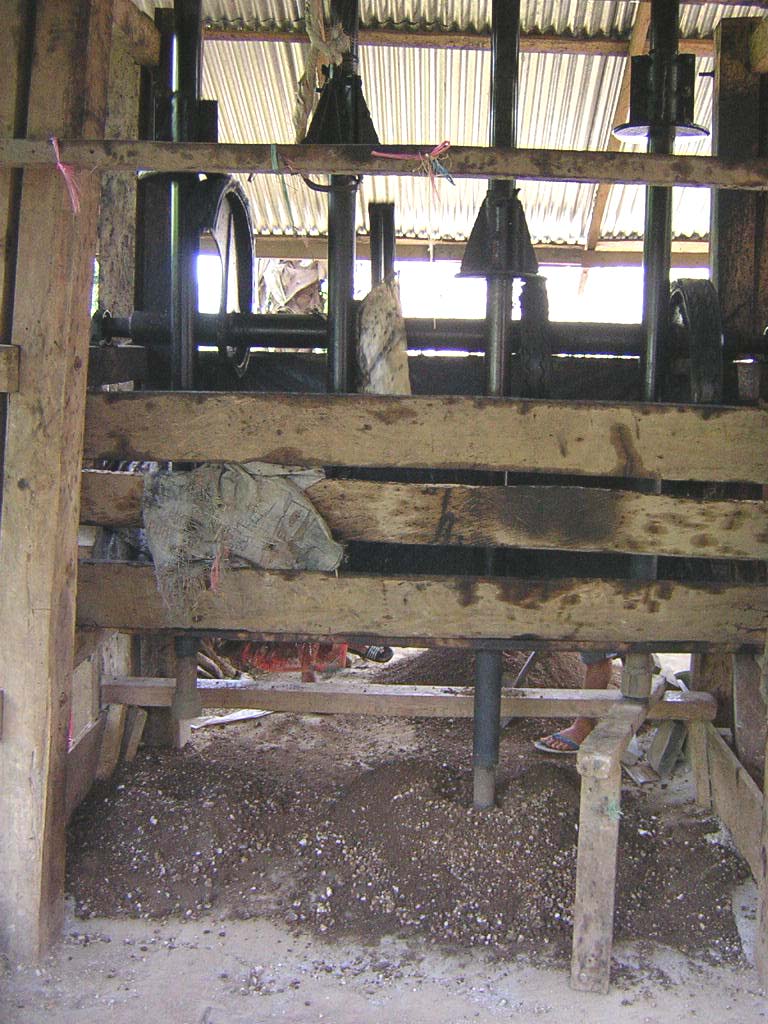

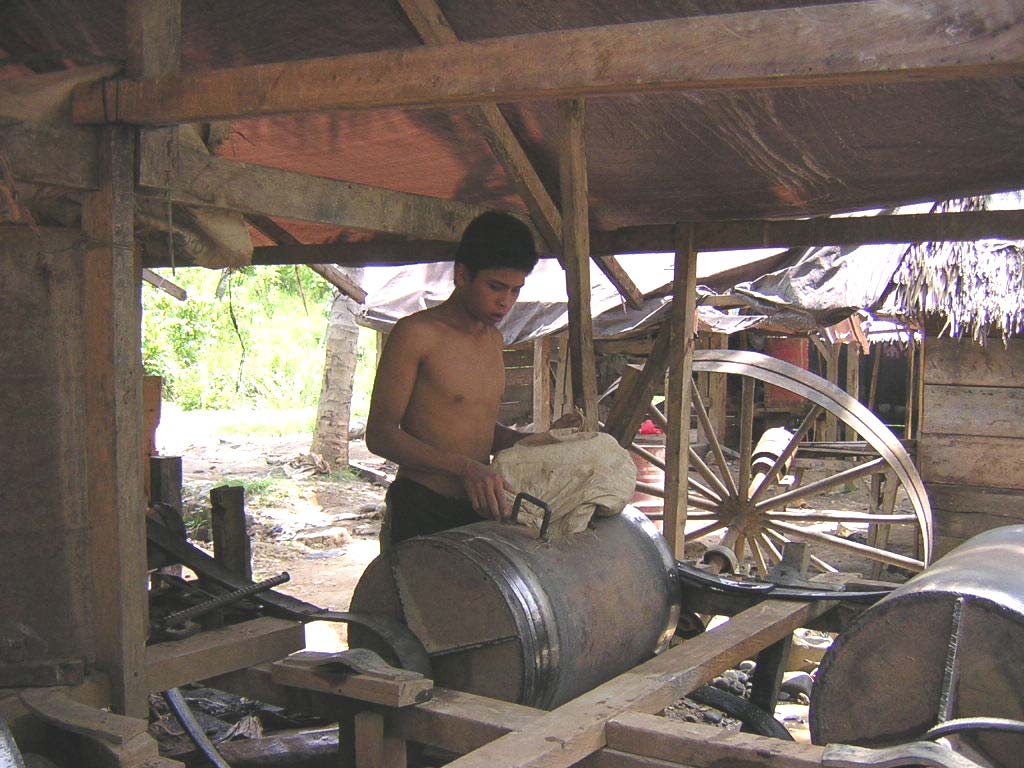

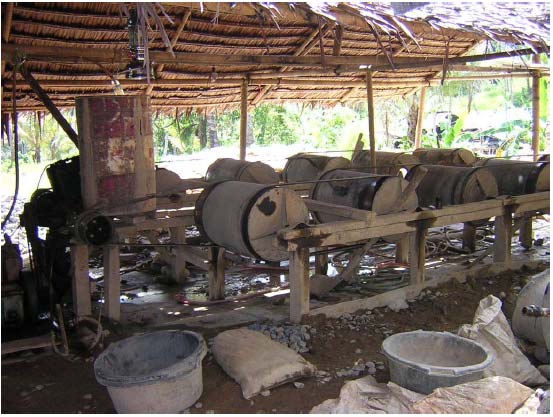

Mineral Processing

· Further transported to ball mills

(,,trommels")

· 2 km downhill close to Talawaan Creek

Mineral Processing (cont.)

· Crushing the ore by

stomp mills

· High grade ore

· Less material, less

physical impact

· Chemical impact ??

Mineral Processing (cont.)

· Filling crushed ore into ,,trommel"

· Further crushing and direct

amalgamation - without gravity

concentration

Mercury Loss - Tatelu

· 1 kg Hg per trommel

· 3 cycles/day

· 12 trommels per unit

· 100 units in Tatelu

· ~ 1000 tons/year used!

(not lost)

· Hg recycling of 98%

Mercury Loss Tatelu (cont.)

· Consumption/Loss of

15 kg Hg/month/unit

· Au production of ~300

kg/year in Tatelu

· Estimate of 18

tons/year lost to the

environment

· Huge ratio Hg:Au of

60 ! (normal ratios fall

in the range of 1 to 2)

Mercury Loss Tatelu (cont.)

· Roasting of amalgam

without retort in any

corner

· An occupational

health hazard Hg release

to the nose

· Average 10g Au/day

for a group of 10 miners

Cyanidation - Tatelu

· Sacking of amalgam

wastes for cyanidation

· Cyanidation tanks (20

tons/batch)

· Average Au prod. 400

g/batch

· Average Hg recovery

800 g/batch (only)

Cyanidation Tatelu (cont.)

· Au-Hg-loaded

charcoal burned in

open air

· Remaining Hg goes

to cyanidation tailings

in neutralization ponds

· Unkown effects of

cyanide-Hg complexes

to both the

environment and

health

Emission Sources of Hg

in North Sulawesi

· Gold fields of primary deposits; direct

amalgamation; no gravity concentration

(high Hg losses)

· Gold shops and amalgam roasting (Hg to

the atmosphere)

· Cyanidation of amalgamation tailings

· Erosion of naturally Hg-enriched soils:

through both long-term atmosferic

precipitation from diffuse emissions and Hg

bearing minerals (volcanoes)

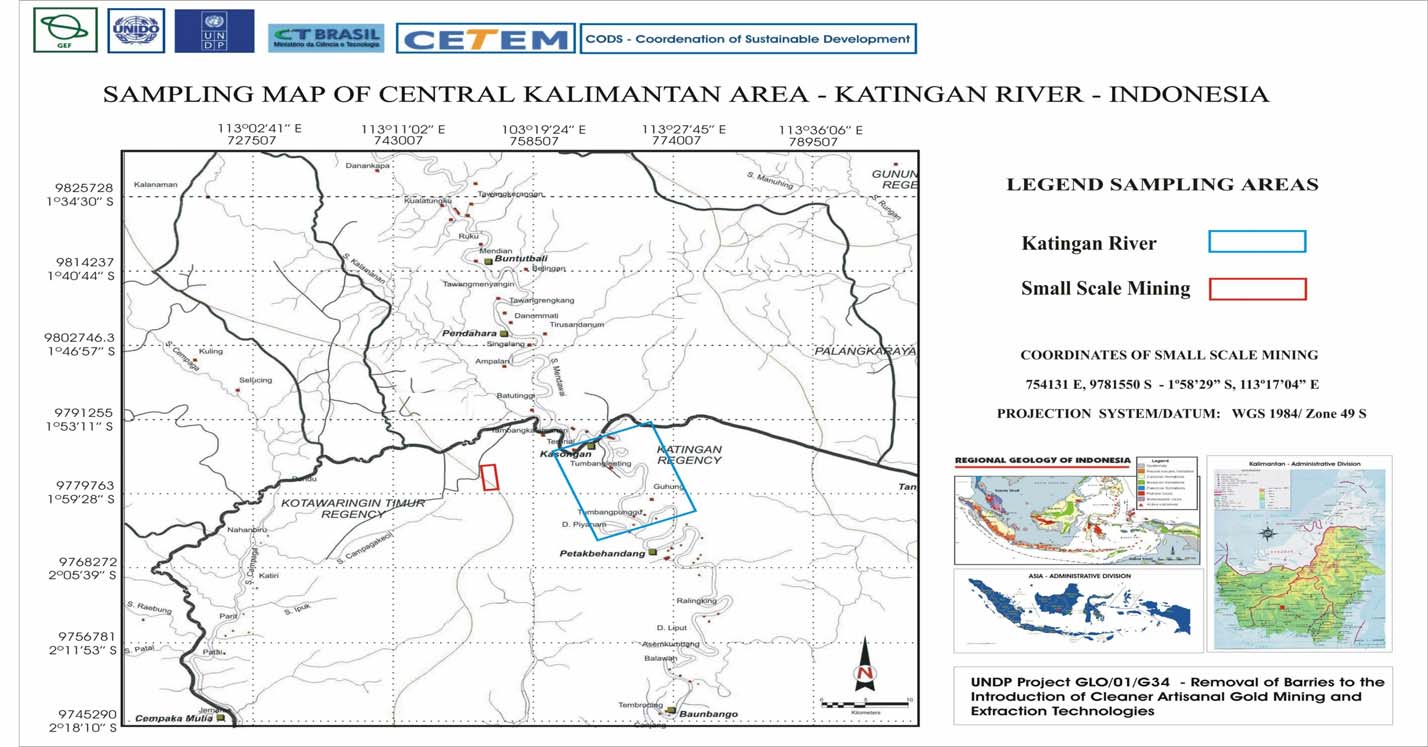

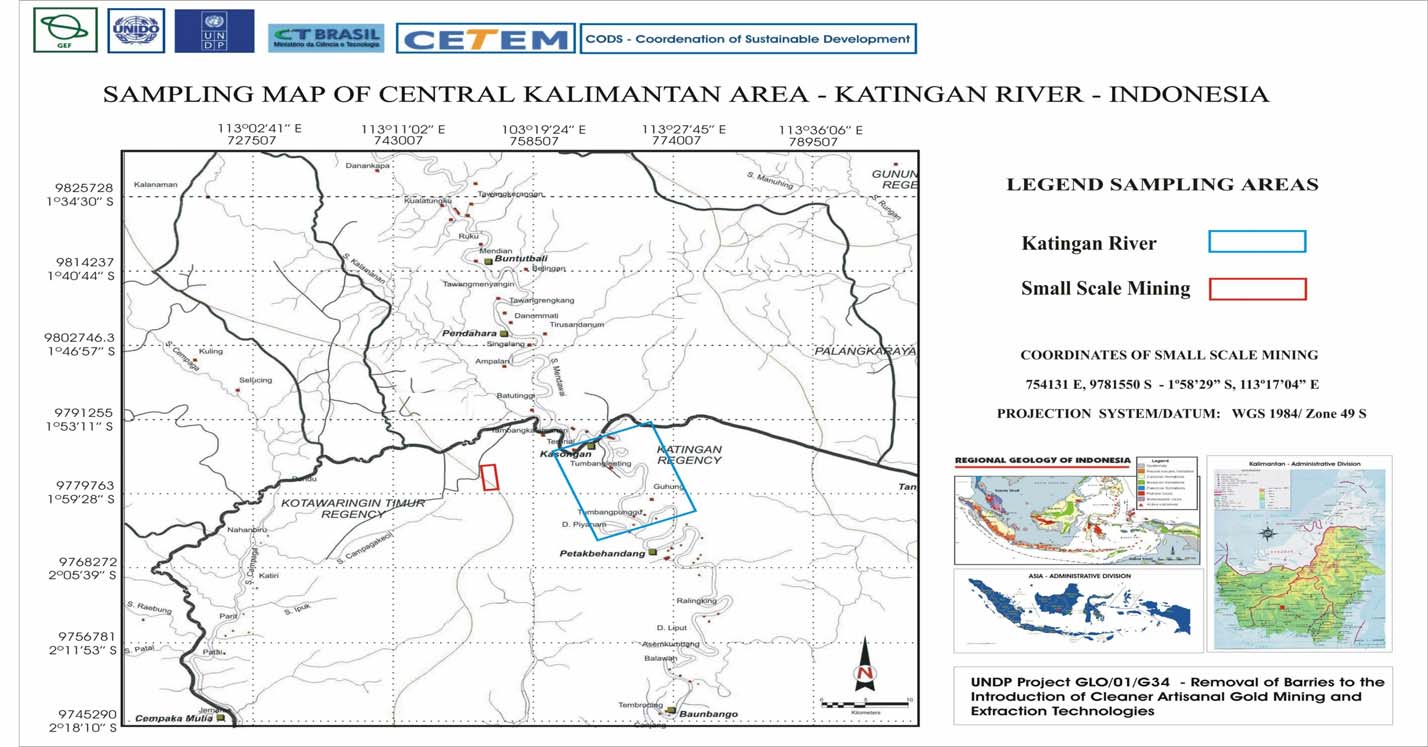

Central Kalimantan - Indonesia

Central Kalimantan Indonesia

Sampling Campaign September 2003

· 262 fish samples

· 199 inorganic samples (soils,

sediments and water)

· 43 bioindicators other than fish (plants,

roots, mussels and corals)

· 250 human samples (blood, hair and

urine)

· Total of 754 samples

Central Kalimantan - Indonesia

· Galangan Mining site, an alluvial plain

· Former rain forest (intensive logging)

Central

Kalimantan

Indonesia

· Sand, gravel and

peat (dark drainages)

not directy affected

by volcanic eruption

· Alluvial gold

exploration

· Huge physical

impact

· Chemical impact ?

Mineral Processing

· Au concentrate, without mercury, recovered

from sluice boxes (relatively low Hg losses)

· Amalgamation of Au concentrate in ponds,

also used for bath (white mud is caolinite)

· Estimated 2000 miners

Mercury Loss - Galangan

· 1 kg Hg per operation

· 20 kg of concentrate

· 1 cycle/day

· 500 units in Galangan

· Carefull panning

· Hg recycling of 99%

Mercury Loss Galangan

(cont.)

· Amalgam after

squeezing ready for

roasting in open air

· Gold bying shops in

Kereng Pangi, 5 km

from Galangan

· Estimate of 2 tons/year

of Hg lost

· Ratio Hg:Au of ~ 2.4

RESULTS TALAWAAN

NORTH SULAWESI

· Hg in sediments, soils, tailings and

biota

Hg in sediments and tailings

Hg in undisturbed sediments

Talawaan upstream - silt-clay fraction

Hg

(ppm)

50

Anomalous Hg background

45

Mean Hg = 31 ppm (Volcano ?)

40

35

30

25

20

15

10

5

0

B3

B1

B2

Hg in sediments - Talawaan Watershed

Silt-clay fraction

Hg in mining tailings - Talawaan

Watershed Mining sites

Hg Hotspots

Hg (ppm)

Hg in sediments - Talawaan

downstream - 5 to 20 km from

mining sites - silt-clay fraction

16

Hg

(ppm)

14

12

10

Mean Hg = 8 ppm

8

6

4

2

0

T38

T34

T42

T43

F30

T32A

T32

T40

T41

T44

T45

T47

T48

Hg in catchment soils - Talawaan

Watershed

Hg in wild plants and vegetables -

Talawaan Watershed Mining

sites

300

Aquatic plant in

Hg

(ppm)

cyanidation pond

250

(High Bioavailability)

200

150

100

50

0 T12 T12 C12 C12 C13 C15 C16 C18 C19 C19 C21 T18 T20 T22 T51 T52

Hg in mollusks medium course and estuary

Talawaan River

Hg (ug/g)

Talawaan (downstream)

9

8

Hg Average = 2,6 ug/g

Stardard Deviation = 3,5 ug/g

7

(High Bioavailability)

6

5

4

3

2

Estuary

1

0

A308

A309

A310

A311

A610

Hg in Fish North Sulawesi

Site

Sampling location

N

Hg-µg/g

T1

Upstream of the gold mining areas; 1

0.044

fish farming activities

T2

5 Km downstream of T1; gold 38 0.84±0.40

mining activities

T3

Downstream of cyanidation plants

35

0.54±0.40

T4

3 km upstream of estuarine region

21

0.68±0.62

T5

Estuarine region, high fishing 33 0.38±0.19

activity

T6

Reference area. Toldano river

6

0.02±0.01

Hg in Fish North Sulawesi

0,9

0,8

g)

0,7

ug/

(

0,6

h

s

0,5

Fi

n

i

0,4

g

l

H

a

0,3

Tot

0,2

0,1

0

North Sulawesi

T1 (n=1)

T2 (n=38)

T3 (n=35)

T4 (n=21)

T5 (n=33)

T6 (n=6)

(n=134)

Hg in Water North Sulawesi

· A reduced number of water samples were checked

for assessing their quality in relation to guidelines for

drinking water.

· In the main mining sites, mean Hg level in water

reachs 1.8 µg/L, while down to the estuarine region Hg

levels drop to a mean value of 0.1 µg/L, which falls

below the maximum limit of Hg for drinking water

established by the World Health Organization (WHO,

1980).

RESULTS GALANGAN

CENTRAL KALIMANTAN

· Hg in sediments, soils, tailings and

biota

Hg in sediments, soils and tailings

Hg in sediment core sections

Katingan River - upstream

Hg in sediment core sections

Katingan River - downstream

Hg in sediment core sections

Katingan River - downstream

Hg in mining tailings - Galangan

Hg in sediments of the Katingan River -

silt-clay fraction 20 km downstream

12

Hg

(ppm)

10

8

6

4

2

0

K95

K91

K96

K99

K101

K103

K106

K109

K112

K115

K118

KI21

AVBL29 KVB <4

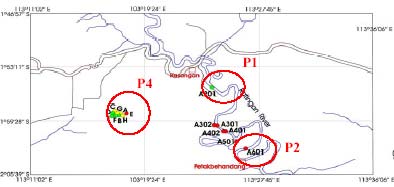

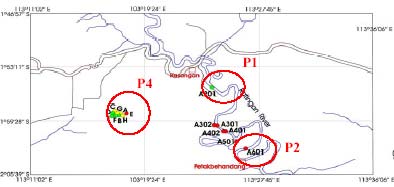

Hg in Fish Central Kalimantan

Sampling location

N

Hg (µg/g)

P1

Katingan river, upstream of mining 86

0.06±0.05

sites

P2

Katingan river, downstream

69

0.11±0.08

P3

Reference area 1

37

0.16±0.05

P4

Pit lakes in mining site areas

25

1.60±1.76

P5

Fish market from Palangkraya

48

0.08±0.09

P6

Kalamanan river, close to Samba 9

0.23 ±0.04

region

P7

Reference area 2; Orangotangos

5

0.17±0.08

reserve

Hg in Fish Central Kalimantan

1,8

1,6

g) 1,4

ug/ 1,2

(

h

s

1

Fi

n

i 0,8

g

l

H 0,6

a

Tot 0,4

0,2

0

Central

P1 (n=86)

P2 (n=69)

P3 (n=37)

P4 (n=25)

P5 (n=48)

P6 (n=9)

P7 (n=5)

Kalimanta

(n=279)

Hg x fish lenght

·Hg levels in fish from North Sulawesi are

significantly higher than fish from Central

Kalimantan (p<0.0001)

·While fish from North Sulawesi are smaller

(92.9±29.1mm) than fish from Central

Kalimantan (166.0±138.0mm)

·Almost 50% of fish from North Sulawesi

showed Hg levels above WHO limit of Hg level

to human consumption (0.5 µg/g), while less

than 10% of fish from Central Kalimantan did.

Mercury in fish

0.7

0.6

0.5

)

/

g

g

u 0.4

(

h

i

s

f 0.3

in

g

H 0.2

0.1

N=130

N=258

0

North Sulaw esi

Central Kalimanta

Mercury in fish

1.4

) 1.2

/

g

g

1

(u

h

s 0.8

fi

0.6

r

y

i

n

u 0.4

r

c

e 0.2

M

0

T1 T2 T3 T4 T5 T6 T7 P1 P2 P3 P4 P5 P6 P7

Alternative low cost method for

mercury determination in fish:

Training of local users in Manado,

Indonesia

· Colorimetric method developed by

CETEM for the GMP

· The huge extension where mercury

polluted areas are found; the lack of

laboratory infrastructure and the difficult

access; the high cost of conventional

analyses has inspired the development of

a semi-quantitative, low cost method

Training of local users in Manado,

Indonesia

11 local users trained

Conclusions

· Despite of the very high Hg background

in the Talawaan watershed, Hg levels in

both fish and sediments from the mining

sites indicate a very significant anthropo-

genic source

· Hg levels in small fish in North

Sulawesi are similar to those in large fish

of the Amazon region

· Direct amalgamation of whole ore,

without gravity concentration, must be

phased out

Conclusions (cont.)

· Regardless environmental and health

concerns, the current mineral processing

technique used in North Sulawesi does

not improve Au recovery (waste of Hg,

waste of money)

· There is an indicaton that cyanidation

of amalgamation wastes is further

releasing Hg under a more bioavailable

chemical form (cyanide-mercury

complexes)

Conclusions (cont.)

· Higher Hg bioavailability in North

Sulawesi than in Central Kalimantan

area;

· Hg contamination in North Sulawesi is

widespread along the Talawaan river;

· Hg levels in fish from pit lakes in

mining areas from Central Kalimantan

showed the highest Hg levels.

Conclusions (cont.)

· It is predictable that the huge mercury

burden found in both biological and

inorganic samples from the Talawaan

River is also, to a certain extent, being

taken up by the marine biota living in the

Manado Bay.

Conclusions (cont.)

· Although there are technological

alternatives to Hg (cyanide, electro-

leaching with sodium hypocloride), they

are hardly implementable in most of

SSM communities (illegal, poor)

· Strategies for reduction of Hg releases

are more feasible, e.g.: use of retorts;

gravity concentration prior to

amalgamation; cyanidation without

amalgamation; use of fumehoods.

Special Fume Hoods Installed in a Town in Brazil

Gold is melted in front

of the miner

Residual Hg vapor is

collected...

... and condensed

Residual Hg is retained

by filter with iodide

solution

CETEM (1989). Poconé Report

Retorts

Condense Hg vapors and

recycle Hg

Solutions for Hg Pollution in ASM

Accessible Clean Technologies

Processing Centers (with or without Hg)

Centralized amalgamation operations; under control

Policy and Education

Capacity building (governments and ASM communities)

Legislation framework appropriate to encourage ASM

communities to become legal (ASM cooperatives, ASM

companies)

Legal activity, environmental and social responsability

Benefits to the miners: credit, long-term planning,

citizenship

Benefits to the society: environmental protection;

safe fish consumption

Processing Centers Can Also Be

Training Centers

· Improve mining and processing techniques

· Limit Hg use

· Improve occupational hygiene

· Enable to organize (legalize) the activity

· Enable to provide access to financing

· Access to medical and other social services

· Reduce illegal gold purchase

Veiga & Beinhoff (1997)

Healy & Veiga (1997)

Amalgamation Center in Venezuela

Retorts

Trained operators do the job for miners

Document Outline