E1288

v 11

Public Disclosure Authorized

Public Disclosure Authorized

Public Disclosure Authorized

Public Disclosure Authorized

i

ii

ACKNOWLEDGEMENT

This code was developed through the joint effort of the following Central Safety

Committee members:

Ruben L. Carandang

Chairman, CSC

Conrado P Soriano

Secretary/ V-Chairman, CSC

Rogelio D. Del Rosario Jr. Operations

Orlando T. Tabula

SOBA

Carlos Angeles

Corp. Com.

Gil O. Matias

Legal Department

Rolando Maileg

PMG

Myrna Padron

PMG

Leandro Dela Rosa

Corp. Logistics

Noel D. Villanueva

RED

Teresita S.A. Lim

HR/ Administration

Benjamin C. Reyes

CEBA

Normen P. Kahulugan

NEBA

Dominador A. Roxas Jr

NWBA

Amante C. Peralta

Corp. Logistics

Jose P. Gahol

Corp. Logistics

Gilbert R. Reyes

Safety Dept.

Dexter Alister V. Bacani

Safety Dept.

Emerson B Mendoza

Safety Dept.

Roberta F. Estimo

MWSA

Ruben Diaz

KKMK

Bonifacio De Guzman

KKMK

This is also to acknowledge the comments and inputs from SAVP Francisco A.

Arellano of Environment Management Department, AVP Eric O. Montilla of

Administration and to Col. Arnulfo R. Ramirez, VP- Customer Care and Public

Relations Management for his untiring support.

This Code cannot be reproduced in part or whole without written permission from

Maynilad Water Services, Inc.

iii

TABLE OF CONTENTS

Pages

MWSI Safety Code Approval --------------------------------------------------------- i

Foreword ---------------------------------------------------------------------------------- ii

Acknowledgement ---------------------------------------------------------------------- iii

Table of Contents ----------------------------------------------------------------------- iv

Chapter I - General Rules ------------------------------------------------------- 1

Chapter II - Basic Safety Rules ------------------------------------------------- 22

Chapter III - Safety in the Office ------------------------------------------------- 49

Chapter IV - General Construction and Safety Guidelines ---------------- 51

Chapter V - Guidelines on Handling of Vehicular,

Personnel Accidents and Damages ----------------------- 67

Chapter VI - Safety Measures in the Workplace ------------------------------- 78

Chapter VII - Personnel Protective Equipment --------------------------------- 89

Chapter VIII - Tools and Equipment ------------------------------------------------94

Chapter IX - Electrical & Underground Works ----------------------------------96

Chapter X - Fire and other Natural Calamities ----------------------------- 102

Chapter XI - First Aid Treatment ---------------------------------------------- 113

Appendices: Exhibit Forms/ Excavation Barriers/ Warning Signs/

ESH Policy/ Safety Policy/ Policy on the Creation of

CSC (Policy No. A-503-99) ----------------------------------------133

iv

CHAPTER I

GENERAL RULES

SECTION 1

STATEMENTOF POLICY

1.01 COMPANY MISSION/ VISION

We are a water utility firm committed to service excellence, improving

quality of life of the Filipino and becoming one of the world's best.

1.02 MISSION STATEMENT

We will provide reliable and high quality water and wastewater services at

a fair price to meet the needs and expectations of our customers.

We will protect the environment to conserve our natural resources for

future operations.

We will promote efficiency and productivity to enhance shareholder value.

We will enhance the personal and professional well being of our employer.

We will treat our service providers as valued partners to achieve our

business objectives.

We will conduct ourselves in accordance with the highest ethical

standards because our reason for being is to serve the public.

1

1.03 ENVIRONMENT, SAFETY AND HEALTH POLICY

21.MAYNILAD WATER SERVICES, INC. is committed to excellence and

leadership in the protection of the environment and in the promotion of

health and safety in the workplace.

We will create a work culture that will encourage all our employees,

contractors, suppliers and shareholders to support this commitment.

We will protect the environment by minimizing and managing the impact of

our operations on the environment, optimizing the use of our resources

and increasing operating efficiencies.

We will establish an environmental management system to ensure that

protection and sustainability is an integral part of our business

management.

We will design and execute systematic programs that eliminate all

hazardous acts and conditions to prevent work related injuries, illnesses

and accidents at the workplace. We will pursue the establishment of high

standards on safety and occupational health awareness, practice and

discipline.

In keeping with this policy we will comply with all the regulatory

requirements and international standards on environment, health and

safety. We will achieve this through the use of appropriate technology and

best practice in the pursuit of growth and viability.

We call on all employees to ensure that there is consistency in the

implementation of this policy.

2

1.04 SAFETY POLICY

MAYNILAD WATER SERVICES, INC., a private utility in the service of

the public, is committed to protect the life and well being of its people by

providing a safe working environment.

The company recognizes people as its most valuable asset. To enable the

company to attain its goals, it will rely on every individual's positive

contribution. These goals are best achieved when each individual is

healthy in body and mind.

In fulfilling this commitment, the Company will guarantee a safe and

healthy work environment in accordance with industrial standards and

practices. It will also initiate proactive efforts to eliminate potential causes

of accidents in the work place that may result in fire, property damage,

injury or illness. Part of the effort is to educate and involve all employees

on safety.

The Group Head or Area Manager will guarantee a safe working

environment and will be responsible for implementing an effective program

on safety.

Each manager/ supervisor will be directly responsible for ensuring safety.

It is his duty to inspect the workplace, investigate all accidents, correct

unsafe conditions and practices, and promote consciousness on the

importance of safety in the workplace.

The Central Safety Committee, with the support of management, will

provide guidance and logistical support to all operating units for functions

and activities related to safety, health and protection of the environment.

It will be the responsibility of each individual to look after his safety and

that of his co-workers and general public and to report situations that

compromise safety conditions in the workplace.

3

1.05 POLICY ON THE CREATION OF CENTRAL SAFETY COMMITTEE

1.05.01 POLICY

It is the policy of Maynilad Water to ensure the health, safety and

welfare of its employees at work and the communities it serves either directly or

indirectly. The discharge of this responsibility shall be accorded equal priority

with those of its statutory duties and commercial objectives.

1.05.02 OBJECTIVES

It is the objective of this policy to organize a Safety Committee to

establish and adopt in writing the MWSI Safety Code and other administrative

policies on Safety to guide its employees and contractors on how to maintain a

safe, accident free and healthy working environment and system of work.

1.05.03 MEMBERSHIP

A representative from the hereunder operating units will be members of

the committee:

1. Customer Care and Public Relations Management

2. Customer Services

3. Operations Division

4. Project Management Group

5. Business Areas (CEBA, SOBA, NEBA and NWBA)

6. Administration

7. Costumer Management Services

8. Revenue Enhancement Directorate

9. Corporate Logistics

10. Corporate Financial Services

11. MWSA

12. MWSU- PTGWO

1.05.04 DUTIES AND RESPONSIBILITIES OF THE COMMITTEE

1. Assist in developing effective organization responsible for the

employees' safety, health and protection of our company's assets and

properties.

2. Assist in conducting monthly scheduled meetings to assist and review

company's Safety Program and its implementations.

3. Notify the Safety Department of any accidents and incidents in the area

of concern immediately. Coordinate with the supervisor concerned and

gather all vehicular, personal accidents reports and other data, for

submission to the Safety Department.

4

4. Assist in investigating major accidents and causes and recommends

measures to prevent their recurrence.

5. Assist in supervising Safety awards and contest.

6. Assist in establishing safety standards and operating methods for the

company.

7. Assist in instituting internal programs to disseminate safety policies and

regulations in your workplace.

8. Assist in spearheading mobilization works in case of emergency in their

respective area and coordinate said works with Safety Department.

9. Perform other functions assigned or in accordance with the safety

policy.

5

1.06

POLICY ON THE CREATION OF SAFETY SUB-COMMITTEE

1.06.01

OBJECTIVE

The objective of this policy is to strengthen and support the

execution of all safety programs, objectives and functions conferred

to the CSC.

1.06.02

RULES & REGULATIONS

TITLE

This policy shall be known as the policy on the creation of MWSI

Safety Sub-Committees.

1.06.03

DEFINITION OF TERM

Safety Sub-Committee Member refers to an MWSI employee who

is duly selected or appointed by the CSC as Sub-Committee

Member, representing his/her Business Area, Division or

Department, where he/she is currently assigned.

1.06.04

FUNCTIONS OF A SAFETY SUB-COMMITTEE MEMBER

1. Coordinate with the supervisor concerned to gather all

vehicular, personal accidents reports and other needed data

and be submitted to CSC member/s in the area.

2. Provide assistance and render support in pursuit to the

objectives of CSC on the following:

a) Planning what has to be done

b) Organizing the resources

c) Leading employees towards the set goals

d) Controlling process efficiency

3. Support CSC directives in the area on all safety related activities

and programs.

4. Shall be an advocator in coordination with CSC, in the

regulations and enforcement of safety policies in all workplaces.

5. Readily available for mobilization in cases of emergency in

coordination with the CSC member in his respective area.

6. Perform other functions assigned or in accordance with the

safety policy.

6

1.06.05

REPRESENTATION

All Divisions or Departments shall be represented by at least two

(2) Sub-Committee Members. However, it shall be increased

depending on the magnitude of the activities prone to accidents and

the number of personnel in the area or department represented.

Medical personnel shall automatically be either CSC members or

Sub-Committee members.

1.06.06

SELECTION PROCESS

The incumbent CSC member in the Area, Department or Division in

coordination with Area Business Manager/ Department Manager

shall be responsible in the submission of at least five (5) candidates

from their respective offices, from which CSC members may

choose qualified Sub-Committee Members.

1.06.07

OATHTAKING AND EFFECTIVITY OF TASK AS A SUB-

COMMITTEE MEMBER

a.) The selected Sub-Committee member shall be inducted by the

chairman of CSC, preferably on the occasion of monthly CSC

meeting.

b.) Effectivity of membership shall be effective upon receipt of

notice duly signed by the CSC chairman, even without oath-

taking yet.

1.06.08

DISQUALIFICATON

a.) Disqualification of a Sub-Committee member shall be in

coordination with his immediate CSC member with the latter's

verbal or written recommendation/s based on legal grounds.

Disqualification or expulsion of a sub-committee member shall

by a vote of the majority of all the members who are present

during the meeting. Fifty (50) percent of the total CSC members

present shall constitute a quorum to validate a vote of

disqualification. In case of tie, the CSC chairman shall render a

vote in order to break the deadlock. In case the latter is absent

or unavailable, the vice-chairman shall take his post.

b.) Any written recommendation/s by CSC member or manager for

disqualification or replacement of Sub-Committee member shall

be taken by CSC in a meeting called for the purpose.

7

1.06.09 RESIGNATIONS AND REPLACEMENT

Any voluntary written resignation by a Sub-Committee member

shall be resolved immediately. Replacement shall be in accordance

with Rule 1.06.06.

1.06.10

SAFETY POLICY VIOLATIONS & PERFORMANCE

INEFFICIENCY

a) SAFETY POLICY VIOLATION:

Safety violations committed by a Sub-Committee member shall

be taken during the meeting. If found guilty, a disqualification

letter shall immediately be executed.

b) NEGLECT OR NON-PERFORMANCE

Negligence of duty or non-performance by a Sub-Committee

member is a ground for disqualification but it shall be confirmed

or tried by CSC members.

For inefficiency, CSC members by a majority vote shall

determine causes and grounds and render appropriate

measures.

8

SECTION 2

APPLICATION AND RESPONSIBILITY

2.01 These rules and regulations shall be known as the MWSI Safety Code.

2.02 Every section/ unit shall be given a copy of this Code by Safety

Department.

2.03 Each employee shall carefully study and observe the rules embodied in

this Code, more particularly those performing safety duties. Safety rules

shall be strictly observed and ignorance will not be accepted as an excuse

for their infractions.

2.04 All employees are encouraged to make suggestions for changes in the

rules or working conditions to promote safety in the company.

Suggestions should be submitted to Safety or through the Central Safety

Committee and Sub-Committee member in your area/ division.

SECTION 3

MANAGER'S/ SUPERVISOR'S RESPONSIBILITY

3.01 Managers/ supervisors are responsible in enforcing and implementing this

Code. Each manager/ supervisor shall see to it that employees under his

direct supervision are aware of the safety rules and its proper observance.

(Penalty of managers/ supervisors equivalent to the penalty of the rule

violated by subordinate)

3.02 The supervisor or the employee acting as such shall undertake other safety

precautions as necessary in the performance of a job. He shall ensure safe

work operations. Qualifications and competence shall always be observed

in assigning workers to a delicate work operation.

3.03 The manager/ supervisor, in case of doubt of any employee as the

meaning and intent of any part of this Code, shall explain the same to the

latter. In case of further doubt, the case maybe referred to the Group Head/

Area Manager who may resolve the question or refer same to Safety

Department.

SECTION 4

REPORTING PERSONAL ACCIDENTS AND INJURIES

4.01 ON-DUTY ACCIDENTS

a. Any injury sustained by an employee, regardless of gravity, must be

reported at once to the employee's immediate supervisor. In case of

major or serious injuries, the manager/ supervisor shall promptly report

the same to MWSI Call Center (MCC)/ Administration-HR which in turn

shall notify the following:

1. During Regular Office Hours:

Administration-HR, Safety Department, Legal Department.

2. During Off Office Hour, Saturdays, Sundays and Holidays:

Safety Engineer on call, personnel on call of Legal Department.

b. The employee, or his immediate superior in case of the former

incapacity, should then formally report the accident or injury by

9

accomplishing and submitting to Section Head the Personnel Accident

Report Form (Exh. I) within twenty four (24) hours from the time the

accident occurred. However when the event occurs on a weekend or

holiday, such report should be submitted on the next working day. (A)

4.02 OFF-DUTY ACCIDENTS

a. In case of major or serious injury, the employee shall promptly advice or

cause to be advised his immediate superior or Administration-HR.

b. For both serious and minor injuries, the employee or his immediate

supervisor/ manager, should then formally report the accident or injury

by accomplishing and submitting to the Section Head the Personnel

Accident Report Form (Exh. I) within twenty four (24) hours from the

time of the accident. (However if in the event occurred on weekend or

holidays, such report maybe submitted on the next working day.) (A)

4.03 PUBLIC ACCIDENTS

a. In case of injuries sustained by the public occasioned by the employee's

performance of his assigned work, the latter or his immediate supervisor

shall immediately notify about the accident to the MCC which shall in

turn, informed the following (A)

1. During regular Office Hours:

Safety Department, Legal Dept., Administration-HR

2. During Off-Office Hours; Saturdays, Sundays, Holidays

Safety Engineer on Call, Legal investigation Staff on Call

b. The employee and his immediate supervisor shall jointly prepare a

report of the accident through Personnel Accident Report Form (Exh. I)

within twenty four (24) hours from the time of the incident. (A)

SECTION 5

PENALTIES

5.01 For purposes of this Code, any employee of the MAYNILAD WATER found to

have violated any of the provisions of this Code shall be administratively

dealt with and shall be punished in accordance with the schedule of

penalties.

The code letter "A", "B", "C", "D" is affixed to each rule to indicate the

category of the offense for purposes of applying the appropriate penalty.

The penalty or penalties for safety rule violations are as follows:

10

5.02.01

SCHEDULE OF PENALTIES FOR MWSI EMPLOYEES

(See table # 1)

SCHEDULE OF PENALTIES FOR MWSI EMPLOYEES

(Table # 1)

Gravity

First

Second

Third

Fourth

of

Offense

Offense

Offense

Offense

Offense

Offense

Written

1 Working Day

2 Working

3 Working Days

"A"

reprimand

Suspension

Days

Suspension

Suspension

Offense

1- Working

2 Working

4 Working

8 Working Days

"B"

Day

Days

Days

Suspension

Suspension

Suspension

Suspension

Offense

10 - Working

15 Working

30 Working

Dismissal

"C"

Days

Days

Days

Suspension

Suspension

Suspension

Offense

30 - Working

Dismissal

"D"

Days

Suspension

5.02.02 IMPOSITION OF PENALTIES

MWSI EMPLOYEES

I.

The penalties for succeeding violation are progressively more severe than

the penalty for a first violation. However, this "cumulative" rule applies only

when the violations occur within a single 12-month period counted from

date of first offense. Any other or further violation occurring after this

period shall be considered as first offense.

II.

If at the time of the commission of the last offense, the employee shall

also have previously committed at least two other violations of a safety

rule or rules other than the rule involved in this last offense, all committed

within a 12 - month period, such last offense shall be punishable by the

next higher step of the penalty prescribed thereof.

III.

Where the fourth violation of the same rule is punishable by a penalty less

than dismissal the fifth and subsequent violations, if committed within a 12

- month period, shall be meted out the same penalty as that provided for

the fourth violation.

11

IV.

When a single act constitutes two or more offenses under this policy, or

when an offense is a necessary means for committing the other, the

penalty for the most serious offense shall be imposed.

V.

All penalties to be imposed, including reprimand, shall be in writing, and

shall include a warning (except in case of dismissal) that subsequent

violations will be dealt with more severely. Copies thereof shall be

furnished.

a.

Safety Department

b.

Administration-HR

c.

Respective Manager

d.

Legal Department

VI.

Department Managers shall impose the penalties provided for in this

policy after conducting the required investigation. However, where the

offense is punishable by dismissal, the Department Manager shall elevate

the case to the Legal Department for proper disposition.

VII.

Management may impose a penalty graver in degree than what is

provided in this code, particularly when the violation resulted to injury upon

persons or damage to property, or both, and when the violator/s is

habitually delinquent, in which case, it shall be adjudged in accordance

with applicable provisions of Maynilad Water Services, Inc. (MWSI) Safety

Code

and

Human

Resources

and

Organization

Development

(Administration-HR) Policies on Disciplinary Action, and Criminal and Civil

Law, if necessary.

VIII.

This Code supercedes the Table of Penalties for Safety Violation stated

under the MWSI Code of Conduct.

5.02.03 IMPOSITION OF PENALTIES

MWSI CONTRACTORS

5.02.03.01 DEFINITION OF TERMS:

a. Written Reprimand - a first notice for immediate compliance

issued to contractor for violation of Safety requirements of a

particular project, stating therein all the circumstances or

jurisdictional facts of every violations. Contractor, upon receipt,

must comply immediately with the Safety requirement deficiencies

without need of further notice. This is a strong categorical

reprimand that confirmation of further violation of any Safety

requirements for second time, or oftener, on the same or different

project would results to Monetary Penalty.

b. Monetary Penalty a penalty in the amount of Three Thousand

Pesos (P 3,000.00) for every confirmed Minor Safety Violation per

day and Ten Thousand Pesos (P10,000.00) for every confirmed

Major Safety Violation per day for contracts. These penalties shall

12

be deducted from their project billings. Certified violation refers to

the second discovery of Safety Violation of the same project.

c. Severance Of Contract this is a hostile act by MWSI against

violating contractor/s that the latter's ties being a contractor of the

former is terminated by reason of complete disregard or non-

compliance to MWSI Safety provisions and directives.

5.02.03.02

SCHEDULE OF PENALTIES (MWSI CONTRACTORS)

(See table # 2)

SCHEDULE OF PENALTIES (MWSI CONTRACTORS)

(Table # 2)

Description of Violations

First

Second

Third

Classification

Offense

Offense

Offense

of Violation

1.0

[Early Warning Device Signages]

Written

Monetary

Severance

Major Violation

a. Failure to install at strategic locations of the

Reprimand

Penalty

of contract

construction site/s warning sign/s or Early

Warning Device (EWD) which state that the

"Work Is Going On" or "Excavation Ahead" or

any informative danger signs. (Rule-21.01.a)

Major Violation

b. Failure

to install sufficient (with, but

insufficient)

wooden/steel/concrete

barricades at strategic locations visible or

around the construction site/s, with the

prescribed distance between each other.

(Rule 21.01.b)

2.0

·

Monetary

Severance

Major Violation

Failure to install any single barricade or

Penalty

of contract

E.W.D.

(completely

zero)

within

the

construction area. (Rule 21.01.e)

3.0

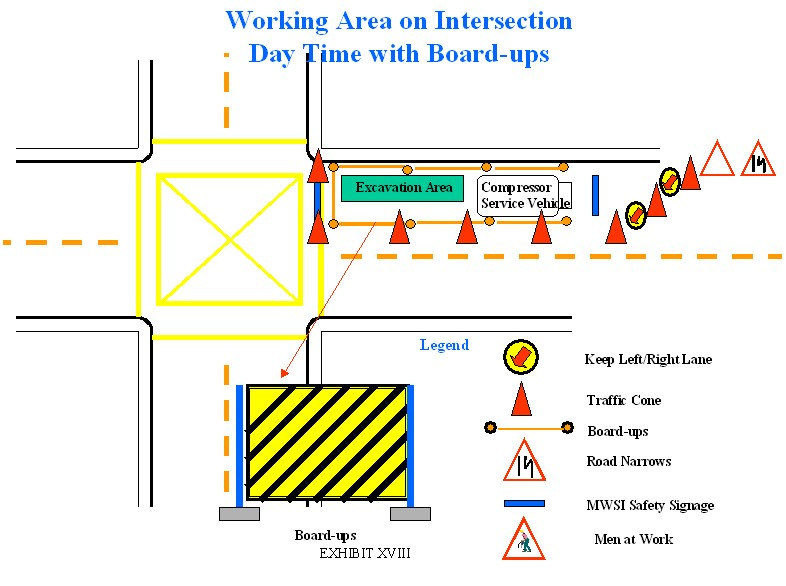

a. If reduction of passable road lane is involved

Written

Monetary

Severance

Major Violation

rubber/concrete cones/blocks, painted with

Reprimand

Penalty

of contract

black and yellow, shall be used along major

thoroughfares and national roads, so as to

guide motorists of lane changes and the

excavation work being undertaken. (Rule

21.01.e)

13

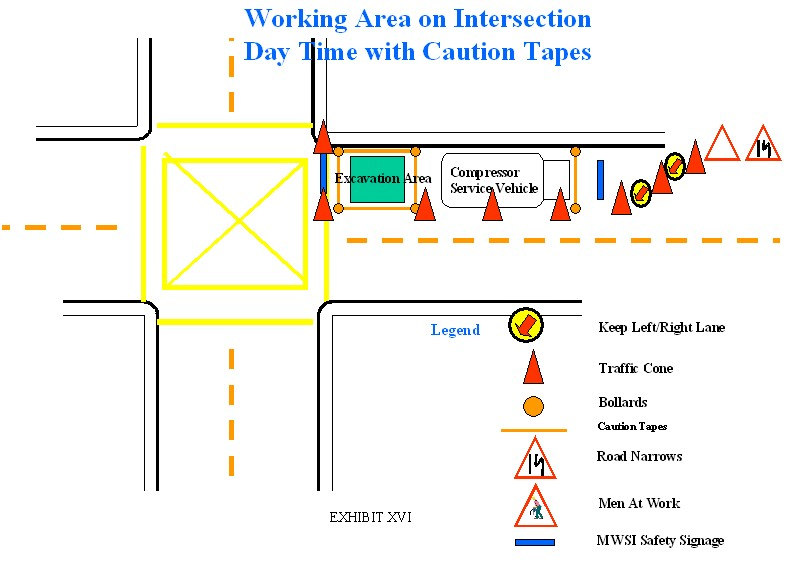

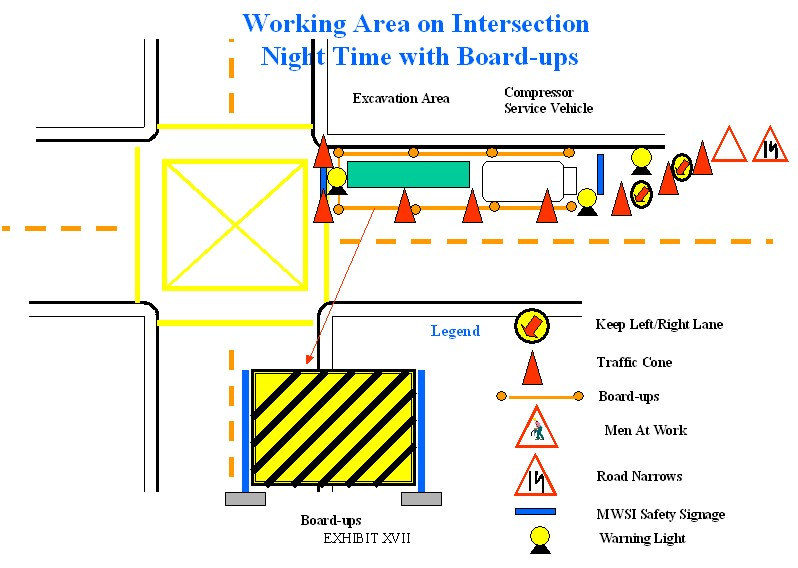

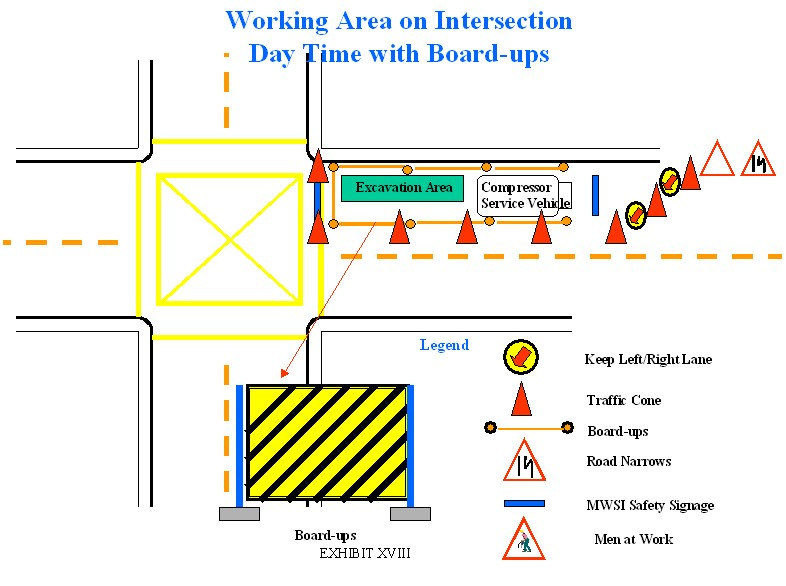

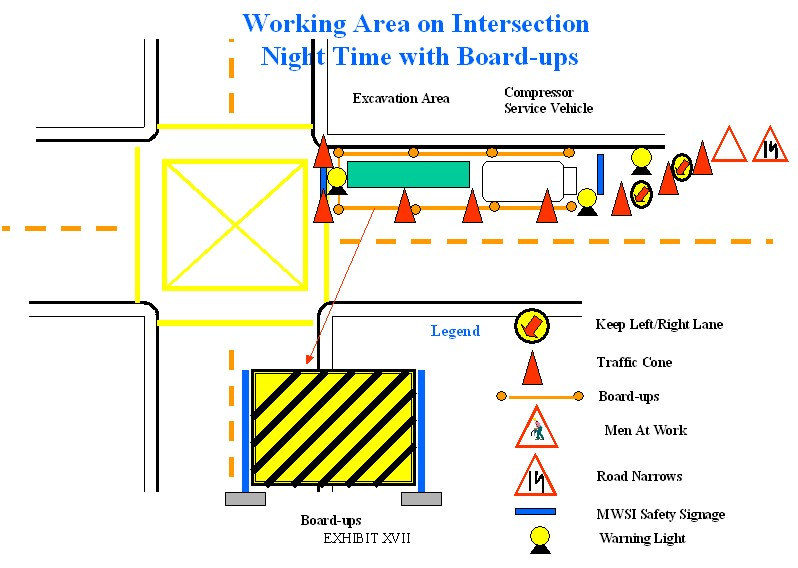

b. If reduction of passable road line is involved

boards-ups painted black and yellow strips,

Written

Monetary

Severance

Major Violation

2.4 m. in length and 1.5 meter in total height

Reprimand

Penalty

of contract

shall be placed to enclosed excavation area

along major thoroughfares and national road.

(Rule 21.01d.)

c. Failure to install amber (Red) flashing lights,

or in case of breakdown of flashing lights,

Written

Monetary

Severance

Major Violation

E.W.D.

with

reflectorized

surface,

at

Reprimand

Penalty

of contract

equipment parking sites within the motorist

passable way.(Rule 21.01.e)

4.0

[EXCAVATION]

Written

Monetary

Severance

Major Violation

a. Road right- of way to vehicle use, failure to Reprimand

Penalty

of contract

excavate at a time portion by portion of not

more than 50% of the road width leaving the

remaining 50% satisfactorily passable,

except for compelling reason.( Rule 21.02.b )

b. Non- observance to excavation by sections Written

Monetary

Severance

Major Violation

of not more than 150 meters at a time Reprimand

Penalty

of contract

measured

longitudinally,

except

for

compelling reason.

(Rule 21.02.a)

Written

Monetary

Severance

Major Violation

c. Unfinished excavation crossing road shall be Reprimand

Penalty

of contract

provided with temporary steel plates with

sufficient thickness to allow safe passage of

vehicles and pedestrians. (Rule 21.03.b)

5.0

[CONSTRUCTION EQUIPMENT AND

VEHICLES]

Written

Monetary

Severance

Minor Violation

Failure to provide central storage site for all

Reprimand

Penalty

of contract

construction equipment and vehicles. (Rule 4.a)

Contractors shall ensure that temporary storage

and parking sites, if there were any, would not

affect traffic flows. (Rule 21.04.b)

6.0

[MATERIAL STORAGE]

Written

Monetary

Severance

Minor Violation

a. Failure to provide construction material Reprimand

Penalty

of contract

storage site (if necessary) which pose

problems on traffic and pedestrian in the

construction area. (Rule 21.05.a)

b. Violation of Guidelines on Dumping of waste Severance

Major Violation

and excess materials, posing danger to of contract

public safety. (Rule 21.05.b)

14

7.0

[MAINTENANCE AND CLEANLINESS

IN WORK AREAS]

Written

Monetary

Severance

Minor Violation

Failure to maintain housekeeping along roadway Reprimand

Penalty

of contract

or passageway (Construction Area) which may

pose

hazards

to

the

riding

public

and

pedestrians. (Rule 21.06.a)

8.0

[DAMAGE TO ADJOINING UTILITY

LINES]

Failure of Contractor to make written report to Severance

Major Violation

company concerned of accidental damages to of contract.

water main lines. (Rule 21.07.a)

9.0

[GAS LEAK]

· Detection by Contractor of Gas leakages on Written

Monetary

Severance

Major Violation

occasion or by reason of the construction notice for

Penalty

of contract

shall be immediately reported to the Gas compliance

Company while the same (Contractor) is (2nd Notice)

undertaking measures, if appropriate, to

prevent ignition of any kind. (Rule 21.08.a)

10.0

{DAYTIME WORK STOPPAGE]

Severance

Major Violation

a. Failure of contractors to place sufficient steel of contract

plates of sufficient thickness for cover of

open trenches, when traffic conditions call for

a Mgmt. Work schedule. (Rule 21.09.a)

b. During non-working time, contractor/s must Written

Monetary

Severance

Minor Violation

ensure that no materials, equipment and Reprimand

Penalty

of contract

tools shall be parked along roadway that

poses problems or danger to the public.

(Rule 9-d)

11.0

[EXCAVATION & SHORING]

Monetary

Severance

Major Violation

a. To prevent possibility of excavation cave-in, Penalty

of contract

sheet piling, cribbing, shoring another

support systems, if necessary, shall be built-

in in accordance with Engineering Standards.

(Rule 21.10)

Written

Monetary

Severance

Major Violation

b. Failure of Contractor to frequently inspect notice for

Penalty

of contract

installed bracing or shoring after heavy rain immediate

or typhoon and failure to do necessary repair Compliance

or adjustment if necessary. (Rule 21.13)

15

Severance

Major Violation

c. Failure of Contractors to sufficiently install of contract

barricades and Early Warning Devices on

open excavations. (Rule 21.18)

12.0

[MACHINE EXCAVATION]

Written

Monetary

Severance

Major Violation

a.

No digging, using heavy equipment

Reprimand

Penalty

of contract

machines, shall be allowed close to

underground water facilities. Proximity of

limits for machine operation must be

established then completes the excavation

by labour digging. (Rule 21. 20a)

b.

Failure of contractors to warn workmen

Written

Monetary

Severance

Major Violation

about existence of underground water line

Reprimand

Penalty

of contract

facilities such that excavation-using driving

picks or any other powered tools is done

carefully. (Rule 21.20.b)

13.0

(TEMPORARY WALKWAYS)

Severance

Major Violation

Failure of Contractors to provide temporary

of contract

walkways to construction area needing the same

to prevent accident of any kind on occasion or by

reason of the on-going project. (Rule 21.22.a)

14.0

[GOOD HOUSEKEEPING]

Written

Monetary

Severance

Minor Violation

Non-observance by contractors of the operating

Reprimand

Penalty

of contract

standard procedures in Good Housekeeping in

construction sites which greatly affects the image

of

the

company

resulting

from

poor

housekeeping. (Rule 21.23.a)

15.0 (PERSONAL PROTECTIVE EQUIPMENT

AND DEVICES)

Written

Monetary

Severance

Minor Violation

Non-wearing of personal protective equipment Reprimand

Penalty

of contract

(PPE) appropriate for the exposure and the work

to be performed.

5.02.03.03

SUBMISSION OF CONTRACTOR'S SAFETY

PROGRAM

The Construction Safety and Health Program to be submitted by the

Contractor before the start of the project must be approved by BWC,

DOLE / MWSI Safety, shall state the following:

a. Composition of the Construction Safety and Health committee, if

one has been formed, otherwise, an understanding to organize

16

such committee and appoint its members before the start of

construction work at the project site;

b. Specific safety policies which the General Constructor undertakes

to observe and maintain in its construction site, including the

frequency of and persons responsible for conducting toolbox and

gang meetings;

c. Penalties and sanctions for violations of the Construction Safety

and Health Program;

d. Frequency, content and persons responsible for orienting,

instructing, training and supervising all workers at the site with

regard to the Construction Safety and Health Program under which

they operate;

e. The manner of disposing waste arising from the construction.

f. Validity of Construction Safety and Health Program will depend on

the duration of every contracted project.

5.02.03.04

SAFETY SEMINAR

Every MWSI Contractors are required to have at least two (2)

personnel that are trained in Occupational Safety and Health Seminar

(Forty Hours).

5.02.03.05

FABRICATION OF SAFETY SIGNAGES AND

BARRICADES

Every MWSI Contractors are obliged to secure their safety signages

and barricades from MWSI designated official fabricator.

5.02.03.06

SEPARABILITY PROVISIONS

a. All applicable provisions of this Code shall apply to all MWSI

Accredited Contractors and be a part of their Project Contract with

Maynilad Water.

b. In cases where the Safety Violations committed by any Contractor

is not defined and penalized under this Code, the Safety

provisions appearing in the executed Project Contract with

Maynilad Water shall control. If a Safety violation is both penalized

by this Code and the Executed Project Contract, the violation with

graver penalty shall be imposed.

c. It is incumbent upon every Accredited MWSI Contractor to comply

with the requirements being imposed by DOLE Department Order #

13, series 1998: re; Guidelines Governing Occupational Safety and

Health in the Construction Industry.

17

SECTION 6

SAFETY ORGANIZATION

6.01 There shall be a Safety Department, which will be created to oversee the

deployment of this code. This department will be composed of the

following;

a. Chief Safety

Functions:

1.Determines the safety requirements of MWSI.

2.Drafts and recommends the safety policies and reviews safety code for

revisions and amendments.

3.Plans, develops and recommends safety programs.

4.Oversees the implementations of all safety programs.

5.Monitors compliance of all operating units and their activities on

established safety code and policies through inspections and

investigations and submits recommendations, sanctions on violations.

6.Conducts safety meetings of the company.

7.Develops and maintains disaster contingency plan.

8.Plans and develops accident prevention program.

9.Oversees the activities of the Central Safety Committee.

10.Attends to all the safety requirements BWC-DOLE and other

government agencies.

11.Undertakes safety contests and awards distinction for outstanding

accomplishments.

b. There will be three (3) units on this department with the following

functions:

b.1) POLICIES AND DOCUMENTATION UNIT

Functions:

1. Plans, develops and maintains accident prevention program.

2. Formulates safety and other administrative policies in

coordination with the CSC and other safety units.

3. Serves as the secretariat of the Central Safety Committee.

4. Initiates, submits and supervises safety and health training for

employees.

5. Maintains records and reports covering all aspects of the Safety

programs.

6. Represents MWSI on safety seminars, trainings, meetings as

required by DOLE- BWC and Government Safety Regulations.

7. Evaluates safety gadgets/equipment of every area/division.

8. Convenes the review committee for accidents and incidents.

9. Oversees the conducts of awards and contests on safety

18

b.2) EMERGENCY PREPAREDNESS RESPONSE UNIT

Functions:

1. Plans, develops and maintains disaster contingency plan.

2. Prepares programs for Safety implementation during Confined Space

Works, Water Service Interruptions, Energization and the like.

3. Conducts safety training for CSC/ Employees and Contractors as

needed.

4. Conducts annual emergency preparedness program and other risks

management activities.

5. Mobilizes needed resources for disaster relief, evacuation activities

and acts as the lead unit in this undertakings. Links the same with

establish networks.

6. Liaises with government and other agencies regarding company

emergency preparedness programs.

7. Assists in the conduct of awards and contests on safety.

b.3) INSPECTION/ INVESTIGATION MONITORING UNIT

Functions:

1. Plans, develops and maintains safety programs on workplaces.

2. Conducts regular safety inspection on all MWSI areas including

constructions activities.

3. Reports violations on safety policies and recommends sanctions for

erring violators.

4. Issue non-compliance order and recommends works stoppage.

5. Checks safety and health programs of contractors.

6. Assists in the developing and planning of safety program.

7. Prepares monitoring compliance reports and recommend action

programs to enhance performance of the respective units.

8. Identifies training gaps and recommends needed trainings

9. Attends Safety Seminars/Training as required by DOLE-BWC and

other foreign regulatory bodies.

10. Assists in the conduct of awards and contests on safety.

19

SECTION 7

CENTRAL SAFETY COMMITTEE (CSC)

CENTRAL SAFETY COMMITTEE

ORGANIZATIONAL CHART

CHAIRMAN

VICE CHAIRMAN/ SECRETARY

SECRETARIAT

OPERATIONS DIVISION

ADMINISTRATION

CUSTOMER CARE AND

PUBLIC RELATIONS

BUSINESS AREAS (CEBA,

MANAMENT

SOBA, NEBA and NWBA)

CORPORATE

CUSTOMER SERVICE

MANAGEMENT SERVICES

CORPORATE

PROJECT MANAMENT

FINANCIAL SERVICES

GROUP

REVENUE ENHANCEMENT

CORPORATE LOGISTICS

DIRECTORATE

MWSA

MWSU-PTGWO

20

7.01.05 GROUPINGS OF CENTRAL SAFETY COMMITTEE

1. MANAGEMENT GROUP

To advise and assist the Management in implementing a well-organized

Safety Program and to recommend as appropriate all changes in the

overall program to improve efficiency and encourage employees to

increase their safety efforts.

FUNCTIONS:

Regular meetings-planned and instructive- for passing on information to

other employees.

2. Action of the committee as a clearinghouse for ideas, activities, and

follow-ups.

3. Investigation of major accidents and causes, and recommendations to

prevent their occurrence.

4. Supervision of Safety Awards and Contests.

5. Assistance in establishing Safety Standards and Operating Methods

on engineering works.

6. Suggestion for a Safety Education Program.

7. Inspection and suggestions for specific job practices.

2. WORKING GROUP

To create interest in Safety within the work force and to emphasize

employee responsibility for the prevention of accidents.

FUNCTIONS:

1. Reporting to Central Safety Committee on unsafe conditions and

practices.

2. Instructing and warning fellow workers of dangerous practices.

3. Assisting

in

the

investigation

of

accidents

and

making

recommendations for accidents prevention.

4. Improving a cooperative spirit between employees and management.

5. Functioning an opportunity for workers to take an active interest in the

Safety program.

6. Maintaining interest of all employees in the Safety Program.

3. ACCIDENT REVIEW GROUP

FUNCTIONS:

To review and determine the causes of accidents. Determines the extent

of an employee's responsibility in an accident and makes effective

recommendations to prevent occurrence of similar accidents.

21

CHAPTER II

BASIC SAFETY RULES

FIRE LOSS PREVENTION AND CONTROL

SECTION 8

FIRE LOSS PREVENTION

8.01 The Safety Department/ Facilities Management Department shall check

for fire hazards at regular intervals-electrical such as equipment,

machinery and processing equipment, housekeeping conditions and other

possible sources of fire. (A)

8.02 The Safety Engineer shall regularly check fire fighting equipment to be

sure that they are ready for any emergency. Each designated employee

must become proficient in handling fire Fighting equipment installed at the

area or station where he works. (A)

8.03 All concerned employees shall handle gasoline, gases and volatile (low

flash point) oils with great care. Open flames, lighted cigars, cigarettes or

pipes shall be kept away from them.

8.04 Employees shall eliminate or immediately put out small fires or report to

their immediate supervisor any fire hazard, particularly in their work area,

which may cause the loss of life or destruction of the System's property.

(A)

8.06 FIRE EXITS

a. All approaches to fire exits shall be cleared of any obstruction

and properly marked to make the direction of egress clear. (B)

b. Doors leading into or out of any building or floor shall not be

locked or fastened during working/office hours. (B)

c. All doors, in or leading to exits shall be maintained open from

the inside without the use of a key or any special knowledge or

effort at all times when the building or area served thereby is

occupied. (A)

d. Relevant rules and regulations on fire protection and control

regarding exits, stairways and fire doors shall be obeyed as per

provisions of Rule 1940, OSHS of DOLE and Rule 3, Division 4

of the Philippine Fire Code. (B)

e. Fire exit drills shall be conducted at least once every six (6)

months to maintain an orderly evacuation of buildings for major

installations. It shall only include evacuation of persons and

shall not include salvage operations. (B)

22

8.07 HOUSEKEEPING

a. Oil-soaked and paint saturated rags, papers, waste and other

combustible refuse shall be deposited in non-combustible

receptacles having self-closing covers, and thereafter removed

daily from the work areas for proper disposal. (B)

b. A procedure on safe collection and disposal of all combustible

waste and rubbish shall be a part of the fire prevention-training

program. (A)

c. Accumulation of all type of dust shall be cleaned at regular

intervals from overhead pipes, beams and machines,

particularly from bearings and other heated surfaces. (A)

d. Roofs shall be kept free from sawdust, shavings, and other

combustible refuse. No such materials shall be stored or

allowed to accumulate inside air shafts, or elevator and stair

shafts, tunnels, out-of-the-way corners, near electric motors or

machinery, around steam pipes, or within three meters of any

stove, furnace or boiler. (A)

8.08 RUBBISH DISPOSAL

a. Combustible rubbish, dried weeds and grass shall not be

allowed to accumulate in plant yards, particularly near buildings,

other combustible materials, or storage tanks containing

flammable liquid and gases. (B)

b. Rubbish shall be burned only in designated areas away from

buildings, sheds, lumber piles, fences and dried grass or other

combustible materials. (B)

c. Wind and weather conditions shall be considered before fires

are started. Only controllable quantity of rubbish shall be burned

at one time. No fire shall be started on a windy day where there

is a possibility of igniting nearby combustible materials. It is

required to have a fire hose or other suitable fire fighting

equipment near the fire site. (B)

8.09 ELECTRICAL

a. Only approved equipment shall be used where flammable gases

or vapors are present. (B)

b. Temporary makeshift wiring shall be used unless absolutely

necessary, in which case, it shall be adequately protected and

properly barricaded, and shall be removed as soon as possible.

In no instance shall defective wires be used. (B)

c. Portable electrical tools and extension cords shall be inspected

at frequent intervals and repaired or replaced promptly when

found defective. (A)

d. Waterproof cords and sockets shall be used in damp places and

explosion-proof fixtures and lamps shall be used in the

presence of highly flammable gases and vapors. (B)

e. Portable lamp bulbs shall be protected by heavy lamp guards or

by adequately sealed transparent enclosures, and left away

23

from sharp objects and kept from falling. Bare bulbs shall never

be used when exposed to flammable dusts or vapors. Lamp

bulbs shall be considered as potential hazards in areas where

flammable dusts or vapors exist; they shall be safeguarded

accordingly. (B)

f. All electrical machines/equipment shall be unplugged during

lunch hours and at the end of the working day. (B)

g. The use of electrical octopus connections shall be avoided. (B)

h. Employees shall be instructed in the proper use of electrical

equipment and shall be prohibited from tampering and blocking

circuit breakers and from using improperly rated fuses or bypass

wires. (B)

i. Personally owned electrical cooking appliances such as

percolators, stoves and the like shall not be plugged into the

System's building electric facilities. (B)

j. Electrical installations and all electrical equipment shall be

periodically inspected and tested to ensure continued

satisfactory performance and to detect deficiencies. (A)

8.10 SMOKING

a. All areas where smoking is prohibited shall be provided with "No

Smoking" signs. (B)

b. Employees are prohibited from carrying matches, lighters and

other spark-producing devices to areas where flammable and

combustible liquids, chemicals, gases and the like are stored or

handled. (B)

c. Wastebaskets shall never be used for cigarette disposal. (B)

d. Lighted cigarette butts shall always be totally put out and left n

non-combustible ashtrays. (B)

e. Before leaving the office for coffee break, lunch or after office

hours, floors, tables, chairs and top of cabinets shall be checked

by a designated employee for lighted cigarette inadvertently left

behind. (B)

8.11 OPEN FLAMES

a. Open flames using kerosene, liquefied petroleum gas, acetylene

or alcohol and other torches shall be placed at least 0.50 meters

from wood surfaces. These should not be used close to

flammable liquids, papers, excelsior or similar materials. (B)

b. When portable furnaces, blowtorches and the like are used,

there shall be an overhead clearance of at least 1.2 meters.

Combustible materials shall be removed or protected by a non-

combustible insulating board or sheet metal and preferably by a

natural draft hood and flue of non-combustible material. (B)

24

SECTION 9

PORTABLE AND MANUAL FIRE CONTROL

9.01 SELECTION OF EXTINGUISHERS

Extinguishers shall be selected for the specific class or classes or hazards

to be protected against in accordance with the following:

a. Extinguishers for Class "A" hazards, such as wood, cloth, paper,

rubber and other similar ordinary materials, shall be selected

from foam, loaded stream, multi-purpose dry chemical and

water types.

b. Extinguishers for Class "B" hazards, fires in flammable liquids,

gases and greases, shall be selected from carbon dioxide, dry

chemicals, foam loaded stream and multi-purpose dry

chemicals.

c. Extinguishers for Class "C" hazards, fires which involve

energized electrical equipment where the electrical non-

conductivity of the extinguishing media if of importance, shall be

selected from carbon dioxide, with non-metallic horn, dry

chemicals and multi-purpose dry chemicals.

Before any dry chemical extinguishing equipment is considered for use to

protect electronic equipment or delicate electrical relays, the effect of

residual deposits of dry chemical on the performance of this equipment

shall be evaluated.

9.02 INSPECTION AND MAINTENANCE

a. Fire extinguishers shall be maintained in a fully charged and

operable condition, and kept in their designated places at all

times except when being used, tested, repaired or replaced. (B)

b. Fire extinguishers removed from the premises where they are

regularly installed for recharging or repair shall be replaced by

spare extinguishers of the same type and capacity, during the

period they are serviced. (A)

c. Fire extinguishers shall be inspected monthly, or at more

frequent intervals when circumstances require to ensure that

they are operable and in their designated places, that they have

not been tampered with and are fully charged and pressurized,

and to detect any physical damage, corrosions, or other

impairments. Extinguishers or parts thereof, which are not in

good operating condition, shall be immediately recharged,

repaired or replaced by qualified suppliers. (A)

d. Each fire extinguisher shall have a durable identification tag

securely attached to show the maintenance of recharge date

and the initial or signature of the person who performed this

service. (A)

e. Caps shall always be replaced on the same shell from which

they were removed to prevent mismating of threads. A small

amount of Vaseline or any other acceptable substitute shall be

25

applied to cap threads. Caps shall be screwed on tightly,

making sure that the threads are properly engaged. (A)

9.03 INSTALLATION

a. Fire extinguishers shall not be obstructed or obscured from

view. In large rooms and in certain locations where visual

obstructions cannot be completely avoided, the location of

extinguishers shall be indicated conspicuously with a red arrow.

(A)

b. If fire extinguishers intended for different classes of fires are

grouped, their intended use shall be marked conspicuously or

color-coded to ensure use of the proper extinguisher for the

class of fire that occurs. (A)

c. In situations where fire extinguishers shall be temporarily

provided, they shall be installed on portable stands, consisting

of a horizontal bar or uprights with feet, or set on shelves unless

the extinguishers are of the wheeled type. (A)

d. Fire extinguishers mounted in cabinets or wall recesses, or set

on shelves shall be placed in a position such that the

extinguisher operating instructions face outward. The location of

such extinguishers shall be marked conspicuously. (A)

9.04 HYDROSTATIC TEST

Inspection, maintenance, hydrostatic test and recharging of portable fire

extinguishers shall be in accordance with the provisions of NFPA No. 10.

(B)

9.05 CARE OF FIRE HOSES AND ACCESSORIES

The care of fire hoses, nozzles, couplings and gaskets shall be in

accordance with the provisions of NFPA No. 198. (B)

SECTION 10

VEHICULAR AND TRAFFIC SAFETY GUIDE

GENERAL RULES

10.01

National and local traffic laws and regulations shall be observed at all

times. (B)

10.02

When driving along public or private roads, prescribed speed limits and

regulations shall be observed. (B)

10.03

No employee shall operate any System's vehicle unless he is duly

licensed, and has been examined and authorized by proper authorities.

(B)

10.04

Authority to drive is not transferable. (D)

26

10.05

No driver shall allow another person to drive the vehicle assigned to

him, unless the latter is duly authorized by the System. (B)

10.06

No passenger shall be allowed to ride on the running board, fender,

tailboard and/or any other part of the System's vehicle, except on seats

provided or inside the body of walls. (B)

10.07

No part of the human body shall extend outside the vehicle. (A)

10.08

No passenger shall be allowed to board or alight from a moving vehicle

or from a stopped vehicle at the traffic side of the road. (A)

10.09

No driver shall drive a vehicle while under the influence of liquor,

narcotics, or sleep-inducing drugs, or the like. (D)

10.10

No employee shall drive any private vehicle inside the MWSI

compound while under the influence of liquor, narcotics or sleep-

inducing drugs, or the like. (C)

10.11

The driver shall conduct daily checks on the following: (A)

B -

rake

E -

lectricity

W -

ater

A -

ir

G -

as

O -

il

N -

oise (steering)

S -

teering

10.12

Regular, contractual and casual MWSI drivers, for purposes of

monitoring driving competence and psychophysical fitness, shall

undergo the Psycho Physical Test once a year. (B)

10.13

Drivers with test results below the set standards for the Psycho

Physical Test shall be reassigned to non-driving assignments to be

identified by the Fleet Management. (B)

SECTION 11

LOADING AND UNLOADING

11.01

Overloading the vehicle shall not be allowed. The load shall be

properly distributed, secured in place and not piled too high in order to

maintain stability and to satisfy required overhead clearances. (A)

27

11.02

Tailgates and all detachable equipment in the vehicle shall be properly

secured before traveling. (A)

11.03

Loads shall be handled at the curbside of the vehicle. Where this

cannot be avoided, flagmen should be stationed and/or appropriate

warning signs shall be placed at all traffic approaches. (A)

11.04

Trailers shall be provided with proper stop and taillights. (A)

11.05

Vehicles and trailers with loads projecting beyond body lines shall have

the extreme projections provided with fully secured red flags and stop

lights in the daytime and with red lights and stop lights at night time.

When practicable, a marker shall be attached halfway between the

truck and end of load projection, such as when poles are being

handled. (A)

SECTION 12

PARKING AREA AND GARAGE

12.01

Before moving a vehicle from a parked position, the driver shall check

around and under the vehicle for possible hazards. (B)

12.02

The driver shall conduct a brake test before operating a vehicle from

the MWSI parking area and garage. In case of any indication of a faulty

brake, he shall stop the vehicle, park it properly and report the

condition immediately to the MWSI Motor Pool.

SECTION 13

PARKING IN PUBLIC PLACE

13.01

Whenever a driver has to leave his vehicle unattended along a

highway, he shall move his vehicle entirely off the traveled portion of

the road, turn off the ignition switch, notch effectively the hand brake

and keep the ignition key with him. He shall place the early warning

device (EWD) at the required distance in front of and behind the

vehicle, check traffic before opening the door to get in and out of the

vehicle and keep doors securely closed at all times. (B)

13.02

When parking downhill, he shall slightly turn the front wheels to the

right towards the curb or side of the road, leave the vehicle in reverse

gear and hand brake notched effectively. When parking uphill, he shall

turn front wheels towards the curb or side of road and leave the vehicle

in low gear and hand brake notched effectively. Wheel chucks shall be

used to lock the wheels when parking downhill or uphill and most

especially when it is necessary to keep the motor running. (B)

28

SECTION 14

SAFE DRIVING

14.01

In addition to the provisions of the Land Transportation and Traffic

Code, every employee who is authorized to drive the MWSI vehicles

shall observe and practice the following defensive and safe driving

habits:

a. Signal intentions well in advance at all times regardless of the traffic

conditions. (A)

b. To avoid hitting a vehicle being followed, maintain a safe distance

of at least one vehicle length for every ten (10) KPH of speed. This

required distance should be doubled at night or when road is

slippery. (A)

c. To avoid being hit by a vehicle from behind, the driver shall:

1. Make every stop or reduced speed in a smooth and gradual

manner. (A)

2. Signal intentions well in advance. (A)

3. Try to keep the vehicle behind from riding your tail, e.g., find

means of preventing the vehicle behind from staying too close to

your bumper. (A)

d. To avoid head-on or sideswipe collisions, the driver shall:

1. Always drive as far to the right of the center of the centerline of

a highway as much as possible. (A)

2. Reduce speed and slow down before entering a curve. (A)

e. To avoid angle collisions, the driver shall:

1. Approach all intersections with the right foot off the accelerator

and step on the brake pedal, ready for any eventuality such as

pedestrians and other drivers who do not obey the traffic rules.

(A)

2. Bring the vehicle to full stop before entering any through street,

highway or railroad crossing. (B)

3. Check traffic to the left, then to the right, to see if there are

vehicles crossing the street. Proceed only when traffic is clear.

Do not rely on your having the right-of-way. (A)

4. Signal well in advance and proceed to the correct turning lane

from a reasonable distance. Let approaching traffic clear first

before making a left turn. (A)

f. To avoid a sideswipe collision, the driver shall:

1. Slow down when being overtaken on left or right to make it easy

for the other vehicle to pass. (Do not race the other vehicle.) (A)

2. Check your rear side mirror; make a signal and change lane

only when it is safe to do so without disrupting the flow of traffic.

(A)

3. Signal well in advance, slow down gradually and keep as close

to the right or curb when making a right turn. (A)

4. Check the rear, signal intentions and wait for a break in traffic

before pulling out of a curb or parking space. (A)

29

g. To avoid head-on-sideswipe and angle collisions, the driver:

1. Shall not drive to the left side of the centerline of the highway in

overtaking or passing another vehicle preceding in the same

direction unless the left side is clearly visible and is free of

incoming traffic. This is to allow for a sufficient distance ahead

to permit such overtaking or passing to be made safely. (A)

2. Shall not overtake when he himself is being overtaken or when

another vehicle tries to tail him in his attempt to overtake

another vehicle.

3. Shall not overtake or pass another vehicle proceeding in the

same direction when approaching a crest of a grade, upon a

curve in the highway, at any railway grade crossing, at any

intersection of highways and at all "no passing or overtaking

zones." (B)

4. Shall not pass a car that has stopped to permit pedestrians or

other vehicles to cross. (B)

14.02

He shall always slow down and be ready to step on the brakes when

passing through any busy streets where long lines of cars are parked

and where pedestrians may dart across at any moment. (B)

14.03

Vehicles shall always descend steep grades at low gear. (B)

14.04

The driver shall always devote his full attention to driving, anticipating

danger in time to avoid it. (A)

14.05

The driver shall be alert for signals from traffic police officers and other

drivers, traffic signals signs, etc. (A)

14.06

The driver shall avoid beating traffic stop signals. (A)

14.07

The sounding of horns does not give anyone of the right-of-way. The

driver shall use it only as a warning and shall proceed cautiously.

14.08

He shall slow down upon approaching school zones, parks,

playgrounds, crowded streets and thickly populated areas and be

always on the alert for children. The law gives the right-of-way to

pedestrians. (B)

14.09

Headlights shall be put on not later than one half-hour after sunset and

until at least one half hour before sunrise and whenever weather

conditions so require. Parking lights shall not be used in lieu of

headlights. (A)

14.10

At night, the driver shall always dim his light when within 150 meters of

oncoming vehicles and when following another vehicle within 60

meters. Glare may cause the other vehicle to swerve his oncoming

30

vehicle toward the other lane. The same rule shall be observed when

driving along well-lighted and thickly populated areas. (A)

14.11

After passing through flooded streets, the driver shall check his brakes

to make sure that they are working properly before proceeding to

normal speed. To dry the brake linings, he shall press his foot brakes

slightly several times while his vehicle is in low motion until assured

that the brakes are functioning normally before proceeding the normal

speed. (B)

14.12

In case of sudden tire blowout, the driver shall not step hard and

abruptly on his brakes. This will cause his vehicle to turn turtle or

swerve suddenly when driving at high speed. Instead, steer straight

and gradually bring the vehicle to a stop by applying slight on and off

pressure (fanning) on the foot brakes. (A)

14.13

For trucks with or without trailers, enclosed vans and similar vehicles

where the rear view of the driver is limited, a signalman shall be

assigned. The foreman, leadman, supervisor, as the case may be,

shall designate a signalman for the day. (A)

Any backing motion of the vehicle shall be done slowly with extra care

and under the direction of the signalman on the ground that has an

unobstructed view of the intended path of the vehicle. The same shall

be observed when there is difficulty in maneuvering the vehicle by

reason of its position or location. (A)

If backing is to be done, he shall personally make sure that all is clear

behind at the time. He shall never assume that the other vehicle has

not driven up behind or that pedestrians have cleared off the back area

since he last looked. (A)

14.14

The driver shall stay on his own lane of the road at intersections,

railroad crossings, no passing zones, hills and curves where his view is

obstructed. Right-of-way is better than sight-of-way. (B)

14.15

The driver shall not straddle lane lines. This is inconsiderate and

constitutes "hugging". (A)

14.16

The driver shall not drive a vehicle with his hands and soles of shoes

wet and/or greasy. (A)

14.17

The driver shall not be allowed to smoke when looking into the fuel

tanks, the cooling water of radiator or the battery. (B)

14.18

The driver shall not keep oil, rags, waste or other flammable objects

under the hood or elsewhere inside the vehicle where combustion

might occur. (B)

31

14.19

Safety containers used for fuel handling shall be checked for leaks,

excessive rusting and weak spots. (B)

SECTION 15

MOTOR WORKS

15.01

Vehicles jacked-up or hung-on chain hoists shall always be blocked

under with stanchions, pyramid, jacks or wood blocks (which have first

been carefully inspected). (B)

15.02

When a man is working under a vehicle that is blocked up, other

workers shall not work on the car in such a manner that the car will be

knocked off from its support blocks. (B)

15.03

Use electric lamps with extension cords, portable electric tools with

cords and fittings and safety guards that are all in good condition. (B)

15.04

Always wear goggles or face shields when operating sandblast spark

plug cleaners. (A)

15.05

Concrete or clay hollow blocks and other brittle/weak materials shall

not be used to support jacked-up vehicles. (B)

15.06

Vehicles with more than three (3) wheels that are jacked-up on two

wheels shall be provided with wheel stops on both ends of the other

wheels. No chassis repair shall be allowed unless effective wheel

stops are provided on these wheels. (B)

15.07

Vehicles under chassis repair shall be provided on all sides with

adequate barricades and warning signs to protect protruding legs of

workers. (B)

15.08

Never operate an engine in an enclosed room without adequate

ventilation. Carbon monoxide is poisonous and may cause death.

15.09

Do not leave gasoline standing around in open containers. Use

kerosene or other suitable safe preparations to clean parts whenever

possible. (B)

15.10

Keep a pair of safety goggles handy and wear them when performing

work in which eye protection is needed. (A)

15.11

Be on guard against flashes or explosion of gasoline vapors and

hydrogen from storage batteries. Keep flames and sparks away. (B)

32

15.12

If your clothes soaked with oil or gasoline, better changed them. Do not

take the risk to be caught by fire. (B)

15.13

Make sure all the lock washers and cotter pins are properly in-place.

(C)

15.14

Grease and oil spilled on the floor shall immediately remove in order to

prevent accidents. (B)

SECTION 16

TIRE OPERATIONS

16.01

Only workmen thoroughly familiar with the hazards and safe methods

involved in handling tire equipment shall inspect, install, repair and

replace tires and rims. (B)

16.02

Keep in safety cans rubber cement and flammable solvents used for

patching inner tubes and casing compounds used for filling tire cuts.

(B)

16.03

Tiremen shall inflate tires in steel "cages" or similar devices that shall

restrain flying objects during the inflation process. A locking ring shall

be seated properly and shall not be yanked free by being twisted.

Defective locking rings shall be replaced. (B)

16.04

Electric heating elements used for vulcanizing or branding tires shall

be inspected regularly, and defective rings shall be replaced. (B)

SECTION 17

WASHRACKS OPERATION

17.01

The concrete floor of washracks shall have a rough trawled finish to

produce a non-slip surface. (A)

17.02

While washing vehicles, workers shall wear rubber boots with non-slip

soles and heels, gloves and eye goggles. (A)

17.03

Keep working area clean and free from stray tools and parts. Place

tools in their tool box when not in use. (B)

17.04

Washrack water hoses are high-pressured and shall not be directed at

persons while in use. (B)

17.05

Workmen shall use the hose carefully in such a way as to avoid being

struck by a backlashing stream of water and dirt. (A)

33

SECTION 18

TOWING

18.01

No person shall be allowed to stay between the towing truck and the

towed vehicle whether at stop or in motion. When at stop and work is

to be done the towing truck driver shall be warned not to move the

vehicle until such work is completed, after-which he shall be given the

go signal to move the vehicle. (C)

18.02

The towing vehicle and the vehicles being towed shall be properly fixed

before moving them. (C)

SECTION 19

HEAVY EQUIPMENT AND TOOLS

A. HEAVY EQUIPMENT

19.01 Only duly authorized personnel shall operate heavy equipment. (B)

19.02

Drivers of mobile heavy equipment and trainers shall be duly licensed

and also authorized by MWSI. (B)

19.03 Operators shall be responsible for the proper condition and cleanliness

of the heavy equipment assigned to them, and for making reports of

any defect or unusual condition found therein. (A)

19.04

At no time shall the operator allow anybody under a boom except the

rigger doing rigging work. (B)

19.05

Booms, forkholders, payloaders and the like shall be kept at a safe

distance from overhead-energized lines. If it should be absolutely

necessary to cross or work in close proximity with energized lines, the

electric company shall be requested for appropriate assistance in the

provision of safety measures. (C)

19.06

The operator shall not allow unauthorized persons to operate the

equipment assigned to him nor allow such persons to ride on the

equipment while same is in motion. (B)

19.07

No operator shall operate any equipment unless he is physically able

and mentally sound. He shall not operate a vehicle if he is under the

influence of liquor and/or prohibited drugs or any drug that causes

drowsiness. (C)

34

19.08

Operators shall receive directional signs only from duly authorized

persons designated for the purpose. (B)

19.09

No operator shall move his equipment with his suspended load except

when authorized by the superior. (B)

19.10

All booms shall be lowered after each work shift, except when

otherwise authorized by the superior. (B)

19.11

The operator shall determine the safe clearance of overhead

obstructions and building openings, and shall proceed only when such

clearances meet the requirement. (B)

19.12

Detailed regular inspection of all hoists with special attention to load

hooks, ropes, brakes and limit switches, shall be scheduled. (A)

19.13

The safe load capacity of each hoist shall be shown in conspicuous

figures on the hoist body of the machine. (B)

19.14

Flanges and hoist drums with single-layer grooves shall be free of

projections that will damage the cable. (B)

19.15

All hoists shall be attached to their support (fixed member of trolley)

with shacklers, or support hooks shall be placed properly or have

safety latches. Latches are recommended also for load hooks. Hoist

supports shall also have an adequate safety factor for the maximum

loads to be imposed. (B)

19.16

Travelling hoists operating on rails, tracks or trolleys shall have positive

stops or limiting devices either on the equipment, rails, tracks or

trolleys to prevent over running safe limits, and shall be equipped with

over-speed control devices. (B)

19.17

A load shall be picked up only when it is directly under the hoist;

otherwise, stresses for which the hoist was not designed shall be

imposed upon it. If the load is not properly centered, it will swing (upon

being hoisted), and injury could result. Everyone shall stay away from

under raised loads. (C)

19.18

AIR HOISTS

a. After a piston-type air hoist has been in operation for a time, the

locknut that holds the piston on its rod may become loose so that

the rod will pull out of the piston, thus letting the load drop. It is

recommended that the locknut be secured to the piston rod by a

castellated nut and cotter pin. Whenever an air hoist is overhauled,

a check shall be made to see that the piston is well secured to the

rod. (B)

35

b. If an ordinary hook is used to hold the hoist from its support, the

cylinder may come unhooked if the piston rod comes in contact with

an obstruction when lowering. A clevis or other device should be

used to prevent the hook from being detached from the hoist

support. (B)

c. To prevent the hoist from rising or lowering too rapidly, a choke

such as a washer with the correct opening shall be placed in the

airline coupling. (B)

d. It is recommended that a rotary air hoist be provided with a closed

loadline guide. (B)

19.19 ELECTRIC HOISTS

a. An electric hoist shall have a non-conducting control cord unless a

grounding device is provided. Control cords shall have handles of

distinctly different contours so that even without looking, the

operator shall know which is the hoisting and which is the lowering

handle. (A)

b. Each control cord shall be clearly marked "hoist" or "lower". (A)

c. Control cords, usually made of fiber or light wire ropes, shall be

inspected periodically for wear and other defects. (A)

d. On pendant-controlled electric hoists, means for effecting automatic

return to the "off" position shall be provided on the control so that a

constant pull on the control rope or push on the control button shall

be maintained to raise or lower the load. (B)

e. A limit stop should be installed on the hoist motion, and at least two

turns of rope shall remain on the drum when the load block is on

the floor. (B)

19.20 HAND-OPERATED CHAIN HOISTS

a. Chain hoists shall be of larger capacity than the regular work

requires. (B)

b. Supports for the hoists shall be strong enough to carry the load

imposed on them. (B)

19.21 CRANES (MOBILE)

a. Open hooks shall not be used to support human loads, loads that

pass over workmen or loads where there is danger of relieving the

tension on the hook, due to the load or hook catching or fouling. (B)

36

b. Outside cranes shall be provided with secure fastenings adequate

enough to hold the crane against strong winds. When necessary,

provide special anchorage. (B)

c. Structural members of the crane shall never be made of cast iron or

other brittle material. In the fabrication and assembly of structural

work such as girders and frames, operator's cages, booms and

bracket, hot driven rivets or welding shall be used instead of bolts.

Where bolts shall be used, they shall be of the "through" type with

locknuts or conventional nuts and lock washers. (B)

d. Each controller and operating lever shall be marked with the motion

it controls and its direction. These levers shall have spring returns

so that they will move automatically into the "off" position and latch

themselves there as the operator releases the handle. (B)

e. Operating a crane on soft or sloping ground or close to the sides of

trenches or excavation is dangerous. The crane shall always be

level before it is put into operation. Outriggers can be relied upon to

provide stability on the soil upon which the crane is operated. (C)

f. The use of any makeshift methods to increase the capacity of a

crane, such as timbers with blocking or adding counter-weight, is

not permitted. (C)

g. If the crane tends to tip when hoisting or lowering a load, the

operator shall lower the load as quickly as possible by snubbing it

lightly with the brakes. Workers, therefore, are not allowed to ride a

load that is being hoisted, swung or transported. (B)

h. Never move the load or the crane unless you are sure you

understand the floor signal. (B)

i. When there are several riggers, obey the signal given by the head

rigger only. (Obey an emergency stop signal given by anyone.) (A)

j. When filling the fuel tank of a crane, always provide a metallic

contact between the fuel container and the tank. (B)