Global Mercury Project

Project EG/GLO/01/G34: Removal of Barriers to Introduction of Cleaner Artisanal Gold Mining and Extraction Technologies

Information about the Project Sites in

Zimbabwe

Dennis S. M. Shoko, PhD

Assistant to Country Focal Point,

GMP-Zimbabwe

Marcello M. Veiga, PhD

Small-scale Mining Expert,

GMP - Vienna

January 2004

Table of Content

Page

1. Introduction.................................................................................................................................3

2. Description of the Site................................................................................................................3

2.1. Physiography (relief and drainage) .....................................................................................3

2.2. Outline Geology of the Area ...............................................................................................6

2.3. Climate (temperatures and rainfall) ....................................................................................6

2.4. Access and Infrastructure.....................................................................................................7

2.5. Administrative and Institutional Structures........................................................................7

2.6. History of Gold Extraction in the Chakari-Golden Valley Area.......................................8

2.7. Community Socio-economic Profile...................................................................................8

2.7.1. Demographic Data .......................................................................................................8

2.7.2. Economic Activities.....................................................................................................9

2.7.3. Gender Aspects: Women Involvement in Mining .....................................................9

2.7.4. Education Levels of Adult Community....................................................................10

2.7.5. Housing.......................................................................................................................10

2.7.6. Occupational Hygiene/Sanitation .............................................................................10

2.7.7. Water...........................................................................................................................10

2.7.8. Health Facilities .........................................................................................................10

2.7.9. Education Facilities....................................................................................................11

2.7.10. Diet............................................................................................................................11

3. Ore milling and gold processing..............................................................................................11

3.1. Grinding Process ................................................................................................................12

3.2. Concentration Process........................................................................................................13

3.3. Amalgamation Process.......................................................................................................14

3.4. Cyanidation.........................................................................................................................15

3.5. Gold Sales ...........................................................................................................................16

3.6. Pros and Cons of the Custom Milling Centers .................................................................16

3.7. Gold Panning in the Kadoma-Chakari Area.....................................................................17

3.8. Mercury Losses ..................................................................................................................18

4. Environmental impacts.............................................................................................................18

4.1. Barriers to the Introduction of Cleaner Gold Extraction Technologies..........................19

1. Introduction

The Kadoma-Chakari area lies within one of the largest gold belts (greenstone belts) of

Zimbabwe and has the highest density of small scale gold miners, millers and panners of all

the country's gold belts. Geographically, the area occurs about 150 km south-west of Harare

along the main Harare-Bulawayo highway and is located within the Zambezi Basin (Fig. 1 and

2). Access into the mining areas from Kadoma City is very good along paved all-weather

roads and good dry season roads. The Zambezi Basin and its water resources are shared by

eight of the fourteen Southern African Development Community (SADC) states. The long-

term environmental well-being of the Zambezi River, its tributaries, and associated dams and

lakes depend on the types and volumes of economic activities that take place within the basin.

These activities include urbanisation, logging, agriculture, manufacturing, tourism and mining.

More recently, small scale mining and alluvial gold panning activities have taken centre stage

as a result of both the economic structural adjustment programmes (ESAPs) and recurrent

droughts within the SADC region. It is estimated that up to two million people directly and

indirectly benefit from small scale mining and alluvial panning of gold within the Zambezi

Basin (Shoko, 2002). It has also been estimated that in Zimbabwe, there are between 300,000

and 400,000 artisanal gold miners sustaining the livelihoods of at least two million people

(Maponga and Ngorima, 2003)1.

2. Description of the Site

2.1. Physiography (relief and drainage)

The town of Kadoma is situated on the highveld and is a few kilometres to the north west of

the main watershed separating the Zambezi drainage system to the north and north-west and

the Save-Limpopo drainage system to the south and south-east. The general relief in the area

is in the region of 1250 metres above sea level with occasional hills rising to nearly 1300

metres above sea level. The major drainage system in the area is that of the Muzwezwe river ,

which is a major tributary of the Munyati river in the Kadoma area. The Claw dam which

supplies the bulk of Kadoma's water requirements is situated on the Muzvezve river. Drainage

within the Muzvezve river system is to the north-west into the Munyati river, which itself is a

tributary of the Zambezi river. Kadoma falls within Hydrological Zone C which constitutes

the Sanyati Catchment area. The Chakari area is drained by the Shagari river which is a

tributary of the Mupfure river. The Mupfure eventually drains into the Munyati river which is

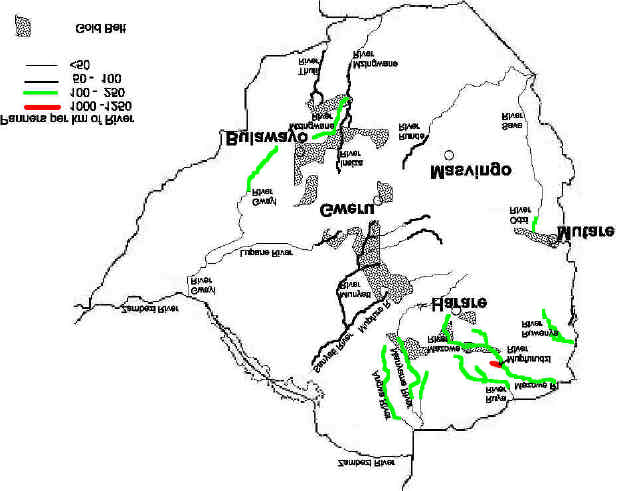

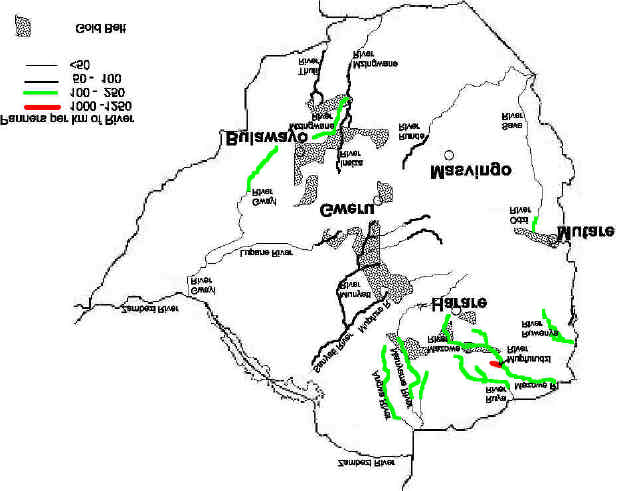

a tributary of the Zambezi river (Fig. 2)

1 Maponga, O. & Ngorima, C.F., 2003. Overcoming Environmental Problems in the Gold Panning Sector through

Legislation and Education: the Zimbabwean Experience. J. Cleaner Production, v. 11, p.147-157

21 °E

24°

27°

30°

33°

9

TANZANIA

°S

Ruhuhu

DEMOCRATIC

N

REPUBLIC

OF CONGO

ZAMBIA

ANGOLA

12°

Zambezi

Lake

Malawi

Luena

Kabompo

Lungue Bungo

Lunga

Kafue

Luanginga

Luangwa

Mulungushi

Shire

15°

Cuando

L. Cahora

Bassa

Zambezi

Luiana

L. Kariba

Mazowe

ANGOLA

Zambezi

Hunyani

18°

Sanyati

Umniati

Chobe

Zambezi

NAMIBIA

Shangani

Gwayi

MOZAMBIQUE

0

250

500 km

Indian

BOTSWANA

ZIMBABWE

Ocean

Fig. 1 - Sketch map showing the main rivers, lakes and sub-catchments of the Zambezi basin.

(in the square: project site)

Fig.2. - Small-scale and artisanal gold mining in Zimbabwe. Formal small-scale mining

of gold is widespread in all the gold belts indicated. Informal artisanal riverbed mining of

gold in Zimbabwe is indicated for rivers in 1999-2000.

2.2. Outline Geology of the Area

Most of the area is covered by Bulawayan Group rocks which have been folded into the

north-east trending Kadoma anticline, with minor folds on both the north-east and south-east

limbs. The core of the Kadoma anticline is occupied by the Mafic Formation, the lowermost

of the two formations of the Bulawayan Group in the area. This formation consists of basaltic

greenstones, now converted to fine grained, chlorite and hornblende schists, together with

epidiorites, coarser grained rocks of a generally similar composition, which are believed to be

contemporaneous intrusives. The overlying Felsic Formation outcrops on both limbs of the

Kadoma anticline. The formation consists predominantly of quartz-mica schists with

intercalated basaltic greenstones. Shamvaian sediments occur sporadically at the top of the

stratigraphy.

2.3. Climate (temperatures and rainfall)

The area, as is the case with most of the country, has a tropical climate, with distinct wet and

dry seasons. The wet season (November-March) is marked by brief convectional

thunderstorms and drizzle (light rain), otherwise known as guti, light drizzle is particularly

common towards the end of the rainy seasons.

Maximum air temperatures are lowest between June and July. The highest air temperatures

are in October. Highs are also common in the period from November to the end of January

(Fig. 3). The cooling effect of rainfall moderates air temperatures in the latter period. Micro

conditions have a highly significant influence on temperature. Areas on higher elevation have

a highly significant influence on temperature. Areas on higher elevation have very low

temperature figures recorded at Kadoma station for the period indicated. The mean annual soil

temperatures do not pose any germination problems for most of the important crops produced

in Zimbabwe. This makes the soil temperature regimes insignificant in their limitation of crop

establishment in the area. The most important factor becomes soil moisture and this is directly

related to levels of precipitation and evapo-transpiration.

35

30

25

20

15

10

temperature (0C)

5

0

JUL

AUG

SEP

OCT

NOV

DEC

JAN

FEB

MAR

APR

MAY

JUN

Fig. 3 Ten-year Mean Monthly Max Temperatures for Kadoma

The Kadoma area has one distinct wet season. Precipitation is received in the period between

November and March. Figure 4 shows ten-year mean annual rainfall figures for the area. Most

of the heavy rainstorms are a result of convectional activity. These storms are usually brief

and heavy. This impacts negatively on effective soil moisture, as most of the received rain is

lost through run-off. The cropping season in this area starts about mid November ending in

April. The cropping season is approximately 130days.

250

200

150

100

rainfall (mm)

50

0

JULY

AUG

SEPT

OCT

NOV

DEC

JAN

FEB

MAR

APRIL

MAY

JUNE

Fig. 4 Ten-year Mean Monthly Rainfall for Kadoma

2.4. Access and Infrastructure

Kadoma is situated along Zimbabwe's main watershed and is linked by the country's main

Harare-Bulawayo Highway and the trunk Mutare Harare-Bulawayo railway line. There is a

daily passenger train and a very frequent bus service between Kadoma and all the major cities

of Zimbabwe. Tarred roads connect the city to Cam & Motor mining area in the east and the

Chakari-Golden Valley-Patchway mining area to the north and north west (figure 3). Small

dirty, dry-weather roads branch out from the all-weather roads to mine and mill locations

scattered throughout the project demonstration site. The town has many medium to large sized

hotels and country lodges at competitive rates. Tele and electronic communication

(telephones, telefaxes and internet electronic mail) are all readily available at good rates. Field

accommodation can be in hotels or lodges or camping at the town's Caravan Park.

2.5. Administrative and Institutional Structures

The political administrative structure consists of a District Administrator (DA) as the most

senior government official from the Local Government Ministry. Reporting to the DA are

Rural District Councillors headed by a Chief Executive Officer. Chiefs are at the top of Ward

and Village Committees as part of the traditional leadership hierarchy. The DA and his

hierarchy administers the district through the Rural District Councils Act while the chiefs

largely implement the Traditional Leaders Act. The former is responsible for infrastructure

and service provision as well as supervising natural resources conservation and exploitation

while the latter is responsible at very local level for the allocation of land and water use rights

and for arbitration over petty crimes and other forms of conflicts at local level.

Mining activities are administered by the Mining Commissioner, assisted by representatives

of the Mining Engineer, Geological Survey and Metallurgy. The small-scale mining

associations include the Miners Federation of Zimbabwe and the National Miners Association

of Zimbabwe.

Natural resources management, including the supervision of small scale mining activities, is

performed by the District Development Committee chaired by the District Administrator and

comprising of Rural District Councils, Traditional Leadership structures, Natural Resources

Board, Forestry Commission, Agricultural Extension Services, Mining Commissioner and the

Zimbabwe National Water Authority. Other members of the District Development Committee

include the Zimbabwe Electricity Supply Authority, Post and Telecommunication

Corporation and the road section of the Ministry of Transport. All these departments have

offices in Kadoma. The President of the Miners Federation of Zimbabwe is also based in

Kadoma where he runs a medium sized custom ball mill.

2.6. History of Gold Extraction in the Chakari-Golden Valley Area

The Kadoma mining district, together with the Kwe Kwe mining district have for many years

been the leading gold producers in Zimbabwe. Large mines included Dalny, Patchway,

Golden Valley, Globe and Phoenix, Cam and Motor, Gaika, Brompton and Indarama. There

are more than one hundred small gold mines in the area which have also been productive at

different times throughout the twentieth century. Less than half of these have accounted for

over 90% of the production. Most of the large mines stopped gold production more than two

decades ago to include Cam & Motor, Gaika, Globe and Phoenix. Collectively, the mines in

this area have produced hundreds of tonnes of gold over the years. All the mining activities in

the Kadoma area are situated within commercial and resettlement agricultural areas which

have a tradition for being the leading producers of cotton and significant quantities of maize.

The Chakari-Golden Valley area is well known for its high density of three and five stamp

custom mills. There are about seventy custom mills in the area with more than thirty being

operational. There are a few existing ball mills. Each milling site uses irrecoverably up to 5kg

of mercury per month. This approximates to between 100 and 150 kg of mercury used

irrecoverably every month within the project site and would translate to about 1.5 tonnes of

mercury used in the area annually.

It is estimated that over 20 000 small-scale miners are active within the project site area. Less

than 5 000 of these are involved in reef mining and dump re-treatment while the bulk are

alluvial gold panners. The latter category account for more than 75% of mercury use. Most of

this mining activity is concentrated in the vicinity of three large mines (Dalny, Golden Valley

and Patchway). Where reef mining occurs, there are shallow shafts and tunnels and manpower

access and ore hoisting is by windlass and bucket. The ore is transported by road to the

nearest functional stamp or ball mill.

2.7. Community Socio-economic Profile

2.7.1. Demographic Data

According to recent unpublished census data from the Central Statistical Office, the Kadoma-

Chakari area has a total population of 6354 people. Of these 3227 (51 %) are male and 3127

(49%) are female. The mining community is however predominantly male. This might be due

to the fact that most miners or mill workers are young unmarried males. Some male miners

have families staying in their rural homes away from the vicinity of the mining area. The

community is of mixed ethnicity. The dominant languages spoken in order of popularity

within the sample are Shona (53% ), Chewa (37%) and Ndebele (9%).

2.7.2. Economic Activities

The majority of people in the area are miners or employed at the mills. They stay either at the

mine or mill sites or in mining compounds belonging to Falcon Gold Mine. There is a

considerable proportion of resettled farmers who have occupied the surrounding farms in the

area. In mining settlements there are no clear leadership structures. However in the resettled

farms, while there are no traditional leadership structures, political leadership structures exist.

The main income-generating activity besides mining in the Kadoma-Chakari area is farming.

Almost all the part-time farmers are engaged in mining (i.e. are part-time miners) and only

engage in farming during the rainy season when it is not conducive to mine due to the filling

up of shafts with water and related high incidences of shaft collapses due to wetness of the

earth. Farming is therefore an alternative source of income and subsistence for miners. Of

those engaged in full-time mining, the majority are mill workers since mill operations are

done through out the year.

The average income in the area is Z$40 000 (US$14.8)/month. Most miners have families at

their rural homes outside the mining area. However transport costs are prohibitive for them to

commute to these rural homes. As a result they tend to resort to prostitution that is rampant in

the mining areas. This can be linked to the high cases of sexually transmitted infections in the

area. This also impacts on the livelihoods of their family as very little of the money earned

filters into the rural homes.

2.7.3. Gender Aspects: Women Involvement in Mining

Women make up only 11% of all the miners in the area. Mining is predominantly manual and

hence is it is the domain of men. In all the mills visited none of the mill workers were female

and the millers explained this as being due to the manual nature of the work. Digging by

women was however close to the surface (not exceeding 10m) while that done by men could

go to depths beyond 30 metres

Most adults in mining communities are concentrated in the 20-40 year age group. Amongst

the farmers, the dominant age group is also 21-30 years.

Within non-mining and non-farming communities, as in the farming communities, the

dominant age group is 21-30 years. Their occupation is quite varied including vendors, radio

repairers, mechanics and civil servants. The majority of people in the economically active age

range (21-40 years) are miners. The number of adults tapers off considerably above 50years

amongst miners. Most people that are engaged in mining beyond 40 years are mill workers.

There are more people above 40 in the farming and non- mining and non-farming sectors of

the community. The age distribution amongst children shows no distinct pattern in all

occupations. Besides children at mills who do not engage in mining, most boy-children in the

mining community are at some stage in their lives engaged in mining with their fathers. The

majority of the children are of primary school level (5-13 yrs) and stay with both their parents.

2.7.4. Education Levels of Adult Community

Literacy levels in the area are good, with the majority (52%) of the adult community members

having attended secondary (Ordinary Level) education. Primary education level is from Grade

1-7 and is normally done at the age of 6-13 years. Secondary education is from Form 1-4 or

Form 1-6 and is normally done at the ages 14-19 years. Levels of illiteracy are however

considerable (17%) as shown above. 31% of the community has primary level education.

2.7.5. Housing

Workers' houses at the mill sites visited (with the exception of Glasgow Mill and the Falcon

Gold compounds which have brick and asbestos or corrugated iron sheet roofs) are

deplorable. They comprise thatch, pole and dagga structures that are hardly suitable for

human habitation. At one site the workers are asked to construct their own housing structures.

Resettled farming villagers either had the opportunity of occupying farmhouses and farm

compounds or have built temporary housing structures. Those miners staying in Falcon Gold

compounds pay a rental of Z$500-Z$1000 (US$ 0.19-0.37) per month.

2.7.6. Occupational Hygiene/Sanitation

On all the mine and mill sites visited, lack of sanitary facilities is quite striking. With the

exception of two mills (Glasgow and Coetzee) that provide basic toilets in the form of pit

latrines and Blair toilets respectively, there are no toilet facilities on all other mill or mine

sites visited. Bathrooms are in the form of grass-thatch surrounded structures constructed by

the workers themselves. Only miners staying in Falcon Gold Mine Company compounds have

the privilege of flush toilets and shower facilities. They however say that the toilet systems

are usually mulfunctional.

2.7.7. Water

Most of the water used for domestic purposes in the area is borehole derived or pumped from

disused mine shafts, with the exception of Falcon Gold compounds in Chakari which are fed

from dam water. Water is said to be of good quality, however the possibility of contamination

cannot be ruled out. Workers at mill sites and people staying on Falcon Gold compounds have

easy access to water, which is usually close to their houses. However for most of the resettled

villagers away from farmhouses and compounds and mine claim sites, water sources can be

up to 5 kilometres away. Fetching water is primarily done by women who either carry it on

their heads or use wheelbarrows.

2.7.8. Health Facilities

Health facilities are an area of concern to the communities. Despite having clinics in their

vicinity, most of the small-scale mining communities cannot access these as they are reserved

only for current workers of Falcon Gold's Dalny Mine. They therefore have to travel

distances of 20 to 40km to access health facilities in or near Kadoma. Ordoff Clinic near

Kadoma is the most frequently visited, followed by facilities in Kadoma city.

2.7.9. Education Facilities

Education facilities include those in Kadoma and Chakari as well those within the mining

sites. Most schools are in the range of 2-7 km away from most of the mining sites. Attendance

at the schools has been adversely affected by small-scale mining activities at both primary and

secondary level. Absenteeism is quite rife as students help out in gold digging activities in

small-scale mining dependent households, particularly so in the dry season. This affects both

sexes at the schools. This however does not affect communities living at the mills as there is

no case there of child labour involvement in milling activities. School dropouts are also a

common aspect. Promiscuity and pregnancy feature amongst girls in the communities

affecting even primary school girls who fail to complete their primary education. Also

rampant is drug abuse, especially alcoholism. Most of the children from small-scale mining

households are said to be malnourished and have poor hygiene. Payment of fees is also poor

as most of the money from gold digging is spent on food. These aspects impact significantly

on school performance by children from the mining communities.

2.7.10. Diet

Sadza (thick cornmeal porridge) is the staple food. Most people eat sadza twice a day. This is

understandable as it is the country's staple carbohydrate source. This is mainly accompanied

by vegetables, which are also eaten two times a day by most people. Meat is eaten with less

frequency (1-2 times a week), as is milk and beans. Beans are mainly consumed when in

season. Fish is eaten when in season (usually in summer) and is usually brought in by vendors

from outside the area since there are very few rivers in the area and those rivers that are there

contain no fish. However Kapenta, (Limnothrisa moidon), a small non-carnivorous fish

caught in lake Kariba that is usually caught and sold dried in packets in shops) is eaten

whenever families can afford it. The choice of relish is largely influenced by cost rather than

preference. While most people would prefer to have meat twice daily they cannot afford it and

therefore consume vegetables more frequently because they are cheaper. Meat is either bought

from surrounding butcheries or brought in by vendors.

3. Ore milling and gold processing

In Zimbabwe, it is estimated that there are between 300,000 and 400,000 artisanal gold miners

sustaining the livelihoods of at least 2 million people2. About 20,000 to 30,000 people are

directly involved in gold extraction in the Kadoma-Chakari region. There are 3 categories of

people in the artisanal gold mining operations:

1. miners who excavate and extract semi-weathered gold ore and take this for

processing at custom milling centers. There are about 3,000 to 5,000 people involved

in this activity. The miners extract ore from narrow shafts as deep as 50 m and hire

trucks once a month to take the material to the milling centers. They do not process the

ore. The monthly production of one team of miners (3 to 4 people) was reported to be

around 20 tonnes, which is enough to produce 200 g of gold (if gold recovery of 10

g/tonne of ore processed is assumed).

2 Maponga, O. & Ngorima, C.F., 2003. Overcoming Environmental Problems in the Gold Panning Sector

through Legislation and Education: the Zimbabwean Experience. J. Cleaner Production, v. 11, p.147-157

2. millers who work in the milling centers where the ore is milled and concentrated for

the miners. There are probably about 1,000 to 2,000 people in 70 milling sites in the

Kadoma-Chakari region. Millers have more capital and more education than the

majority of miners and panners.

3. panners are individuals who concentrate alluvial gold by panning the gravels in

creeks and rivers or re-processing tailings from former industrial mining operations.

They represent the majority of individuals extracting gold. They are nomads and can

represent a contingent of 15,000 to 25,000 people in the Kadoma-Chakari region.

3.1. Grinding Process

The technology employed by the custom milling centers varies. For crushing and grinding,

some of them use wet stamp mills (3 or 5 stamps) with capacity of 0.2 to 0.5 tonne/h (Fig. 5)

and some use jaw crushers followed by grinding with ball mills (Fig.6) with a capacity of

between 0.7 to 2 tonnes/h.

Fig. 5 Overview of a Custom Milling Center in Kadoma Region

Fig. 6 Small Ball Mill Used in Custom Milling Centers in Kadoma

An installed custom milling center

with jaw crusher, small ball mill

(0.7 tonne/h) + centrifuge +

amalgamation barrel was acquired

by a miller in May 2003 for about

Z$ 47 Million (US$ 13,430)3 and a

center using 3-stamp mills

(14'x15') and amalgamating

copper plate costs Z$ 35 M

(US$10,000). The monthly

operating cost of one of these

milling centers is between Z$ 1 M

and 1.5 M (US$ 285-428). The

centers charge between Z$ 10,000 Fig. 7 Zimbabwean Centrifuge to Concentrate Gold

(US$ 2.86) to Z$ 14,000 (US$ 4)

per hour of grinding and concentration depending on the hardness of the ore. Using stamp

mills, hard rocks take 5 hours/tonne to be ground and concentrated, whereas soft ores take 1.8

hours/tonne. The stamp mills operate with water and the pulp is discharged through a 48 or 65

mesh screen (0.3 to 0.2 mm). The pulp (about 20% solids) is discharged into a centrifuge (Fig.

7) or on copper-amalgam plates (Fig. 8).

Milling facilities are very well set up and

the techniques are very adequate for the

custom-milling scheme. Miners prefer

milling centers with stamp mills as they

believe that ball mills retain part of the

gold in the internal liners. Stamp mills

seem to be an accepted technology in the

region (the entire process is VISIBLE and

TRANSPARENT) despite their

inefficiency in grinding and their longer

grinding time. The lack of gold liberation

is an evident problem and is the main

reason why the miners recover less than

Fig. 8 Copper-amalgam plates

30% of the total gold by gravity separation

followed by amalgamation.

3.2. Concentration Process

The concentration process is either conducted in a Zimbabwean centrifuge (known as "speedy

bowl") or the whole ore is amalgamated using copper-amalgam plates. The centrifuges used

in Kadoma are 120° cones, like a "batea", with riffles on the wall. They are copies of the

Knudsen Concentrator developed decades ago in California. There is no fluidization to

promote mineral exchange in the concentrate bed and it seems that gold is lost when the

riffles are full. A local manufacturer is improving the efficiency of this type of centrifuge

introducing a rake to scratch the concentrate bed. This can definitely improve the exchange-

3 It was adopted the Government auction rate (Jan 2004) US$ = Z$ 3500.

concentration process. A Brazilian mining company, CVRD, has 3 or 4 units of a larger

version of these Zimbabwean centrifuges to concentrate gold from iron ore in their plant in

Itabira, Brazil. Those centrifuges cost a fraction of the price (between US$ 1000 and 2000) of

the available centrifugal concentrators such as Knelson and Falcon. Local equipment

manufacturers have very good technical capacity to develop any type of equipment suitable

for small-scale miners. They do not downscale conventional processing equipment but in fact,

they actually have developed appropriate technology for the needs and production scale of the

small miners. About 30 to 33 kg of gravity concentrate is produced from a batch of 15 to 20

tonnes of ore processed.

3.3. Amalgamation Process

The milling centers have their own operators but they leave the amalgamation step to the

miners who bring their own mercury and use as much as they want. Some miners add three

teaspoons (50 g/teaspoon) of mercury into the centrifuges. This poor practice "flours" part of

the mercury that is lost with the tailings. Millers wash out the concentrate from the centrifuge

and give it to the miners who perform the amalgamation in barrels, adding 400 to 800 g of Hg

to amalgamate 30 to 33 kg of concentrate. In many cases, miners prefer to conduct

amalgamation manually adding mercury to pans or plastic trays. Amalgamation barrels are

much more appropriate to promote an efficient contact between gold and mercury within 30

to 40 minutes. However, when barrels run for too long (e.g. 4 hours) and with many iron balls

inside, this causes mercury "flouring" and consequent loss of mercury to the tailings.

The millers provide the miners with amalgamation barrels and they do not charge extra for

this service, which is conducted by the customers (miners). Miners can add whatever they

want into the amalgamation barrels, including soap, acids, etc. Many miners add sodium

cyanide tablets into the amalgamation barrels to clean the gold surface and increase

amalgamation. In many cases the pH of the pulp is 7 or lower where there is a presence of

sulphides in the ore. The possibility of producing HCN gas which is extremely poisonous is

either ignored or unknown. The material discharged from amalgamation barrels is

concentrated by panning in a plastic bowl and the tailings pass through an amalgamating

copper plate.

Some miners take home the amalgamation tailings. They re-grind, sometimes add more

mercury, pan them at their backyards and roast them in kitchens. The fate of these

amalgamation tailings is unknown. As the tailings are contaminated with Hg, this is

dispersing mercury all over the region, in many cases into urban areas. Whenever the miners

leave behind their amalgamation tailings, the millers collect them for leaching in cyanidation

tanks (Fig. 9).

The use of copper-amalgam plates at the stamp mill discharge is very popular in the region

and yet it is a bad practice which amalgamates the whole ore. This would reduce mercury

emissions drastically. Miners responded that they have to be very attentive when working

with copper-amalgam plates. They must constantly rub the surface of the plates. Quite often,

mercury (and gold) accumulate on a given point of the plate surface, and with the attrition of

the ore pulp, it is lost. "If I sleep and I do not spread the mercury on the plate, I lose mercury

and my gold, and the miller will recover it later on when he uses cyanide", a miner lamented.

The great majority of miners in the region do not use retorts. They burn amalgam on wood

fire without any protection. At low temperature, the retorting process is very incomplete.

Retorted gold beads with more than 20% of residual mercury were observed. The burning

process is done either under supervision of a large number of people or furtively in the bush.

One miller revealed that he had purchased a retort but it was too big and too thick. He

mentioned that he was not using it because it took too long to retort the amalgam using wood

fire. In fact, the retort had never been used. Miners within the project demonstration site do

not use blow torches either. An example of a home-made torch using gasoline, as used in

Indonesia, was shown to them. The use of blow torches will facilitate the introduction of

retorts as the burning is faster than in bone fires. Other options discussed with miners and

millers was the use of an iron-smith-coal blower, such as the ones used in Prague (Czech

Republic) to demonstrate to tourists how iron can be hand-forged.

A retort was manufactured in Kadoma using water pipes and connections, but the price was

far too high for the local economy. The retort was fabricated at a cost of Z$ 35,538 for the

material plus Z$ 8,000 for welding, making a total of US$ 17.

3.4. Cyanidation

In both the stamp mill and ball

mill processes, most of the gold is

left in the primary tailings and the

millers apply vat-cyanidation to

extract this remaining gold.

Miners receive no compensation

for the extra gold extracted by

cyanidation. Most Centers have 5

to 10 cyanidation tanks (Figure 9)

to extract residual gold using vat-

leaching. About 20 to 70 tonnes of

tailings from the gravity circuit

and from the amalgamation

process are added to cement tanks

to be leached with 18 kg

Fig. 9 Cyanidation Vat-leaching Tanks

NaCN/tank. No pH control is

done. Operators add 50 kg of Ca(OH)2/tank and wait an average of 6 days to end complete the

leaching step. Since no forced aeration is provided to the pulp, the leaching process is slow

and sometimes it takes 10 to 15 days, depending on the gold concentration and accessibility of

the cyanide solution to the gold in the ore particles. The solution percolates through the ore

and it is recovered at the bottom of the tanks where a sand-filtering process is set up. The

gold-laden cyanide solution is analyzed using a SnCl2 colorimetric method to check the gold

content. The solution passes through 6 PVC columns lined with activated charcoal to remove

gold from the cyanide solution. As the millers do not have access to the stripping technique,

they remove the first three columns and send them to a company in Kwe Kwe which performs

the elution (gold stripping) process. This company charges Z$ 175,000 (US$70) per load to

strip gold from the carbon and deposit it by electro-winning onto iron wool. The millers do

not have any control over the amount of gold in the carbon given to the elution company. The

millers dissolve the iron wool with HCl or H2SO4 to obtain pure gold. The final tailings of the

vat-leaching, with residual cyanide, are carelessly disposed of in the milling centers. Some

centers re-vegetate the dump sites. The concentration of the cyanide solution after the

stripping process is adjusted and re-circulated to the vats.

When the Hg-contaminated tailings are leached, part of the mercury goes into solution and

part stays with the final tailings. The fate of Hg-cyanide in the tailings is unknown but it has

been shown in laboratory experiments in other countries, that mercury in the leached tailings

becomes more soluble. The partial oxidation-reaction of Hg in the cyanidation process can

also exacerbate the Hg methylation potential in tailings.

3.5. Gold Sales

Gold price in Kadoma fluctuates substantially. The Government has established an official

price of Z$ 35,000 (US$ 7.50) per gram when the international market price is US$ 11.58/g

(considering US$ 360/oz) or almost twice the price offered by the Government. There are

many panners and miners who cannot afford to travel to cities to have better prices. This has

resulted in a great number of gold buyers in the region who most probably smuggle the gold

out of the country.

3.6. Pros and Cons of the Custom Milling Centers

The custom milling centers are an appropriate solution for the artisanal mining activities. In

one respect, this procedure organizes the activity and prevents the use of mercury in many

different places, as seen in the panning activities. In Zimbabwe, the milling centers are well

organized and any intervention to reduce Hg emission, rehabilitate impacted areas and create

environmental and health awareness is easier when the source of pollution is concentrated in

just a few points (in the region there are 70 milling centers with about half of these

operational at any one time).

Most millers have very basic knowledge about the cyanidation process. The process was

introduced by a local company, but it is operated by non-qualified personnel. In the process of

analyzing for gold in the cyanide solution by colorimetric process, the operators add Zn dust

to the cyanide solution, decant the solution and add aqua-regia. The process is performed in

almost all milling centers in improvised laboratories with no fume hoods. The HCN fumes are

generated and the millers run out of the `laboratory' until the gas dissipates. The fumes of

nitrous gas are visible and intoxicate the operators.

A miller who also runs a mine estimated that 30% of the gold he produces comes from gravity

concentration using a centrifuge followed by amalgamation and 70% comes from the

cyanidation process. Assuming that a similar distribution occurs in all milling centers, this is

potentially a source of serious conflicts in the region between miners and millers. Miners are

aware that millers are taking advantage of their situation and they prefer to do their own

concentration-amalgamation. As these miners lack skills and capital, this can increase

mercury loss and promote the misuse of cyanide. It appears that the conflict between millers

and miners is not limited to the gold extraction process. Millers generally belong to a higher

socio-economic level than miners and a miller is currently managing the Miner's Federation

of Zimbabwe. The credibility of this Federation is weak among the miners.

3.7. Gold Panning in the Kadoma-Chakari Area

Gold panners in the Kadoma-Chakari area are either working in local rivers and streams

especially the Muzvezve River, or panning tailings from former mining company operations

(sometimes with their authorization). Panners are from remote areas, some of them from

neighboring countries and they are frequently harassed by local police while working in

illegal areas. In the dry season, they divert the river and excavate the gravels to concentrate

gold in improvised sluice boxes (known as James Tables). They process from 1.5 to 2 tonnes

of material per day recovering 0.2 to 0.4 g Au and losing equal quantities of mercury (50g per

4 months). The gravel is excavated manually and washed in rudimentary home-made screens

(a sheet of iron with ½ inch holes) to discard coarse pebbles. The fines (- ½ inch) pass through

the sluice boxes lined with pieces of clothes. After several runs of the excavated material,

they wash the cloth loaded with gold in an excavated pool which can be located in or outside

the river. They add mercury to the plastic trays to amalgamate the gold. The amount of

amalgam obtained is minuscule and they just burn it in a wood fire. The amalgamation

tailings are either left in the pools (forming "hotspots") or taken to other areas to be manually

re-ground and re-amalgamated.

Panners in the Muzvezve River have diverted the river and screen the gravels before passing

the material through rudimentary sluice boxes. They reported that upstream of the place

where they are working, there is a water dam which serves Kadoma city. The municipality has

an agreement with the farmers downstream of the mining activities to open the dam once a

month to provide irrigation water. This is done without any prior warning. The sudden water

flow killed 18 people during the month of July, 2003.

As most of the panners utilize mercury in small pools near the river margins, these

environments seem very propitious to Hg oxidation and consequent methylation (shallow pits,

full of organic material and which is well aerated). When the water flows through these pools,

it carries all soluble Hg downstream. These sites must be investigated in the Environmental

and Health Assessment.

There are thousands of panners in the Muzvezve River and all living in rudimentary straw

huts along the river. They mentioned that there is a very limited amount of fish (almost none)

in the areas they are working. Catfish was reported to be a common species downstream.

While any initiative to bring training or demonstration of cleaner techniques seems to be very

well accepted by miners and millers, panners are very dispersed and generally have very low

education levels. They are also nomadic (and sometimes illegal) which makes any training or

demonstration exercises ineffective. However these panners constitute the majority of the

people involved in artisanal gold mining within the project site and therefore, they cannot be

ignored. Simple measures, such as better sluice box designs, better carpets, use of retorts, will

provide a huge technological leap for the panners

3.8. Mercury Losses

During interviews with the main mercury importers of Zimbabwe, it was reported that 20

tonnes of Hg per annum are imported from Netherlands. Likely, this Hg enters the country

legally (for dental use?) and later is diverted to artisanal mining activities in Zimbabwe and

neighboring countries (Mozambique?). Mercury is freely sold in the Kadoma region at an

average price of Z$ 30,000 to 33,000/kg (US$ 12 to 13.2) which is 3 times higher than the

international price of US$4/kg. Some people are re-selling small amounts of 50 g at a price of

Z$2500 (US$ 1). This results to in a price of US$ 20 per kg of mercury.

It is difficult to establish a ratio Hglost:Auproduced as many millers do not acquire Hg and they

do not know how much gold the miners produce. The miners bring their own mercury and use

it freely during any part of the process, except grinding. At two operations visited where

centrifuges are used, the amount of gold produced at each milling center was around 2 to 3

kg/month. The amount of Hg lost was between 2 and 3 kg/month (amount being bought). This

results in a ratio Hglost:Auproduced = 1. When copper plates are used to amalgamate the whole

ground ore, the miners estimate that they lose twice as much mercury. Assuming that all 70

milling centers in the region are losing between 2 and 4 kg of Hg /month, approximately 1.7

to 3.4 tonnes of Hg is being emitted to the environment in the Kadoma-Chakari region just

from the milling operations. If we consider the use of Hg by panners, the Hg losses in the

region must be between 3 to 5 tonnes/a.

4. Environmental impacts

Environmental impacts associated with small scale mining and gold panning in the Kadoma-

Chakari area includes land disturbance and siltation, deforestation, water pollution and

depletion. Small scale mining activities result in the general scarification of large areas as

seen in the area surrounding Dalny mine and in several other areas in the Kadoma-Chakari

region. Alluvial gold panning activities, as seen along the Muzvezve river involves the

digging up of the river channel and its banks, paleo-channels and their floodplains, as well as

surface trenching using picks and shovels. The most noticeable effects of these activities are

the siltation of the river and dams across it, a deterioration of water quality, the reduction of

grazing areas for domestic and wild animals and an overall reduction in biodiversity. Siltation

also results in the reduction of conveyance and storage capacities of rivers and dams and is

believed to play a major role in the frequency and magnitude of flooding affecting

Mozambique, Zimbabwe and South Africa. It is also responsible for the destruction of

habitats for fish and other aquatic organisms. The rapid sprouting of overnight settlements at

newly discovered gold deposits leads to rapid `urbanisation' in the form of haphazard

settlements that not only result in deforestation but also social ills associated with unplanned

settlements. These vices include alcohol and drug abuse, prostitution, land-use conflicts with

local communities, water pollution, infant and child labour and disease outbreaks.

Deforestation is driven by the need for the construction of shelter, underground support props,

panning dishes and firewood. Absolute dependence on the use of large amounts of water in

mining operations dictates that the former be located as close to water sources as possible, and

in some cases at the water sources. The reliance on water for mineral concentration results in

the accelerated evaporation of surface water, the drainage of wetlands and the siltation of

rivers and dams.

4.1. Barriers to the Introduction of Cleaner Gold Extraction Technologies

The implementation of the Global Mercury Project in Zimbabwe to date has been through a

launch workshop in September 2002, two field trips to the Kadoma-Chakari area in July and

August 2003. The latter field trip culminated with the hosting of a workshop for the main

stakeholders in Harare on the 18th August 2003 at the University of Zimbabwe. Interactions

with stakeholders on field trips and at the two workshops showed overwhelming support for

the GMP in Zimbabwe. More importantly, government officials and officials from the small

scale mining associations fully appreciated and supported the project objectives. The miners

and millers around the Kadoma-Chakari area were fully aware of the dangers of open mercury

use and contended that they were practicing it for lack of cleaner, cheaper and more

accessible mineral extraction methods. Socio-economic hurdles remain which will need

careful negotiation and navigation. Best available technology uptake will critically depend on

the cost variable, simplicity and adaptability of the technology to the already existing socio-

economic profile of the miners. There is no doubt that the uptake, success and sustainability

of the introduced technology will heavily depend on systematic and comprehensive awareness

campaigns and dependence on local manufacturing innovations for both compatibility with

existing technology and spares back-up. In all initial contacts with stakeholders, the idea of

mobile demonstration units is generally well received although further consultations will be

necessary before a decision can be taken on the issue.