Removal of barriers to the introduction

of cleaner artisanal gold mining

and extraction technologies

in the Kadoma-Chakari area, Zimbabwe.

Part A: Environmental Assessment

Final Report

BRGM/RC-53320-FR

September, 2004

Removal of barriers to the introduction

of cleaner artisanal gold mining

and extraction technologies

in the Kadoma-Chakari area, Zimbabwe.

Part A: Environmental Assessment

Final Report

BRGM/RC-53320-FR

September, 2004

UNIDO Contract No. 03/089.

Project No. EG/GLO/01/G34. Activity code: 420C51

P. Billaud, V. Laperche, R. Maury-Brachet,

A. Boudou, D. Shoko, S. Kahwai, Ph. Freyssinet

Checked by:

Approved by:

Original signed by: F. BLANCHARD

Original signed by: D DARMENDRAIL

The quality management system of BRGM is certified according to AFAQ ISO 9001:2000.

Keywords: Mercury, Amalgamation, Gold, Environmental Assessment, Health Assessment,

Artisanal mining, Cleaner technology, Fish, Muscle, Chakari, Kadoma, Zimbabwe.

In bibliography, this report should be cited as follows:

Billaud P., Laperche V, Boudou A., Maury-Brachet R., Shoko D., Kahwai S., Freyssinet Ph.

(2004) Removal of barriers to the introduction of cleaner artisanal gold mining and extraction

technologies in the Kadoma-Chakari area, Zimbabwe. Part A: Environmental assessment

Final Report. BRGM/RC-53320-FR, 139 p., 65 ill., 4 app., CD with pictures.

© BRGM, 2005. No part of this document may be reproduced without the prior permission of BRGM.

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Executive summary

Introduction

In response to a request from the Government of Zimbabwe and in the framework of

the general project entitled 'Removal of barriers to the introduction of cleaner artisanal

gold mining and extraction technologies', a contract was signed in September 2003

between the United Nations Industrial Development Organisation (UNIDO) and BRGM,

in order to carry out the environmental and health assessment in the Kadoma-Chakari

area. This area is characterised by the presence of thousands of artisanal gold miners

using mercury for gold recovery.

The ultimate aim of the project is to replace mercury amalgamation practice in this area

by alternative technologies, while improving the income and the health of the people

using mercury. It includes a more efficient Hg and gold recovery process, increasing

knowledge and awareness and provides policy advice on the regulation of artisanal

gold mining.

The fieldwork of the environmental assessment of the artisanal gold mining activity in

the Kadoma-Chakari area, selected by UNIDO, was carried out by a joint French

(BRGM) and Zimbabwean team in November 2003 just before the rainy season and

completed in April 2004 during the health assessment survey.

Two fieldwork reports have already been submitted to UNIDO:

- The first one, entitled "Removal of barriers to the introduction of cleaner artisanal

gold mining and extraction technologies in Kadoma-Chakari area. Zimbabwe.

Fieldwork report 1. BRGM/RC-52796-FR", dated December 2003, concerns the

environmental assessment carried out in November 2003.

- The second one, entitled "Health Assessment of small-scale miners in a mercury

contaminated area (Kadoma area. Zimbabwe)" describes the health survey carried

out in April 2004. During this second mission, some additional work was

accomplished for the environmental study.

The final results of the project are given in two separate reports:

- This Final Report (Part A) deals with the environmental survey. It summarises the

fieldwork carried out during the missions of November 2003 and April 2004, the

organisation, the planning and the methodology used for site selection and

sampling. The chemical analysis results are provided site-by-site, followed by the

interpretation, the evaluation of exposure to Hg and the recommendations.

- The Final Report of the health survey (Part B) was completed in November 2004 by

the health team. It summarises the fieldwork carried out in April 2004 and presents

all the specimen analyses and statistical results, with recommendations to improve

the health conditions and reduce hazard relative to the professional use of mercury.

BRGM/RC-53320-FR Part A: Final report

3

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Site selection

On the basis of the sociological survey, the environmental assessment started by a

preliminary survey north of the town of Kadoma to describe the gold mining and milling

processes implemented by miners and millers and the extent of the milling sites. The

final objective was to select milling sites for the environmental and health survey.

Following the advice of the Kadoma Mine Department, the study was extended south

of Kadoma. Ten milling sites were selected north and south of Kadoma. The detailed

study was completed taking into account the size of the milling centre, the equipment

available for gold processing and its technical status, quality and maintenance, the

number of millers and miners involved, the quantity of mercury used, the presence of

villages near the milling centre, and also the presence of watercourses with a regional

or national impact. According to these parameters, two groups of milling centres could

be determined: the first being representative of gold processing north of Kadoma and

the second representative of the south.

Ore processing and use of mercury

Amalgamation: After extraction by miners, the ore is crushed in custom milling center

with, most of the time, wet stamp mill (with two to four stamps) in batch of 1 to 5 tons.

Jaw-crushers and ball mills are only used in some of the newly equipped mill center.

The pulp produced by the stamp mill through a 48 or 65 mesh screen and composed of

around 20% solids is sent onto a copper-amalgam plate (copper-plate) coated with a

film of mercury.

The quantity of mercury used in the process varies from one place to another, but it is

said that at least 150 g m-2 (3 teaspoons of 45 g each) of mercury are used for this

operation. At the end of the process, when all the batch of ore is crushed, the copper-

plate is scoured with sand or tailings to remove any remaining amalgam. The resulting

bright metallic copper is then rinsed with clean water and washed with a 2 to 3%

solution of cyanide (if available). The millers can use solid Na-cyanide tablets to clean

up the plate by hand without glove or mask protection. Following this procedure, the

amalgam with fine sand particles is collected by hand and then squeezed in a cloth to

remove unused mercury that will be recycled in the next process.

In the milling centre newly equipped with a jaw-crusher and a ball mill, but also in some

of the well-maintained milling centres equipped with a stamp mill, the copper-plate is

replaced by a bowl-concentrator (also called Zimbabwean centrifuge, ABJ bowl or

"speedy bowl") where mercury is added at the beginning of the process at a rate of 25

to 30 g of Hg per ton of ore. At the end of the process the heavy concentrate is

collected at the bottom of the bowl.

Some millers provide the miners with amalgamation barrels, but in many cases, the

miners complete the amalgamation by hand, adding up to 800 g of mercury in plastic

trays. The final separation between the amalgam and heavy minerals is accomplished

by panning. The amalgam is then squeezed in a cloth to remove unused mercury.

4

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

After the copper-plate or the bowl-concentrator, the tailings are evacuated by open

channel or pipes to a settling pond, for clarification and drying. Most of the time, the

water is collected and recycled in the crushing process. Once dry, the tailings are

loaded onto truck and transported to concrete tanks for cyanidation, to recover the

remaining gold.

Roasting: The amalgam is roasted always in the same open places in the milling

centre or back home by the miners. Except at Even Milling Centre and New Plus,

miners, they burn amalgam on a wood fire without further protection. They do not use a

retort or any home-made torch. At low temperatures, the roasting process remains

incomplete resulting in around 20% of residual mercury remaining in the gold beads.

Cyanidation: The rest of the gold contained in the dried tailings, is recovered by vat-

cyanidation. The tailings are leached with Na-cyanide solution for an average of six to

ten days in concrete tanks. The solution that percolates through the tailings is

recovered at the bottom of the tanks where a filtering process (layer of sand) is set up.

The gold-cyanide solution is analysed for gold content using a SnCl2 colorimetric

method. The solution passes through a few columns lined with activated charcoal to

remove the gold from the cyanide solution. After this process, the concentration of the

cyanide solution is adjusted and then re-used in the vats.

Gold extraction from the charcoal is never performed in the milling centre. The millers

send the activated charcoal to other companies that carry out the elution process.

The final tailings of vat-leaching with residual cyanide are generally dumped in outlying

parts of the milling site, but also close to the village, as in the case of Amber Rose. It

can be also used as track construction materials (Tix village).

A general flow sheet summarises the main artisanal gold processing.

Sampling and methodology

In each selected site the sampling locations were determined according to the technical

organisation and composition of the processing equipment, the geomorphology, the

local drainage, the landscape and the proximity of the village. The objective was to

check the source of Hg contamination, its pathways and the level of Hg in the potential

identified targets.

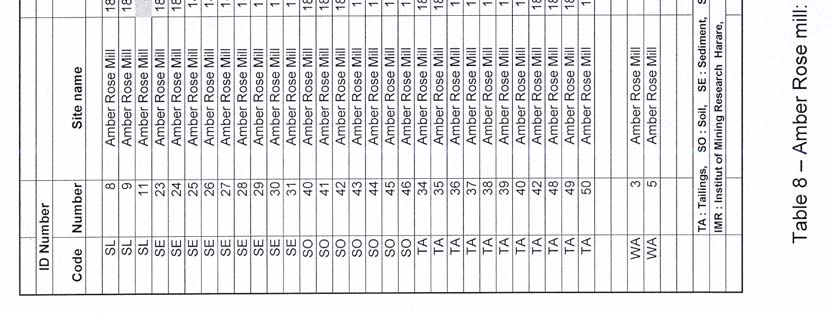

For the environmental survey, a total of 49 soil samples, 39 stream sediment samples,

12 dust samples, 56 tailings samples and seven water samples was collected on the

ten selected sites. Fifty-two fish samples were collected from six sites, in the southern

zone only. Air monitoring was carried out on the three most important sites situated in

the southern zone. All the solid samples were analysed at BRGM laboratories using a

LUMEX RA915+ and 33 duplicate samples of soil, dust and tailings were analysed in

the IMR laboratory in Harare using conventional CV-AAS. Fish samples were analysed

at the University of Bordeaux (LEESA) in France.

BRGM/RC-53320-FR Part A: Final report

5

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Results

The environmental assessment confirms that miners and panners use large quantities

of Hg in the selected area. The estimation of the quantity of mercury annually

consumed in the Kadoma-Chakari area is difficult according to the lack of available and

official data. It ranges from 1.2 and 17.5 tons of mercury taking into account a range of

100 000 to 700 000 tons of processed ore and 50% of Hg recycling. Amalgamation and

amalgam roasting processes were observed in all sites. Most of the time, these

operations are carried out without any precaution to protect human health. If some

precautions do indeed exist, such as the amalgam roasting room at New Plus and a

shelter for amalgamation at Even Milling Centre, the survey shows that they are not

efficient. At New Plus, the dispersion of Hg in the air during roasting operations is only

shifted several meters further away by the exhaust pipe, but the risk to humans

remains the same. At Even Milling Centre, Hg concentrations continue to be high in the

soil near the shelter provided for amalgamation.

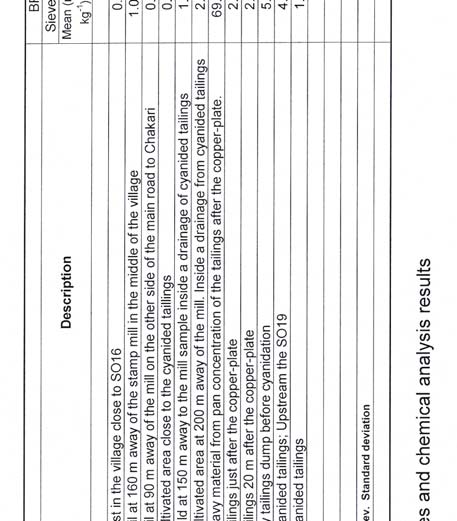

Fish analysis

Total mercury concentrations were measured in 52 fish samples, from six different

species, collected in the Muzvezve River during the sampling campaign in November

2003. This river is roughly 250 km long and flows into Lake Kariba on the Zambezi

River, which constitutes the boundary between Zambia and Zimbabwe in the north-

western part of the country. Fish were captured in six sites along the Muzvezve River.

Sampling sites were determined according to the location of the milling centres (official

gold mining sites) and panning areas (illicit gold mining sites). Mercury determinations

in the dorsal muscle of the fish revealed mercury accumulation for some fish with

concentrations two to four times in excess of the WHO safety limit (0.5 µg g-1 on a fresh

weight basis or 2.5 µg g-1 on a dry weight basis). Average mercury concentration in the

52 samples collected was 0.41 ± 0.46 µg g-1 fresh weight. Differences among species

can depend on the diet of the species, with comparatively high levels in the carnivorous

fish (1.05 ± 0.44 µg g-1 Hg fresh weight,) and lower levels in the omnivorous species

(0.12 ± 0.09 µg g-1 Hg fresh weight), except for one omnivorous species that had a

mercury concentration of 0.88 ± 0.25 µg g-1 fresh weight. No sizeable fish was

collected. If the results of the small-sized samples are representative of the area, it is

very likely that most of the fish eaten by the local population along the Muzvezve River

is contaminated with mercury.

Hg hot spot

Two types of "hot spots" are identified, both defined as sites containing high Hg

concentrations relative to the local contamination in soils and sediments.

The first one, called a single-source hot spot, corresponds to a well-delimited pollution

source and is associated with a specific technique used in gold processing, such as

amalgamation, roasting... There is no hot spot with an unknown source. The area

concerned is small a few hundred square meters but the consequence in terms of

human exposure is potentially very important for the population of miners.

6

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

The second one, called a multi-source hot spot, corresponds to a wider area

characterised by several but associated single-source Hot Spots. The concerned area

is much more extensive than in the previous case, and the associated pollution can

affect a regional level, spreading far through the mining and milling area with

environmental consequences in a radius exceeding the tens of kilometer scale. The

contamination is more diffuse and may affect the whole population living in the area

and the aquatic environment at a regional scale.

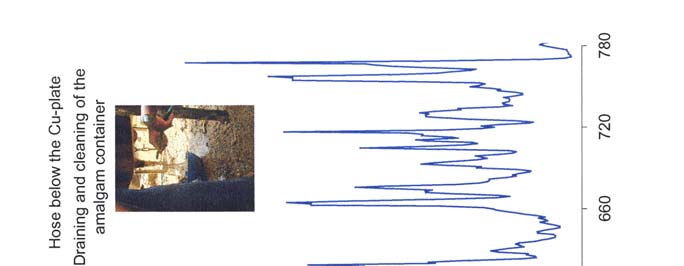

Single-source hot spot: Three main single-source hot spot are found:

- Copper-plate areas are the most contaminated spots as observed in the surrounding

soils within a radius of 10 to 20 m and also in the tailings such as at Tix, New Plus,

Etena, Summit and Glasgow mills. Contamination of soils does not seem to disperse

very far from these emission sources. In contaminated places, the Hg values in the

soils are ten to four hundred times the local background that is 0.02 to 0.12 mg kg-1.

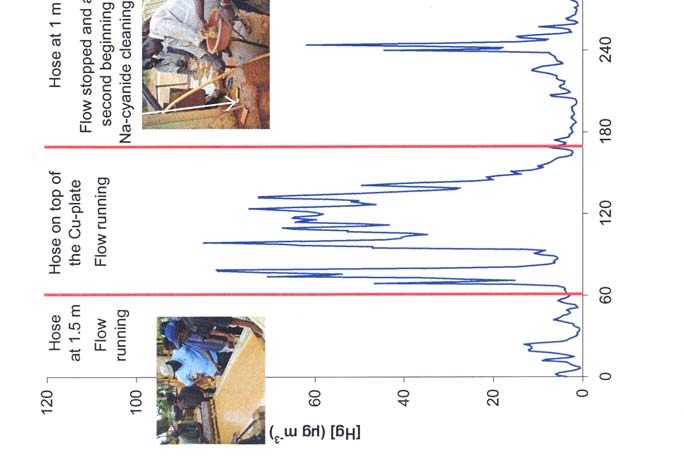

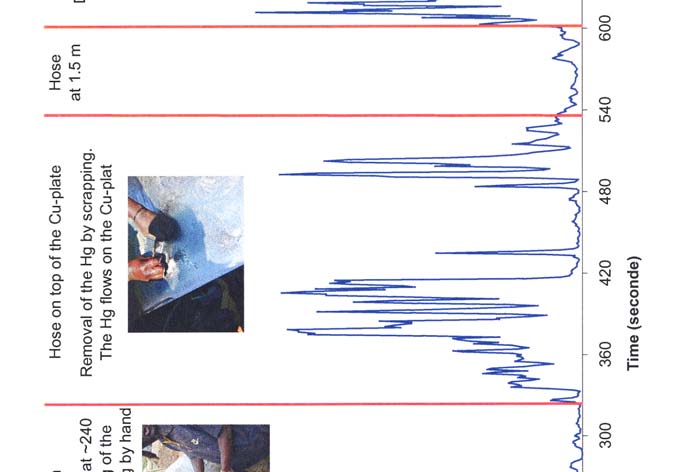

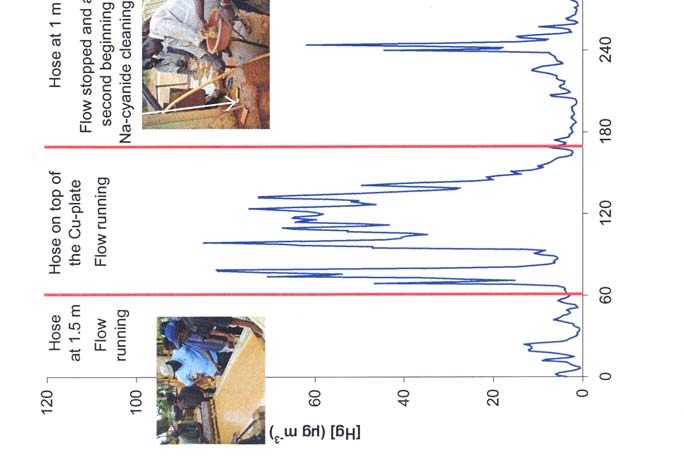

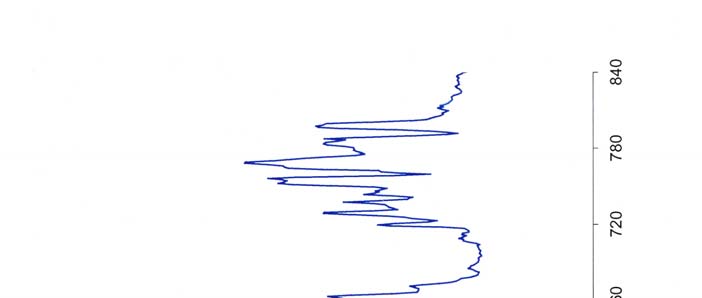

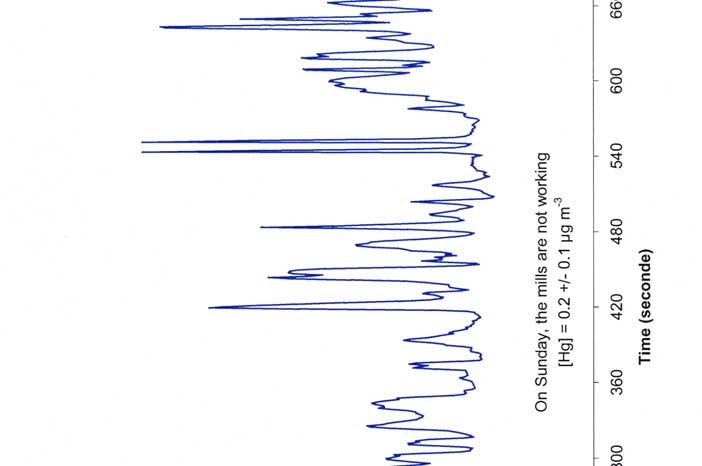

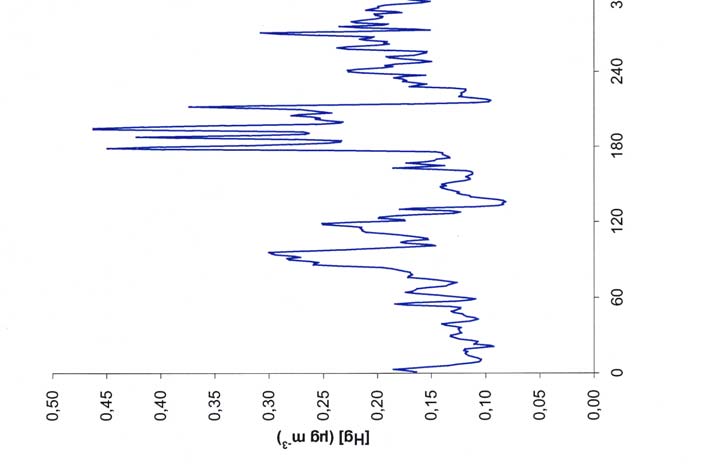

The air monitoring carried out at Tix mill shows a Hg concentration sixty times higher

(108 µg m-3) than the local background (1.7 µg m-3) during the operations on the

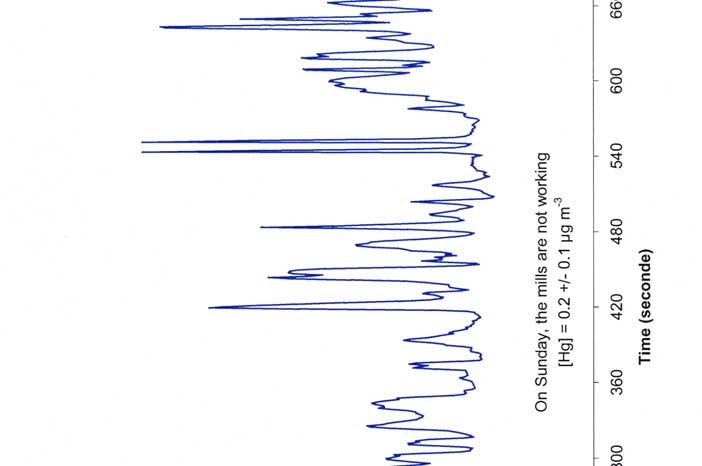

copper-plate. By comparison, at Amber Rose, where a bowl-concentrator is operated,

the Hg concentration in the air reaches 67 µg m-3 that is forty times the local

background. At Tix, the loss of Hg in these areas follows two pathways;

· first, the tailings, which flow on the copper-plate throughout the process, and

· second, the air, mainly at the end of the process, when the miners are scraping

and washing the copper-plate.

It is also in this area that the concentration of workers (miners and millers) is the

most important during the process.

- The second single-source Hot Spot corresponds to:

· the free amalgamation sites,

· the bowl-concentrator surrounding area in the mill centre, where miners are up-

grading manually the amalgam mixed with tailings, and

· amalgamation sites such as in the villages (Tix) or on the bank of a reservoir (Claw

Dam) or river (small stream or Muzvezve River) where miners and panners use

pans to concentrate the gold particles and plastic basins to amalgamate the gold.

At Even Milling Centre, which is one of the better and cleaner milling centres, the

Hg concentration in soil (23.55 mg kg-1) is more than one hundred fifty times the

local background 5 metres away from the amalgamation shelter. The dust

collected within a radius of 3 m on the concrete floor around the workers, who

perform amalgamation under the shelter, reaches 74.60 mg kg-1 that is five

hundred times the background.

At the Claw Dam bank, downstream from Tix village, the Hg concentration in

sediments can reach 8 to 10 mg kg-1 that is twenty times the local background at

the sites of digging, panning and amalgamation activities. These kinds of sites are

favourable environments to generate methylmercury (MeHg). These sites are also

known as fishing spots, where fish with high Hg levels were collected.

- The third single-source hot spot corresponds to the free roasting sites or roasting

rooms. High concentrations of Hg were measured during the air monitoring within a

BRGM/RC-53320-FR Part A: Final report

7

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

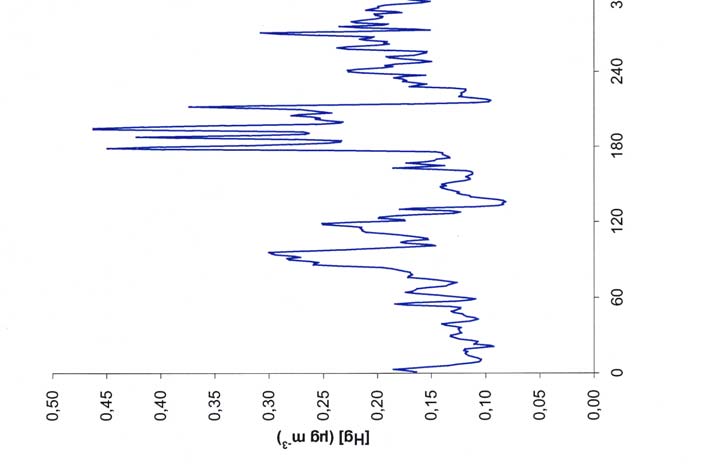

radius of 1 to 3 meters around the free roasting sites located in the middle of the

village, such as at Tix. The Hg concentration reaches nine to eighty times the local

background of air (0.2 µg m-3 outside the copper-plate area). Even when a specific

room is built, with specific equipment including an air extractor, to roast the

customers' amalgam, the risk is still present, as at New Plus, where the dust

collected on the concrete floor close to the exhaust pipe reaches 50.5 mg kg-1 Hg.

Multi-source hot spot: Among the sites studied, the multi-source hot spots can be

located:

- At Tix, which is the most important, including the mill, the village, and the area

surrounding the mining and amalgamation activities on the Claw Dam banks. This

area is characterised by a group of scattered single-source hot spots, such as four

copper-plates, many but not well located roasting areas at the entrance to the mill, in

the village itself, and many amalgamation areas along the Claw Dam bank.

Moreover, the same types of activities have been observed during the

environmental assessment in other villages close to Tix, such as Mhisi and May

Flower. Artisanal activity has been in progress for many years. Several tens of

thousands of people are exposed directly or indirectly to this multi-source hot spot.

- At Amber Rose, contamination is less important than in Tix. But the contaminated

tailings are dumped very close to the village and often spread out on the tracks in

the village. Tailings may also contaminate the sediments in the tributaries of the

Muzvezve River. Roasting locations may also contribute to the local contamination

of the environment by their emissions.

- All along the Muzvezve River, where panners use Hg over a distance of at least

7 km corresponding to the studied zone. This distance is certainly longer than that,

but an inventory of the panning areas upstream and downstream from the zone

visited is necessary to ascertain the actual extent. Results of Hg concentration in

carnivorous fishes, which are good bioindicators of the contamination, show the Hg

contamination reached the living aquatic environment.

- The Etena area, in the northern zone can be classified as a multi-source hot spot

according to the Hg concentrations found in the tailings close to the stamp mill, but

also in the soils near the many amalgamation and roasting sites in the village.

Evaluation of exposure

Direct exposures to Hg contamination have been observed for miners and millers men

and sometime women who are working close to the copper-plate. Exposure to mercury

occurs by skin contact, vapour inhalation, and particle ingestion.

Amalgamation and roasting areas are also the sites of direct exposure through the

same way. Young men who are frequently involved in the amalgamation process are

affected.

Passive exposure may be suspected because this artisanal activity is performed in

villages and along the riverbanks. Children and women are frequently present in the

proximity of this activity.

8

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

The following table summarises the exposure pathways and related risks.

Non

Exposure

Professional

Sources

professional

Observations

route

exposure

exposure

Skin contact

***

0

Copper plate

Inhalation

***

*

Most of the milling centre

Dust ingestion

**

*

Free

Skin contact

**

0

All milling centre, villages,

amalgamation

Inhalation

**

*

the Claw Dam bank and

sites

Dust ingestion

**

**

the Muzvezve River

Inhalation

***

*

Mainly at free roasting

sites in milling centres and

Amalgam roasting

villages, but also at

sites

Dust ingestion

*

** (children)

organised roasting rooms

in milling centre.

Fish consumption

** ?

** ?

Depending of the diet

Local contamination with

Drinking water

?

?

Hg cyanide ?

Summary of the exposure pathways and the related risks (probability of occurrence:

***high, **moderate, *possible, 0 none).

Recommendations

The extension of the mining activity in the Kadoma-Chakari area, its economical

importance and the amount of ore processed have reached semi-industrial levels. This

situation justifies an adapted action plan to develop alternative technologies and the

progressive ban of mercury in the mining process in the area.

Recommendations contain first urgent actions to reduce significantly the exposure of

workers and their family to mercury. They concern the ore processing technologies,

practices and actions to rehabilitate and preserve the environment.

Medium- to long- term actions aim at improve the management of the artisanal mining

activity and reduce the environmental impacts.

The support and the management of these short-medium and long-term actions require

the creation of a Task Force involving all the key stakeholders at the local, regional,

national and international level.

BRGM/RC-53320-FR Part A: Final report

9

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Acknowledgements

This work benefited from the efficient support of Noba Ernest Allai, organisation UNIDO

representative for Zimbabwe and Zambia. He facilitated contact and formalities with the

local authorities, and gave all facilities to D. Shoko to take part in the organisation and

the successful realisation of the two field work projects.

Special thanks go to Dr. Oliver Maponga, Chairman of the Institute of Mining Research,

who gave us advice and scientific and technical assistance during the whole project

and, in particular, allowed Spencer G.T. Kahwai to participate in the project and to

facilitate considerably the two field work missions.

Many thanks are owed to the Kadoma Mine Department for assistance during field

work, and also for the site selection.

We are grateful to Dr Christian Leveque, (CNRS, Meudon, France) who determined the

species and food regimes of the fish collected during the study in Zimbabwe.

The authors greatly appreciated the contribution and the motivation of the Zimbabwean

Team, who made possible the success of work in the Kadoma-Chakari area and also in

Harare.

BRGM/RC-53320-FR Part A: Final report

11

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Contents

1. Introduction.............................................................................................................19

2. Organisation and schedule....................................................................................21

2.1. PROJECT TEAM ...............................................................................................21

2.1.1.Main team.................................................................................................21

2.1.2.Local workers ...........................................................................................22

2.2. EQUIPMENT......................................................................................................22

2.2.1.Schedule...................................................................................................22

3. Generalities and methodology ..............................................................................25

3.1. GENERAL CONTEXT AREA SELECTION ....................................................25

3.2. GOLD PROCESSING IN THE KADOMA-CHAKARI AREA ..............................27

3.2.1.Main artisanal gold processing .................................................................27

3.2.2.Individual artisanal gold processing..........................................................32

3.2.3.Mercury consumption in the Kadoma-Chakari area .................................32

3.3. SITE SELECTION AND SAMPLING LOCATION ..............................................34

3.3.1.Milling site selection..................................................................................35

3.3.2.Sampling locations ...................................................................................35

3.3.3.Selected sites for air monitoring ...............................................................36

3.3.4.Fish sampling locations ............................................................................37

3.4. SAMPLING: METHODOLOGY ..........................................................................40

3.4.1.Superficial layer, soil, tailings, sediment and water ..................................40

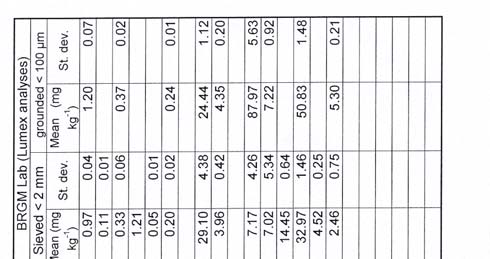

3.4.2.Fish sampling conditions and procedures ................................................41

3.5. ANALYSIS OF SOLID SAMPLES......................................................................42

3.6. AIR MONITORING.............................................................................................43

3.6.1.Operating principle ...................................................................................43

3.6.2.Problems ..................................................................................................43

3.6.3.Air monitoring at the custom milling centres.............................................44

3.6.4.Air monitoring in the villages.....................................................................45

BRGM/RC-53320-FR Part A: Final report

13

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

3.7. ANALYSIS......................................................................................................... 45

3.7.1.Tailings, soils and sediments ................................................................... 45

4. Results .................................................................................................................... 47

4.1. SOIL, SEDIMENT, TAILINGS AND WATER BY SELECTED AREA ................ 47

4.1.1.Southern zone.......................................................................................... 47

4.1.2.Northern zone .......................................................................................... 63

4.1.3.Main outcomes on solid samples ............................................................. 73

4.1.4.Drinking water .......................................................................................... 76

4.2. AIR MONITORING ............................................................................................ 76

4.2.1.Tix site...................................................................................................... 78

4.2.2.Amber Rose site....................................................................................... 83

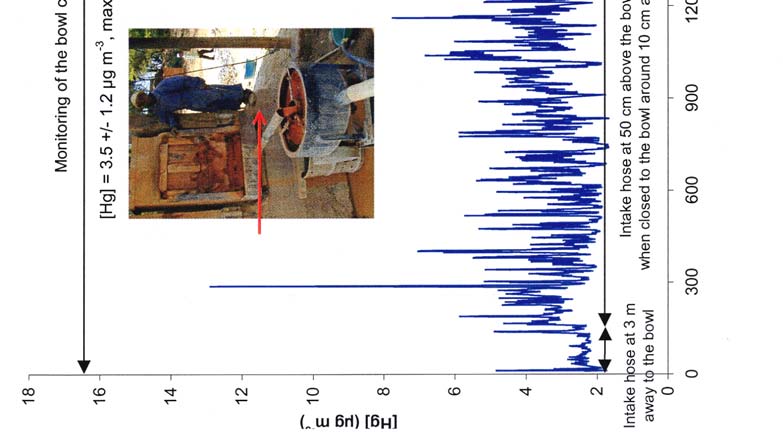

4.2.3.Even Milling Centre .................................................................................. 85

4.2.4.Main outcomes for air monitoring............................................................. 85

4.3. FISH SAMPLES ................................................................................................ 87

4.3.1.Fish characterisation ................................................................................ 87

4.3.2.Global biometric characteristics and mercury contamination levels in

fish............................................................................................................ 88

4.3.3.Mercury contamination levels according to the trophic level of fish and

to the sampling sites ................................................................................ 89

4.3.4.Comparison between mercury concentrations in fish muscle in this

study (Zimbabwe) and in other artisanal gold mining sites ...................... 92

4.3.5.Conclusion ............................................................................................... 93

5. Evaluation of exposure to Hg................................................................................ 95

5.1. SINGLE-SOURCE HOT SPOTS....................................................................... 95

5.2. MULTI-SOURCE HOT SPOTS ......................................................................... 97

5.3. EVALUATION OF EXPOSURE......................................................................... 98

6. Recommendations ............................................................................................... 101

6.1. GENERALITIES .............................................................................................. 101

6.2. URGENT ACTIONS ........................................................................................ 101

6.2.1.Actions on ore processing technologies and practices .......................... 102

6.2.2.Actions to rehabilitate and preserve the environment ............................ 102

14

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

6.3. MEDIUM- TO LONG-TERM ACTIONS............................................................103

6.3.1.Improvement in the management of the artisanal mining activity...........103

6.3.2.Reduction of environmental impacts ......................................................103

6.3.3.Support and management of these actions............................................104

7. Conclusion ............................................................................................................105

8. References ............................................................................................................109

List of illustrations

Illustration 1 - Composition of the main project team................................................................21

Illustration 2 - Project schedule as of October 2004. ................................................................23

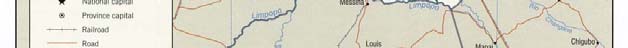

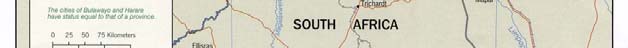

Illustration 3 - Situation of the Kadoma-Chakari area. ..............................................................25

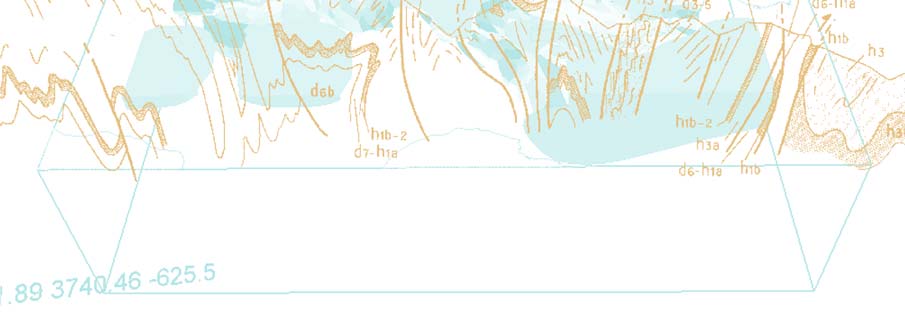

Illustration 4 - General map of the Kadoma-Chakari area showing the localisation of the

north and south zones........................................................................................26

Illustration 5 - General flow sheet of artisanal gold processing in the Kadoma-Chakari

area. ...................................................................................................................28

Illustration 6 - A to F Amalgamation process at Summit mill. ...................................................30

Illustration 7 - Etena Mill - Empty bowl-concentrator with amalgam droplets in the riffles at

the end of the concentration process. ................................................................31

Illustration 8 - Individual artisanal gold processing in different villages. ...................................33

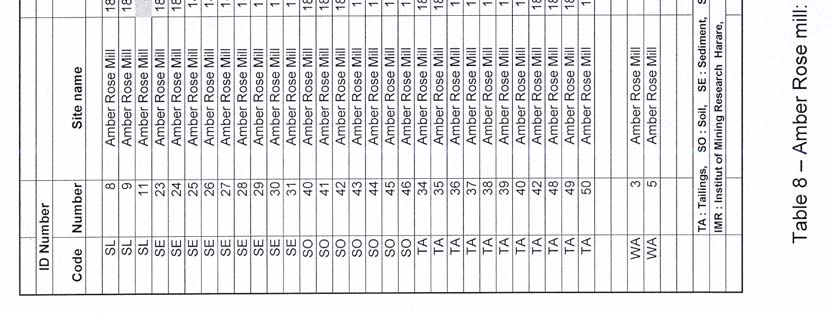

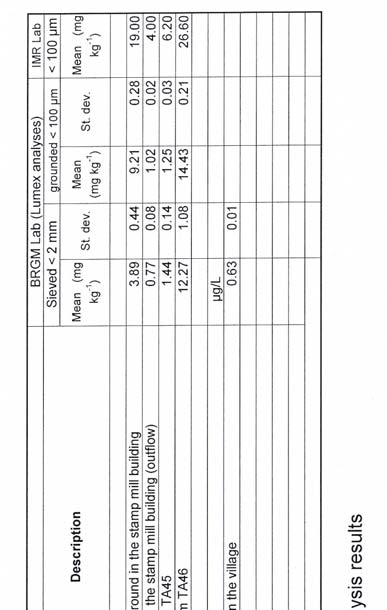

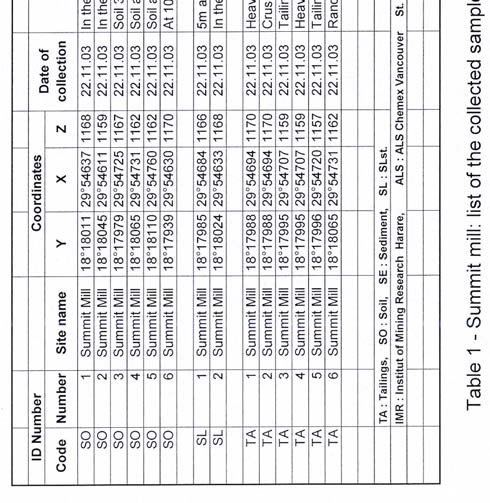

Illustration 9 - List of collected samples. ...................................................................................35

Illustration 10 - List of collected samples site by site. .................................................................36

Illustration 11 - Main biogeochemical steps entailed in gold mining activities using

amalgamation procedures and human population exposure, via the

ingestion of carnivorous fish species, at the top of the aquatic food chain

(from Boudou 2004). ..........................................................................................37

Illustration 12 - The six fishing points on the Muzvezve River, Amber Rose mill (A) and Tix

mill (T )................................................................................................................39

Illustration 13 - The LUMEX RA-915+ analyser equipped with the RP 91C attachment.............42

Illustration 14 - Local sketch of the Tix area. Sampling location and Hg results. .......................48

Illustration 15 - Example of sample locations on the Tix site. .....................................................49

Illustration 16 - Sketch of Tix mill and village. Sampling location and Hg results. ......................51

Illustration 17 - Hg distribution in soil samples following the process at Tix mill.........................53

Illustration 18 - Hg distribution in various tailings samples at Tix mill. ........................................54

BRGM/RC-53320-FR Part A: Final report

15

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Illustration 19 - Tailings "channel" at Tix mill. ............................................................................. 55

Illustration 20 - Surrounding area of Amber Rose: sampling location. ....................................... 56

Illustration 21 - Site of Amber Rose: sampling location.............................................................. 58

Illustration 22 - Hg content distribution in various samples following the ore process at

Amber Rose. ...................................................................................................... 59

Illustration 23 - Hg content in the Muzvezve River samples....................................................... 61

Illustration 24 - New Plus Mill. Dust sampling on the concrete floor around the roasting

house with an exhaust pipe. .............................................................................. 62

Illustration 25 - Hg content in New Plus samples. ...................................................................... 62

Illustration 26 - Hg distribution in various samples following the process at Summit Mill........... 64

Illustration 27 - Hg distribution in various samples following the process at Glasgow site. ....... 66

Illustration 28 - Hg distribution in various samples following the process at Coetzee site. ........ 67

Illustration 29 - Bowl-concentrator and copper-plate in a closed building at Lilly mill. ............... 68

Illustration 30 - Hg contents in samples collected at Lilly mill..................................................... 68

Illustration 31 - Tailings sample location at Lilly mill................................................................... 69

Illustration 32 - Drinking water installation at Lilly mill. ............................................................... 69

Illustration 33 - Hg contents in the samples of Even Milling Centre. .......................................... 70

Illustration 34 - Dust collection by miners on the concrete floor of the shelter for

amalgamation at Even Milling Centre. ............................................................... 71

Illustration 35 - Roasting room at Even Milling Centre. .............................................................. 72

Illustration 36 - Sampling location at Etena village..................................................................... 72

Illustration 37 - Synthesis of the chemical analyses on TA, SO, SE, SL and WA...................... 74

Illustration 38 - List of the different air monitoring carried out in November 2003...................... 77

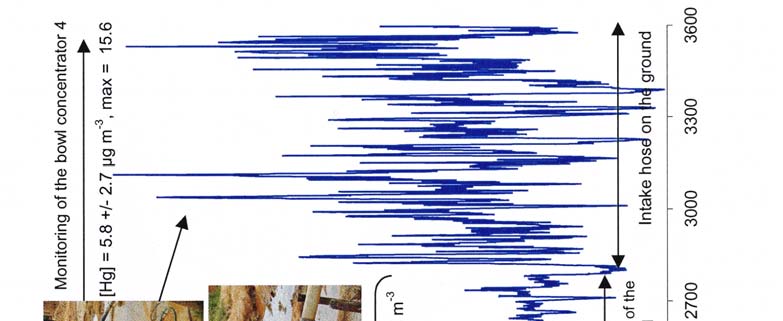

Illustration 39 - Mercury monitoring in air at Tix mill. .................................................................. 78

Illustration 40 - Monitoring on the copper-plate at Tix mill (ZI2511A.xls). .................................. 79

Illustration 41 - Deposit of mercury droplets during the air monitoring of the copper-plate at

Tix mill. ............................................................................................................... 80

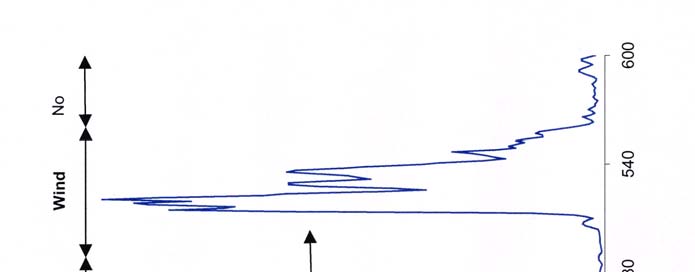

Illustration 42 - Mercury monitoring in air at Tix village. ............................................................. 80

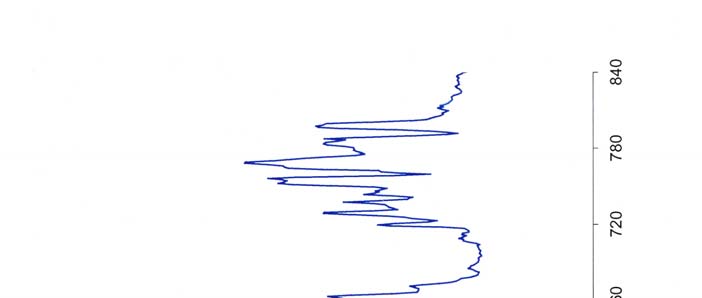

Illustration 43 - Monitoring in an open area 200 m from Tix mill (ZIB2311F). ............................ 81

Illustration 44 - Monitoring in the bar house in the village close to Tix mill (ZIB2311D.xls). ...... 82

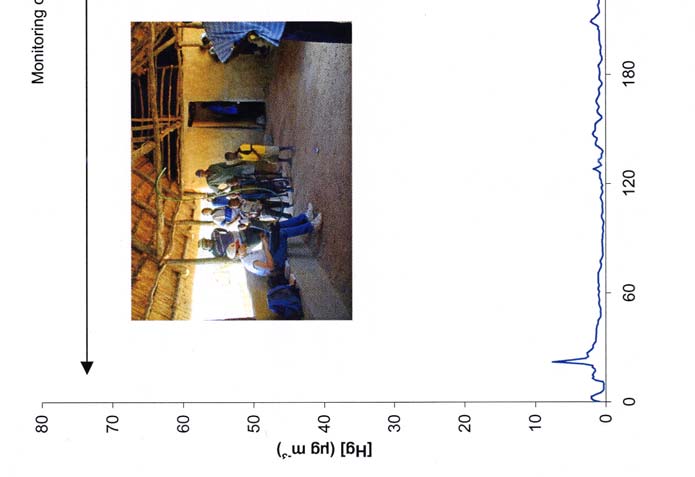

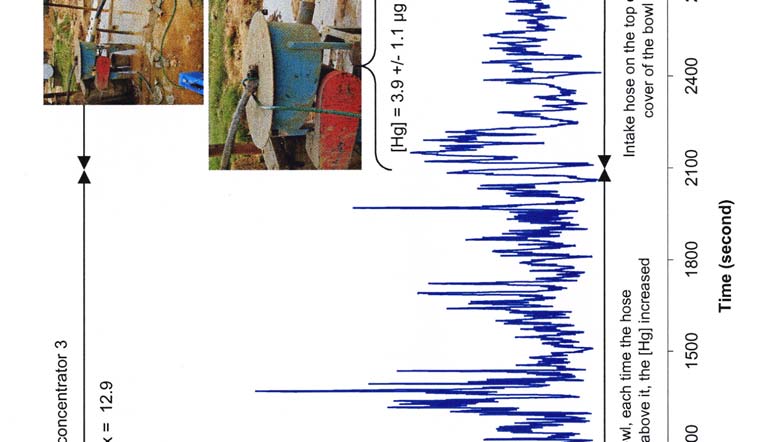

Illustration 45 - Mercury monitoring in air at Amber Rose mill.................................................... 83

Illustration 46 - Air monitoring at Amber Rose mill. (ZIB2711A.xls). .......................................... 84

Illustration 47 - Mercury monitoring in air Amber Rose village. .................................................. 85

Illustration 48 - Mercury monitoring of air at Amber Rose mill.................................................... 85

Illustration 49 - Balance of the sampled fish species and numbers, from the six sampling

points.................................................................................................................. 87

Illustration 50 - Photographs of the six different species caught in the Muzvezve River. .......... 87

16

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Illustration 51 - Mean biometric data (standard length and body weight), mercury

concentrations in the dorsal muscle and diet for the fish species collected

in the six sampling points. ..................................................................................88

Illustration 52 - Fish species common to the sampling points. ...................................................88

Illustration 53 - Average mercury concentrations in the muscle of all the fish species

collected. ............................................................................................................89

Illustration 54 - Mercury concentrations in the muscle of the 3 fish species collected from

the sampling spot 2. ...........................................................................................90

Illustration 55 - Relationships between fish body weight and standard length and between

fish body weight and mercury concentration in muscle of all the species..........91

Illustration 56 - Mercury concentrations in the muscle of all fish species collected from the

six sampling spots, relationships between fish body weight and mercury

concentrations in muscle....................................................................................92

Illustration 57 - Comparison between mercury concentrations in carnivorous fish collected

during UNIDO missions in Sudan, Zimbabwe and Lao PDR. ............................93

Illustration 58 - Main contamination sources and route to Hg exposure.....................................96

Illustration 59 - Summary of the exposure pathways and the related risks (probability of

occurrence: ***high, **moderate, *possible, 0 none)..........................................99

Illustration 60 - Comparison of measured and certified values of total mercury

concentrations using three standard biological reference materials. ...............128

Illustration 61 - List of samples selected for control analyses (in mg.kg-1). ..............................129

Illustration 62 - Correlation LUMEX < 2 mm versus ALS..........................................................130

Illustration 63 - Correlation LUMEX < 100 µm versus ALS < 100 µm. .....................................130

Illustration 64 - Histogram of the control analyses. ...................................................................131

Illustration 65 - Correlation LUMEX < 2 mm vs. LUMEX < 100 µm..........................................132

List of appendices

Appendix 1 - List of collected samples with results of the chemical analyses...........................113

Appendix 2 - Quality control.......................................................................................................125

Appendix 3 - Biometric data and mercury concentrations in the 52 individual fish....................133

Appendix 4 - Characteristics of each fish specie (identification, diet)........................................137

BRGM/RC-53320-FR Part A: Final report

17

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

1. Introduction

n response to a request from the Government of Zimbabwe and in the framework of

Ithe general project entitled "Removal of barriers to the introduction of cleaner

artisanal gold mining and extraction technologies", a contract was signed in September

2003 between the United Nations Industrial Development Organisation (UNIDO) and

the BRGM, in order to carry out the environmental and health assessment in the

Kadoma-Chakari area. This area is characterised by the presence of thousands of

artisanal gold miners using mercury for the gold recovery.

The ultimate aim of the project is to replace mercury amalgamation practice in this area

by alternative technologies, while improving the income and the health of the people

using mercury. It includes a more efficient Hg and gold recovery process, an increasing

knowledge and awareness and provides policy advice on the regulation of artisanal

gold mining.

In accordance with the decision taken during a meeting with UNIDO in November 2003

in Vienna (Austria), the study has been divided in two field steps. The first one was

completed in November 2003 in order to carry out the environmental survey before the

rainy season, and the second, focussing on the health assessment, was conducted in

April 2004 at the end of the rainy season.

Two fieldwork reports have been submitted to UNIDO:

- The first one entitled "Removal of barriers to the introduction of cleaner artisanal

gold mining and extraction technologies in Kadoma-Chakari area. Zimbabwe.

Fieldwork report 1. BRGM/RC-52796-FR", dated December 2003, describes the

environmental assessment carried out in November 2003.

- The second one, entitled "Health Assessment of small-scale miners in a mercury

contaminated area (Kadoma area. Zimbabwe)" describes the health survey carried

out in April 2004. During this second mission, some additional work was

accomplished for the environmental study.

The final results of the project are given in two separate reports:

- This Final Report (Part A) deals with the environmental survey. After the

presentation of the project team, it summarises the fieldwork carried out during the

November 2003 and April 2004 missions, the organisation and planning, the

methodology used for site selection and the sampling. The chemical analysis results

are given site by site, followed by interpretation and recommendations.

- The health survey Final Report (Part B) was completed in November 2004 by the

health team (Boese-O'Reilly, 2004). It summarises the fieldwork carried out in April

2004 and presents all the specimen analysis and statistical results, with

recommendations to improve health and reduce hazard relative to the use of

mercury.

BRGM/RC-53320-FR Part A: Final report

19

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

2. Organisation and schedule

The fieldwork completed in November 2003 is described in detail in the Field Work

Report BRGM/RC-52796-FR dated December 2003.

Complementary data given hereafter synthesise the entire organisation and schedule

of the work accomplished between November 2003 and August 2004, including the

field work carried out in April 2004.

2.1. PROJECT TEAM

2.1.1. Main team

The project team was composed of two groups, the first for the environmental survey

and the second for the health survey. These two groups received a considerable and

necessary assistance from local people (illus. 1).

Environmental assessment

Name

Organisation

Activity in the project

Dr. Pierre Billaud

Project manager

BRGM Orléans

Dr. Valérie Laperche

Geochemist

Dr. Régine Maury-Brachet

LEESA CNRS, University of Aquatic Ecology and Ecotoxicology

Prof. Alain Boudou

BORDEAUX

Health Assessment

Leader of the health survey.

Dr. Stephan Boese-O'Reilly Institute of Forensic

Paediatrician, master of public

Medicine, Ludwig-

health, Environmental medicine

Dr. Felicitas Dahlmann

Maximilians University,

Physician

Munich

Pharmacist. On site mercury

Beate Lettmeier

analyses

Local team for the environmental and the health assessment

Dr. Dennis Shoko

UNIDO

National Expert

Institute of mining research.

Spencer G. T. Kahwai

Analytical Chemist (+ field works)

University of Zimbabwe

Dr. Edwin Muguti

Medical Expert

Tapuwa Mwanjira

Kadoma hospital

Nurses to assist the medical

Vigilance Parirenyatrwa

Kadoma hospital

examinations

Joan Marembo

Kadoma hospital

Felicitas Navahya

Translator

Ezequiel Maponga

IMR

Driver

Illustration 1 - Composition of the main project team.

The two teams benefited, in the organisation of field work and also during the full time

of the missions, from the efficient assistance of D. Shoko, UNIDO National Expert of

the Global Mercury Project in Zimbabwe.

BRGM/RC-53320-FR Part A: Final report

21

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Moreover, Dr. O. Maponga, Chairman of the Institute of Mining Research of the

University of Zimbabwe (IMR), granted us the scientific, technical and administrative

support of the Institute and also permitted Spencer G. T. Kahwai, chief of the chemistry

laboratory, to participate in all the fieldwork.

Prof. Alain Boudou (Univ. Bordeaux, LEESA) provided fish sampling kits and analysis

facilities.

The assistance of Dr. L. Christian Leveque (CNRS, Meudon, France) determined the

species and food regimes of the collected fishes.

2.1.2. Local workers

Local workers were hired on each surveyed site to help in the sediment, soil, and tailing

sampling and in the panning operations (see fieldwork report, Billaud and Laperche,

2003).

2.2. EQUIPMENT

The list and origin of the equipment used for the environmental assessment is given in

the Field Report (Billaud and Laperche, 2003). Equipment used for the health

assessment is listed in the Field Report dated June 2004 from the Institute of Forensic

Medicine.

2.2.1. Schedule

According to the briefing meeting held at the UNIDO headquarters in Vienna in

November 2003, the field work was divided into two periods due to the availability of

the health team and the imminence of the rainy season, during which it would have

been difficult to carry out the sampling and health survey.

The first fieldwork was completed in November 2003 just before the rainy season and

concerned the environmental survey. The second mission, corresponding to the health

survey, was scheduled and carried out in April 2004 at the end of the rainy season.

The schedule of the project is summed up in illustration 2.

22

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Global Mercury Project : Kadoma - Chakari area. Schedule as of 31.08.04

2003

2004

Tasks

Nov

Dec

Jan

Feb

Mar

Apri

May

June

July

Aug

Sep

Oct

Environmental assessment

Main field works

Field work report

Chemical analyses

Additional site sampling

Fish analyses and interpretation

Final report

Health assessment

Field works

Field work report

Analyses (Hair, blood, Urine)

Final report

Illustration 2 - Project schedule as of October 2004.

BRGM/RC-53320-FR Part A: Final report

23

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

3. Generalities and methodology

3.1. GENERAL CONTEXT AREA SELECTION

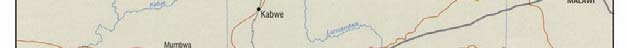

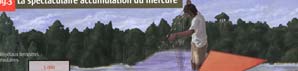

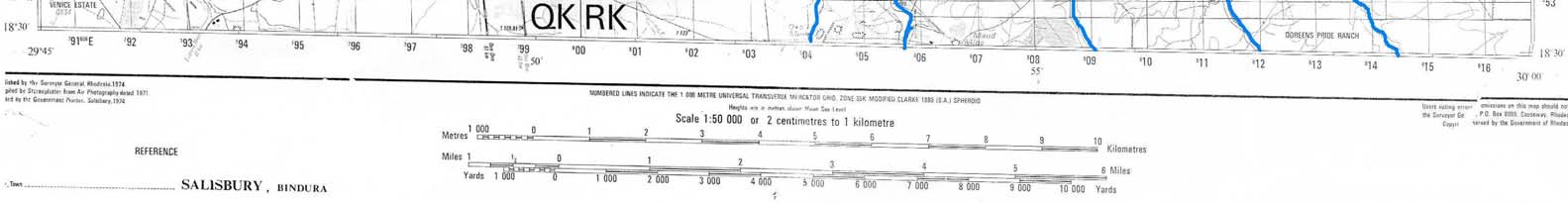

The Kadoma Chakari area, which was selected by UNIDO, is located roughly 150 km

west south west of Harare (illus. 3). Kadoma, the most important city of the area, can

be easily reached from Harare by the wide blacktop road going to Bulawayo. The area

is covered by the topo-sheet No.1829B2 and 1829B4 at 1:50,000 scale.

Kadoma-Chakari region

Illustration 3 - Situation of the Kadoma Chakari area.

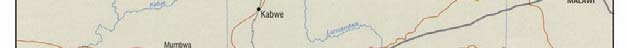

The short preliminary survey carried out during the first days of the field mission in

November 2003 allowed us to sketch in a rough map of the area (illus. 4) showing two

main zones:

BRGM/RC-53320-FR Part A: Final report

25

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

- The northern zone, with the mining town of Chakari in the north and the town of

Kadoma in the south, has a fairly flat relief and no major river between Chakari and

Kadoma. Consequently, no major panning activity was found. The main activities

are farming, with big cotton, maize... producers, large-scale cattle breeding with

extensive farms, and mines. The industrial activity is centred on gold mining and

processing by local and international companies and numerous self-employed

miners and millers scattered throughout the area. The gold deposits are vein and

shear-zone types within the Archaean volcanic-sedimentary belt. The self-employed

miners extract the ore from laterite and semi-weathered rocks and use mercury for

gold amalgamation in the milling centres or in their own villages. The roasting of the

amalgam is done essentially near the milling centre, but also in the villages.

1829B2

Nth

Chakari

Coetzee

North zone

Glasgow

Summit

1829B4

Kadoma

To Harare

Even Milling center

Muzvezve river/lake

Road, Wide tarred

South zone

Road, Narrow tarred

Tix

Alexander

Claw Dam

Milling center

Panners area

Panners

Amber Rose

City

To Bulawayo

Illustration 4 - General map of the Kadoma Chakari area showing the localisation

of the north and south zones.

- The southern zone is somewhat hilly and crossed by a major river, the Muzvezve

(pronounced Mujeje), flowing to the west-north-west for roughly 250 km, to the Lake

Kariba on the Zambezi River, which forms the boundary between Zambia and

Zimbabwe in the north-western part of the country. In this zone, all the streams are

tributaries of the Muzvezve River. The area is covered by forest and bush. The main

activities are small farms and gold mining. Self-employed and small-scale gold-

mining miners and millers work in the area, and panners are found along the whole

26

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

length of the Muzvezve River. Gold is mined from semi-weathered Archaean

volcanic-sedimentary units, resembling those in the northern zone, but it is also

panned from alluvial deposits and sometimes from old tailings. Miners and millers

are mainly grouped in villages installed close to the milling centres.

3.2. GOLD PROCESSING IN THE KADOMA-CHAKARI AREA

The main preliminary data about the artisanal gold mining and processing in the

Kadoma-Charkari area can be found in the UNIDO report dated October 2003 (Veiga

and Shoko, 2003). Following the first fieldwork carried out in November 2003,

additional information is given in the fieldwork report No.1 (Billaud and Laperche,

2003). Other general information is presented in a more recent document of UNIDO

available on the GMP website (Shoko and Veiga, 2004; Hinton and Veiga, 2004).

Three kinds of artisanal gold processing are conducted in the area. The main one,

which concerns stockpiles of 1 to 5 tons of ore, takes place in custom milling centre

using a copper-amalgam plate or bowl-concentrator for the amalgamation process. It is

carried out by miners or groups of miners who are renting the services of millers. The

second one, which concerns only a small quantity of ore, less than one ton, involves

hand crushing with a hammer and a grinder, followed by panning and amalgamation in

buckets or plastic trays. It concerns isolated miners or women and children of miners.

The last one is performed by panners in the riverbed, where gold is collected though a

sluice, then panned, followed by amalgamation in pan or bucket. For all of these

processes, roasting is the last operation.

More than 20,000 individuals are engaged in artisanal mining in this area. These are

roughly comprised of 3,000 to 5,000 miners, 1,000 to 2,000 millers located in the

recorded 70 milling centres and 15,000 to 20,000 panners.

3.2.1. Main artisanal gold processing

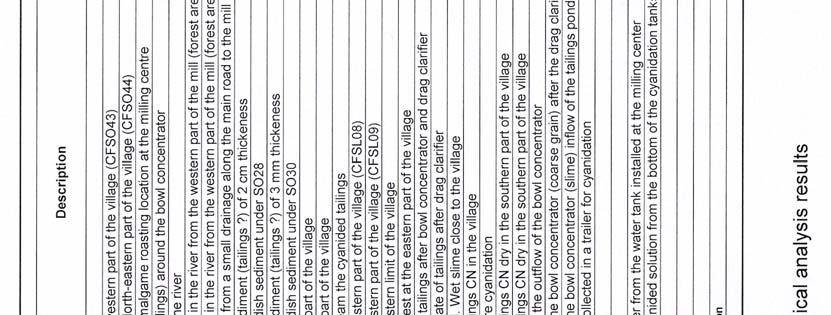

The main artisanal gold processing is summarised in the general flow sheet shown in

illustration 5.

a) Crushing and grinding

After extraction, the ore is sent to the custom milling centre by the miners, where the

work is carried out by batches of 1 to 5 metric tons of ore. Two kinds of equipment are

found. The most frequent one, which is also the oldest, the least expensive but also the

least efficient, is the wet stamp mill (with two to four stamps) having a capacity of 0.2 to

1.5 metric tons/hour. The second equipment, more recent (2002) operating only on one

site (Even Milling Centre), is composed of a jaw-crusher followed by a ball mill. The

crushing capacity is 0.7 to 2 metric tons/hour. The objective of crushing is to free the

gold from its gangue. With the stamp mills, the ore is never ground finely enough to

free the gold or to expose it at the surface of the grain. With this level of crushing, only

30% of the gold is extracted and recovered by the miners.

BRGM/RC-53320-FR Part A: Final report

27

28

Globa

l mercury pro

ZIMBABWE GLOBAL MERCURY PROJECT

Kadoma - Chakari area

Summary of the beneficiation

from ORE EXCAVATION

feed

j

ect: Environ

from ORE EXCAVATION

ore stock pile

ore stockpile

jaw crusher

barren solution

m

e

n

AC column adsorption

Legend :

stamp mills

tal assessm

feeder

Samples collected

adsorption circuit

§

Soil

Tailings

R

G Air monitoring

ball mill

reagents

Hg in

ent Kad

G

R OF

Bowl concentrator

§

AC column desorption

desorption

Cyanide

solution

o

G

ma-Chak

vapor

Hg in

G

amalgam clean up

Copper plate

OF

R

BRGM/RC-53

G R

Electrolyzer

§

acidified solution

amalgam clean up

OF

acid

fines

a

drag clarifier

r

R

loaded

i are

R

cathodes

Hg out

G

Tailing

§

Hand cloth

ponds

a

filter press

cyanide

AC regeration

recyclied AC

, Z

§

Hg vapor

i

amalgam

mbab

32

tailing ponds

out

heater

0-F

Pregnant

G

solution

fluxes

Hg out

Burner

Vat leaching

Hg vapor

we

R

condenser

Part A: F

Solids

sponge

out

acid HNO3

Furnace

slags

Liquids

liquid

Leaching

impurities +Hg

DORE BAR

Clarifier

fines

fluxes

i

Hg vapor

nal re

out

slags

Furnace

§ R

tailing dams

port

DORE

Illustration 5 - General flow sheet of artisanal gold processing in the Kadoma-Chakari area.

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

The remaining gold is collected by the millers through a cyanidation process.

Depending on the quantity of the stockpile and the hardness of the ore but also on the

technical status of the stamp mill (quartz takes more time than laterite), the crushing

operation for one batch takes between a few hours to one day.

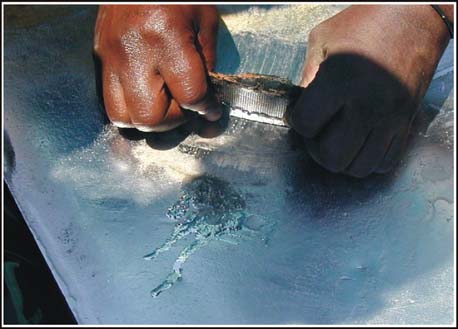

b) Amalgamation / mineral concentration

Most of the time, the pulp coming from the stamp mill through a 48 or 65 mesh screen

(not always well maintained) and composed of around 20% solids is sent directly to a

copper-plate covered with a film of mercury. In the milling centre newly equipped with a

jaw-crusher and ball mill, but also in some of the well-maintained milling centres

equipped with a stamp mill, the copper-plate is replaced by a bowl-concentrator (also

called Zimbabwean centrifuge, ABJ bowl or "speedy bowl") where mercury is added at

the beginning of the process.

The copper-plate consists of a sheet of pure annealed copper. At the beginning of the

process, the plate is coated with as much mercury as the plate will adsorb. The

quantity of mercury used varies from one place to another, but it is said that at least

150 g m² (3 teaspoons of 45 g each) of mercury are used for this operation. This

mercury film immediately amalgamates any gold particles that come in contact with it.

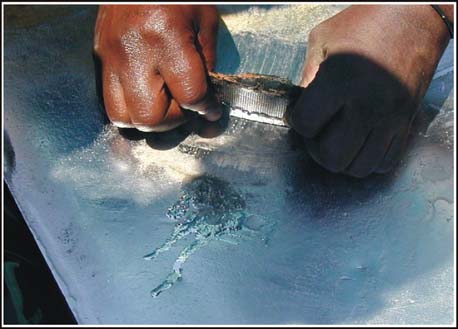

At the end of the process, when all the ore is crushed, the copper-plate is scoured with

sand or tailings to remove any remaining amalgam. The resulting bright metallic copper

is then rinsed with clean water and washed with a 2 to 3% solution of cyanide (if

available). Most of the time, the millers use solid Na-cyanide tablets to clean the plate

by hand with no glove nor mask protection. Following this procedure, amalgam with

fine sand particles is collected by hand and then squeezed in a cloth to remove unused

mercury. The quantity of water necessary to keep the pulp travelling slowly down the

copper-plate depends on the slope of the plate (10%), on the fineness of the crushing,

as well as on the nature of the gold (coarse or fine).

Illustration 6 shows some part of this process.

With bowl-concentrators, the pulp flows directly into the bowl composed of a 120° cone

containing horizontal ribs (riffles) welded along the inside wall. Rotational forces allow

separate heavy from light particles. The light particles are carried away by the water

flowing out of the upper part of the bowl, while the heavy materials are concentrated at

the bottom of the bowl with amalgam. At the beginning of the process, the miners add

roughly 150 g of Hg directly into the cone (3 teaspoons) to amalgamate the gold

particles. Mercury consumption appears to be roughly 25 to 30 g t-1 of ore in the bowl-

concentrator (Amber-Rose mill). Clean up is accomplished by stopping the rotation of

the bowl, opening the drain at the bottom, and flushing out the concentrate (illus. 7).

About 30 kg of heavy concentrate is produced from a batch of 15 to 20 metric tons of

ore. Some millers provide the miners with amalgamation barrels, but in many cases,

the miners finish the amalgamation by hand, adding up to 800 g of mercury in plastic

trays. The final separation between the amalgam and heavy minerals is accomplished

by panning. The amalgam is then squeezed in a cloth to remove unused mercury.

BRGM/RC-53320-FR Part A: Final report

29

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

A: Stamp mill and copper plate

B: Copper plate at the end of the process

C: Amalgam recovery on the copper plate

D: Copper plate cleaning by hand

with sand and cyanide tablets

E: Amalgam recovery in a piece of cloth

F: Amalgam after squeezing to remove

unused mercury

Illustration 6 - A to F Amalgamation process at Summit mill.

30

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

After the copper-plate or the bowl-concentrator, the tailings are evacuated by open

channel or pipes to a settling pond, for clarification and drying. Most of the time, the

water is collected and recycled in the crushing process. Once dry, the tailings are

loaded onto a truck and transported to concrete tanks for cyanidation, to recover the

remaining gold.

At New Plus, a sluice box has been installed just after the copper-plate in order to

increase the gold and amalgam recovery by the miners before sending the tailings to

the settling pond.

a) General view of the bowl-concentrator

b) Remaining amalgam droplets in the riffles

Illustration 7 - Etena Mill - Empty bowl-concentrator with amalgam droplets in the riffles

at the end of the concentration process.

c) Roasting

Following this process, the miners carry away their amalgams for the roasting

operations, these take place in the same open places in the milling centre or back

home. In all the sites visited, except at Even Milling centre and New Plus, miners burn

amalgam on a wood fire without further protection. They do not use a retort or any

home-made torch. At low temperatures, the roasting process remains incomplete

resulting in around 20% of residual mercury remaining in the gold beads.

d) Cyanidation

To recover the rest of the gold in the dried tailings, which can contain 70% of the total

gold content of the crude ore, the millers apply vat-cyanidation. The milling centres

have between five and ten concrete tanks for cyanidation. The tailings are leached with

Na-cyanide solution for an average of six to ten days. The solution percolates through

BRGM/RC-53320-FR Part A: Final report

31

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

the tailings and is recovered at the bottom of the tanks, where a filtering process (layer

of sand) is set up. The gold-cyanide solution is analysed for gold content using an

SnCl2 colorimetric method. The solution passes through a few columns lined with

activated charcoal to remove the gold from the cyanide solution. After this process, the

concentration of the cyanide solution is adjusted and then re-used in the vats.

Gold extraction from the charcoal is never performed in the milling centre. The millers

send the activated charcoal to other companies that carry out the elution process. One

of them is installed in Kwe-Kwe, approximately 50 km from the mining area.

The final tailings of vat-leaching with residual cyanide are generally dumped in outlying

parts of the milling site, but also close to the village, as in the case of Amber Rose. It

can be also used as track construction materials (Tix village).

e) Remarks

Despite the poor efficiency of the stamp mill, most of the miners prefer milling centres

with stamp mills over those with ball mills because they think the ball mill is holding

back some parts of the gold. Moreover, they can see all the process steps and they

clean the stamp mill by hand at the end of the process. The cleaning of the ball mill is

done only after grinding several stockpiles of different origins and from different miners.

Nevertheless, it is well known that the gold recovery is better with the ball mill, and the

grinding capacity is between 0.7 and 2 t h-1, instead of 0.2 to 1.5 t h-1 for the stamp

mills.

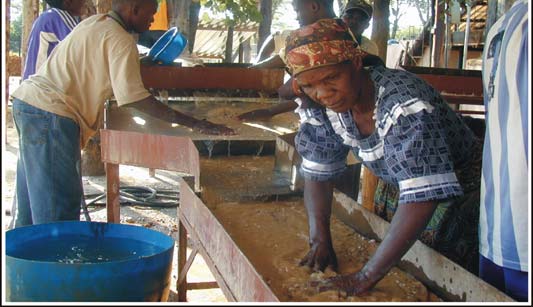

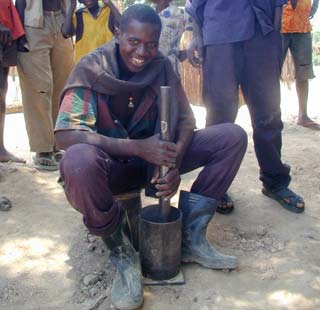

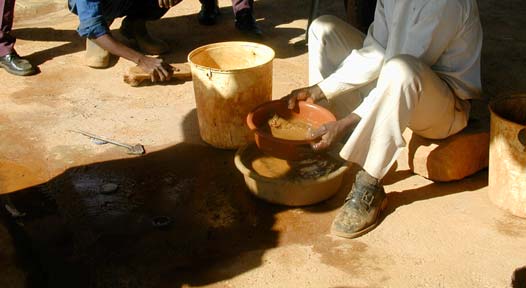

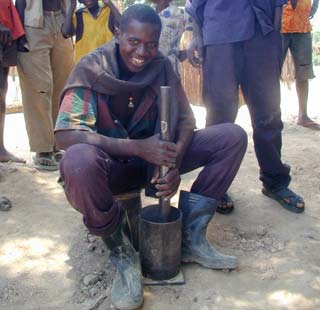

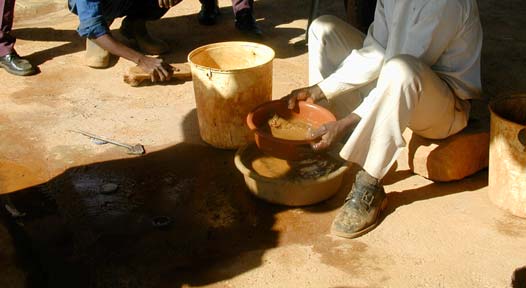

3.2.2. Individual artisanal gold processing

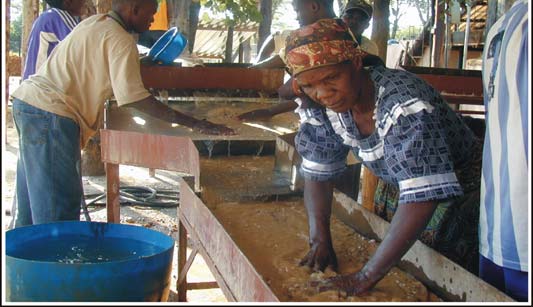

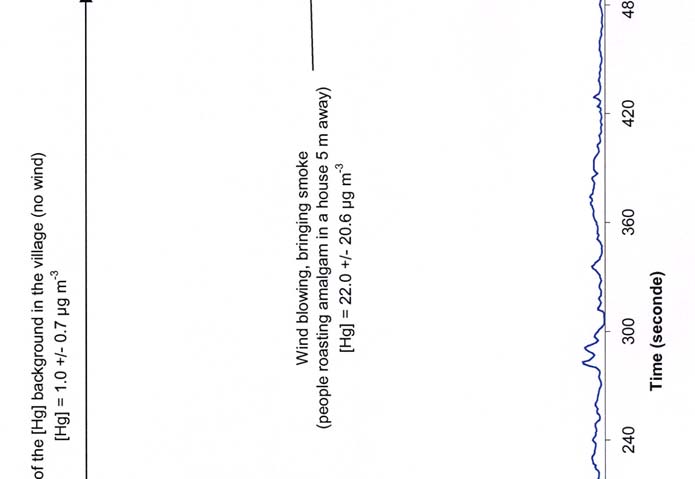

Another kind of gold processing is carried out by isolated miners, women and children,

but on a small quantity of ore (a few hundreds of kg). The ore is crushed with a

hammer directly on the extraction site then carried out in bags to the processing place,

which is generally close to their houses in the village (a few meters away) (illus. 8).

There, the ore is reduced to powder in a small iron grinder before panning. At the end

of the panning process, some mercury is added to the heavy material in the pan or

bowl and mixed by hand to facilitate amalgamation. The panning process is carried out

completely in order to separate the amalgam from the tailings. Amalgam is then

squeezed in a cloth to remove unused mercury before being roasted as described

above.

3.2.3. Mercury consumption in the Kadoma-Chakari area

The assessment of the mercury consumption in the Chakari-Kadoma area is a difficult

exercise because no official statistics are available about the mercury market. No

measurement of the mercury recycling, no information concerning the tonnage of ore

processed in the different milling center or of gold produced by the miners and by the

millers exist. Moreover people are not ready to give clear information about the

mercury and gold market.

32

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

a

b

c

d

a) Ore grinding at Tix village

b) Panning and amalgamation at Tix

c) Small artisanal sluice box at Etena

e

d) Amalgam roasting at Tix village

e) Detail of the amalgam roasting on a wood

fire showing the sponge-like gold "doré"

Illustration 8 - Individual artisanal gold processing in different villages.

BRGM/RC-53320-FR Part A: Final report

33

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

Data that can be used are coming from discussions with miners, millers, agents of the

Kadoma Mine Department and from O. Maponga and also from the literature.

They can be summarised as follows:

- 70 mill sites with 1 to 4 stamp mills (including a few ball mills) have been inventoried

by the Kadoma Mine Department. That represents around 140 stamp mills,

considering an average of 2 stamp mills per milling site.

- An estimation of 12 working hours per day (including breakdowns, stand by periods

for ore supplying, cleaning and maintenance periods...) for 280 working days per

year. So we can estimate 470,400 working hours for all the 140 stamp mills and for

one year in this area.

- As said previously (§ 3.2.1.) the capacity of one stamp mill ranges from 0.2 to

1.5 t h-1. So, the annual quantity of ore crushed and ground ranges from 94,000 to

705,600 tons.

- The quantity of mercury used on the copper plate is roughly 150 g for one batch of

ore ranging from 3 to 5 tons. That is 30 to 50 g of mercury per ton of ore.

- The mercury consumption in the bowl concentrator ranges from 25 to 30 g ton-1 of

ore.

- The mercury recycling is estimated at 50%.

Finally the annual quantity of mercury used in this area can range:

- from 94,000 x 25 / 2 = 1,175,000 g of Hg rounded up to 1.2 t;

- to a maximum of 705,600 x 50 / 2 = 17,640,000 g of Hg rounded up to 17.5 t.

3.3. SITE SELECTION AND SAMPLING LOCATION

The strategy for site selection and sampling location was chosen in line with the risk

assessment approach as explained in the field work report and summarised as follows:

- Where are the main sources of mercury pollution in the artisanal gold mining of the

Kadoma-Chakari area, presuming that the visited and studied sites are

representative of this activity in this area?

- What are the main pollution vectors (pathways) that are likely to transfer the mercury

towards a target?

- What are the main target(s) exposed to the direct or indirect effects of the known

pollutant?

This analysis enabled us to classify the sites we visited according to their specific

features and their ability to represent the main local and regional risks arising from the

artisanal mining activity in this area.

34

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

3.3.1. Milling site selection

The site selection was done during the preliminary survey, at the beginning of the first

field work program in November 2003. It is described in detail in Field Work Report

No.1 (Billaud and Laperche, 2003).

The following sites were selected (illus. 4):

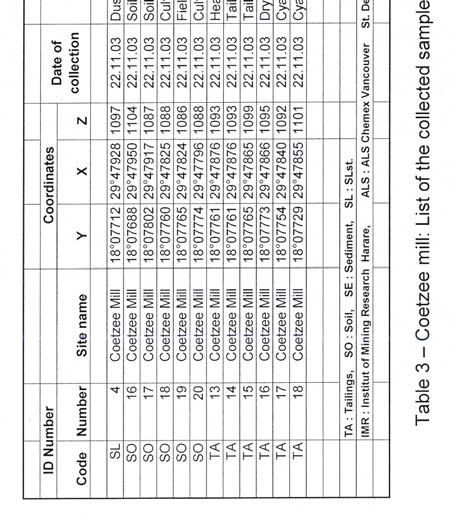

- in the northern zone: Summit, Glasgow, Coetzee, Even Milling Centre, and Lilly;

- in the southern zone: Tix, Amber Rose, and a few panning sites along the Muzvezve

River downstream Claw Dam.

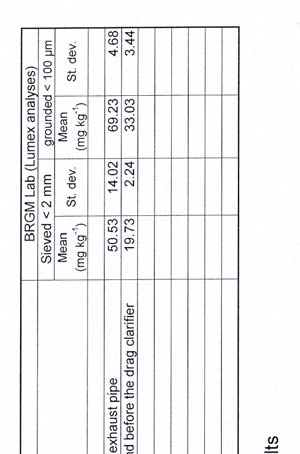

During field work in April 2004, some additional sampling focussed on Lilly and Etena

mill in the northern zone and on New Plus mill in the southern zone.

3.3.2. Sampling locations

In each selected area, the sampling locations were determined individually on each site

according to the technical organisation and composition of the processing equipment,

the geomorphology, the local drainage, the landscape and the proximity of the village.

The objective was to check the sources of the Hg pollution, its pathways and the level

of Hg in the potential targets that had been identified (surface or groundwater, plants,

animals or humans). It is important to note that the number of samples collected is

sufficient to provide information on the level, pathway as well as an indication of the

extension of mercury pollution. Nevertheless, the number of samples is insufficient to

allow us to draw up detailed maps of the pollution for each selected area. However, a

comparison of the mercury level in the different types of milling centres and associated

villages is possible and particularly interesting for making recommendations concerning

the reduction or elimination of Hg pollution.

The geographical co-ordinates of the samples were collected with a portable Global

Positioning System GPS (Datum number: Zimbabwe ARC1950) and recorded in an

"Excel" database with all the other information, such as sample number, sample

description, sample location, chemical analysis results... (app. 1). The list of the

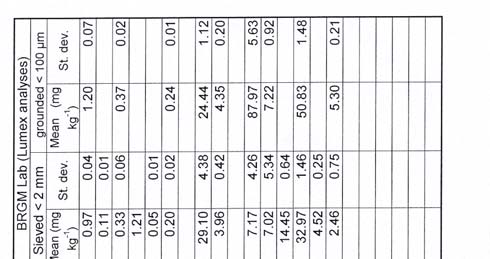

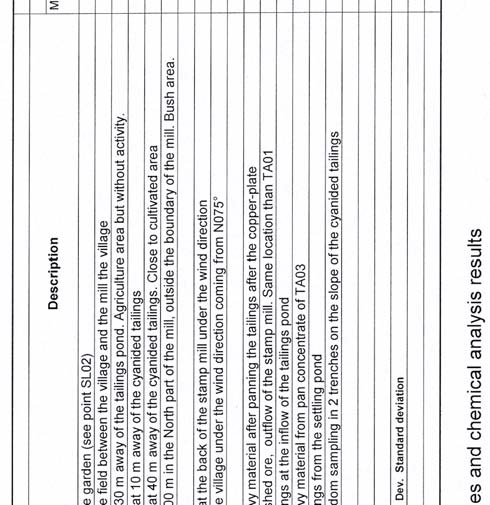

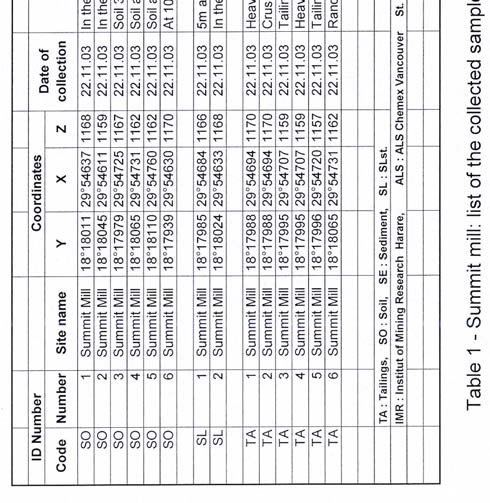

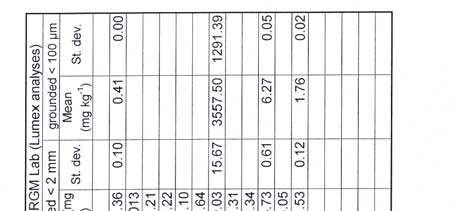

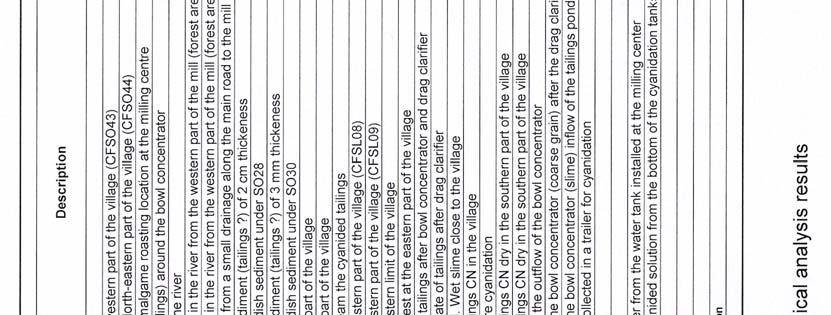

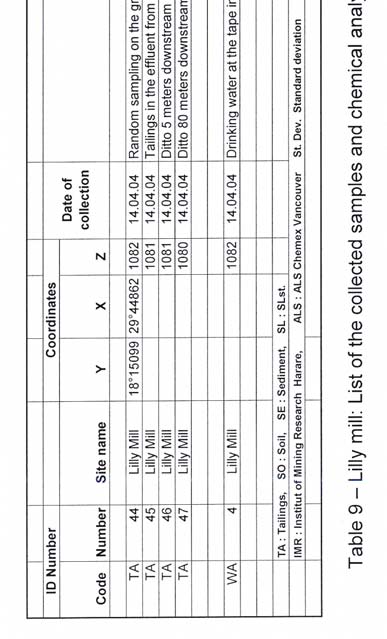

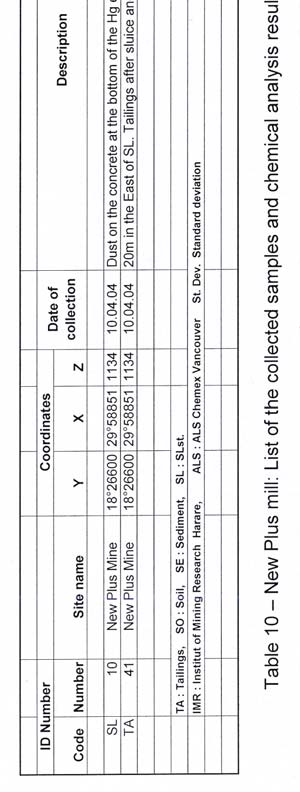

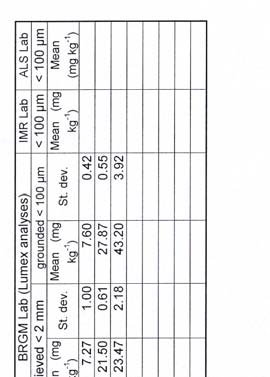

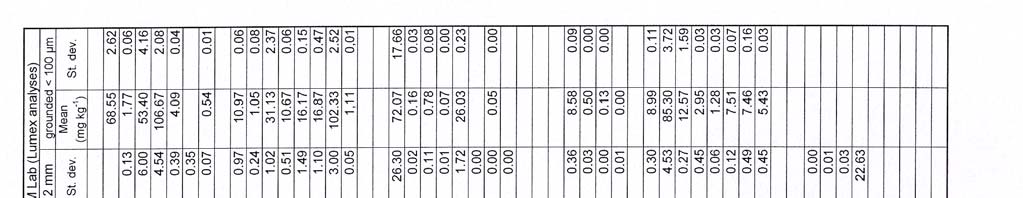

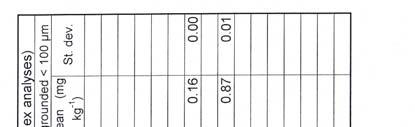

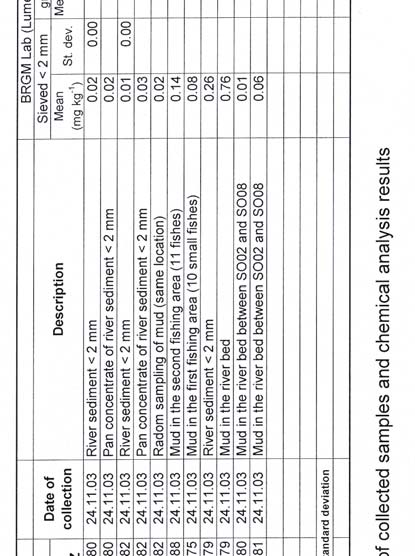

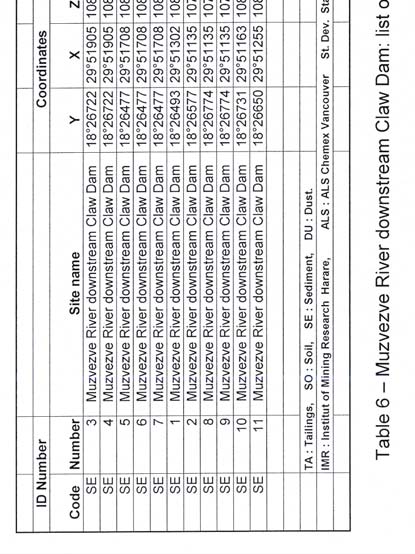

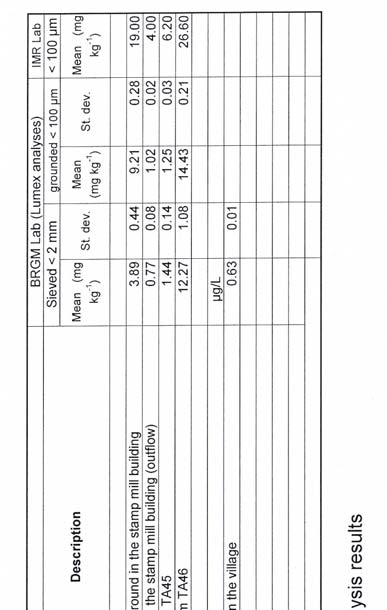

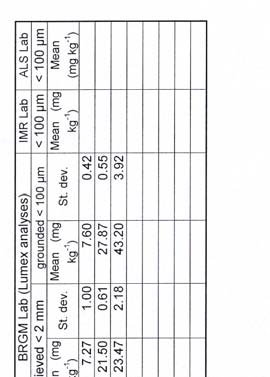

collected samples is given in illustration 9.

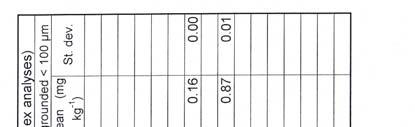

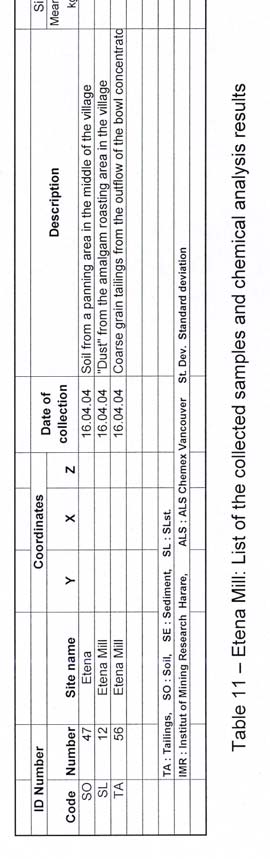

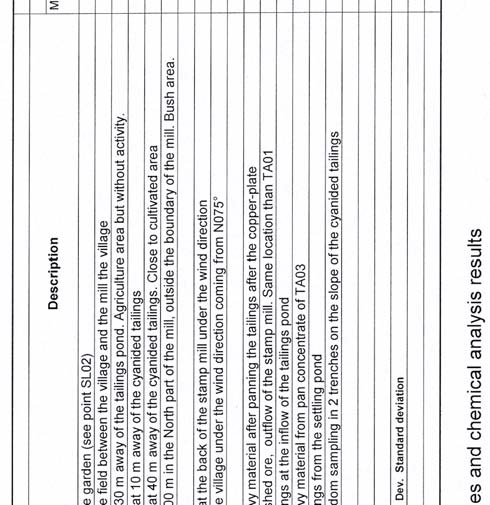

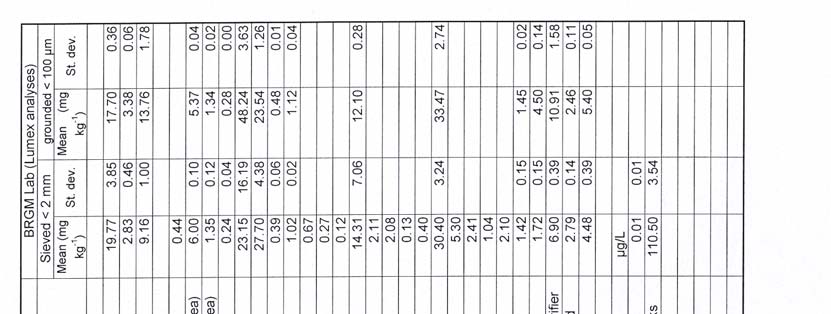

Sample type

Code

Quantity

Number: from / to

Soil

SO

49

1 to 47*

Superficial layer**

SL

12

1 to 12

Stream sediment

SE

39

1 to 39

Tailings

TA

56

1 to 56

Drinking water

WA

7

1 to 7

*

Sample SO35 is composed of SO351, SO352 and SO35b.

** The superficial layer corresponds to the fine particles (< 2 mm) deposited on the soil and collected with

a paintbrush. It contains dust.

Illustration 9 - List of collected samples.

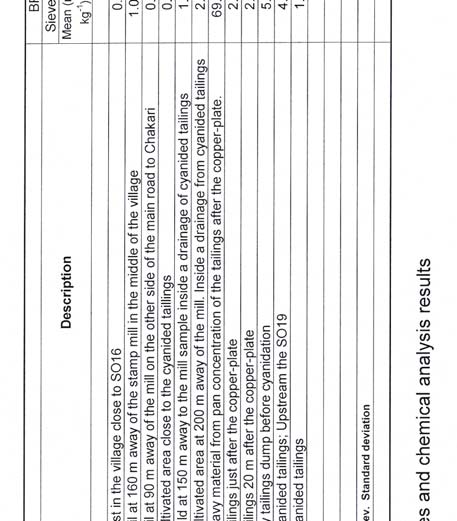

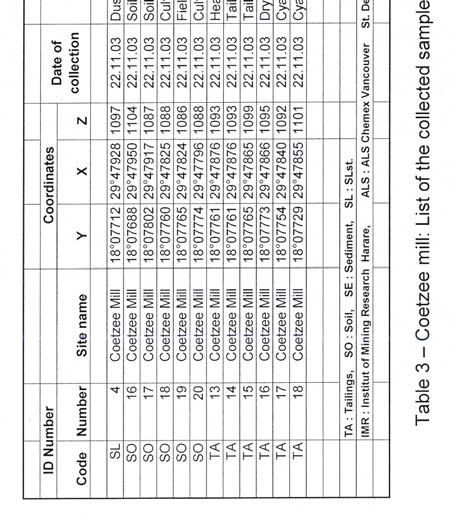

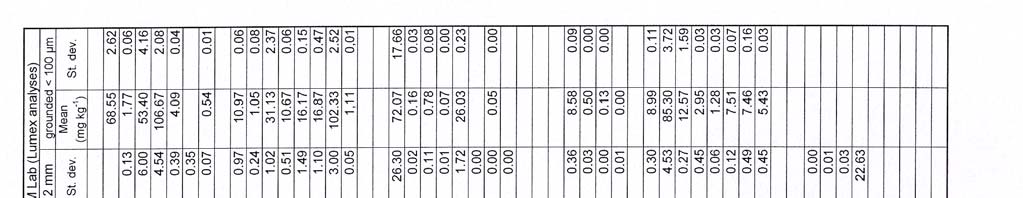

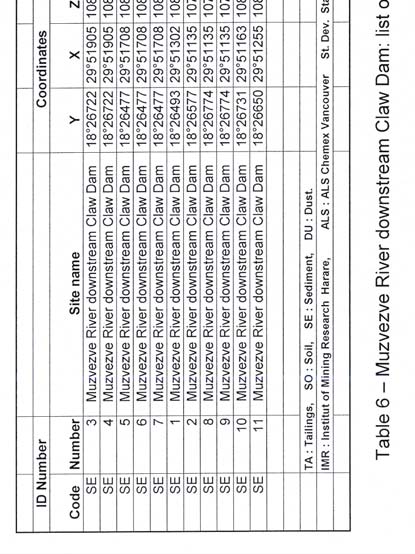

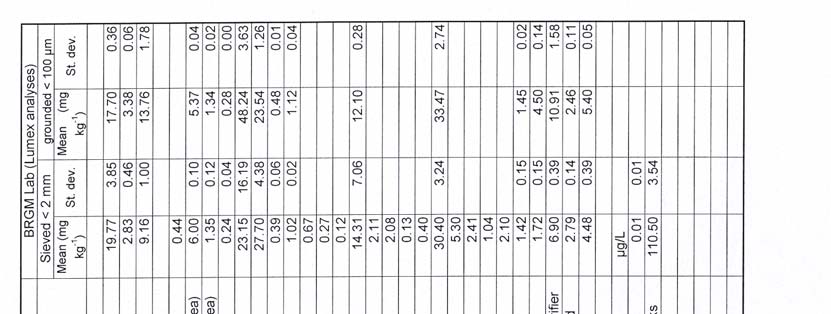

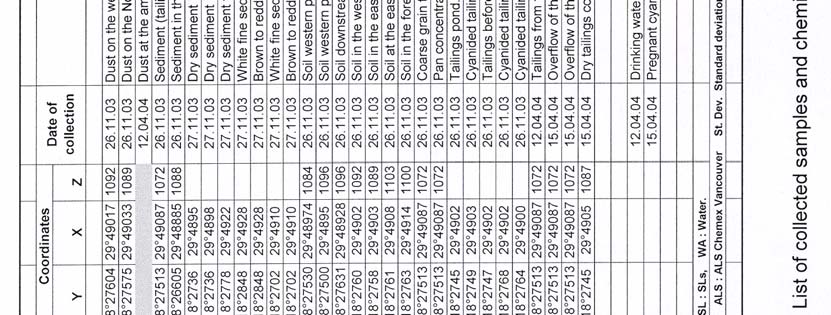

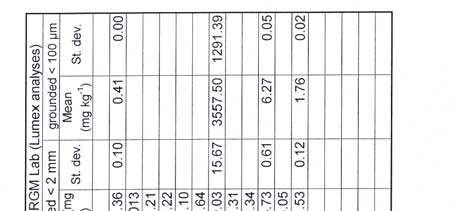

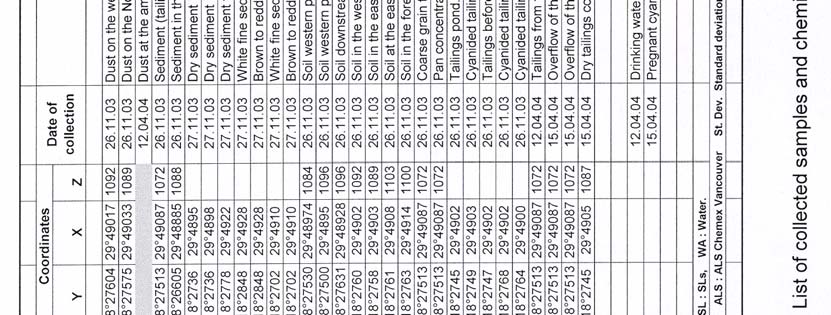

Illustration 10 gives, site by site, the detail of the collected samples.

BRGM/RC-53320-FR Part A: Final report

35

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

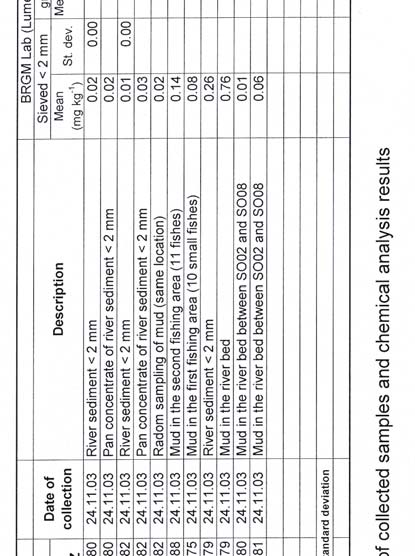

Sample quantity

Site

SO

SL

SE

TA

WA

Summit mill

6

2

6

Glasgow mill

9

1

6

Coetzee mill

5

1

6

Lilly mill

4

1

Even Milling Centre

8

1

6

Tix mill

12

2

14

14

4

Muzvezve River: Alexander farm

6

Muzvezve River: downstream Claw Dam

11

Amber Rose mill

7

3

9

11

2

New Plus mine

1

1

Etena

1

1

1

Total

48

12

40

55

7

Illustration 10 - List of collected samples site by site.

Only drinking water used in the miners' villages or on the milling sites was collected.

The samples were taken from the tap of the water tanks used by the inhabitants.

At Tix mill and village, the drinking water is pumped on the bank of Claw Dam and

transported by a 2-km-long pipe. One sample was collected near the pumping raft and

another at the tap of the water tank in the village.

At the pumping area, miners dig a lot of small pits for ore extraction. This place is also

very close (some tens of meters) to the point where the small watercourse flowing from

Tix village and mill reaches Claw Dam. At Amber Rose mill the drinking water stored in

a tank comes from a borehole drilled outside the milling centre. At Lilly village, the

drinking water comes from a borehole installed close to the tailing dumps in the middle

of the processing area.

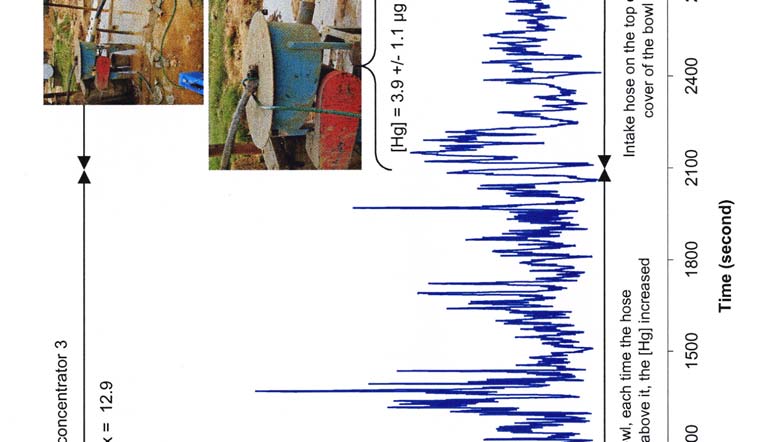

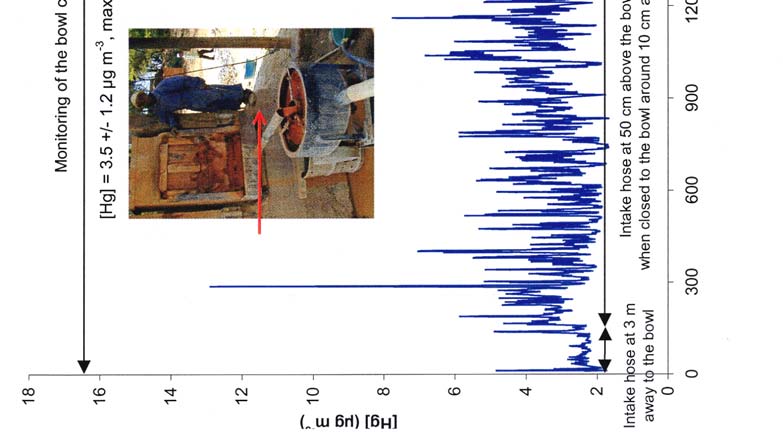

3.3.3. Selected sites for air monitoring

Three sites were selected for air monitoring:

- Tix and Amber Rose mills in the southern zone were selected for air monitoring

because they both have villages close by and use different amalgamation

processes. Whereas amalgamation is carried out on copper-plate at Tix mill, bowl-

concentrators are used at Amber Rose mill. Both sites have four stamp mills, drag

clarifiers and a cyanidation process.

- Even Milling Centre in the northern zone was selected for air monitoring because it

is new and well organised. In addition to the ball mill and bowl-concentrator, the

biggest improvement in this centre compared to the others is the well-organised

burning room. The person in charge of roasting uses a torch, and the amalgam is

placed inside an air extractor during roasting. The exhaust air flows out through a

pipe to the forest area just behind the roasting room. It is a custom amalgam burning

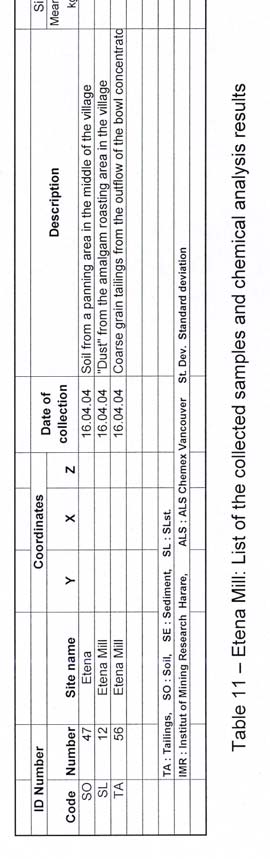

site where roasting is done by batch for each miner successively.

36

BRGM/RC-53320-FR Part A: Final report

Global mercury project: Environmental assessment Kadoma-Chakari area, Zimbabwe

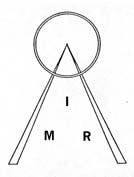

3.3.4. Fish sampling locations

a) Generalities

Fish are exposed to mercury present in the aquatic system, either through fresh water, via

the respiratory exposure, or through their diet (Snodgrass et al., 2000), and are therefore

good indicators of mercury contamination in the environment. Besides, they constitute a

substantial proportion of the protein ration for people living along the rivers, and

consequently represent for them a source of exposure to mercury. Additionally there exists

a direct exposure concerning people directly involved in the extraction of gold combined

with this metal. Mercury contamination levels in the water column of rivers and lakes are

generally very low (ng L-1), and mercury is mainly present in inorganic form (HgII). The

trophic route of exposure, via ingestion of metal accumulated in prey, represents a more

important pathway of contamination for most fish species than direct water exposure

(Boudou and Ribeyre, 1997; Mason et al., 1995; Wiener et al., 2002).

The resulting biomagnifications (cumulative trophic transfers of the methylated form of

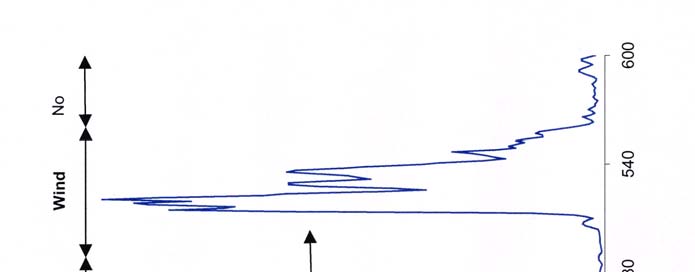

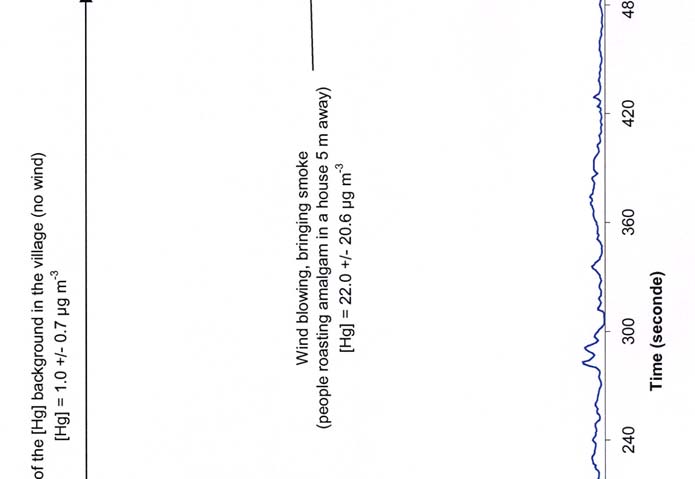

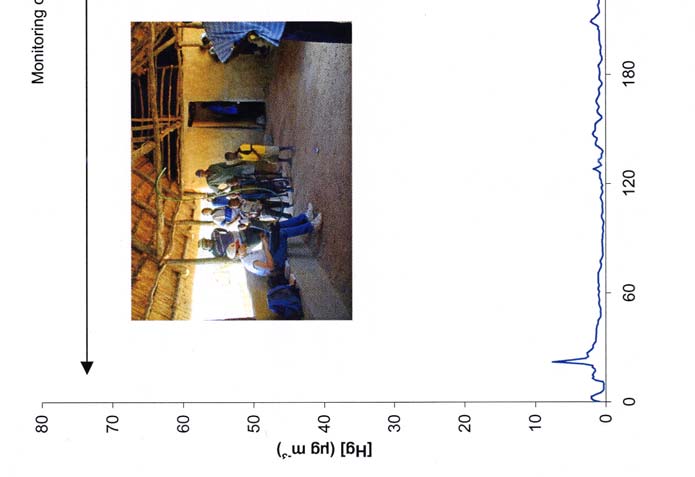

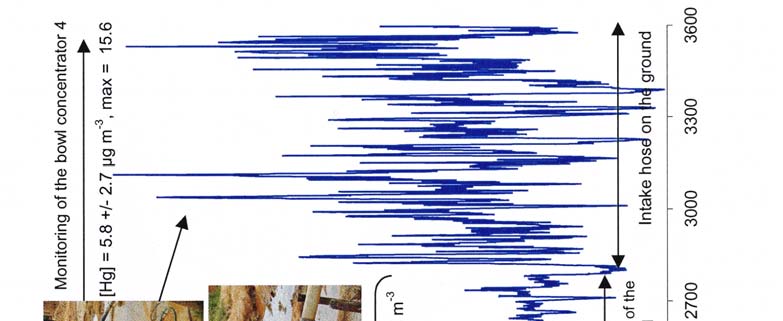

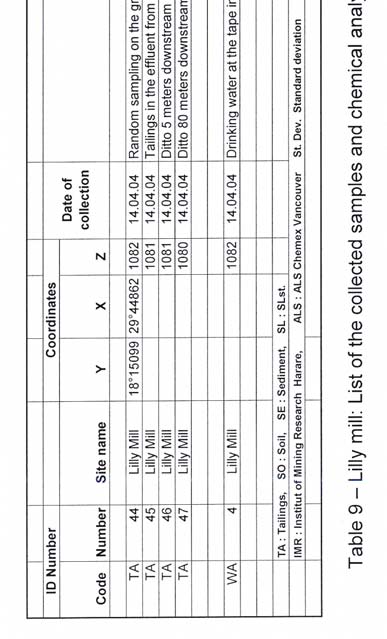

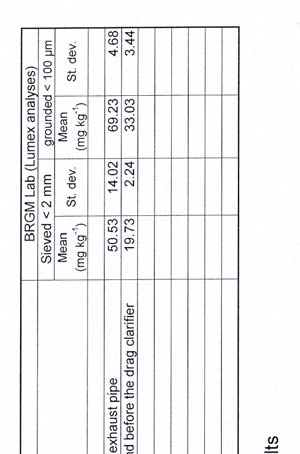

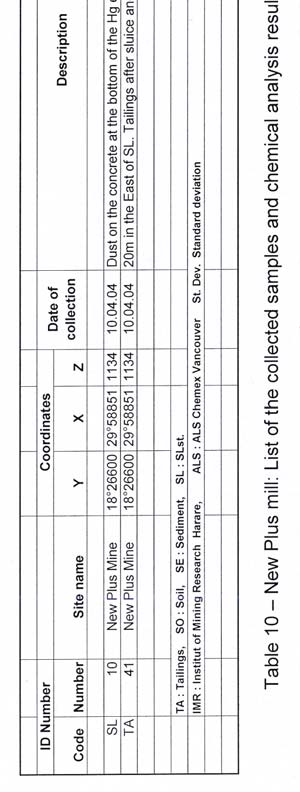

mercury, MMHg: monomethylmercury CH3HgX, between prey and predators) can