Global Mercury Project

Project EG/GLO/01/G34:

Removal of Barriers to Introduction of Cleaner Artisanal Gold Mining and Extraction Technologies

GLOBAL MERCURY PROJECT

ACTIVITIES IN ZIMBABWE

2002-2007

Final Report

October, 2007

Project EG/GLO/01/G34

Removal of Barriers to Introduction of Cleaner Artisanal Gold Mining and Extraction Technologies

GLOBAL MERCURY PROJECT

ACTIVITIES IN ZIMBABWE

2002-2007

Global Mercury Project, Coordination Unit, Vienna

Pablo Huidobro, Project Manager, UNIDO

Marcello M. Veiga, Chief Technical Advisor, UNIDO

Svitlana Adler, Administrative Assistant, UNIDO

Primary Authors

Stephen Metcalf, UNIDO and University of British Columbia

Samuel Spiegel, UNIDO and University of British Columbia

Disclaimer: The designations employed and the presentation of the material in this document

do not imply the expression of any opinion whatsoever of the Secretariat of the United Nations

Industrial Development Organization (UNIDO) concerning the legal status of any country,

territory, city or area of its authorities, or concerning the delimitation of its frontiers or

boundaries. Mention of company names and commercial products does not imply the

endorsement of UNIDO.

©Copyright UNIDO, 2007

Global Mercury Project Zimbabwe Final Report 2007 i

Acknowledgements

The authors are deeply grateful to so many people many more than can be named on a single page.

Evans Ruzvidzo, Stanley Tavengwa, and Oliver Phiri of the Zimbabwe Panners Association (ZPA),

deserve special recognition for their contributions to the GMP's successes, as do all of the ZPA trainers.

Bulawayo mining and mineral processing engineers Patience Singo and Givemore Sakuhuni provided

valuable chain of custody data and insight into mineral processing practices in Zimbabwe. Cont and Styx

Mhlanga of Amakhosi Productions, Ellen Ncube of Women in Mining and Bernard Mateo and the actors of

Kadoma's Tamuka Theater Company generated a compelling play that entertained and informed 7000

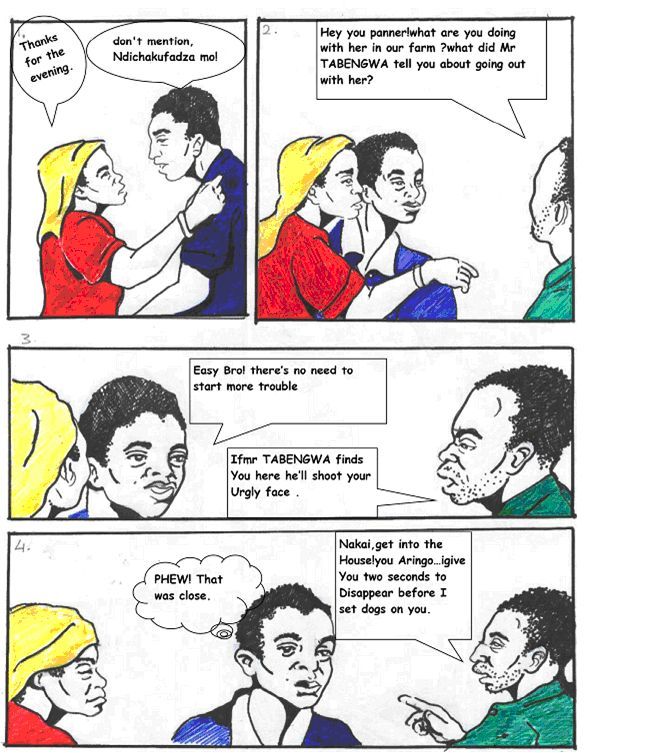

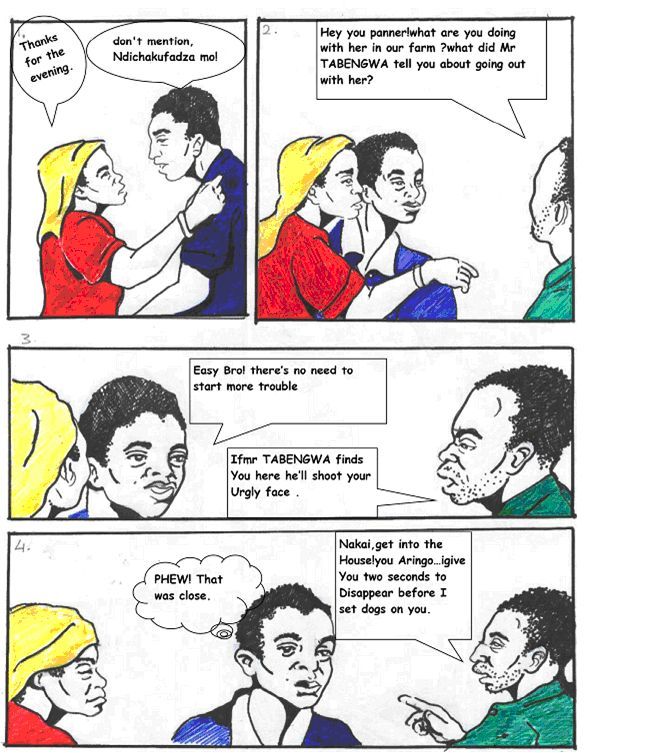

people about the hazards of mercury. Levi Phiri, a first-rate artist from Bulawayo produced a beautiful

cartoon book following the story's plot line.

Dr. Stephan Böse-O'Reilly's (Germany) assessment of the health profile of Zimbabwe's artisanal miners

was a key element in the argument that the GMP take an integrated approach to mercury management:

"more gold, less mercury, better health". Professor Hermann Wotruba of RWTH Aachen University

(Germany) introduced vinyl loop carpeted sluices during his training of trainers program in Kadoma, and

Trust Masiya of the Institute for Mining Research and Wonder Chigwida of Zimbabwe's Ministry of Mines

subsequently proved that these carpets are a suitable replacements for Zimbabwe's whole ore

amalgamation practices. David Love and Pilot Dube's studies provided needed guidance on legal issues

and micro credit. Finally, Tich Mushayandebvu, UNIDO's representative in Zimbabwe during the

implementation period of the GMP, provided invaluable logistical support from the UNDP offices in Harare.

Global Mercury Project Zimbabwe Final Report 2007 ii

Table of Contents

I. EXECUTIVE SUMMARY ...................................................................................................1

II. MAIN ACTIVITIES AND ISSUES .....................................................................................5

MINERS AND THEIR COMMUNITIES .............................................................................5

GMP PROJECT SITE IN KADOMA-CHAKARI .................................................................5

ZIMBABWE'S CURRENT ECONOMIC CLIMATE ............................................................6

NEW ENVIRONMENTAL LEGISLATION AND CRACKDOWNS......................................7

CURRENT MINING AND MINERAL PROCESSING PRACTICE .....................................8

Surface and underground mining ..................................................................................8

Mineral processing and gold recovery at custom milling centers...................................8

Cyanidation at milling centers......................................................................................11

IMPROVING MERCURY POLICY IN ZIMBABWE..........................................................12

Promoting cleaner and equitable technology policies: Banning whole ore

amalgamation..............................................................................................................12

Addressing environmental practice at milling centers..................................................13

Regulating mercury trade ............................................................................................13

Improving gold pricing policy and fairness of gold trade..............................................14

TRAINING OF TRAINERS..............................................................................................14

TRANSPORTABLE DEMONSTRATION UNIT (TDU) ....................................................15

AWARENESS CAMPAIGN .............................................................................................16

National Retort Campaign ...........................................................................................16

The Play "NAKAI" ........................................................................................................16

Pending awareness activities ......................................................................................17

III. CONCLUSIONS AND RECOMMENDATIONS..............................................................18

IV. BIBLIOGRAPHY ...........................................................................................................20

V. APPENDICES ................................................................................................................21

Appendix I: Voices of miners on major priorities: Interactive workshop 2006 ..............21

Appendix 2: List of Trainers.........................................................................................27

Appendix 3: Schedule of Theatre Performances .........................................................28

Appendix 4 - Theatre Education Program ...................................................................29

Appendix 5: Zimbabwe Mercury Imports, 2001-2005 ..................................................32

Appendix 6: Educational Cartoon by Levi Phiri Scene From The Play "NAKAI" .......33

Global Mercury Project Zimbabwe Final Report 2007 1

I. EXECUTIVE SUMMARY

It is axiomatic that throughout the world

artisanal and small-scale mining (ASM) is

driven by poverty. This is especially the

case in Zimbabwe, where 80% of the

population is unemployed, with most

people living in conditions of extreme

poverty. Mining can produce environmental

and health risks but also significant

contributions to low income communities

and the economy, and there is a growing

need for development assistance in this

sector in Zimbabwe.

Once considered the "Breadbasket of

Stamp mill operators: The Coetzee family

Africa," the combined lack of fertilizer,

farming equipment and expertise, and

drought has caused extensive damage to Zimbabwe's agricultural sector. Shortages of

foreign exchange have led to insufficient imports of critical supplies such as fuel,

medicine and many other necessities. At the time of this report, inflation is the highest in

the world, having now reached well over 10,000% per annum, posing major challenges

for economic, environmental and human security. Livelihood options have been critically

limited. For many, ASM is the only viable option to generate earnings.

Zimbabwe saw an upsurge in ASM gold mining in the 1990s as a result of

unemployment caused by the downscaling of large-scale mining activities, the collapse

of the agricultural sector due to drought and the implementation of the land reform

program, and the layoff of public sector workers during structural adjustment programs.

Beginning in 2002, the GMP began holding consultations with miners and other

stakeholders and conducting health, environmental, legal and socio-economic

background studies. These assessments guided the GMP intervention program that

took place during 2006 and 2007.

In 2003, GMP researchers estimated that as many as 300,000 to 400,000 people were

actively gold mining, while as many as 2 million of the country's 13 million people

directly or indirectly relied on mining for their livelihoods. Beginning in late 2006,

however, police supporting "Operation Chikorakoza Chapera" began to enforce the

country's new environmental legislation, as they tried to control the illegal activities

associated with ASM such as trade in gold on the black market. This suppressed

virtually all ASM operations and led to the arrest of at least 32,000 miners.

The estimated numbers of people mining in Zimbabwe has ranged considerably. Just

prior the beginning of Chikorakoza Chapera, estimates suggested there could be as

many as 500,000 miners in the whole of the country, but the police actions have made it

difficult to test the number of active artisanal miners. Even though the precipitous

decline of the national economy suggests the number of people seeking a living in the

Global Mercury Project Zimbabwe Final Report 2007 2

sector should be growing, some observers now believe that as few as 100,000 miners

are currently active, and that most of these are working clandestinely.

The GMP Health Study showed that children who handle mercury and miners who burn

amalgam have a high incidence of mercury intoxication, based on analysis of hair, urine

and blood samples and on neuropsychological tests performed in 2003 and 2004.

Avoidance of exposure to mercury vapor, particularly by pregnant women and children,

has become one of the project's chief recommendations. The study emphasized that

mercury intoxication is only one of many health challenges Zimbabwe's miners face--

poverty, HIV/Aids, malaria and water borne diseases are arguably more significant

contributors to the poor health of Zimbabwe's mining communities than mercury

exposure (Böse-O'Reilly, 2004)

Small mining and milling operations in Zimbabwe have used both mercury and cyanide

for about 100 years (Phimister, 1975), and it is no surprise that fish in the project area

are bio-accumulating mercury--even small carnivorous fish have 2 to 4 times the WHO

limit for consumption In some instances, drinking water mercury levels are elevated, but

remain below WHO guidelines, when contaminated with Hg bearing silt or with dissolved

mercury from the cyanidation of amalgamation tailings. At face-height above freshly

dressed copper plates, air contains about 4 times the 8-hour TLV worker exposure limit

for mercury (Billard et al, 2004).

National losses of mercury are about 25 tonnes per year, and it is estimated that up to

2/3rds of this mercury is lost to tailings that eventually undergo cyanidation. It is not

known exactly how much of this waste mercury is dissolved and lost in the elution

process, how much remains with the cyanide tailings, or how much is adsorbed to

improperly disposed process slimes. It is likely, however, that virtually all of the mercury

lost during whole ore amalgamation is eventually mobilized in the environment.

It has recently come to light that about half of the mercury loss is associated with

burning the amalgam (about 4 out of 8 tonnes) and another half is lost when amalgam is

dissolved in a pre-treatment of the amalgam with nitric acid before burning or retorting.

This practice is the standard throughout Zimbabwe, and miners and millers simply

discard the waste acid containing the dissolved Hg on the ground. Miners use nitric

before burning or retorting because the sponge texture that develops in the amalgam

during acid treatment is more porous than the melted button that comes from retorting,

allowing the nitric to dissolve the accessory metals found with the gold, including copper

from scraping and scouring the copper plates. Nitric acid is employed because buyers

will not purchase doré with gold content less than 70%.

Development of financing schemes with microfinance banks is, for the vast majority of

artisanal and small scale mining operations in Zimbabwe, currently all but impossible

because of the country's extreme inflation rate. The GMP's financing study identified the

programs that offer, or have offered, micro-credit for ASMs. In essence, the GMP

recommended that the Zimbabwe government develop special loan guarantee and

flexible payment schemes similar to financing programs already available to the nation's

small farmers who face unpredictable outcomes analogous to the mining sector.

Furthermore, the GMP recommended that Fidelity Printers, the gold buying arm of the

Zimbabwe Reserve Bank and the only authorized gold buyer in the country, provide

Global Mercury Project Zimbabwe Final Report 2007 3

seed capital for a revolving loan fund. Fixing loans in gold would insure that the lending

institutions received the real value of their loans on repayment (Dube, 2005).

In 2004, the GPM estimated that between 1.7 and 3.4 tonnes Hg/year are lost at milling

centers in the Kadoma-Chakari area (Shoko and Veiga, 2004). In a subsequent study

completed in 2006, the GMP surveyed mercury imports into Zimbabwe and concluded

that official imports have totaled between 20 and 25 tonnes per annum (Handelsman

2006, Appendix 5). These recent estimates square reasonably well with the GMP's 2002

figures, since it is believed that Kadoma-Chakari produces about 10% of the country's

ASM gold. It is assumed that virtually all of the mercury imported into the country is lost

to the environment.

In September 2007, the price of mercury from commercial suppliers in Kadoma was

USD 62.50 per kg, down from about USD 110.00 per kg in early 2006 (note that at the

same time, Fidelity Printers sold mercury at a reduced price of USD 75.00 per kg). In

2006, the average international price of mercury was USD 18.84/kg according to Platt's

Metals Week.

Stakeholders consistently identified the following legal and technical obstacles facing

miners: Permitting and Environmental Impact Assessments, finding and financing of

mining operations, dewatering mines, hauling ore to mill sites, high real-cost of milling,

and poor understanding of modern mineral processing methods. In addition, miners are

concerned about child labor and disruption of family units as family members seek

mining opportunities far from home, sexually transmitted infections, alcoholism, drug

use, and the widespread lack of water, sanitation, and antenatal care for expecting

mothers (Appendix 1).

Responding to stakeholder concerns, the GMP trained 32 ASM trainers (1/3rd are

women) to communicate simple messages about the impacts of mercury on family

health, and to train miners in the use of better gold recovery methods. The Institute for

Mining Research (IMR) was subcontracted to run the awareness campaign, and to

assemble and operate the GMP's Transportable Demonstration Unit (TDU) containing a

ball mill, a hammer mill, a centrifuge, a generator and a steel sluice equipped with vinyl

loop carpets. The IMR trained 569 miners in 2006 and 100 in 2007.

The GMP worked closely with the Zimbabwe Panners Association (ZPA), a community

based, grass-roots mining organization which managed most of the GMP's interventions

on the ground, and which traveled to all of the major mining centers in the country where

it taught better gold recovery methods and showed how to make and use low cost

retorts. In addition, the ZPA trained a cohort of its regional members to sustain the

mercury awareness and improved gold recovery training programs in all of the country's

gold mining districts.

Awareness of mercury hazards was communicated primarily through a GMP community

theater play, "Nakai" (or, "Precious Little Thing"), the story of a farmer's daughter

exposed to mercury by her artisanal miner boyfriend (Appendix 4) which reached about

7,000 people as it played in 18 mining communities in the project area. A cartoon book

following the story line of "Nakai" was designed (Appendix 6) but not yet produced by

the IMR, owing to the above difficulties.

Global Mercury Project Zimbabwe Final Report 2007 4

The GMP partnered with the Ministry of Mines, providing special funding to the Institute

for Mining Research to scientifically prove that low-cost vinyl loop carpets are more

efficient than copper plates, and to determine the optimum amount of cyanide necessary

to recover all the gold while minimizing the dissolution of mercury in amalgamation

tailings. A statutory instrument banning whole ore amalgamation will be promulgated

following the introduction of the carpets to miners and millers by the Ministry of Mines'

metallurgists in 2008. This regulation primarily seeks to ensure that centralized mills

phase out whole ore amalgamation with less hazardous and more efficient means. The

GMP also made recommendations to clarify the responsibilities of toll mill operators with

respect to other health and safety concerns, based on stakeholder consultations.

Global Mercury Project Zimbabwe Final Report 2007 5

II. MAIN ACTIVITIES AND ISSUES

MINERS AND THEIR COMMUNITIES

As many as 500,000 people have been earning their livelihood from mining alluvial and

primary gold ores in Zimbabwe, but as indicated above, only about 100,000 of these are

currently active. Few of these miners are employed in the country's large-scale gold

mines. In 2003 and 2004, the Global Mercury Project established first order socio-

economic, health and environmental baseline studies, held stakeholder workshops, and

established an awareness and training program designed to convince miners and

millers that mercury can and should be used more safely. The key message is that the

worst exposure pathway--breathing mercury vapor when burning amalgam--can be

avoided with relatively little effort. At the same time, simple mineral processing

technologies were tested and introduced, including vinyl loop carpeted sluices which are

now a proven and viable replacement for whole ore amalgamation with both copper

amalgamation plates and mercury-containing Knudsen bowl centrifuges.

GMP activities included socioeconomic, environmental, health, mercury importation and

micro-credit studies, stakeholder consultations and policy initiatives; an awareness

campaign based on the locally developed drama, "Nakai;" establishment of a mercury

analysis laboratory; training of trainers; creation of a Transportable Demonstration Unit;

tests of more efficient cyanidation and gravity recovery techniques; a national retort

campaign coupled with capacity building of a key community based organization; and

the development of a sustainability strategy for further mercury awareness and training

programs.

GMP PROJECT SITE IN KADOMA-CHAKARI

The GMP Kadoma-Chakari project area is located about 2 hours drive southwest of

Harare in the Hartley and Kadoma districts of Mashonaland West Province. An active

gold mining area for many centuries, first by indigenous Shona and later by European

colonists, the Kadoma-Chakari area spans roughly 1,350 square kilometers (map

sheets 1982-B2 and 1982-B4).

The towns of Kadoma and Rimuka (Kadoma's high-density suburb) are home to about

120,000 people. Access to Kadoma is by good paved road, and most villages in the

project area are accessible by relatively good secondary gravel roads, however heavy

rains in November, December and January can limit access in some places. Local

transportation consists of mini buses, but fares are often beyond peoples' means owing

to the inflated cost of fuel in local currency.

The average income in the region is approximately USD 15 per month. Many miners

have families in rural homelands in other regions, and this disruption of basic family

structure is thought to contribute to prostitution and the high prevalence of sexually

transmitted diseases including HIV/AIDS. In 2006, the prevalence of HIV/AIDS in

Zimbabwe was about 19%, down from previous years. In the GMP mining communities,

Global Mercury Project Zimbabwe Final Report 2007 6

the prevalence is thought to be considerably higher, but concrete data in this regard is

lacking.

Literacy amongst the mining communities is remarkably high with 50% of the population

having attended high school--fewer than 10% are illiterate, thanks largely to the efforts

of the independence government. Shona is the dominant language for day-to-day life

for most people, but many Zimbabweans are multi-lingual and most people in the project

can readily converse in English.

Sadza, a thick porridge made from ground maize or "mealy-meal", is the staple food in

Zimbabwe and is usually served with stewed vegetables and meat, if available. Fish is

imported from other regions because local stocks have been depleted. Maize

production, both at the commercial and family level, has been severely limited due to

droughts during the past 7 years--many children in mining communities are reported to

be undernourished. The drought during the 2006-2007 rainy season was particularly

severe, and the WHO and UNICEF have warned that as many as 1/3rd of the nation's

people may experience food shortages by the end of 2007.

With few exceptions, rural sanitation and water quality are now substandard, having

declined from the 1980s when the new independence government was a world leader in

water and sanitation programs. At that time borehole wells and "ventilated improved pit

latrines" (VIPs) or "Blaire toilets" named after Zimbabwe's Blaire Research Institute were

installed throughout the rural countryside, but currently insufficient government funds

are available for water and sanitation programs.

Healthcare is limited to the services of visiting rural nurses and a few regional clinics.

Acute cases are referred to the Kadoma District Hospital which is under-equipped and

understaffed, or to Harare. Private vehicles or public jitneys serve as emergency

vehicles, although the district hospital has recently acquired an ambulance.

Elementary schools are within 1 to 7 kilometers from most mining villages, but

increasing uniform and tuition costs are making basic education prohibitive for many

mining families. Schools are generally poorly supplied and physically decaying. For

example, the concrete floors of the Mayflower School which is located one kilometer

from the site of the GMP environmental study at Tix Mill, are cratered with 20 cm

diameter holes and blackboards are cracked and crumbled. Absenteeism is common

during the active mining season due to children's (particularly boys') participation in

mining activities.

ZIMBABWE'S CURRENT ECONOMIC CLIMATE

The growth of contemporary small scale mining in Zimbabwe mirrors the evolution of the

nation's drastic economic situation. Inflation, now officially running at 7,600% per year

has increased since the late 1990s as monitory policy reacted to the decline in GDP and

foreign exchange credits. Massive unemployment, now at least 80%, is the result of

structural adjustment programs and the collapse of the agricultural sector due to drought

and land reforms.

Fuel shortages, regular power blackouts, and an extremely oversubscribed

communications infrastructure make day-to-day business operations almost impossible.

Global Mercury Project Zimbabwe Final Report 2007 7

For example, in September 2007 the Institute of Mining Research's offices and

laboratories at the University of Harare had water and power service only two days a

week, while the University's internet server has been often out of service since the

beginning of 2007.

Gold mining contributed about 30% of the of the nation's foreign currency earnings in

2001, but deliveries to the Reserve Bank have since declined drastically--in 2006

producers declared 10.96 tonnes of gold, down from 13.45 tonnes in 2005. Despite this,

gold mining remains a key economic activity in Kadoma-Chakari mining District, where

most of the GMP activities have taken place. Kadoma-Chakari accounts for about 10%

of Zimbabwe's ASM gold production.

NEW ENVIRONMENTAL LEGISLATION AND CRACKDOWNS

Until recently, as many as 78% of the region's residents were thought to be directly

involved in gold production, if only casually during the dry season. In late 2006

however, artisanal and small scale miners and millers were subject to a police

crackdown dubbed "Operation Chikorokosa Chapera" ("finished with illegal gold

panners"), as the government attempted to manage the environmental effects of mining

activities, control the diamond rush in the Eastern Highlands, and put an end to the

illegal activities associated with gold mining, especially the trading in gold and foreign

currency on the black market. Early this year, the Governor of the Reserve Bank

estimated that about USD 50 to 60 million of gold is smuggled out of the country per

month.

In early January, a new Environmental Management Act (EMA) abruptly began requiring

miners and millers to have approved Environmental Impact Assessments (EIA) and

Environmental Management Plans (EMP), effectively making ASM illegal because most

small-scale operations had not applied for certification. In the ensuing regulatory chaos,

many police were "overzealous" in enforcing the new EMA. Miners reported that the

lack of an EIA and EMP was often used to confiscate gold, ore and equipment as police

bulldozed what were arbitrarily deemed substandard workers' housing, destroying or

confiscating their meager household possessions. Chikorakoza Chapera is ongoing,

and at least 32,000 miners have been arrested, most in the first few months of 2007. On

reflection, some government officials feel that many charges were not justified under the

EMA.

Before Chikorkoza Chapera, there were an estimated 20,000 to 30,000 artisanal miners

in the GMP area. Approximately 75% of these were thought to be alluvial panners,

while the rest exploited primary ore in surface pits and underground. About 10% of

miners were women, however women did not work at mill sites, or underground.

Women were more commonly engaged in processing of high-grade ore in villages, and

constituted the bulk of the workforce at enclosed mining and processing sites run the

Reserve Bank of Zimbabwe's Carslone Corporation. Currently, between 25% and 50%

of the project area's miners are back to work, but most are forced to work clandestinely

because they continue to lack EIA/EMPs. Most of these miners are producing only high

grade ore, leaving little low grade feed for custom milling operators whose stocks of

tailings for cyanidation are running out.

Global Mercury Project Zimbabwe Final Report 2007 8

The existence of the illegal gold market is a result of the low price that Fidelity Printers

(the official government gold buyer) pays miners for their gold. In March 2007, for

example, the "support" or official price for gold was $Z 16,000/g compared to the black

market rate of $Z 3-400,000/g. In theory, this official price valued the gold at USD 64/g

if one calculated based on the official currency exchange rate of $Z 250/USD. However,

because the official exchange rate for USD does not reflect the real costs of goods

which follow black market rates, the real price the government paid the miners was only

about 2 USD/g--one thirtieth of the officially calculated rate.

CURRENT MINING AND MINERAL PROCESSING PRACTICE

ASM gold mining in Zimbabwe has a very long history, and miners still rely on many of

the simple ore extraction methods that were used by pre-colonial indigenous and early

colonial miners (Summers, 1969, and Phimister, 1974). Primary gold ore is extracted

from narrow discontinuous quartz veins and zones of enrichment in the oxidized layer,

and manually hauled up through narrow workings. Alluvial ores are also mined by non-

mechanized methods. Mineral processing also still relies heavily on technologies

introduced over 100 years ago: stamp mills, amalgamation plates and cyanidation

circuits. These historical observations are not trivial--the nation's millers and miners

trust the old ways and are reluctant to switch to new technologies, even if the old

technologies may be inefficient and toxic. Mercury use has withstood the test of time.

Mercury is an integral part of ore processing in Zimbabwe and is broadly not believed to

be a serious human health or environmental hazard.

Surface and underground mining

Alluvial mining in Zimbabwe is rarely mechanized. Tools for digging gold-rich eluvial or

"rubble" deposits range from shovels, picks and bars to small sticks and fragments of

metal for scraping softened surface material. Primary ore is extracted from surface pits

and from relatively primitive underground workings using hammers, chisels and picks;

when possible, underground operations utilize rented compressors and explosives to

advance workings. Ore is hauled to the surface in buckets by rope or steel cable by

manual windlasses. Mine shafts are narrow, typically a meter in diameter. Workings,

whether pits or shafts, are not backfilled and wasted dumps are not reclaimed. This has

proven to be a considerable hazard for livestock, as well as people in many areas.

Protective clothing and mechanical underground ventilation are rare.

Miners sometimes work in small syndicates mining in shifts 24 hours a day. A

syndicate/team of 4 miners can produce 20 t/month, producing 200 grams of gold per

month if they recover 10g/tonne. Depending on the arrangement of the miner or miner's

syndicate with the claim owner, tribute is paid for the right to mine. In the Kadoma-

Chakari area, tribute is typically 5%, but a Women in Mining operation reported paying

tribute of 20%.

Mineral processing and gold recovery at custom milling centers

High-grade ore is often processed artisanally in villages using steel mortars and pestles

and concentrated on blanket-lined earthen sluices, and then panned and amalgamated.

Global Mercury Project Zimbabwe Final Report 2007 9

Low-grade ore is processed at custom stamp mills and concentrated on amalgamation

plates or in mercury containing centrifuges. In September 2007, there were 243

operating milling centers in Zimbabwe delivering gold to Fidelity Printers. There are

currently 117 registered custom milling centers in the Kadoma-Chakari area, but at any

given time however, less than half of these are likely to be operating. A given milling

center may have multiple mills. At the M+K mill, for example, there were 46 workers

operating 6 mills and attendant cyanidation operations. More mills are operating in the

dry season when the water table is lowest. Altogether, there are probably about 1000

milling sites in the entire country.

In early 2007, most mills were shut down by operation Chikorakoza Chapera, but by

September, about 70% of these mills had obtained valid EIA/EMPs. Before

Chikorakoza Chapera, there were about 1000 to 2000 workers at milling centers in the

project area. Currently there is a high degree of police surveillance of gold recovery

processes at custom milling centers. Miners are thus often now reluctant to ship any ore

to mills and this is causing a shortage of feed at a number of mills. In addition, the

current disruptions in electricity supply are restricting the output of many milling

operations.

Miner's hand-crush their ore to about -10 cm, reserving the highest grade material for

eventual hand milling in villages. The low-grade material is transported in hired trucks

or tractor-trailers to custom milling centers where the miner pays a nominal fee for the

milling, typically between USD 1 to 3 per hour. Ore delivered to the mill usually grades

between 5 and 30 g/tonne. Once milled, the miner's share is immediately

amalgamated.

Usually, a member of the syndicate accompanies the ore to the milling center, where

they insure that the milling, concentration and amalgamation are accomplished as

efficiently as possible. Unless prohibited by their tribute arrangements, miners are free

to chose where they mill their ore, allowing the option to use a ball mill. However, ball

mills are relatively uncommon in Kadoma-Chakari, and the extra transportation costs to

a center that operates a ball mill may outweigh any benefits from more efficient

liberation.

Stamp mills are electrically powered by large drive belts that turn 50 cm eccentric cams

which lift and drop tall vertical steel shafts which are attached to 25 cm stamps. A mill

worker shovels the ore into a narrow mortar box where the ore is mixed with water and

crushed between the 250 to 800 kg stamps and anvils. Water flow is adjusted to flush

the crushed ore through the discharge screen at a density of about 20% solids. A good

mill will stamp at the rate of 90 to 100 times per minute. Output can be up to 1.0

tonne/hr for a 3 stamp mill, depending on the hardness of the rock. The discharged pulp

flows to either a Knudsen bowl type centrifuge, or to a mercury-coated copper

amalgamation plate, usually 1 meter wide, and 1 ½ meters in length.

Stamp mills are fitted with coarse screens that pass -1mm particles. When these -1mm

particles contain partially or un-liberated gold, they are often not caught by the

amalgamation plate and report to the tailings and become the property of the stamp mill

owner. Miners receive only what is recovered in the mortar box, on the amalgamation

Global Mercury Project Zimbabwe Final Report 2007 10

plate and in the centrifuge. The 50 to 70% of the gold that reports to the tailings

becomes the property of the miller and is subjected to cyanidation.

By law, all milling centers are required to have two-stage concentration systems and

miners must be allowed to collect gold from both stages (the law stipulates that the

system may be some combination of sluices, centrifuges or copper plates). However,

two-stage systems are not always offered, and often miners are allowed only to collect

gold from a single concentrator, maximizing the gold passed to the miller's cyanidation

circuits. The most common single concentrator is the copper plate, but more and more

milling centers are offering single stage systems composed of centrifuges, which some

miners believe to be more efficient than copper plates. Unfortunately, because the

Knudsen-bowl type centrifuges produced in Zimbabwe are not very efficient, the usual

practice is to introduce one or two spoonfuls of mercury into the centrifuge.

Ball mills are available at only 5 custom milling centers in the project area--miners tend

to prefer stamp mills because gold accumulates in the ball mill liners, but in areas where

stamp mills are not available, such as in Sanyati which is 90 km west of Kadoma,

miners are using ball mills out of necessity and are finding that the increased recovery

from more efficient grinding outweighs the losses to the liners.

The copper amalgamation plates are freshly dressed with about 150 grams of mercury

before each batch. The mercury is kept active as the pulp flows over the plate by

rubbing a piece of NaCN briquette over the feed plenum; yellowish patches of mercury

on the plate are cleaned directly with the cyanide briquette. Once the feed and pulp flow

is exhausted, the amalgam is scraped with a rubber squeegee and collected in a small

piece of cloth for squeezing off the excess mercury. The plate is then scoured with

coarse sand in an attempt to recovery any gold remaining in the scratches and crevices

on the plate, a practice unique to Zimbabwe and that puts large amounts of mercury to

the tailings, necessitating the use of nitric acid to remove the scoured copper from the

amalgam. Of the 150 grams applied to the copper plate per one tonne batch, it is

estimated that approximately 120 grams are recycled by squeezing excess mercury

from the amalgam scrapings, 20 grams are lost to tailings during the scouring, and

about 10 grams stay with the amalgam (assuming recovery at this stage of 10 g Au/t).

Again, it must be emphasized that where copper plates aren't used, mercury is

invariably used in centrifuge. Miners estimate that the loss of Hg from centrifuges is

about half that of copper plates.

Amalgamation barrels are required at mills by law, but many miners prefer to

amalgamate concentrate by hand in bowls. Soap is used to keep the surface of the gold

clean. Hand amalgamation is suitably effective and does not tend to flour the mercury

as do amalgamation barrels when they are run too long or used with steel balls to

promote mixing. It is reported that many miners use a little NaCN in the amalgamation

barrels to promote amalgamation. This practice has been shown to be effective, but

since cyanide readily complexes both gold and mercury, this can lead to losses of both

gold as well as mercury. When amalgamation barrels are used to concentrate

centrifuge concentrates, between 400 to 800 grams of mercury are mixed with about 30

to 33 kg of concentrate (Shoko and Veiga, 2004).

Global Mercury Project Zimbabwe Final Report 2007 11

Retorts are also required by law to be used at milling centers, but it appears that they

are seldom used. Almost always, miners use nitric before burning or retorting because

the sponge texture that develops in the amalgam during acid treatment is more porous

than the melted button that comes from retorting, allowing the nitric to dissolve the

accessory metals found with the gold, including the copper from scraping and scouring

the copper plates. It is estimated that at least half of the mercury in the amalgam is

dissolved and lost during pre-treating of the amalgam with nitric acid in this fashion, and

miners and millers simply discard the dissolved Hg on the ground. After pre-treating with

nitric acid, the amalgam is toasted on the burning end of a l0-15 cm diameter log,

blowing the embers with the mouth to maximize the heat; the toasted amalgam is then

mixed with a little borax and smelted with a torch. These processes expose the

operators directly to inhalation of Hg vapor.

All gold recovered at custom milling centers must be sold to the miller who is required in

turn to sell it to Fidelity Printers. Before Chikorakoza Chapera, much of the gold

produced at mills was sold on the black market. Miners took possession of their

amalgam, boiled it in nitric acid and toasted it without retorts wherever convenient. As

indicated, it is believed that up to USD 60 million of gold per month was smuggled out of

the country in 2006.

Cyanidation at milling centers

Small scale milling and cyanidation practice is relatively sophisticated in Zimbabwe.

Because millers make their money from cyanidation, not from the nominal milling fee,

they rely on the low recovery rates of the stamp mill and amalgamation plate or

centrifuge circuit to maximize the gold content in their cyanidation processing. Custom

millers must be sufficiently competitive with neighboring mills to insure a constant supply

of feed to their cyanidation tanks. Millers sometimes attempt to attract the best ore in

order to maximize the gold content of tailings sent to their cyanidation circuits by

providing miners with legal and technical support (e.g., loans to complete environmental

assessments, geological services, etc.).

The chemical consumption for passive cyanidation tanks is about 1 kg CN per tonne of

ore (0.1% CN in solution). Depending both on the ore and on the operator, lime or

caustic soda (about .5 kg/tonne) is used. Current cost of cyanide in Kadoma is just

under USD 4/kg. The GMP has established that the main manufacturers of cyanide for

small scale cyanide use in Zimbabwe are Tongsuh, Taekwang, and Dupont.

Most mills have 5 to 10 tanks for cyanide leaching. Each tank holds between 20 and 70

tonnes of tailings. Twenty tonne tanks are charged with about 18 kg NaCN and 50 kg of

Ca(OH)2. Typically these tanks are dug into the ground, with the top edge of the vat at

ground level. Cyanide solution is pumped into the tank and re-circulated through

activated carbon cells. The tanks are not agitated, and no air is injected. Leaching

takes an average 6 days, but depending on the ore can sometimes take as long as 2

weeks. The cyanide solution containing the dissolved gold passes through 3 or 4

activated carbon cells which, once loaded, are subjected to a chemical process (elution)

to concentrate the gold. Gold content of the pregnant solution, free cyanide and

alkalinity levels are monitored by the colorimetric methods (Singo, 2006).

Global Mercury Project Zimbabwe Final Report 2007 12

It is estimated that as much as 90% of the metal mercury in the amalgamation tailings is

dissolved during cyanidation. A good deal of this mercury reports to the carbon cells

and is lost during elution: Mercury vaporizes in the 100 to 110 degree Celsius

pressurized elution vessels (tiny beads of Hg are often observed on the lid and sides of

elution vessels, and during electro winning). In addition, mercury plated with the gold on

the steel wool cathode is subsequently dissolved in nitric acid and discarded on the

ground. Some millers have their own elution equipment, but others send the loaded

carbon to toll elution centers for stripping--operators of these toll elution plants observe

that loaded carbon contains varying amount of mercury, suggesting that mercury losses

to tailings vary according to practices at toll mills. Cyanidation tailings are not

neutralized or washed.

IMPROVING MERCURY POLICY IN ZIMBABWE

The GMP worked with the Zimbabwe Ministry of Mines to develop appropriate policies

for mercury use in ASM gold mining at milling centers and other processing sites near

habitation in towns and villages. Following stakeholder consultations, GMP experts

worked with government to prepare recommendations for mercury management in

ASM, setting standards on practices to eliminate hazardous mercury emissions,

exposures, and to address other environmental health challenges. These

recommendations include proposed regulations the purchase, trade and storage of

mercury.

These GMP recommendations encourage positive changes in the mining sector that will

improve livelihoods, the environment and economic sustainability. It is recognized that

core the Global Mercury Project goal of "removing barriers to the adoption of improved

small-scale mining practices" requires an integrated approach that is responsive to local,

national and regional needs. It is hoped that the GMP can continue to play a significant

role in bringing together stakeholders to problem-solve and strengthen development

institutions in Zimbabwe.

The GMP facilitated meetings, small workshops and large seminars with national and

local officials from the Ministry of Mines, the Ministry of Environment, and the Ministry of

Health, as well as with mining associations such as the ZPA and the Zimbabwe Mining

Federation. These talks reinforced a shared commitment to develop policies to phase

out mercury in ASM over the long term. In the short term, efforts focused on instituting

clear regulations and codes of practice to minimize mercury exposure and other

environmental hazards in ASM.

Promoting cleaner and equitable technology policies: Banning whole ore

amalgamation

The GMP policy recommendations provide standards for amalgamation and the use of

retorts and for the reduction of mercury lost to tailings. Specific provisions protect

pregnant women and children from exposure. The recommendations include

mechanisms for community-based enforcement and monitoring, but also suggest a

statutory instrument to ban the whole ore amalgamation, whether with copper plates or

in centrifuges: Banning whole ore amalgamation will significantly improve

Global Mercury Project Zimbabwe Final Report 2007 13

environmental health while promoting more equitable sharing of gold recoveries

between miners and millers.

The Ministry of Mines' Department of Metallurgy and the Institute of Mining Research

has conducted successful trials of low cost vinyl loop carpets sourced from China. A

short sluice lined with these low cost carpets has already been proven to be more

efficient than current practices. Once this new technology has been demonstrated to

stakeholders through out the country, it is expected that the Ministry of Mines will

formally introduce a Statutory Instrument under the Mines and Minerals Act that will ban

whole ore amalgamation.

Addressing environmental practice at milling centers

In Zimbabwe, miners generally bring their ore to milling centers for processing. Mercury

is used intensively on these premises, and tailings management and mercury handling

often present serious risks to health and the ecosystem. Because the relationship of

miners and millers is not generally of a formal employer-employee nature, traditional

legal definitions of employer responsibility do not necessarily apply.

GMP policy experts prepared recommendations and draft regulations on water

protection, the duties of claim-holders and milling centre owners and managers that

resulted from its policy reviews and stakeholder consultations. These proposals were

presented and discussed on a preliminary basis with the national directors of the

Ministry of Mines. These draft measures propose clear lines of responsibility for miners

and claim-holders as well as milling centre owners and managers, and suggested

penalties for infractions.

The draft measures acknowledge the need for shared responsibilities among the

different people involved in ASM mining and processing. Responsibilities that were

addressed in the draft regulations relate to mine management, fair labor practice, safety,

health and the preservation of the environment. Millers would be responsible for sound

mercury management on their premises and for ensuring compliance with regulations.

The draft provisions stipulate that milling centers must not exist within 100 meters of

water bodies, and prohibit the combined use of cyanide together with mercury.

Regulating mercury trade

The GMP believes that the regulation of mercury sales to miners is a crucial step to

decrease the negative health, social and environmental impacts caused by mercury in

Zimbabwe. In December 2005, GMP policy experts prepared draft regulations under the

Mining Laws to address trade and distribution of mercury within the ASM sector. These

were discussed with senior directors of the Ministry of Mines as potential measures that

could become part of a larger national effort to regulate the trade of mercury. The draft

measures propose licensing the use and trade of mercury and require penalties for

contraventions. Provisions for mercury trade stipulate that "...no person may purchase

mercury for amalgamation purposes unless they hold an amalgamation license."

"1) The use of mercury for amalgamation purpose shall require an amalgamation

license, which shall be applied for by the manager of the mining location at which the

amalgamation is being contemplated.

Global Mercury Project Zimbabwe Final Report 2007 14

2) An amalgamation license shall be issued by the Mining Commissioner and shall

specify the mining location at which amalgamation is being licensed, to whom the

license is granted, and the site within the mining location at which amalgamation shall

take place, designated by a plan.

3) An amalgamation license shall be valid for 1 (one) year and may be renewed.

4) In the event of breach of these regulations, the Mining Commissioner may cancel the

amalgamation license for the mining location for which the breach has taken place."

Improving gold pricing policy and fairness of gold trade

Due to the current economic crisis in Zimbabwe, gold mining has grown in importance

as a source of survival. As many as 2 million people depend, directly and indirectly, on

artisanal and small-scale gold mining. As the mining sector has grown, so too has

smuggling, illegal mining, and mercury use as well as other environmentally destructive

practices. The GMP found that these problems were mainly fuelled by the underlying

failure to implement economic policies that pay miners fair and appropriate gold prices.

Between February and April, 2007, the GMP conducted stakeholder meetings in

Zimbabwe to bring together miners, government decision-makers from different

agencies, and other organizations, to identify and advance strategies for bringing

solutions to the challenges facing the mining sector. The aim of the meetings was to

allow participants to express a diversity of concerns and to influence policy changes. In

addition to conducting stakeholder meetings, the GMP participated in Special

Committee Hearings in Parliament to review gold mining policies. A variety of GMP

recommendations were generated, including increasing the gold price to the level of the

international bullion market.

Following these advocacies advanced by the GMP and other stakeholders, The

Reserve Bank of Zimbabwe established a review committee to ensure that gold prices

are regularly evaluated and adjusted to inflation. On October 1, 2007, for example, the

official purchase rate was increased from Z$3,000,000/gm to Z$5,000,000/gm which is

equivalent to USD 520 an ounce at the official exchange rate of $Z30,000/USD. This

significantly reduces the illegal trade of gold, and provides a viable economic basis for

gold mining. It is expected that the government will continue to adjust the price of gold

upwards.

The GMP advocates that, in addition to maintaining fair gold prices, it is crucial that

official gold buying centers and agents be located near mining areas so that miners

have access to equitable markets.

TRAINING OF TRAINERS

A four day training of trainers workshop was conducted in Kadoma on May 25 to May

28, 2006. Thirty two stakeholders received instruction in the objectives of the GMP, an

overview of Zimbabwe Health and Environmental studies and strategies to effectively

communicate the effects of mercury on health, how to minimize exposure, how to use

and reuse mercury safely, how use of retorts, and how to achieve high efficiency gravity

concentration. In addition, trainers presented an exhaustive review of mining practices

Global Mercury Project Zimbabwe Final Report 2007 15

and equipment used by artisanal and small scale miners around the world. Mining

engineer Patience Singo, a UNIDO small scale mining expert based in Bulawayo,

Zimbabwe, presented an overview of underground mine safety. Participants included

the Ministries of Health, Environment and Mines, local medical staff, the Institute for

Mining Research (Harare), the Zimbabwe School of Mines (Bulawayo), Amakhosi

Theater (Bulawayo), the Zimbabwe Panners Association and independent miners

(Appendix 2)

During the training, an interactive workshop identified ASM legal, health, social, micro-

credit, and technical needs from the perspectives of the miners themselves and

government stakeholders. Stakeholders consistently identified the following legal and

technical obstacles facing miners: Permitting and Environmental Impact Assessments,

finding and financing of mining operations, dewatering mines, hauling ore to mill sites,

high real-cost of milling, and poor understanding of modern mineral processing

methods. In addition, miners are concerned about child labor and disruption of family

units as family members seek mining opportunities far from home, sexually transmitted

infections, alcoholism, drug use, and the widespread lack of water, sanitation, and

antenatal care for expecting mothers.

A 1 x 2 meter sluice lined with 3M Nomad carpet (medium traffic with backing, Type

6050) was installed and demonstrated at Tix Milling Center. Participants of the

workshop received copies of the Global Mercury Project's "Manual for Trainers of

Artisanal Miners" and a copy of Patience Singo's manual, "Good Practices in Gold

Processing for Small Scale Mining".

TRANSPORTABLE DEMONSTRATION UNIT (TDU)

TDU operations were subcontracted to the Harare based Institute of Mining Research in

July 2006. Training began in September and continued until mid-December 2006, by

which time 569 miners (188 women and 381 men) had been trained at seven milling

centers. In its December report, the subcontractor reported that it had purchased a

generator, ball mill, camping equipment, tents and chairs, tools, first aid kit, scales and

fuel cans. During these first 4 months, the IMR had developed a comprehensive

curriculum and met reasonable expectations of the number of individuals trained.

Operation Chikorakoza Chapera shut down virtually all mining and milling operations in

the project area until April 2007 when a few operations managed to complete the

requisite environmental assessments. In early June, the IMR reported that its foreign

currency assets had been frozen by the Zimbabwe government in an investigation of

illegal currency trading by the NMB Bank. About half of the IMR's assets were released

in early July, enabling some field work (mostly testing of the Chinese vinyl loop carpets)

in late July and August. The IMR has not yet reported its current accomplishments, but it

is estimated that only about 100 miners were trained between January and September

2007. Thus far, the brochures, posters and billboards slated to be produced based on

the play "Nakai" have not yet been produced.

Global Mercury Project Zimbabwe Final Report 2007 16

AWARENESS CAMPAIGN

Mercury has been used in ASM for over 100 years, and as indicated above, most

miners do not believe its use leads to negative health or environmental consequences.

Awareness building and offering acceptable solutions are therefore are the first steps

toward safer practices. The grass roots awareness program in Zimbabwe was built

around the community theater production "Nakai" which illustrates the hazards of

mercury use while demonstrating alternatives. The IMR is responsible for production of

all GMP awareness materials including cartoons, posters and billboards and is required

to report on this at the end of the TDU training contract. To date, the IMR has not

provided a report of their contributions to the awareness campaign, but it appears that

they have not yet produced or distributed any of the required materials.

National Retort Campaign

In June and July of 2007, the ZPA trainers carried out a national outreach program to

raise awareness about the dangers of mercury, demonstrating retorts to make mercury

use safer and vinyl loop carpets to increase gold recovery. The ZPA trained over 1000

people at 27 mill sites and one school. The ZPA found that the signs and symptoms of

mercury poisoning were common amongst miners in many communities throughout

Zimbabwe. At one site, the ZPA observed that "children were engaged in gold mining

activities. The situation was bad, most of these children are aged between 8 to 12 years.

However they seemed very bright as it was easy for them to catch up on the use of

retorts." By and large, miners were unaware that mercury is a poisonous substance and

they were surprised to see so much mercury recovered in retorts. Invariably, miners

were very appreciative that the United Nations was making the effort to bring these

kinds of messages to them.

The Play "NAKAI"

"Participatory" or "community theater" is often used in Africa to create awareness about

health and other issues. Community theater is an approach to awareness building that

can enable people to assume agency over their lives. Research has shown that

community members gain power to solve the problems they face when they are involved

in the development of such a play, when they participate informally during the play (e.g.,

singing and dancing with the performers, or voicing comments and suggestions) or

when they participate in post-performance audience discussions.

In order to increase awareness of the hazards of unsafe mercury use, the GMP

contracted the Amakhosi Theater group to produce a play to communicate directly to

mining communities the message that mercury makes people sick. Amakhosi has

produced community theater in Zimbabwe for over 20 years, notably focusing on

HIV/Aids and on the need for post abortion care. Importantly, Amakhosi has credibility

amongst ASM communities because it produces the popular, award-winning weekly

television drama, "Amakorakosa" which contrasts the lives of poor gold panners with the

lives wealthy small-scale mine owners.

During 2005 and 2006, Amakhosi held a series of workshops with the Zimbabwe

Panners Association and the Kadoma-based Tamuka Theater Group to generate an

Global Mercury Project Zimbabwe Final Report 2007 17

entertaining script that carries the core GMP messages. The plot follows the blossoming

love of two young people, Nakai and her miner boyfriend Aringo. Much like

Shakespeare's Romeo and Juliet, the two lovers come from families with a history of

animosity--one's father is a farmer whose land has been invaded by gold panners, and

the other's is a successful gold miner. In the course of the story, Aringo develops

symptoms of mercury intoxication (irrational behavior and impotence) and Nakai has

complications with her pregnancy. In the end, the feuding families find common ground

in the love of their children, and resolve to support safer mercury use and better waste

management. The play's Shona title, "Nakai," means "precious little thing" and refers

equally to the gold amalgam that artisanal miners recover and burn, and to the wife and

unborn child of the artisanal miner who are all exposed to mercury vapor.

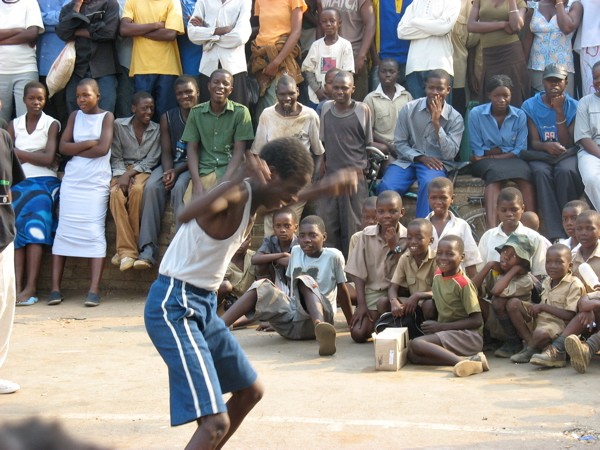

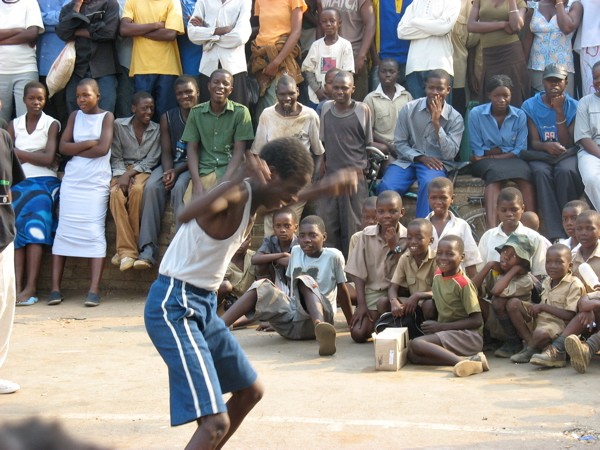

Performances of "Nakai" are

proceeded by 45 minutes of the

Tamuka Theater's energetic

traditional singing and dancing, which

projects a feeling of vitality and

contextualizes the story of "Nakai" in

a milieu of positive health and power.

Again, research shows that people

gain power as they learn to take their

place with confidence in a physical

space and have their voice heard by

others. The vitality of Tamuka's

dance and dramatic performance

inevitably sparks joy in the audience

Performance of "Nakai" in Kadoma, 2007

joy itself is an agent of

transformation.

Pending awareness activities

A cartoon book, commissioned from the Bulawayo-based illustrator Levi Phiri followed

the plot line of the community theater play and embedded core GMP messages. The

graphics were delivered to the IMR for publication in Shona in April, 2007. Selected

cartoons are to be used by the IMR in hand bills, posters and billboards placed along

the main mining roads leading to Kadoma.

Global Mercury Project Zimbabwe Final Report 2007 18

III. CONCLUSIONS AND RECOMMENDATIONS

Even though the GMP faced many challenges in Zimbabwe, many barriers to the

adoption of cleaner technologies were substantially lowered. For example, high

efficiency, low cost vinyl loop carpets have been introduced and accepted as a viable

substitute for whole ore amalgamation, and a cadre of committed grass roots trainers

has been established. Awareness of mercury hazards and more productive gold

concentrating methods has dramatically increased in the project area. Local stakeholder

participation in the policy discussion processes yielded critical insights and some

developments in the short term, with longer term aims identified too. Also, the

entertaining awareness-raising play "Nakai" was presented to about 7000 ASMs and

community members.

Perhaps the greatest legacy of the GMP is the strengthened Zimbabwe Panners

Association. The ZPA now has a network of 30 ASM trainers placed in all of the

country's gold mining districts. These individuals are committed to improving the health

and livelihood of small scale miners.

It almost goes without saying that good interactive relationships with stakeholders are

the key to success, because acceptance of new health and safety practices occurs only

when the messenger is credible. Solid relationships with community-based

organizations have been developed by the GMP in Zimbabwe, but new long-term

commitment is essential if Zimbabwe is to sustain miners' health and safety programs.

The challenge remains to develop programming that can insure that the benefits of the

funds reach the people at the bottom of the socioeconomic spectrum. The experience

of the GMP in Zimbabwe suggests that new mechanisms for accountability need to be

put in place. Such mechanisms might include the creation of community based trusts

directed by local individuals committed to improving the lives of miners, and who

because of their professional standing (e.g., priest, hospital administrator, etc.) are

unlikely to find themselves in a conflict of interest situation.

Action programs such as trainings could be administered by NGOs that have

established relationships with grass roots community based organizations. Government

partners should include the Ministries of Environment and Health, as well as the Ministry

of Mines. The Assistant Country Focal Point position should be eliminated, and activities

should be coordinated by an empowered UNIDO staff member residing in the project

area. Quarterly evaluation visits should be made by senior UNIDO managers.

It has been observed during this project that relatively small programs such as the

ZPA's National Retort Campaign have been more successful than large subcontracts

such as the TDU. Payment schedules for large contracts (e.g., the TDU) should be in

small regular increments during the lifetime of the contract, rather than a large balloon

payment midway through. Contracts should include provisions that clarify the nature of

any extensions to the agreed upon timeframe. Mechanisms should be developed to let

more small subcontracts, rather than fund small interventions through Aide Memoires. In

addition the GMP should develop a way to pay casual wages to locals. Future initiatives

should consider eliminating or revising the DSA system because it has often come to be

Global Mercury Project Zimbabwe Final Report 2007 19

seen a salary entitlement that can break down trust between various stakeholders.

Indeed, trust-building takes a great deal of sensitivity and innovation in numerous ways

and is an integral component of empowerment in development processes.

In spite of the challenges that virtually all development programs face in Zimbabwe, the

GMP has shown that progress, especially through grass-roots interventions, is possible.

GMP should develop funding partnerships with organizations that share common

objectives, such as UNICEF, WHO, UNEP, EU Development Fund, DFID, etc., directing

this funding to community based organizations.

It is incumbent on the international community to increase commitment to achieving the

Millennium Development Goals in Zimbabwe, where families and especially children

face impossible lives: We should not forget that 25% of the country's children (1.6

million) are orphaned, or that 13% of children die before the age of 5 years old, up from

8% in 1990. The FAO and the WFP predict that drought and lack of agricultural inputs

will lead to food shortages for 1/3rd of the population by the end of 2007. Zimbabwe's

impoverished mining families find themselves in a crisis environment, and they need the

help of the international community.

Global Mercury Project Zimbabwe Final Report 2007 20

IV. BIBLIOGRAPHY

Billaud, P., Laperche. V., Maury-Brachet, R., Boudou, A., Shoko, D., Kahwai, S.,

Freyssinet, P., 2004, Removal of Barriers to the introduction of cleaner artisanal gold

mining and extraction technologies in the Kadoma-Chakari Area, Zimbabwe, Part A,

Enviromental Assessment Final Report, Global Mercury Project

Böse-O'Reilly, S., Dahlmann, F., Lettmeier, B, Drasch, G., 2004, Removal of Barriers to

the introduction of cleaner artisanal gold mining and extraction technologies in the

Kadoma-Chakari Area, Zimbabwe, Part B, Health Assessment Final Report, Global

Mercury Project

Dube, Pilot, 2005, Report on the establishment of a micro finance scheme for small

scale artisanal gold miners in Zimbabwe. Global Mercury Project

Handlesman, S. 2006, Unpublished Mission Report: Republic of Zimbabwe & Republic

of South Africa March 23-April 10, Global Mercury Project

Phimister, I., 1975, A history of mining in Southern Rhodesia to 1953, DPhil Thesis

submitted to the Department of History, University of Zimbabwe.

Summers, R., 1969, Ancient Mining in Rhodesia and adjacent areas, Museum Memoir

No 3, The Trustees of the National Museum of Rhodesia, Salisbury, 236 pp.

Shoko, D.S.M. and Veiga, M.M., 2004, Information about the Project Sites in Zimbabwe,

Global Mercury Project

Singo, P., 2006, Training Manual: Good Practices in Gold Processing For Small Scale

Mining, Bulawayo, Zimbabwe 66p.

Global Mercury Project Zimbabwe Final Report 2007 21

V. APPENDICES

Appendix I: Voices of miners on major priorities: Interactive workshop 2006

LEGAL ISSUES

PROBLEM

SOLUTIONS

ROLE OF THE GMP

Poor law enforcement on the

The act should be lawfully enforced

Once the Environmental Protection Act is

hazardous substance act

and individuals should be educated on

operational, the GMP should support the Zimbabwe

the use and control of the hazardous

Panners Association (ZPA) to teach miners how to

substances

comply

Abuse of gold panning legislation

Government should implement

The GMP should recommend legislation concerning

legislation in a friendly but effective

mercury use in mining, maybe following models

way.

implemented in other countries such as those in

Enforcement of gold panning laws is

Latin America.

necessary

Easy availability and accessibility of

There should be law to control the

The GMP should promote awareness about the

mercury

buying and selling of mercury from the

hazards of mercury

manufacturer to the end user.

--e.g., prepare labels with skull and cross

bone/diamond warning label)

Unlicensed panners, buyers and

Government should monitor the

miners

industry seriously so that only licensed

individuals are allowed to operate.

Government should educate people

about how to acquire licenses and

should relax the license requirements

The issue of protective clothing is not

The Government mining inspectors

The GMP Transportable Demonstration Unit should

being emphasized

should make regular inspection of

educate miners about protective clothing, produce

mining and milling sites.

posters and calendars for awareness; TDU trainers

should model safe practice

Mine inspectors are immobile due to

The GMP should draft voluntary codes that are

the lack of fuel

simple enough for miners to follow with minimum

regulator surveillance

Environmental impact assessments

The Government should consider

The TDU should introduce "SSM Env 1 Form" to

and management plans not done

alternatives such as self-assessment

miners

environmental management plans as

Once the environmental protection act develops its

the "environmental impact

new policy, this can be taught to miners by ZPA

declarations" miners complete in

Bolivia and Peru

Global Mercury Project Zimbabwe Final Report 2007 22

GEOLOGY

PROBLEMS

SOLUTIONS

ROLE OF THE GMP

Lack of expertise in geological

Government should expand the

Consider supporting pegging with differential GPS

survey procedures

Ministry of Mines (MoM) geological

survey dept to include extension

services

Ore reserve estimation

Government could periodically provide

TDU can create awareness that miners would

district geologist from KweKwe to

benefit from geological professionals

participate in TDU and other trainings

Prospecting

MoM could provide peggers to control

costs

Government could provide

microfinance to assist prospective

miners pay pegging fees

Suitable Exploration Tools

MoM to resuscitate Mining Investment

Loan Fund (MILF)

MINING

PROBLEMS

SOLUTIONS

GMP

Tools and equipment

TDU should demonstrate low cost heavy duty

Bosch electrical drills (Bosch GBH 11) with 2kW

generator

Finance

Recapitalization of MILF

TDU should provide training in:

(this is not enough)

--how to get investors

-- how to make a good contract

--business planning

The GMP should suggest benefits of partnerships

between millers and miners

Lack of experienced mining

Training

personnel

The Zimbabwe Panners Association

can sponsor ZSM classes in Kadoma

--e.g., mine safety

Access roads are bad or non-

Miners need to take responsibility

existent.

(miners need to solve their own

problems themselves)

Occupational hazards

Government (MoM) should provide

The TDU should focus on safety awareness

--roof collapse/support

training and extension services

--Personal Protective Equipment

The TDU should demonstrate ventilation

--Ventilation and lighting

equipment

--blasting hazards

The GMP should prepare a miners handbook

Environmental degradation

Training, awareness, supervision

TDU should raise awareness of miners about the

responsibilities to future generations of extracting

mineral wealth today

Dewatering pits

TDU should include a demonstration dewatering

pump

Lack of business planning

Teach business planning

Global Mercury Project Zimbabwe Final Report 2007 23

MINERAL PROCESSING

PROBLEMS

SOLUTIONS

GMP

Miners don't understand mineralogy:

Training and Site demonstrations

TDU should provide training in geology and

--e.g., is the ore oxide ore or sulfide

--analyze rock samples

mineralogy:

ore?

--teach basic mineralogy

--distinguish between ores and know how fine to

-e.g., what is gold particle size

grind

range?

--train how to collect a representative sample

-e.g., how does one achieve

--train to use simple methods to test grade (e.g.,

maximum recovery?

the Plattner Blowpipe method for assaying gold

which was a 19th Century method where the weight

of a tiny bead of gold was determined by

measuring it between two sub-parallel lines.

Lack of knowledge:

Training of alternatives such as ball

TDU should demonstrate testing the efficiency of

--milling

mills, hammer mills, shaking tables,

grinding to different sizes

--liberation

sluices, strakes

--gravity concentration

Low Recovery

Use better methods

TDU should educate about proper grinding vs.

--Copper plates

--centrifugal concentrators

over grinding

--Screen sizes of stamp mills are too

--use smaller screen sizes

--demonstrate liberation analysis to determine

coarse leading to poor liberation

--use of other mill types

proper screen size

--Use of stamp mills is not efficient

--use proper sluices and mats

--Clay James tables

Very high milling costs

Government should establish own

mills at low rates

--Government will buy the gold!

Transport

Micro-credit finance

--high charges

--groups could buy tractors, transport

--must pay in gold but the

government price is too low

Existing legislation, SI 329, Custom

Government must amend regulations

Educate how copper plates release Hg to

milling regulations

environment

--Metallurgical requirements

necessitate copper plates

Educate miners on advantages and disadvantages

of copper plates

Support ban of copper plates and mercury in

centrifuges as in Latin America

Global Mercury Project Zimbabwe Final Report 2007 24

SOCIAL ISSUES

PROBLEMS

SOLUTIONS

GMP

Improper Accommodation

Distribution of condoms

GMP should increase awareness of STIs through

--overcrowding

Drama and Brochure

Prostitution leading to spread of STI

and HIV/AIDS

School dropouts

Law enforcement, statutory

GMP should promote awareness that child labor in

instruments (SI), awareness of

mining is bad

Petty and violent crime

children's rights

Poor water and sanitation

Enforce UN convention on child labor

and right to education

Child labor and sexual abuse

Enforcement of SI 275

Disruption of family units and normal

social fabric

Corruption

General

ZPA could:

--enforcing SI of alluvial mining

--Establish a national

--improve conditions of service of

association/council of mining/panners

regulatory agents

associations to lobby government

--awareness and training

(trustees could monitor this national

--introduction of technologies

association to prevent in-fighting and

--mobile clinics/awareness

greed to insure stability.

--ZPA could function as an

intermediate between MoM and

panners

--Panners should define the needs for

training

Global Mercury Project Zimbabwe Final Report 2007 25

HEALTH ISSUES

PROBLEMS

SOLUTIONS

GMP

Pneumoconiosis

Injuries

Respiratory diseases and suffocation

High manifestation of communicable

--Enforcement of SI 271

TDU should educate miners on

diseases

--Awareness and education of

communicable diseases

-- how to refill pits and replant

High incidence of malaria and water

--Awareness and prophylactic

borne diseases

treatment

--how to prevent mosquito habitat

--Rehabilitate mined areas; spraying

insecticides

--BioSand filters

--low cost water treatment units

--boreholes

--larvicide funding needed

--Blair Research Institute of (MoH) has

a plant whose leaves have toxic

effects on mosquitoes--it's up to

miners to implement

No antenatal care for expecting

mothers

No immunization for children

Carbon monoxide poisoning

Methane--explosive

Mercury intoxication

Alcoholism

The GMP should consider if it could address this

complex problem through drama

TDU should support awareness that drinking and

marijuana leads to accidents

Panners Association needs support

GMP should consider loan of project vehicle to