Global Mercury Project

Project EG/GLO/01/G34:

Removal of Barriers to Introduction of Cleaner Artisanal Gold Mining and Extraction Technologies

Equipment Specification for the

Demonstration Units in Sudan

Marcello Veiga,

Small-scale Mining Expert

Vienna, Austria

May 2004

Acknowledgement

This document was elaborated with the close contribution of:

Mohamed S. Ibrahim, Assistant of the Country Focal Point, Sudan

Kevin Woods, Kevin Peacocke and Peter Simpson, Directors of the Small Mining Supplies Ltd,

Harare, Zimbabwe

Table of Contents

1. Background ...............................................................................................................................1

1.1. Number of Miners and Gold Production ...............................................................................1

1.2. Processing Methods and Mercury .........................................................................................1

2. Proposed Solution......................................................................................................................2

2.1. Transportable Demonstration Units (TDU) ...........................................................................2

2.2. Implementation Process........................................................................................................4

2.3. Components of a TDU..........................................................................................................5

3. Selection of Processing/Amalgamation Equipment..................................................................5

3.1. Comminution/Classification .................................................................................................6

3.1.1. Crusher ..........................................................................................................................6

3.1.3. Ball Mill ........................................................................................................................6

3.1.4. Size Classification..........................................................................................................8

3.1.5. Checking Gold Liberation..............................................................................................8

3.2. Gravity Concentration ..........................................................................................................9

3.2.1. Sluices ...........................................................................................................................9

3.3. Amalgamation .................................................................................................................... 12

3.3.1. Amalgamation Barrels ................................................................................................. 12

3.3.2. Amalgamation Plates ................................................................................................... 13

3.3.3. Comparing Barrels with Special-Amalgamating Plates ................................................ 15

3.3.4. Separation of Heavy-minerals from Amalgam.............................................................. 16

3.3.5. Removing Excess Mercury .......................................................................................... 17

3.4. Retorting ............................................................................................................................ 17

3.4.1. Increasing Temperature................................................................................................ 19

3.4.2. Home-made Retorts..................................................................................................... 19

3.4.3. Conventional Retorts ................................................................................................... 23

3.4.4. Glass Retort ................................................................................................................. 24

3.4.5. Comparing Retorts....................................................................................................... 24

3.4.6. Recovering Mercury Coalescence ................................................................................ 25

3.4.7. Filter for Gold Shops ................................................................................................... 25

4. Capital Cost of a Demonstration Unit .................................................................................... 27

5. Operating Cost of a Demonstration Unit................................................................................ 28

UNIDO, Equipment Specification for ASM in Sudan

1

1. Background

1.1. Number of Miners and Gold Production

The chosen artisanal gold mining site lies in the middle of Ingessana Hills, 80 km to the Southwest

of El Damazin town, the capital of the Blue Nile State. The mining sites are scattered around

Gugub village, which lies ~10 km Northwest of the Bau town; the administrative center of the

Inagassna Hills District. Southern Blue Nile region is accessible by a 520 km long Khartoum-El

Damazin asphalt road. El Damazin is connected to Bau and other villages of the Ingassana Hills by

dirt roads. In dry season, it takes 2 hours to drive from El Damazin to reach Gugub, the main

artisanal gold mining village or Bau. Blue Nile River is the major drainage in southern Blue Nile

region and it is fed by a network of big seasonal streams that drain the highlands east and west of

the river into the main course. The seasonal waters end up into the western banks of Roseries Dam

reservoir at a point around 20 km South of the El Damazin town.

There is no reliable information on gold production in Ingessana Hills prior to late 1996. Although

artisanal gold mining activities in the Ingessana Hills is relatively recent, the impact on the

economy of the district is substantial. Chromite mining activity in various locations in the Ingessana

massif started in 1960s.

Artisanal gold miners in the Ingessana Hills are spread in Gugub, Taga, and Salbal villages. Gugub

village of ~1000 inhabitants is the major center of activities. Gugub and the surroundings comprise

about 6 major artisanal gold mining sites. At present, Khor Gidad ~7 km (driving distance) North of

Gugub and Khor Neiwi ~5 km northeast of Gugub are the main sites. There are between 500 and

800 artisanal miners at the mining area of Gugub. Most miners excavate very competent and hard

quartz veins, dipping 45°, and extract material that is manually ground. The work is basically

conducted by women (more than 50% of the labor force; in the rainy season this can reach as much

as 90%, as men go planting). They cut the rocks with hammer and picks at depth no deeper than 20

m. They do not use explosives. As they extract around 0.3g of Au per day, according to information

from a local dealer, the quartz veins must have a grade higher than 30 g Au/tonne. Miners also work

with elluvial material and host altered rock. In this case they can crush and grind more material to

produce up to 10 grams of gold per day. It is estimated that, each miner produces from 0.5 to 1 g

Au/day1. This gives about 150-300 kg Au/a. Since 1997, they have produced about 3 tonnes of gold

in the Gugub area. Miners, men and women, extract manually both alluvial and primary gold.

Women in the 13-35 years age range and children participate in alluvial pitting, rubble panning and

bring water for domestic use.

1.2. Processing Methods and Mercury

Artisanal gold mining in Gugub is practiced by both Dawala and Ingessana tribesmen without legal

titles. The miners do not comply with the provisions provided in the Mines and Quarries Act

(1972). Given the adverse situation created by the civil strife around Kurmuk and Queissan boarder

areas in 1996, and in an effort to develop the sub-sector in a sustainable way, the Government tried

to legalize the gold mining in southern Blue Nile and elsewhere by granting special licenses.

Few mill owners introduced hammer mills into the area in 1997-1998 but authorities soon drove

them out. The primary quartz veins are mined manually from pits as deep as 20 m and the

extraction capacity does not exceeds 20-25/day per individual. Rock crushing and grinding is

currently performed manually by grindstone or steel mortar and the grinding capacity (to

1 Ibrahm, M.S., 2003. Information about the Project Sites in Sudan. Report to GEF/UNDP/UNIDO Global Mercury

Project. October, 2003. 10 p.

UNIDO, Equipment Specification for ASM in Sudan

2

0.074mm) is less than 5 kg/day/individual. Most of the hard work is done by women. Men usually

control the earnings from gold sale proceeds and have the final say in family affairs. Panning is

conducted manually in excavated pools using traditional wooden pans and mercury is added to the

pan at the end of the concentration process. Apparently, all fine gold is lost with the light fraction of

tailings. One of the main local problems is the lack of water in mid summer. Water is provided by

Ingessana women, bringing water for sale from ~2 km away. They carry a pair of 4-gallon plastic

containers on their shoulder with the aid of a stick for making balance. The eight gallons of water

cost S.D.50 (US$ 0.2). As the gold amalgam is roasted in bonfires, the amount of Hg in the

resulting doré is as high as 20%. When miners sell the gold to dealers, they do not melt the beads

and pay everything as pure gold. When dealers go to Khartoum or Omdurman to sell the gold, the

jewelries melt the bead resulting in 20% of loss and consequent emission of Hg vapor to the cities.

Obviously dealers complain that they lose money in this process. The solution is to implement more

efficient ways to retort amalgams and to melt gold before being sold to the jewelries.

The amount of mercury emitted in the Gugub area was estimated by Ibrahim (2003 op.cit.) around

0.3-0.4 tonnes/a. The high price of mercury (US$ 30/kg) is still controlling the levels of Hg

releases. Mercury is provided to miners by local gold dealer. They lend a known amount of Hg to

the miners with the promise that they will have the first option to buy the produced gold. When

miners return the excess Hg, the gold dealers charge them for the mercury lost and buy the gold.

Based on the estimate from some local gold dealers the ratio Hglost: Auproduced is around 1.4 but can

range from 1 to 1.5. Currently in Gugub there are 12 established gold dealers (there were 14 dealers

2 months ago) buying about 6 to 10g Au/day. There are other outside dealers also buying gold in

the area.

2. Proposed Solution

There is no milling center in the Gugub region. Most individuals mine and process in small groups

which is basically a family affair.

The level of education of miners and millers is not high and it seems a bit problematic to introduce

a new type of organization in the area. Preliminary surveys in the area revealed that a large majority

of the miners agree to work in association but in small groups. Organized Processing Centers must

be promoted by the Government and incentives must be provided for someone interested in starting

a business on this matter.

An option to introduce the concept of a Processing Center is thorugh a demonstration site owned by

the Government to provide fair access to all people involved in the mining activities within the

region. Some pieces of equipment can be assembled to teach miners, panners and millers how to

process ore with less environmental and health impact. Business matters can be discussed with

miners. The focus of the initiative should be on TRAINING not custom processing services.

2.1. Transportable Demonstration Units (TDU)

The artisanal mining activities in the Ingessana Hills is extremely widespread. The area occupied by

the artisanal miners can easily be larger than 50 km². There is a need to introduce the GMP

initiative and technological demonstration of appropriate equipment throughout the mining area,

and it is easier to bring a transportable demonstration unit to several thousand people than to bring

several thousand (or even tens and hundreds of thousands) of people to a static demonstration unit.

A static GMP demo unit located in Gugub would be very far from these areas and the nomadic

characteristics of the miners would leave behind the plant as soon as they move.

One of the big challenges in Sudan is how to improve the mining methods. The level of production

of individuals who with picks and hammers extract hard ore is too low. The quartz veins are very

UNIDO, Equipment Specification for ASM in Sudan

3

competent and alternative processes to demolish the veins without the use of explosive or to mine

eroded material, could be brought to their attention. Gold processing is extremely primitive and any

simple solution to increase their recoveries would bring an important improvement. However, it

seems that miners do not accept new procedures quite easily. For example, Cleangold sluice was

tested at the site. At the end of the panning with this new type of equipment, it was very visible the

amount of very fine gold concentrated. The miners became astonished with this simple test but the

tailing owner, an old lady, was very skeptical and took the whole concentrate and mixed back with

the tailings saying that she will do the same at home using her old pan. This is a clear indication that

cultural issues in the area can be a strong impediment to introduce new techniques.

The establishment of static Processing Plants would introduces further problems:

· A static GMP demonstration unit would logically be located in a high-producing area,

amongst existing sites. After scarcity of the easily exploitable ore, miners would move to

more promising areas abandoning the plant.

· A centrally-located, static GMP demo unit in the vicinity of mills would tend to be viewed as

a production facility by ASMs rather than a learning facility.

· Problems of land tenure, services, mineral rights, etc., would be involved with a central static

demo unit.

· The artisanal small-scale miners (ASMs) are nomadic. It would be logical to have a demo unit

that moves with the people and the gold strikes.

As discussed above, for these and many other reasons it would be beneficial to have a mobile or

easily trans-locatable demonstration facility. In addition to overcoming certain problems listed

above, this facility would provide the following advantages:

1. easier to implement than fixed demonstration/training centers;

2. a transportable training unit would prolong the demonstration effect beyond the project

lifetime;

3. as artisanal miners have nomadic characteristics, the training units go after them and not

vice-versa;

4. a variety of technical options for gold concentration, amalgamation and retorting can be

demonstrated to miners and millers; it is up to them to select what is affordable, appropriate

and durable according to their convenience;

5. easy to change and adapt new pieces of equipment used for demonstration without the need

for concrete foundations, etc.;

6. more miners and public can be outreached than in fixed demonstration/training units; more

people will receive brochures and other educational material;

7. a continuous "supply" of new ASMs to educate, rather than the same handful who would be

visiting custom mills close to a static demo unit.

8. the ownership of the training units is easy to decide (Government, University, NGO, etc); no

land or mineral title is required;

9. a Miners' Association (when organized) can embrace this idea without having conflict of

interest; the directors will not be the only ones to have benefits;

10. the units have high flexibility in terms of the subjects to be presented to the miners; the

ability to add "peripheral" education by addition, for example, health & sanitation,

bookkeeping, legal issues, etc);

11. geochemical and medical teams can make use of the units to assess environmental impacts

and neuro-toxicological effects of mercury;

UNIDO, Equipment Specification for ASM in Sudan

4

12. it is possible to demonstrate the use of safety equipment (e.g. different types of masks for

dust, Hg vapour, chemicals);

13. it is easy to incorporate shows (as in a "circus") to attract miners and public to watch skits

and movies about environmental impacts and mercury pollution; this theatrical

performances must be designed to be played with the mining communities highlighting local

aspects and incorporating concepts of environmental and health protection;

14. the technical demonstration and classes can be conducted either at the mine sites or at

populated centers (awareness campaign);

15. it is possible to set up portable classrooms to teach some basic technical concepts;

16. ease of adding space for further infrastructure or equipment by simple addition of a trailer to

the primary mobile carrier (truck);

17. the units can bring ideas to improve the livelihood of different mining communities such as

suggesting economic diversification activities or value-adding techniques (e.g. handcraft,

fish farming, agriculture, brick making using tailings, etc);

One of the main drawbacks of this initiative is the fact that miners may have the impression that the

transportable demonstration units is a solution for processing ore in many different sites, which is

consistent with their nomadic nature. In fact, mobile processing plants are useful to increase gold

production but, as a side effect, they disperse even more mercury pollution and environmental

degradation. The training units should be assembled to accommodate different types of equipment

not necessarily connected to each other. These units must work as pilot plants only for TRAINING

purposes.

2.2. Implementation Process

The steps to implement the transportable demonstration unit (TDU) in Sudan are:

1. selection of the local institution (within the Government) to own and look after these units;

2. discussion of the concept and detailed plan with stakeholders;

3. decision about who will operate the TDU and its sustainability;

4. selection of trainers and elaboration of training material (and eventually awareness

campaign movies, brochures, posters, etc.)

5. operating plan and schedules for training are established;

6. contract an engineering company to manufacture, install and start-up the TDU;

7. contract trainers and unit operators.

A clear letter of understanding should be established between UNIDO and the institution that will

own the TDU to guarantee that the objective and mandate of the training units will not be diverted

(for example to be used as a production unit). In Sudan it has been identified that the Geological

Research Authority of Sudan (GRAS), counterpart of UNIDO in the GMP, has all technical

attributes and personnel to be in charge of such TDU.

The concept and design of the TDU must be thoroughly discussed with the Sudanese stakeholders

including Government agencies, miners and millers' representatives, equipment manufacturers,

academics, NGOs, etc. Details of the design and operation of the units must be discussed and

suggestions to improve the design must be incorporated.

The idea of implementing the TDU in Sudan was discussed with Government representatives and

other mining experts in April 2004 and it was a consensus to focus the training on organizing

processing centers where miners can have better benefits of cleaner technologies.

UNIDO, Equipment Specification for ASM in Sudan

5

2.3. Components of a TDU

In order to design the transportable demonstration units, the main components of the units must be

studied. The main components of the TDU are:

· a platform (or container) to transport and secure all pieces of equipment

· a tent or any type of structure to be used as a portable classroom

· a generator

The main pieces of equipment can be assembled on a fixed wooden platform and other machines,

the heaviest ones can be settled on the ground. A heavy truck, preferably of 7 tonne capacity, can

move the pieces of equipment from one site to another. The demonstration plant can be either

mounted on one site for example for 2 or 3 months or simply assembled in a container. This later

reduces chances of vandalism. It is seems cheaper to rent a truck to move the unit from one site to

another than to purchase a vehicle.

The main pieces of equipment to demonstrate gold processing and amalgamation techniques are not

connected. The trainers use them to demonstrate the principles and advantages of each machine and

it is up to the miners to up-scale, modify, improve or purchase the machines from a local supplier.

A tent or a local simple structure made of wood and straw or an existing classroom is used as a

classroom, office, and laboratory (e.g. health assessment and Hg analysis using portable Hg

analyzer or colorimetric semi-quantitative techniques).

The main components of a transportable unit is shown in the diagram below:

platform or container

mineral processing and

tent or any

amalgamation equipment

existing

house or

school

(part of this is to be

assembled on the ground)

brochures

safety

classroom

equipment

audio-visual equipment

It is advisable to adopt a "bottom-to-top" approach for the demonstration plants and a "top-to-

bottom" approach for the instruction of trainers and training of Government representatives. In this

case, the trainers and local leaders will be trained in practical and theoretical subjects related to

ASM. The implementation of the demonstration units will be done in existing mining/milling areas

and preferentially using tailings as the initial material to be treated. As long as gold is recovered

from tailings, this should bring more credibility to the trainers. Subsequently, primary ore can be

used in the demonstration units comparing the performance of different types of equipment.

3. Selection of Processing/Amalgamation Equipment

The pieces of equipment to be demonstrated to the miners must follow some criteria:

1. must not be very complex (technical knowledge)

2. must be easily accessible (preferentially locally manufactured)

UNIDO, Equipment Specification for ASM in Sudan

6

3. must be inexpensive and locally maintained

The main pieces of equipment should demonstrate all steps of a simple mineral processing cycle

normally used by artisanal miners. This includes:

1. Comminution/Classification

2. Gravity Concentration

3. Amalgamation

4. Retorting

3.1. Comminution/Classification

It is not trivial to suggest simple comminution equipment, as there is no universal recipe for the

most expensive unit operation in mineral processing. Comminution in conventional mining

operations is usually conducted in closed systems with classification (e.g. screens or

hydrocyclones). This is a way to control overgrinding as well as to achieve the gold liberation size.

As no information is available about the gold liberation grain size, the principle of testing different

grinding times is the only one available to evaluate liberation. Concepts like this can be passed to

the miners, who can use a small ball mill and a gravity separation equipment to test their ores. This

will definitely improve their gold recovery by gravity concentration. In order to reach the liberation

size, comminution equipment must work in closed circuit with classification (e.g. screening)

processes. Unfortunately most of the ASM operations conduct their comminution process in open

circuit, without any classification. When using sluice boxes, the only classification observed is a

rudimentary screening process to eliminate coarse pieces of gravel. These concepts must be

discussed with miners in order to implement more efficient techniques. The most popular mills used

by ASM are discussed as follows.

3.1.1. Crusher

The main process used by Sudanese artisanal and small-scale miners (ASM) to crush big blocks of

primary ore is a manual hammer. Pounding the ore blocks with a metallic hammer against a heavy

metal plate or a rock monolith, miners reduce big block to a size of below 50 mm to feed the

fragments into an iron mortar where the ore is ground. A small jaw crusher handling 500 kg/h of

material to reduce it to 1/4"(6.5 mm) it is enough to show the concept of mechanical crushing.

This is an important part of the comminution step and must be part of the demonstration unit.

Table 3.1 Technical Data of a Small Jaw Crusher (Clarson 6"x 3")

Specification

Characteristics

Jaw Opening

6" wide x 3"gap

Max Capacity

0.5 tph

Max Feed Size

2"(50 mm)

Jaws

Ni-hard steel

Jaw Profile

Ribbed

Product Size

nominal 100% passing 9mm

Drive

V-belt drive, 275 rpm

Power

2.2 kW

Extent of Mechanization

Fully mechanized

Shipping Weight

220kg

Price

US$ 5000

3.1.3. Ball Mill

As no information about gold liberation is available, the selection of grinding equipment becomes

difficult. In a visit to Gugub it was observed that ASM have been grinding quartz ores in a iron

mortar to grain sizes below to 0.1 mm, which indicates that gold must be fine. Preliminary

UNIDO, Equipment Specification for ASM in Sudan

7

concentration tests have also demonstrated this. It seems that the fine gold nature claims for a fine

grinding system. In this case a hammer mill would not be efficient. Tumbling mills, such as ball or

rod mills are the most efficient grinding equipment but they are expensive and demand skill to work

correctly. An efficient grinding needs control of critical speed, number of balls, ball sizes, pulp

density, power draw, foundation, etc.

One of the main challenges of introducing ball mills is the lack of water in Gugub region. Ball mills

can also work dry but this requires at least 30% more power than wet grinding. The ball mills must

be hermetically closed to avoid escape of dust. It is clear that introduction of water in the mills will

be very beneficial. In dry grinding the contact between particle and balls is lower than in wet

milling. Gold can also be easily flattened and retained inside the mills when dry grinding is

practiced. Wet grinding does not generate dust and the energy required to grinding is lower than dry

grinding. In the demonstration units it is suggested to test dry milling in an adequate small well-

sealed mill as well as wet milling using high percentage of solids, as much as 80%.

Despite the low production rate of these suggested portable ball mills, the concept of having many

small-batch-ball mills instead of large ones seems interesting. Miners and millers can follow a step-

by-step approach acquiring one mill after another and then increasing their milling capacity. This is

not the best solution in terms of energy consumption, but definitely is adequate for the financial

capacity of the miners, employs more people and it is a fully accepted concept in many ASM

regions. The specifications of a similar ball mill with this capacity are given below.

Table 3.2 Technical Data of a Small Batch Ball Mill

Specification

Characteristics

Size

0.48 (1.6 ft) x 0.6 m (2ft) long (internal)

Lining

25mm thick steel shell and ends, unlined

Critical Speed

Nc = 42.3 D-0.5 (in m) = 61 rpm

Operating Speed

70 - 75% of critical speed; 45 rpm

Feed Capacity

40-50 kg/batch

Feed Size

12mm max

Water required

for 70% solids at 40kg load = 17 18 L

for 70% solids at 50 kg load = 21 22 L

Product Size

Time dependent; typically P80 = 100 mesh (0.150 mm)

Ball Charge Volume

40% of the mill volume

Ball Charge

350kg

max of ball

44mm (see below)

Ball Size for First Charge 50% of 40mm and 50% of 25mm

Type of Ball

Cast or forged steel (0.9 C, 0.85 Mn, 0.2 Si, 0.5 Cr, 0.1 Mo)

Ball Hardness

63-65 Rockwell

Shipping Weight

280kg

Extent of Mechanization Partially mechanized; batch manual discharge

Mode of Operation

Batch

Discharge

Lateral door

Drive

Torque arm gearbox and Vee Belt

Installed Power

2.2 kW

Price

US$ 8340

Note: Calculation of the largest ball (B) diameter (in mm)

F

Sg Wi

B =

3

.

25 4 ...............B= 44 mm

K

100 Cs

.

3 281 D

where:

K = constant for closed wet grinding systems = 350

UNIDO, Equipment Specification for ASM in Sudan

8

F = feed P80 in µm = 2 mm = 2000 µm

Sg = specific gravity of the mineral = 2.7

Wi = Work Index = 10

Cs = fraction of the critical speed = 0.70

D = mill internal diameter (in meter) = 0.48

3.1.4. Size Classification

Size classification is extensively used associated with grinding circuits to prevent the entry of

undersize particles into the grinding machines, to prevent oversize material from passing to the

concentration stage and to prepare a closely sized feed that improve the gravity concentration

process2. Screening is the simplest and cheapest process for industrial sizing but is generally limited

to material coarser than 100 mesh (0.15 mm). Spiral classifiers and hydrocyclones are widely used

to classify fine particles. As gold liberation is the main factor to obtain high gold recoveries, size

particle classification provides control on the gold liberation of the ground product. Unfortunately,

very few artisanal miners appreciate this simple control principle and operate their grinding systems

in open-circuit, i.e. no classification is used. Rudimentary wood or metal-framed screens can be

locally manufactured for wet screens but the screens are not easily available. These can be made of

brass or stainless steel or eventually, improvised with nylon screens. A spiral classifier is fed with

the grinding product and the pulp is diluted to 50% solids. It uses a continuously revolving spiral to

move sands up the slope, while fine flow down with water. The overflow becomes coarser with

increasing dilution and pulp density control is the main problem of the spiral classifiers. Mechanical

classifiers like this could be demonstrated to miners but it is an expensive piece of equipment and

some skills are needed to operate it. It has been seen in Zimbabwe a rudimentary but yet useful

mechanical classifier. The pulp from concentrators or amalgamating-copper plates is added to a

small cemented tank and the coarse material is scooped out to the top of an inclined wall by a belt

with pieces of rubber paddles. This is similar to a bucket classifier, but buckets bring the advantage

of dragging more material than paddles. Hydrocyclones are very efficient for desliming and not

very complicated to be manufactured. However, the principle of hydrocycloning is complex and a

proper design requires skills. An elutriator can also be efficiently used as a hydraulic size classifier.

Controlling the water speed, the rising flow carries the fine particles. Other designs with different

diameters and conic shapes can be easily manufactured in plastic using garden and kitchen

materials.

As water is scarce in Gugub, for the demonstration unit it is suggested to manufacture a 3-deck-

portable screening set in which sieves can be replaced at any moment. The deck should be 0.6m

long, 0.4m wide and 0.2m high. This can work dry or wet and it will provide more control to the

ball-milling process. The first screen is a robust grizzly, with large opening (12 mm) to support the

weight of the balls being removed from the mill. The balls can be washed or brushed (when dry

milling is practiced) on this screen. The second screen has opening of 1 or 2 mm to protect the

finest screen in the third deck. In the third deck, screens with 0.5mm and 0.2mm (or finer) can be

used. The undersize material is collected in a 200 or 300L plastic container.

3.1.5. Checking Gold Liberation

The classical procedure of using microscopy to check liberation size of the mineral of interest does

not work properly for gold, as its concentration is usually very low. It is not trivial to establish the

degree of liberation of low-grade minerals such as gold. There are a series of techniques to evaluate

gold liberation using screened factions. During the training, miners and trainers can run a sequence

of tests with tailings or ore to determine the gold size liberation. A homogenized pile of tailings or

crushed material (about 1000 kg) is formed and thoroughly mixed. About 100 kg of material is

ground at a specific time. As the ball mill has maximum capacity of 50 kg, the material has to be

ground twice. After grinding each 50 kg, the interior of the mill is emptied (washed) and the

2 Wills, B.A., 1988. Mineral Processing Technology. Oxford, UK, Pergamon Press, 785 p.

UNIDO, Equipment Specification for ASM in Sudan

9

material is discharged on the screening deck. The undersize fraction (pulp of 20-30% solids) of the

ground material is pumped to be concentrated using one of the gravity concentration equipment

herein described. The concentrate is subsequently amalgamated and retorted. Increasing the

grinding times, for example 0 (no grinding), 5, 10, 20 and 30 minutes, it is possible to observe that

more gold has been recovered, if the original pile of run-of-mine material is well homogenized. The

amount of gold obtained when grinding and processing each 100 kg of material is registered. The

oversize fractions retained in screen 2 and 3 are dried and weighed. A curve of the amount of gold

recovered by gravity concentration and amalgamation versus grinding time or grain size (e.g. P80 in

screens 2 or 3) provides a clear visualization of gold liberation. An example of this procedure can

be seen below, when a tailing was used to check gold liberation. In this case, it is clear that the

recommended (re)grinding time of this tailing is 10 minutes; consequently the liberation grinding

size is also obtained.

100

90

Gold

80

recovered

(mg)

70

60

50

0

5

10

20

30

Grinding time (min.)

3.2. Gravity Concentration

Often gravity separation methods are confused with size classification as coarse particles of light

minerals can behave like a small particle of a heavy mineral. The most effective gravity separation

processes occur when applied to narrow grain size. The most important factor for a successful

gravity separation is liberation of the gold from the gangue minerals.

The main advantages of gravity concentrators over hydrometallurgical methods are:

· relatively simple pieces of equipment (low capital and operating costs)

· little or no reagent required

· can be applied from relatively coarse particles to fine size materials

Some of the most popular gravity concentration pieces of equipment suggested to the TDU in

Sudan are discussed as follows.

3.2.1. Sluices

Sluice boxes are the most popular gravity separation process used by artisanal gold miners

worldwide as they can be locally manufactured, they do not require power, and provide high

enrichment ratio. They are of simple construction and easy operation. The introduction of sluice

boxes will provide better gold recoveries than the process (panning) actually seen in Gugub. The

lack of water can be a hurdle, but without previous tests, it seems difficult to recommend a dry

pinched-sluice to pre-concentrate the ore. Rather, it is recommended to establish an efficient way to

clarify and recycle water for the sluicing process.

UNIDO, Equipment Specification for ASM in Sudan

10

The principle of operation of a sluice box is simple: heavy particles in a water stream settle and

become trapped by riffles or mates. A very comprehensive report on sluice boxes is provided by the

British Geological Survey (BGS, 2002)3. For an efficient separation, BGS (2002) lists the main

parameters and recommends the following:

· ore slurry: steady and pre-screened slurries (screen <25 mm, ideally 5mm))

· pulp density: <15% solids (weight/volume), e.g. 15g of solids in 100mL of water; pulp

density depends on grain size; for fine fractions or clayey ore, 3 to 5% solids is used

· flow velocity: depends on box width and slope: if speed is too slow, the sluice box becomes

blocked; if it is too fast, gold is washed away; recommended flow speed is 1 to 2 m/sec

· stream depth: 20 to 30 mm

· sluice slope: 10 to 15 degrees

· sluice length: 2 to 5 m

· width: depends on desired flow speed; usually it is between 0.5 and 2 m

· water need: 30 to 70 m³/h/m of width; then a 1m wide sluice box working with a 5% w/v

pulp can process from 1.5 t/h to 3.5 to/h of material.

Miners believe that the long sluice boxes improve gold recovery. However it is observed in long

sluices that most gold is recovered on the first 2 or 3 meters where the flow speed is slower than at

the sluice end. This is the main reason why Brazilian "garimpeiros" (ASM) devised the 2 or 3-deck

sluice boxes. Each deck is approximately 2.8 to 3 m long, 1.5 to 2 m wide and placed in zigzag. The

top box discharges the pulp on the second box. This breaks the flow direction and reduces the water

speed, promoting additional gold recovery at the beginning of the second (and third) deck. It is also

possible to have different lining materials in each deck. These 2-deck sluices are common in Brazil,

Suriname and Guyana. They operate with hydraulic monitors of 4, 6 or 10 inches and the 5% solid

ore pulp is pumped to the sluice boxes at a rate of 4 to 5 m³ ore/h (6-inch pump) to 7 to 9 m³/h (10-

inch pump). This means that up to 24 tonnes/h of material can be processed.

The width of a sluice box is a much more critical parameter than the length. Narrow-width sluice

boxes promote high-speed flows and this consequently affects gold recovery. Pinched sluice boxes

(variable width) is used for pre-concentration. The height of the sluice box usually respects the riffle

height: sluice width ratio of 0.3. This means that, for a sluice box 1.2 m wide, the sluice height must

be around 0.36m.

The choice of the adequate trapping mechanism is key for an efficient gold concentration. Sluices

using riffles (1 to 3 cm high) are usually appropriate for coarse gold (> 0.4 mm). As the riffles

create turbulence, this reduces the chances of trapping fine gold. For fine gold particles, the shape

of gold particle and quality of the matting material has great influence on the gold recovery. Priester

and Hentchel (1992)4 list the lining materials used by ASM in different parts of the world:

· rubber matting

· sisal mats

· fine and coarse fabric e.g. corduroy, cord velvet

· carpets

· meshed hemp or grass cords

· metal grid

· split bamboo

Gold recovery can be increased by frequent clean-ups of the sluice box. In this case rubber liners

are more practical to clean and so not need rifles to fix them to the box bottom. MINTEK (South

3 BGS British Geological Survey, 2002. Good Practice in the Design and Use of Large Sluice Boxes. Booklet

prepared by Styles, Simpson and Steadman. Report CR/02/029N. 39 p.

4 Priester, M & Hentshcel, T., 1992. Small-scale Gold Mining. Published by GATE/GTZ. Vieweg, Germany. 96p.

UNIDO, Equipment Specification for ASM in Sudan

11

Africa) devised interesting sluice boxes (strake) with rubber-mat glued to it. Black ribbed vinyl

mats are also useful to recover gold and easy to clean but it costs in USA, about US$15/m².

In terms of mats, it is interested to demonstrate to miners different types of sisal clothes and carpets.

The most adequate carpet used in ASM operations is the 3M Nomad Dirt Scraper Matting in

particular the type 8100 which consist of a coiled vinyl structure. This is usually recommended for

relatively coarse gold. The price of this carpet in ASM sites can reach up to US$ 40/m². The

Brazilian company Sommer (subsidiary of the German company Tarkett Sommer) sells 2 types of

carpets widely used by Brazilian ASM: "Multiouro tariscado" (which is good for gold speck of rice-

medium size) and "Multiouro liso" (which is good for 100 mesh-fine gold). These carpets can cost

around US$ 10 to 15/m² which is cheaper than the 3 M carpets. However these carpets are not

easily accessible to ASM in Africa.

Extensive use of sisal clothes as sluice-box liners to concentrate gold was observed all over the

mining operations in African countries. The main problem is the use of very opened sisal clothes,

that can work properly for coarse gold but it is unlikely efficient for medium and fine gold particles.

Sisal clothes can cost as low as US$ 3/m², are available in most African countries, and, depending

of the type, they can be used for coarse, medium and fine gold recovery. It is a matter of trying

different types. This definitely must be further investigated and tests can be done together with the

miners to establish the ideal type of sisal cloth.

The American company Keene Engineering offers a large variety of riffled sluice boxes made of

aluminum with rubber ribbed matting and vinyl carpets. The A52 Keene 10"x 51" (25 x 129 cm)

seems an interesting alternative to be demonstrated to ASM. The cost in USA of this sluice is

around US$100. The company also provides pumps (3 to 8 inches) and a large variety of

accessories. This small portable sluice (weighing 5kg) had capacity of processing up to 5 tonnes/h

of ore. It is suggested to manufacture some aluminum or wood sluice boxes or simply use the

Keene's boxes without riffles but with different types of mats. The demonstration unit should be

able to show the advantages of different types of lining (sisal cloth, carpets, rubber, etc.) to miners.

Another interesting sluice box is the one

manufactured by Cleangold, a company based

in Lincoln City, Oregon. The Cleangold sluice

uses polymeric magnetic sheets, with the

magnetic poles aliened normal to the direction

of the flow, inserted into a simple aluminum

sluice box. Magnetite, a mineral usually found

in gold-ore deposits, forms a corduroy-like bed

on the sluice floor, which appears effective at

recovering fine gold. This sluice box can be

available in any size and a 2ft x 6in (60 x 15

cm) sluice costs US$ 75 in USA. The main

advantage of this sluice is the high

concentration ratio. Gold becomes trapped in a

Cleangold Sluice box (60 x 15 cm)

magnetite layer and the sluice can be scrapped

and washed into a pan. Using a magnet, the

magnetite is removed and a high grade of gold concentrate is obtained. In many cases the use of

mercury to amalgamate the concentrate is not necessary. However, as the magnetic separation of the

concentrate can carry some gold, amalgamation or even leaching of the concentrates is

recommended. In one test comparing the Cleangold sluice with a Knelson concentrator, the sluice

obtained slightly better gold recoveries than the centrifuge. In a recent field test in Venezuela

conducted by UNIDO, tailings from hammer mills and Cu-amalgamating plates were re-passed in a

2ft long Cleangold sluice box without re-grinding. About 11% of gold was recovered and the

UNIDO, Equipment Specification for ASM in Sudan

12

concentrate analyzed 2850 ppm Au. The company representative mentioned that they can

manufacture a 60 x 50 cm Cleangold sluice box and it would cost around US$ 165 (in USA).

Cleangold was also successfully tested in Gugub and the ability of concentrating fine gold was

demonstrated to the local miners.

It is suggested for the TDU a static set of 2 Cleangold 60x50 cm sluices (making a 1.2 m long

sluice) with a steel structure to allow slope adjustment. This structure can easily be locally

manufactured.

3.3. Amalgamation

It was not observed miners amalgamating the whole ore in Sudan, but just gravity concentrates

obtained in panning. Manual amalgamation of concentrates using pans is environmentally better

than the amalgamation of the whole ore, however, if not properly conducted, this exposes operators

to high levels of mercury vapor. In addition, this manual process can take more than two hours.

Ideally the best situation is where mercury is avoided all together by alternative processes such as

MINTEK iGoli or CETEM- Saltem processes where gravity concentrates are leached with

chlorine solutions. However these options are not as simple and inexpensive as amalgamation.

The best practice would be the establishment of a Processing Center, like in Venezuela, where

gravity concentrates are amalgamated by skilled operators. Concentrates could also be leached in

these centers using chlorine, or even cyanide. This seems a natural evolution of the artisanal mining

processing system when the miners and millers become more educated and organized. Meanwhile

the training efforts must be concentrated on reducing mercury losses and occupational exposure.

Any process to be introduced must also bring a financial gain to the miners otherwise they will not

accept the technical innovations.

Assuming that amalgamation is still the most accepted gold extraction process in the ASM regions,

the initial approach should be the reduction of the mercury emissions. Some pieces of equipment

capable to improve the amalgamation step are described as follows.

3.3.1. Amalgamation Barrels

Barrel is the most efficient amalgamation process. They are used to amalgamate gravity

concentrates. Recovery of gold from heavy mineral concentrates can be higher than 90%.

Amalgamation barrels with capacity to amalgamate up to 30 kg of concentrate per batch are

adequate to the demonstration units. It is very important to avoid the impression that these barrels

can be used for grinding primary ores. This incorrect practice has been responsible for large

mercury losses in Indonesia, where miners add iron rods and balls into the barrels to grind 40 to 50

kg of primary ore for 4 hours with 1 kg of mercury. It has been demonstrated how grinding reduces

the ability of gold to be amalgamated. In these cases, mercury loses coalescence, i.e. breaks down in

droplets ("flouring effect") and mercury is lost. The action in amalgamation should be attrition of

mercury with gold rather than impact. In Sudan is common to see miners mixing mercury with

gravity concentrates using bare hands in the concentrating pan.

The suggested elliptical amalgamation barrel has a "pelletizing" disk format with control of the

slope and promotes high contact of mercury with gold particles. The use of large rubber balls

promotes good contact between mercury and gold specks. As most of the Sudanese miners

amalgamate very small portion of the gravity concentrate obtained by panning, it is suggested to

have small barrels, as the one suggested below.

UNIDO, Equipment Specification for ASM in Sudan

13

Table 3.3 Technical Data of a Disk Amalgamation Barrel

Specification

Characteristics

Size

tilted disk 0.30m x 0.10m wide

Lining

8mm thick steel shell, rubberized

Max Speed

30 rpm

Max Feed capacity

17 kg concentrate/batch

Ball Material

Rubber

Ball Size

50 mm

Number of Balls

5 to 8

Amalgam Trap

Adjustable discharge tray with mercury trap and adjustable

copper plate

Extent of Mechanization Partially mechanized, batch manual discharge

Mode of Operation

Batch

Discharge Type

Lateral door

Installed Power

2 kW

Drive

Vee Belt

Shipping Weight

100kg with frame and access ladderway

Price

~US$ 2000

Amalgamation barrels can also be made of plastic PVC but in some African countries this can be

more difficult to find and costly than steel. This is definitely very beneficial as no iron balls can be

introduced in the barrels and the mercury flouring is avoided.

The pulp of concentrate with 50 to 60% solids should not exceed half the barrel volume.

The amount of mercury used for amalgamation is usually a function of the gold grade in the gravity

concentrate. As this information is usually not available a common addition of 10 to 20g Hg per kg

of concentrate (1:100 to 1:50 Hg:concentrate ratio) is sufficient to promote good amalgamation.

Amalgamation time above 40 min usually promotes mercury flouring.

The main inconvenient of amalgamation barrels is the relatively high concentration of Hg in the

tailings. Amalgamation tailings from barrels, as observed in Poconé, Brazil, have from 80 to 200

mg/kg of Hg5. It is also common to find amalgamation tailings with 500mg/kg (ppm) of Hg. This is

a result of mercury flouring, i.e. loss of mercury coalescence. A restrict control to avoid mercury

flouring is needed when operating barrels. This is done adjusting amalgamation time, adding

reagents and reducing stress on the concentrate pulp.

Use of chemicals such as potassium permanganate or even sodium cyanide to reduce mercury

surface tension and clean gold particles surface may improve the amalgamation process, but the

benefits for gold extraction do not take into consideration the occupational risks and the

environmental effects. One gram of NaOH per kg of heavy mineral concentrate to be amalgamate is

an efficient method to improve amalgamation without solubilizing mercury.

3.3.2. Amalgamation Plates

Amalgamation Plates are stationary metallic sheets usually dressed with a thin layer of mercury

(usually 150g Hg/m² of plate) use to amalgamate free gold particles in ores ground coarser than 1.5

mm. Working with 10% of slope these plates receive pulp of auriferous ore (10 to 20 % of solids)

and the amalgamation takes place when gold particles contact the plate surface. The velocity of

5 Farid, L.H.; Machado, J.E.B.; Silva, O.A. (1991). Emission Control and Mercury Recovery from Garimpo Tailing. In:

Poconé: Um Campo de Estudos do Impacto Ambiental do Garimpo, Ed. M.M.Veiga and F.R.C. Fernandes,

CETEM/CNPq, Rio de Janeiro, Brazil, p. 27-44. - in Portuguese

UNIDO, Equipment Specification for ASM in Sudan

14

flow has to be sufficiently low that the precious metal particles can sink to the plate surface and yet

high enough that other mineral constituents of the concentrate do not remain on the plate. The most

common plates used in ASM operations are made of copper. The efficiency of the process depends

on the operator ability, but usually is low due to the short time of ore-mercury contact. The method

works better for alluvial gold but it is very limited for primary ore in which quite often gold is not

completely liberated from the gangue minerals. About 0.3 m2 of plate is required to treat 1 tonne of

ore/24 h for pulps with 20% solids. Amalgam is removed (scraping) periodically interrupting the

process. Abrasion of the mercury surface releases droplets that contaminate the tailings. Acidic

water may also cause brown or green spots on the copper plate and mercury is also lost. A large

majority of artisanal miners do not use a mercury trap at the end of the plates. In Venezuela, tailings

from amalgamation Cu-plates typically contain 60 to 80 ppm Hg.

A new technology was developed in Brazil and commercialized by two manufacturers: Goldtech

and Rio-Sul. A thin coating of Hg and Ag is electrolytically deposited onto a metallic plate (brass,

galvanized steel, copper, etc.). About 80 g Hg/m² of plate is added to the plates to amalgamate

gravity concentrates. Gold is captured and firmly fixed to the plate surface. Hg losses are

minimized. When the plates are fully loaded, amalgam is removed by washing with a plastic

scraper. This kind of plates has been successfully tested in Brazil to remove Hg from contaminated

tailing. In recent test in Venezuela, tailings from ordinary Cu-plates containing in average 62.2 ppm

were submitted to a cascade system with four special-plates. More than 95% of Hg was removed

from tailings. Those plates are not indicated to capture gold from the whole ore but only to

amalgamate gravity concentrates or to clean contaminated tailings. A wood structure was built to

hold 4 Goldtech 40 x 30 cm plates placed in zigzag, as seen in the diagram below. About 10 g of

mercury per plate is added. About 10 kg concentrate from carpet sluice boxes was passed 3 times in

less than 10 minutes. Then, the plates are removed from the wood structure and the amalgam was

scrapped off.

The main advantages of using the special-plates to amalgamate gravity concentrates are:

1. amalgamation process is faster

2. no heavy mineral-amalgam separation

3. minimum Hg loss in the amalgamation tailings

The process of manufacturing these special plates in Sudan should be investigated as the price CIF

per plate in Brazil is still expensive: US$ 200 (Goldtech plate 40 x 30 cm) and US$ 600 (Rio-Sul

plate 60 x 40 cm). In any case, this is the best system to promote clean and fast amalgamation of

gravity concentrates.

UNIDO, Equipment Specification for ASM in Sudan

15

Concentrate

3 times

Goldtech

Plates

1.2 m

Tailings

0.3 m

0.5 m

Special Amalgamation Plates in Zigzag

Table 3.4 Technical Data of a Box with Special Amalgamation Plates in Zigzag

Specification

Characteristics

Box Size

1.2 x 0.5 x 0.3 m (internal)

Box Material

Naval Plywood (2cm thick) or C-Steel

Type of Plate

Goldtech 40 x 30 cm (or Rio-Sul 60 x 40 cm)

Number of Plates

4

Arrangement of Plates

Zigzag and cascade

Plate Slope

10°

Max Feed Capacity

100 kg concentrate

Pulp Density

<10%

Extent of Mechanization Manual

Mode of Operation

Batch

Discharge

Frontal

Price

US$ 1500

3.3.3. Comparing Barrels with Special-Amalgamating Plates

The advantages and disadvantages of using barrels or special amalgamating plates to extract gold

from gravity concentrates are shown in the Table below. The main problem is to restrict the use of

these special plates to amalgamate just concentrates. As ordinary copper-amalgamating plates are

widely used to amalgamate the whole ore, miners can have the impression that these special plates

can be used in the same way. This is a mistake as the intense attrition of tonnes of ore pulp on top of

the special plates will degenerate the superficial silver amalgam and release mercury to the tailings.

Miners can also misuse the amalgamation barrels as ball mills, adding iron balls while

amalgamating concentrates or, even worse, the whole ore. This, as seen above, causes huge mercury

losses.

UNIDO, Equipment Specification for ASM in Sudan

16

Table 3.5 Comparing Special Amalgamating Plates with Barrels to Amalgamate 100 kg of

Gravity Concentrate

Zigzag Box with 4-Special

Amalgamation Barrel +

Amalgamating Plates

Elutriator (or Spiral-pan)

(40x30cm)

Amount of Hg needed (g)

40

1600

Typical Hg conc. in tailings (mg/kg)

<1

200 500

Amalgamation time required (min)

10

40

Time to obtain amalgam (min)

20 (scrapping the plate)

20 (using spiral pan)

Need to squeeze amalgam to remove

yes

yes

excess Hg

Relative amount of excess Hg

low

high

Dangerous misuse

use the plates to amalgamate use the barrels to grind ore

the whole ore

together with Hg

Main problem

occupational exposure of

mercury flouring

operators to Hg vapor

Skill needed

low

medium/high

Price (US$)

1500

4500 (including spiral pan)

3.3.4. Separation of Heavy-minerals from Amalgam

When amalgamation of gravity concentrate is conducted in a barrel, the heavy minerals must be

separated from the amalgam (+ excess Hg). When amalgam-heavy mineral separation is made by

panning at the creeks margins, mineral portion with residual mercury overflows to the watercourses

creating "hotspots" which are highly contaminated sites. Mercury from these sites can react with

organic matter and be methylated by a biotic process. The tailing generated in the amalgam-heavy

mineral separation may contain as much as 500 mg/kg (ppm) Hg. In Gugub most of the

amalgamation tailings are left in the pools or miners take these tailings to their homes to be re-

ground and re-amalgamated.

The main techniques to separate the amalgam from the heavy minerals are described below:

Panning

Panning in the water box or excavated pools is one of the most adopted method to separate

amalgam (with excess mercury) from heavy minerals concentrate. The methodology is not very

efficient but simple and inexpensive. This however promotes long contact of the operator's hands

with mercury. When panning is conducted in a water box or cemented tanks, the amalgamation

tailings are temporarily stored. The extraction of mercury from contaminated tailings is usually not

practiced by ASM. The main option for cleaning mercury from tailings is the use of special-

amalgamating plates described above. In this case, it is much better to use the special plates to

amalgamate concentrates in first place.

Spiral Pan

Spiral Pan is a tilted plate with a spiral riffle on the surface of the pan which moves the amalgam

and excess mercury into the center of the wheel where it is collected. The heavy-mineral portion is

discharged at the edge of the wheel. It is fully mechanized and the pan angle controls the efficiency

of the separation. A water pipe with thin holes crosses part of the spiral section to wash the minerals

down. The simplest pans are made of polypropylene plastic with diameter ranging from 30 to 50

cm. The wheel rotation speed is controllable (from 15 to 22 rpm) thanks to a 12 V motor (adaptable

to car battery). The feed capacity is around 30 kg per hour. There are many spiral pan

manufacturers in USA, many of them can be found in the Internet. The prices of these spirals range

from US$ 300 to 500 depending on the level of accessories. The weight of the whole setting is less

UNIDO, Equipment Specification for ASM in Sudan

17

than 10 kg. In terms of heavy-mineral-amalgam

separation, the spiral pans provide better control

than an elutriator and the final amalgamation

tailing contains less mercury. Both techniques are

worthwhile to be demonstrated to miners.

3.3.5. Removing Excess Mercury

The universal process used by most artisanal

miners to remove excess mercury from amalgam is

filtration squeezing the amalgam in a piece of

Spiral Pan

cloth. The cloth retains the amalgam (paste) and

permits mercury to flow through the fabric or

chamois pores. Despite the low absorption of mercury through the miner's hand, it is always

advisable to wear gloves during this artisanal procedure. This process usually results in amalgam

with 40 to 50% Hg.

A creative solution to remove excess Hg from amalgam without using the hand squeezing process

was developed in a Processing Center in Venezuela. The amalgam with excess mercury is

transferred to a porcelain crucible, covered with a piece of fabric on top and placed in a centrifuge.

The centrifuge runs for 1 or 2 min. and the resulting amalgam has less than 20% Hg.

This can be brought to the miners' attention in the demonstration units. This can be built adapting a

domestic food processor (centrifuges).

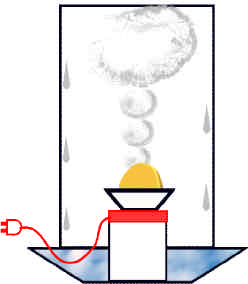

3.4. Retorting

An efficient method to separate mercury and gold from amalgams is by heating above 350 °C.

Mercury becomes volatile leaving gold behind in solid state. A retort is a container in which the

gold-mercury amalgam is placed and heated; volatile mercury travels up through a tube and

condenses in an adjacent cooler chamber. With retorts, mercury recovery is usually higher than

95%. Substantial reduction in air pollution is obtained. There are a large variety of retorts. Some of

them are made with stainless steel while others use inexpensive cast iron. Mercury losses during

retorting are usually less than 5%, but this depends on the type of connections or clamps used.

This operation unfortunately in most artisanal mining sites around the world is usually conducted

burning amalgams in pans or metallic trays using a blowtorch or bonfire. In Sudan it is very popular

the use of bonfires to burn amalgam. The miners place the amalgam on a steel plate or shoe-

polishing tin to be burned in a bonfire. As the temperature is not high enough and the time of

burning is too short (miners leave the amalgam for 10 minutes), the final gold doré contains up to

20% of residual mercury. The only control of the burning is visual. As long as the amalgam ball

becomes superficially yellow, the miners remove the doré from the fire. Inside the bead it is

possible to see residual mercury. As most gold buyers know this fact, they reduce the doré purchase

price. When better retorting techniques are introduced, the gold price must be negotiated with

dealers, showing that less mercury has been retained in the doré.

As occupational exposure is the main pathway in which mercury enters the human body in artisanal

gold mining areas, it is suggested to demonstrate the advantages of using different retorting

processes. In places such as Lao PDR, where mercury in mining areas is purchased by US$ 80/kg it

makes sense to use the economic argument to convince miners to recycle mercury. In Sudan, the

price of one kilogram of mercury is around US$ 30/kg. In spite of being almost seven times higher

than the international mercury price, this is still cheap, i.e. equivalent to three gram of gold. So, the

economic argument should be replaced with other strategy. Despite the introduction of retorts

UNIDO, Equipment Specification for ASM in Sudan

18

through many programs (CETEM, UNIDO, Projekt-Consult GmbH, ITDG, Organization of

American States, etc) and obvious benefits associated with their use, artisanal miners are reluctant,

primarily due to a lack of concern for environmental and health impacts relative to other issues. The

most effective argument to convince miners to use retort is using social and cultural issues. For

example, in 1985, the Secretary of Mining of Goiás State, Brazil, started a campaign promoting

retorts that included a brochure illustrating the effects of mercurialism. Impotence was stressed as

one of the initial symptoms, which is somewhat inaccurate and therefore questionable from an

ethical standpoint, but was extremely effective in capturing the attention of miners.

It is important to understand the main reasons by which miners do not use retorts. Engineers tend to

look for the efficiency of the retorting process, when in many cases, efficiency is not the dominant

factor to introduce a cleaner technology. The arguments are site-specific and sometimes fraught

with misperception. However in some cases there are actual reasons that must be considered when

introducing retorts in a mining site. Some of the most common arguments used by miners for not

using retorts are listed below (Table 3.6). All these factors must be taken into consideration in order

to recommend the adequate type of retort in a specific mining region. In some cases gold buyers use

the miner's perception to lower the purchase price. This is common when miners sell brown

retorted gold.

The doré volume after retorting usually has the same volume as the amalgam. The amount of

mercury in the doré depends on the retorting temperature. A well-done retorting would result in a

doré with 1 to 2% Hg. Using blowtorches, the retorting time ranges from 10 to 20 minutes, in a 1 or

1½"crucible retort. Shorter time provides doré with high content of Hg. Usually this is not seen by

miners, as the surface color is yellow. When using blowtorches, it is possible to melt gold in the

retort crucible. Brazilian miners use to add some borax and a little dash of potassium nitrate to melt

gold and remove impurities. This operation must be conducted in a fume hood equipped with filters.

Activated carbon soaked with potassium iodide makes a very efficient filter to retain residual

mercury vapor.

Table 3.6 Arguments Used by Miners for Not Using Retorts

Arguments

Reasons

Possible solution

it takes time (sometimes

low temperature

use air blower in bonfires or

miners become vulnerable to

blowtorch; avoid crucible made

bandits attack when retorting)

of refractory material such as clay

it needs experience to operate

heating process must be

training

uniform when using

blowtorch

gold is lost during retorting

iron retorts: amalgam is not

glass retorts can demonstrate that

visible; bad perceived by

gold will not evaporate together

miners

with Hg or be trapped

gold sticks to the retort

sometimes gold adhere to

· crucible must be filled with

crucible

crucible bottom

soot, or baby powder or a thin

layer of clay;

· avoid overheating (beyond red

color)

Hg loses coalescence

sometimes condensed Hg

NaCl and radio battery to re-

disintegrates in fine droplets

activate Hg

gold becomes brown

unknown; probably due to a

· still not well studied;

superficial reaction with iron

· oxidizing atmosphere or use of

stainless steel crucibles;

· melt gold;

· hammer gold doré

UNIDO, Equipment Specification for ASM in Sudan

19

Regarding the type of retort to be demonstrated to miners the strategy must be: ANY RETORT IS

BETTER THAN NOTHING. Even a crude method of retorting described in the "Gold Panner's

Manual", a favorite of North American weekend prospectors, is better than burning amalgam in

open pans or kitchen ovens. This simply involves "baking" the amalgam in the scooped out cavity

of a potato. Readers are advised not eating the potato after processing.

The best retorts to be advised to miners are those made of local and easily accessible materials, non-

expensive and easy to demonstrate. Durability can be a factor, but as long as the retorts are cheap

and accessible, this becomes less relevant for miners.

In the demonstration unit it is suggested to have a large variety of retorts, from the simple to the

most sophisticated one, to provide options to miners. It is definitely up to the miners to choose the

most convenient and affordable type of retort for him/her.

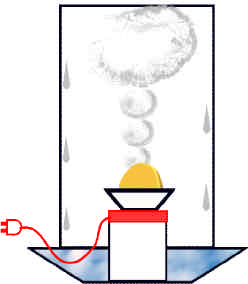

3.4.1. Increasing Temperature

Another important factor to be considered when

suggesting a retort, is the source of heat. Using

blowtorches with propane gas (as in most Latin American

countries) or with gasoline-air (as in Indonesia), the

temperature on the amalgam can easily go above 400 °C

promoting efficient mercury elimination from amalgam in

less than 20 minutes. In a bonfire, more than one hour is

needed to remove more than 90% of mercury from a 5 g-

amalgam. When a bonfire is used, an air-bower is needed

to speed up the process and to justify the use of retorts.

Manual or foot-operated blowers have been used in

Sudan to forge steel. These blowers can easily be locally

Indonesian gasoline-air blowtorch

manufactured. Air-blowers are

definitely needed to be included in the

demonstration units in particular in most

African countries where most miners

use wood as the main heating source.

Burners (such as camping stoves) using

gasoline, paraffin, butane liquid propane

should also brought to miner's attention.

Air blower tested in Gugub; this increases the

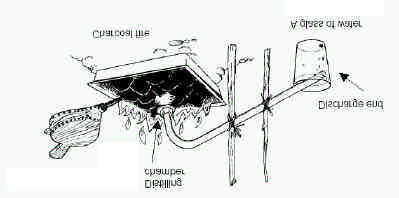

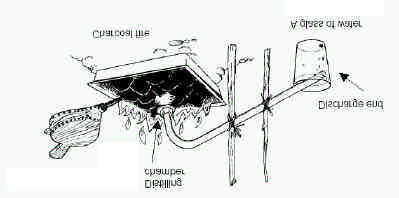

3.4.2. Home-made Retorts

temperature of a bonfire

Home-made retorts are not very efficient

but are easy to be manufactured with local materials. One option is the use of standard plumbing

pipes and connections to make retorts with crucibles (end plug of plumbing pipes) from ¾"to 2".

Smaller crucibles promote faster retorting. For those miners retorting more than 5 grams of

amalgam per batch, retorts with crucible of 1½" are advisable. This costs less than US$15. This

idea, devised by prof. Raphael Hypolito6 from Brazil, has been adopted by many organizations and

6 Veiga, M.M.; Meech, J.A.; Hypolito, R., 1995. Educational measures to address Hg pollution from gold mining

activities in the Amazon. Ambio, v. 24, p.216-220, 1995. Royal Swedish Academy.

UNIDO, Equipment Specification for ASM in Sudan

20

different designs of the RHYP retorts are available. The main drawback is that the pipes are made

of galvanized steel and when mercury condenses, it sticks to the cooling pipe creating an amalgam

with zinc. With the use of the retort, eventually, the accumulate mercury comes off, but this can

bring a bad impression for the miners. In a brochure made by the British NGO, Intermediate

Technology Development Group (ITDG)7, there is the following note: Do not worry if, the first time

you use the retort, only a small part of the expected amount of mercury is recovered. Most of the

mercury is normally trapped in the retort, and will be recovered in second and subsequent uses.

RHYP Retort

RHYP Retort

A manual

blower speeds

up the heating

process

For an appropriate operation, all retort body must be heated

For an adequate operation, the zinc from all plumbing parts must be burned off. Zinc fumes are

relatively toxic. This initial operation must be done in a fume hood. Mercury can also leak through

the connections. For a better operation it is advisable to heat the entire retort body in a charcoal bed

and preferentially using an air-blower to speed up the operation.

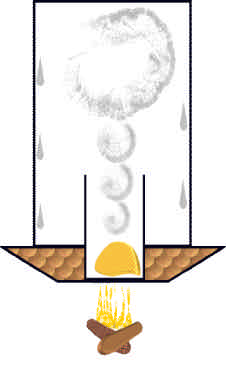

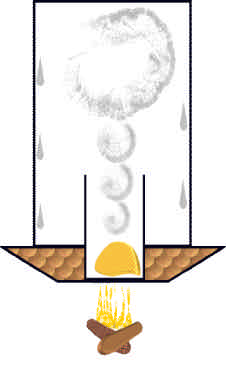

Home-made retorts can also be made of steel tins. An inexpensive option for retorting has been

applied in Papua New Guinea and China. The Chinese two-bucket retort consists of a metallic

bucket and a bowl filled with water. A larger bucket covers the first bucket containing the amalgam.

The PNG "tin-fish-tin" retort employs the same concept, but uses fish tins and wet sand instead of

water. In both cases, the amalgam is heated using wood, charcoal or electric element and mercury

vapors condense on the cover-bucket walls.

7 ITDG. A Simple Retort. www.itdg.org/html/technical_enquiries/ docs/mercury_retort.pdf

UNIDO, Equipment Specification for ASM in Sudan

21

Alternative Design for

RHYP retort

RHYP in use, as promoted by ITDG

bucket

evaporated Hg

condensed Hg

to electric

sand

power

metallic

tray

fish tin

water

electric

bucket

amalgam

element

bonfire

Other types of home made retorts used in China (left) and Papua New Guinea (right)

UNIDO, Equipment Specification for ASM in Sudan

22

Using the same principle of the Papua New Guinea ("PNG retort") fish-tin retort, UNIDO built

some retorts using kitchen material for the ASM in Sudan. On a metallic support (locally used for

cooking on bonfires), a small enameled

steel tray with amalgam is placed inside

another larger steel bowl, covered with a

clay

glass bowl and sealed with sand. The

oven

glass bowl allows the miners to see the

amalgam decomposition, but this can be

replaced with a metallic bowl. Mercury

condenses on the bowl walls and drops

into the sand. This retort took 10 to 15

minutes to eliminate most mercury from

amalgam using a propane blowtorch or

30 minutes using a bonfire with air-

blower. A serious inconvenient of this,

is that sometimes miners remove the

cover from the crucible while the retort

A clay oven increases retorting temperature

is still hot. When this occurs, miners are

exposed to mercury vapor. This retort cost less than US$ 10 to be built. Miners can recover the

condensed mercury panning the sand placed around the small tray.

Using a glazed-steel (enameled) bowl as crucible, yellow gold is obtained, increasing the

acceptability of miners to the retorting process. The firing structure can also be built in clay as used

in Western Africa for cooking. This process increases the temperature of the bonfire and

concentrates the flames under the bowl.

sand is added

amalgam

to seal

The Retort made of kitchen bowls

UNIDO, Equipment Specification for ASM in Sudan

23

Demonstrating in Sudan the principle of the

Retort made of kitchen bowls in Sudan

kitchen-bowl retort

3.4.3. Conventional Retorts

As mercury forms amalgam with

< 2 cm

almost all metals except iron and

platinum, ordinary retorts are made of

45°

steel. Durable retorts can be made of

6 cm

steels that resist to corrosion and creep.

Ø 1"

1 or ½"

or

,

½"

20 cm long,

Other characteristics to be observed are

2 cm

preferentially of

resistance to thermal expansion,

7 cm

stainless steel

7 cm

structural stability and resistance to

fatigue. In applications where the

environment is not corrosive and the

carbon steel

Ø 1½"

piece is not subjected to mechanical

e.g. SAE 1020

strength, carbon steels with low content

of carbon (0.2 to 0.4%) work well. The

strength of a low-carbon steel reduces

Retort devised by CETEM, Brazil (air-cooled)

from 43 kg/mm² (ambient temperature)

to 25 kg/mm² at 540 °C. A simple and cheap air-cooled retort made of low-steel carbon was devised

by CETEM (see diagram below). In order to increase the mechanical properties at temperatures

above 500 °C addition of 0.45 to 0.65% Mo and 0.3

to 0.6% Mn to a 0.2%C steel increases its strength at

Water cooler

540 °C to 35 kg/mm². Creep resistance doubles with

(cup)

small amounts of Mo and Mn in the steel. Addition

of 5 to 6% Cr increases two or three fold the

strength of low carbon steels. The main commercial

Cr steel is the 410 AISI with 0.15%C.

Retorts can also be made of Cr-Ni austenitic steels

such as AISI 304 (0.08% C, 18-20% Cr, 8-11%Ni)

or 310 (0.25%C, 24-25% Cr, 19-22%Ni). These

steels combine high heat resistance with corrosion

resistance up to temperatures around 900 °C.

Stainless steels are much more costly than C-steels

Retort devised by GTZ in Indonesia

but the retorts are more durable. The aspect of

(water cooled) made of stainless steel

durability must be discussed and cost/benefits must

be presented to miners for their decision.

UNIDO, Equipment Specification for ASM in Sudan

24

The advantage of having stainless steel cooling pipes is that mercury does not stick on the pipe wall

when it cools down. Water-cooled retorts are slightly more efficient in Hg condensation than air-

cooled. GTZ designed a 1½" water-cooled retort, used in Indonesia, in which no water circulation is

needed. The price of these retorts made in Indonesia of stainless steel was around US$ 100 to 120.

A creative idea used in Colombia8 is the encapsulation of a stainless steel (AISI 304) retort using a

cylindrical refractory cement, like a furnace. The capacity of this retort (known as "still"), as