Global Mercury Project

Project EG/GLO/01/G34: Removal of Barriers to Introduction of Cleaner Artisanal Gold Mining and

Extraction Technologies

Information about the Project Sites in

the LAO PDR

Eravanh Boungnaphalom

Assistant to the Country Focal Point

Vientiane, Lao, PDR

October, 2003

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 1

Table of Content

Page

1. Introduction ................................................................................................................................. 2

2. Description of the site ................................................................................................................. 2

2.1. Geographic Information ...................................................................................................... 2

2.2. History of the Mining Activities ......................................................................................... 2

2.3. Community Characteristics ................................................................................................. 2

3. Mining and Processing Characteristics...................................................................................... 4

3.1. Number of Miners in the Country and on the Project Site................................................ 4

3.2. Categories of Miners on the Site......................................................................................... 4

3.3. Gold Production Methods ................................................................................................... 5

3.4. Use of Mercury .................................................................................................................... 6

4. Environmental and Health Impacts............................................................................................ 7

4.1. Visible Environmental Impacts........................................................................................... 8

4.2. Visible health impacts ......................................................................................................... 8

4.3. Main Problems and Bottlenecks to Introduce Cleaner Techniques.................................. 8

4.4. How Stakeholders Are Seeing the Global Mercury Project.............................................. 8

5. Conclusion................................................................................................................................... 8

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 2

1. Introduction

This document is a result of field visits as well as consultation of reports prepared by Earth

Link Systems while conducting the sociological survey at the project site in Luang Prabang

Province, Lao PDR.

2. Description of the site

2.1. Geographic Information

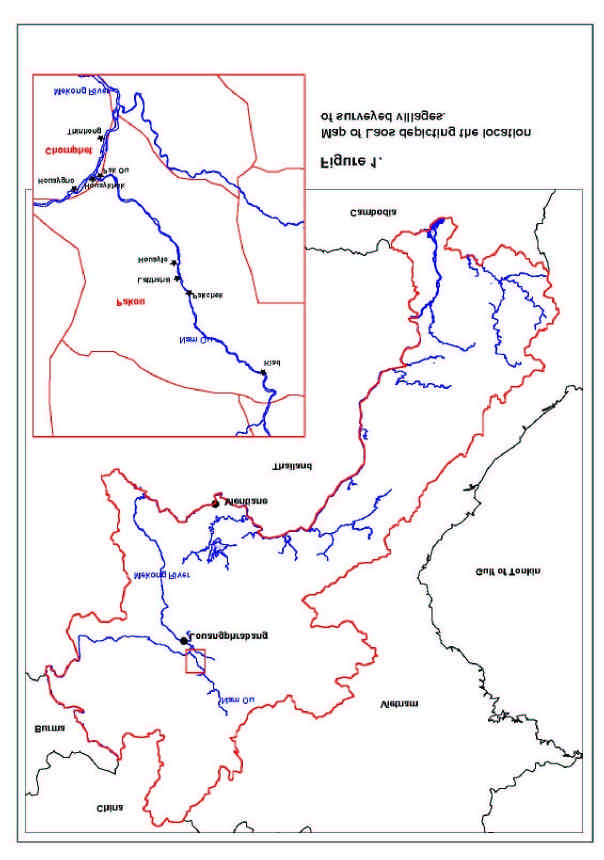

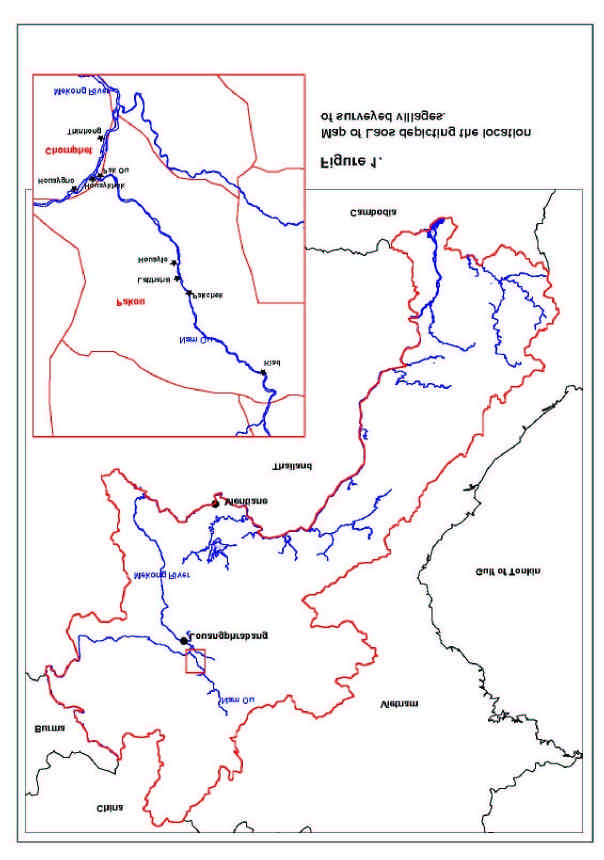

The project area is approximately 25 km from the town of Luang Prabang where there are 8

villages within two districts (figure 1). This region consists predominantly of lowland flood

plains, with altitude ranging from 200 m to 500 m above sea level. The average annual

precipitation is 1200mm and an average annual temperature is approximately 24o C. Most

people are rice farmers. Mekong River and Nam Ou River are the major and vital rivers used

by the community of these 8 villages. The access to the area is either by gravel road or by

boat. This latter makes the area more accessible during the rainy season between June and

September.

2.2. History of the Mining Activities

In this region mining activity particularly panning of gold along the Mekong and Nam Ou

River started in the mid 1970s and was widespread activity by 1980. The peak of the mining

season is between January and April towards the end of the dry season. During this period, the

water level is low, therefore, it is convenient for artisanal gold miners to extract alluvial

sediment. Mining sites are located close to the village. Artisanal gold miners typically have

low technical skills and do not use sophisticated equipment. Generally this is a family affair

and usually 10 to 40 grams of gold (25 to 100 Hun) per annum are produced per household. In

some villages there appears to have been a decline in the industry with a reduction in gold

output. A concentration of activity during the history of mining has possibly reduced the gold

content of the alluvial sediments to marginal levels. It seems that artisanal gold mining

activities are unproductive, uneconomical, poor work safety and unhealthy.

So far there has no evidence of conflict in the mining area. As these miners do not have legal

permits, no tax is collected either. However, all mining activities in Lao PDR are required by

Mining Law to be registered. Small-scale mining gold is considered as an extra work in order

to improve economic outputs.

2.3. Community Characteristics

The predominant occupation of the villages is agriculture with a strong emphasis on rice. This

provides the basic for subsistence as rice is invariably consumed as the staple food. As

population living in rural areas endures harsh conditions in the rice farming activities,

individuals are engaged in activities to generate extra income, such as mining and

manufacturing of handicrafts and textiles to sale for tourists in the nearby town of Luang

Prabang. Facilities and amenities provided in each village vary with village size and access to

the nearby towns, such as Luang Prabang. Some villages were privileged with specific

development projects by international aid agencies.

Local food production includes fishing, wild forest products, rice and other vegetables and

livestock. Food is primarily grown for local consumption, although some cultivated products

and livestock are used for trading with local villagers or in regional market places. Rice is the

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 3

staple food produce throughout the region, and is typically grown away from the river in

paddy fields located on more elevated ground.

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 4

Village populations vary from fewer than 200 persons to almost 650 persons. The population

of eight villages is approximately 3,850 inhabitants, residing in 627 households. The

households in this region are dominated by six different ethnic groups. Of these Lao Loum is

as their principal ethnicity. Leu, Khmu are relatively important ethnic composition of the

region; as the remaining Nhuane, Phutai and Hmong ethnic group are minorities.

Provinces in Lao PDR are divided into administrative districts in which most of districts

comprise more than ten villages. The community structure consists of organization of women,

youths, and so on under the responsibility of a Chief of the village. The primary source of

drinking and cooking water is from different sources: some villages get from mountain

springs, others villages get from shallow well, Nam Ou River and Houay Hong Stream.

Mekong and Ou River as majors rivers in this region people usually use for washing, bathing,

recreational activities and irrigation. Some villages are supplied with electricity and others

have the availability of medical facilities such as pharmacy and dispensary. All villages in the

project site has primary school. Secondary school facilities are only available at the district

centers.

The lack of facilities and relatively high rate of mortality in the region are typically

parameters that indicate of poverty. In this region a measure of literacy varied between 68 and

93% in which most of people had completed primary school. On average men have greater

rate of literacy than women.

3. Mining and Processing Characteristics

3.1. Number of Miners in the Country and on the Project Site

In general, mining activities in the Lao PDR at all levels are quite limited. Artisanal gold

mining at the riverbanks and riverbeds are considered as temporary activities. There is no data

reporting number of artisanal and small-scale miners (ASM), but it is estimated that in the

whole country over 3,000 people are involved in such activity. In the Luang Prabang

Province, it is estimated approximately 1,000 people directly involved in mining, in which

more than 500 live in the project area. In the 8 villages of the project area, more than half of

the population is engaged in ASM.

3.2. Categories of Miners on the Site

Most of the villagers are involved in mining as a part-time jobs usually during the dry season

when the level of water is low. People engaged in this activity are individuals or families,

including men, women and children. In this region, like in many other rural areas in the

country, people have low income (an average of US$ 461 per annum).

Artisanal gold mining in the Lao PDR is not considered illegal. However, the recent increase

of the activity and the use of more sophisticated technologies have indicated that mining can

no longer be considered an artisanal activity and the Government is creating mechanisms to

enforce tax payment.

While men have the responsibility of alluvial mining, women and children carry the ore and

process it in bowls, sluice boxes and pans. The final gold recovery process is usually carried

out at home.

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 5

3.3. Gold Production Methods

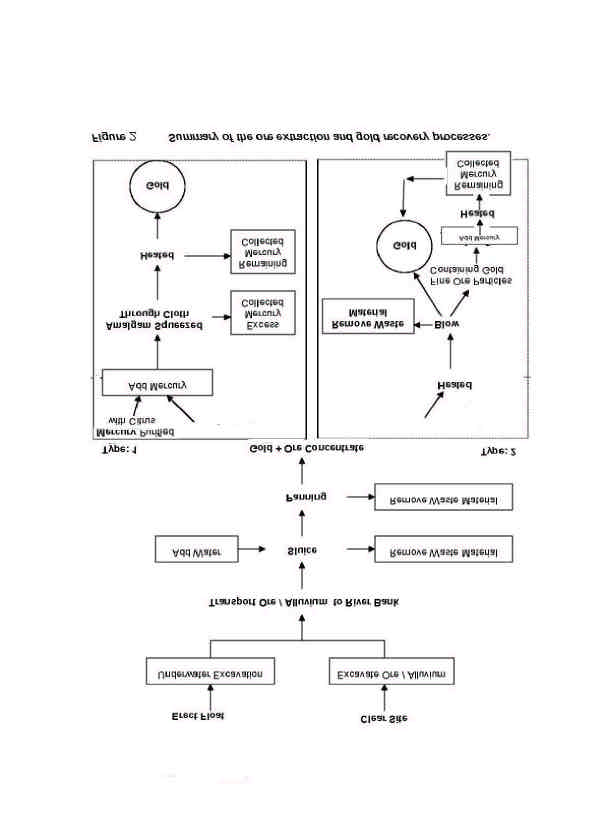

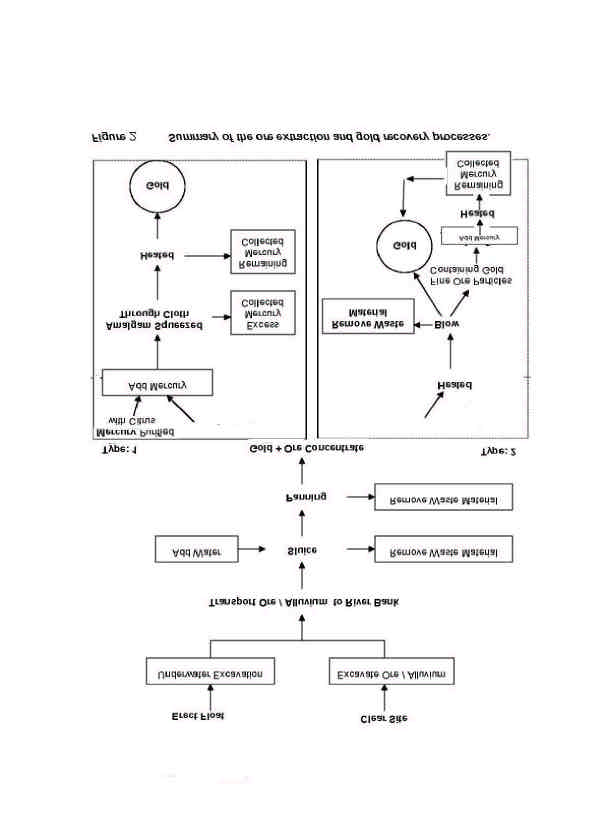

The ore excavation and gold recovery processes vary from villages by the Nam Ou River and

those on the Mekong River (figure 2). The process involves the following steps:

A) Site preparation and removal of the overburden

Riverbanks are cleared of vegetation and large debris. The ground is checked for structural

instability. In underwater excavations, divers is carried out the ore to a large float raft in

which women and children perform sieving and panning. Underwater excavation employs

more specialized tools such as long-handled and chisels and weighted buckets, and may

involve long diving times.

2) Digging pits

The process of alluvial ore extraction is typically carried out by men, and the methods vary

depending on the village and location of the mine. Simple tools (such as shovels, buckets and

long chisels) are used when excavation is performed on the riverbank and seasonal islands, to

loosen the ore and transfer it into buckets for panning and sieving.

3) Transfer of the ore to sluice boxes

The alluvial ore is transferred to the land where it is mixed with water to form a slurry to be

processed in sluice boxes lined with a thick sack cloth to retain gold and other dense particles.

The sack lining is then removed and washed in a bowl where a secondary concentration

occurs. The final concentrate consists of dark, heavy particles.

4) Panning and sieving of the ore

Women and children pan and sieve the remaining material on the riverbank or on floats using

head pans, shallow bowls and sieves made from fishing nets. In this way the ore is

disaggregated further leaving a gold and heavy mineral concentrate (e.g. magnetite).

5a) Forming an amalgam in villages that use mercury

If the village uses mercury in the mining process, it is added to the gold/heavy mineral

concentrate. The gold particles are trapped by the mercury forming an amalgam.

5b) Heating and blowing in villages that do not use mercury

In some villages, Hg is not used. Following the panning and sieving process, the gold/heavy

mineral concentrate is heated to dry the concentrate and the heavy minerals are separated with

a gentle blowing. In some villages using the heating and blowing process, a small portion of

mercury is used to amalgamate the residual gold from the heavy mineral part. In these cases, a

very small volume of mercury is used.

6) Removing excess mercury

The mercury-gold amalgam is then squeezed through a fine cloth, and the excess mercury is

collected for re-use.

7) Heating and mercury evaporation

The amalgam is then heated and mercury evaporated and collected in a short bamboo tube,

erected above the stove. To collect the mercury from the amalgam, the villager put a bowl and

also a bamboo tube in the vertical position around the amalgam. Then the bowl with amalgam

is burned and mercury evaporates and condenses on walls in the interior of the bamboo tube.

The gold remains in the bowl and it is collected to be sold. The condensed mercury is

removed with a chicken feather to be re-used. The amalgam decomposition does not typically

occur everyday. Rather, amalgam is stored until a suitable quantity is accumulated.

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 6

Depending on the village and gold content of the alluvial ore, this might be on weekly or

monthly basis. Women and children typically carry out this process in the home. Retorts are

not used in the region.

8) Recovering Hg coalescence

Lime juice is used to recover Hg coalescence and remove impurities (re-activate Hg surface).

9) Gold sale

Gold resulting from ASM is sold directly to gold buyers who visit the villages once a week

during the mining season. The gold buyers typically come from Luang Prabang and

afterwards they sell the gold to larger dealerships. Between US$ 2.8 and US$ 3.3 are paid for

one Hun of gold (approximately 0.39 grams), depending on its purity (e.g. its mercury/silver

content). This is US$ 7.18 to US$ 8.46/g or at least US$ 100/oz less than the official gold

price. When gold contains a large quantity of mercury or other impurities, the gold buyer

requires further burning (or refining) prior to sale at a regional market or directly to a jeweler.

The gold buyers also provide the villagers with mercury.

10) Gold production

Four villages do not use the mercury (Ban Kiad, Ban Pakchek, Ban Pak Ou, Ban Thinhong)

and they produce about 1,564 g of gold per annum.

The amount of gold produced by amalgamation is about 3,236g/a.

Typically, households involved in gold mining produce between 10 and 40 grams of gold per

year (an average of approximately 24 grams). This corresponds to and average of 0.6 kg Au/a

per village or approximately 4.8 kg of gold produced per annum in the eight villages at the

project area.

3.4. Use of Mercury

The mining process and use of mercury vary depending on the village. The villages on the

Nam Ou River do not typically use mercury. Miners use gravity separation and the heating

and blowing process. However, in the villages along the Mekong River, mercury is

traditionally added at the final panning stage to form an amalgam with alluvial gold particles.

The local miners are usually careful to recover mercury as much as possible from the related

process because of the loss of mercury means loss of the gold. Even that, mainly the loss of

mercury occurs during heating in open air as vapor is released into the atmosphere. In the

eight villages it is estimated that approximately 1,600 g/a of mercury lost to the environment.

The Au produced to Hg lost ratio is approximately 0.3

The cost of one Hong (38 g) of mercury is about one Hun of gold (one Hun of gold

approximately 0.39 grams) which is equivalent to 30,000 (US$2.85) to 35,000 (US$3.33)

Kips (1US$=10,500 Kips). This makes the cost of 1 kg of Hg US$ 75 to 87.6 which is

extremely expensive compared with the international price of Hg of US$ 4/kg. This must be

an incentive for miners to recycle Hg. Usually villagers buy mercury from the gold buyer..

The high cost of Hg supposes to be an incentive for its recovery and re-use, but it is estimated

that only half of those households burning amalgam make an attempt of recovering the

vaporized mercury, and out of these, it is estimated that only 75% are successful (i.e. one

quarter of the mercury is lost). This recovery is typically carried out in homes. The hazard

caused by Hg-vapor inhalation is evident.

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 7

4. Environmental and Health Impacts

It is concerned about the short and long terms effects of environmental pollution from mining

in particular the effects of mercury on agriculture, fishery and health of the communities.

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 8

Common impacts already being observed include severe erosion, loss of vegetation, water

siltation and toxic metal discharge.

4.1. Visible Environmental Impacts

Visible Environmental Impacts from ASM activities especially in the project region are not so

significant. However, some aspects of mining process have been observed as potentially

degrading the environment. For example, when alluvial ore is extracted this causes water

siltation. The same is observed when the riverbanks are mined. Erosion of the river margins is

also observed when the vegetation is removed from the shores. Mercury contamination is not

a visible impact when miners add Hg into the pans in the river. Mercury-contaminated tailings

are directly discharged into the rivers. It is also noticeable the emission of Hg vapors when the

amalgam is burned in open pans. There is no data about Hg concentration in aquatic biota in

the region.

4.2. Visible health impacts

Malaria is typically the most common disease in the region, followed by acute respiratory

illness and diarrhea. There is no recorded of health impacts directly attributed to ASM

activities in this region. However, it is noticeable in the villages, the low level of awareness of

Hg impacts in particular those related to exposure to Hg vapor.

Observing the miner's behavior in the region, one can notice that there are different roles for

men and women. Men just deal with the alluvial ore extraction and they are likely less

exposed to mercury than women. Those, together with their children are those handling

mercury in the gold process. However, no apparent symptoms of mercury poisoning are

identified, and a detailed heath survey is needed to confirm any neurological effect. Only a

small number of households recorded a general perception of risk, and generally lacked any

data or specific information on what hazards mercury can cause or how these hazards can be

avoid. The possibility of mercury methylation and consequent bioaccumulation into the

aquatic life is evident and must be further investigated. This involves a potential risk for the

riparian villagers who have fish as the main source of protein.

4.3. Main Problems and Bottlenecks to Introduce Cleaner Techniques

Awareness of the potential health implications of mercury exposure is invariably low. There

is lack of information about the hazards of handling mercury. Until the date, there is no

environmental and health assessment of Hg in the region as well as how this is affecting .

nearby water bodies. Technical knowledge and technical support is not reaching the miners.

Appropriate technologies are badly needed as the miner's budget to invest in new techniques

is extremely limited.

4.4. How Stakeholders Are Seeing the Global Mercury Project

Global Mercury Project is a very new project in the Lao PDR. Just few people know about

this project. The project came to the public attention during the sociological study. In this

case, part of the public in the villages of the project site became aware of the project goals.

Stakeholder involvement should be intensified especially in the issues dealing with health.

Safety and increase of gold production should be in the list of priorities for the region.

5. Conclusion

Agriculture is the principal occupation of village inhabitants in the project region. Artisanal

and small scale gold mining (ASM) activities in Lao PDR is considered as a seasonal activity,

GEF/UNDP/UNIDO - Information about ASM in Lao PDR 9

but in many instances it appears to be an important source of additional income for rural

communities. This is consistent with the low income of the rural communities in the project

area (average of US$ 461 per annum). In the Luang Prabang Province, it is estimated

approximately 1,000 people directly involved in mining. In the eight villages of the project

area, more than half of the population is engaged in ASM.

The gold production in the eight villages of the project is around 10 to 40 grams of gold per

year (an average of approximately 24 grams) per household. This corresponds to and average

of 0.6 kg Au/a per village or approximately 4.8 kg of gold/a produced in the eight villages at

the project area.

It seems that the numbers of artisanal gold miners using mercury to recover gold extraction is

reducing. This is definitely due to the high cost of Hg in the region (as high as US$ 350/kg)

and limited access of miners to this reagent. This is an interesting situation to promote the use

of retorts. The home made process to condense Hg vapors using bamboo tubes can definitely

be improved and used as a local solution to increase Hg recycling. In the eight villages of the

project site, it is estimated that approximately 1,600 g is emitted per annum to the

environment.

Despite no visible symptoms of mercurialism has been reported, artisanal mining has

potential of resulting severe impacts to the villagers health. The main risk group consists of

women and children, as they are the ones in charge of the amalgamation and process. The

effects of mercury in the environment are still unknown. Awareness campaigns and

demonstration of appropriate technologies are badly needed.