UNITED NATIONS INDUSTRIAL DEVELOPMENT ORGANIZATION

Removal of Barriers to Introduction of Cleaner Artisanal Gold Mining and

Extraction Technologies

GMP IN BRAZIL

FINAL SUMMARY REPORT

ITAITUBA STATE OF PARÁ - BRAZIL

DECEMBER 2007

Global Mercury Project, Coordination Unit, Vienna

Pablo Huidobro, Project Manager, UNIDO

Marcello M. Veiga, Chief Technical Advisor, UNIDO

Svitlana Adler, Administrative Assistant, UNIDO

Authors (UNIDO Consultants)

Rodolfo N. Sousa 1, Marcello M. Veiga1

Contributions (UNIDO Consultants)

Carlos Ribeiro2, Lygia Lobo3

Editing

Rodolfo N. Sousa 1, Marcello M. Veiga1

Pictures

Rodolfo N. Sousa 1, Marcello M. Veiga1

1 University of British Columbia, Norman B. Keevil Institute of Mining Engineering,

6350 Stores Rd., V6T 1Z4, Vancouver, BC, Canada

2 University Federal of Vicosa-MG, Brazil

3 Petro Skills CCCT Consulting Co. Rio de Janeiro-RJ, Brazil

Disclaimer

The designations employed and the presentation of the material in this document do not imply

the expression of any opinion whatsoever of the Secretariat of the United Nations Industrial

Development Organization (UNIDO) concerning the legal status of any country, territory, city or

area of its authorities, or concerning the delimitation of its frontiers or boundaries. Mention of

company names and commercial products does not imply the endorsement of UNIDO.

- 2 -

TABLE OF CONTENTS

ABSTRACT ............................................................................................................................................................ - 5 -

1

INTRODUCTION ......................................................................................................................................... - 6 -

2

OBJECTIVES OF GMP............................................................................................................................... - 7 -

3

THE USE OF MERCURY IN THE ARTISANAL SMALL-SCALE GOLD MINING (ASM)............. - 7 -

4

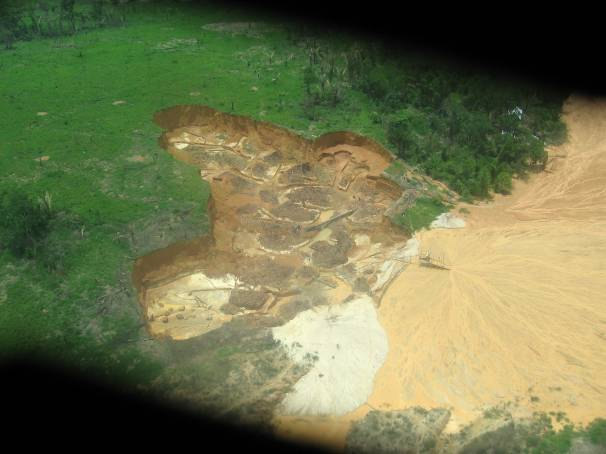

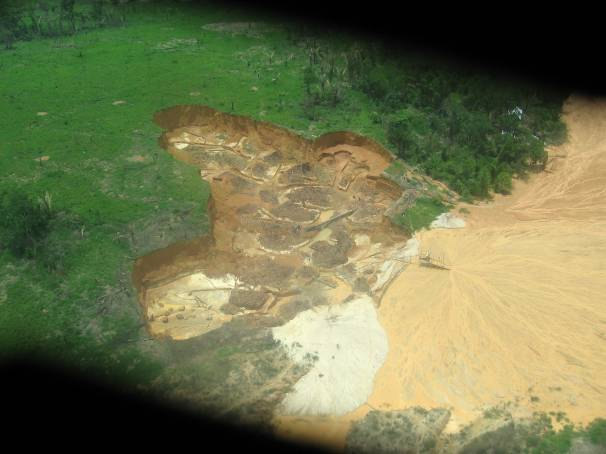

SITE LOCATION: TAPAJOS RIVER BASIN ITAITUBA BRAZIL ............................................... - 8 -

5

THE DIAGNOSTIC PHASE SOCIO, ENVIRONMENTAL AND HEALTH ASSESSMENT ........ - 10 -

5.1 THE ENVIRONMENTAL ASSESSMENT STUDY .............................................................................................. - 10 -

5.2 THE HEALTH ASSESSMENT STUDY ............................................................................................................. - 11 -

5.3 SOCIO-ECONOMIC ASPECTS ....................................................................................................................... - 12 -

6

POLICY AND REGULATIONS ............................................................................................................... - 13 -

6.1 STUDY ON THE ENVIRONMENTAL LEGISLATION ADDRESSING MINING IN PROTECTED AREAS .................... - 14 -

6.2 GMP INFLUENCE ON REGIONAL LEGISLATION ........................................................................................... - 16 -

6.3 MICRO CREDIT INITIATIVE ........................................................................................................................ - 17 -

6.3.1

Micro financing in Brazil ................................................................................................................ - 18 -

6.3.2

Institutional Framework and Regulation ........................................................................................ - 20 -

6.3.3

Recommendations on the GMP Micro Credit Program for Brazil ................................................. - 21 -

7

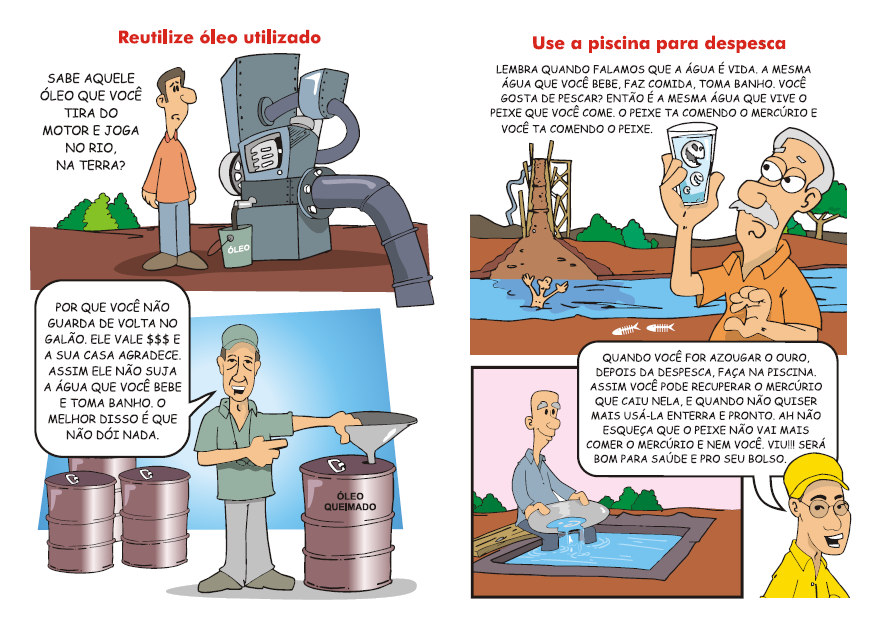

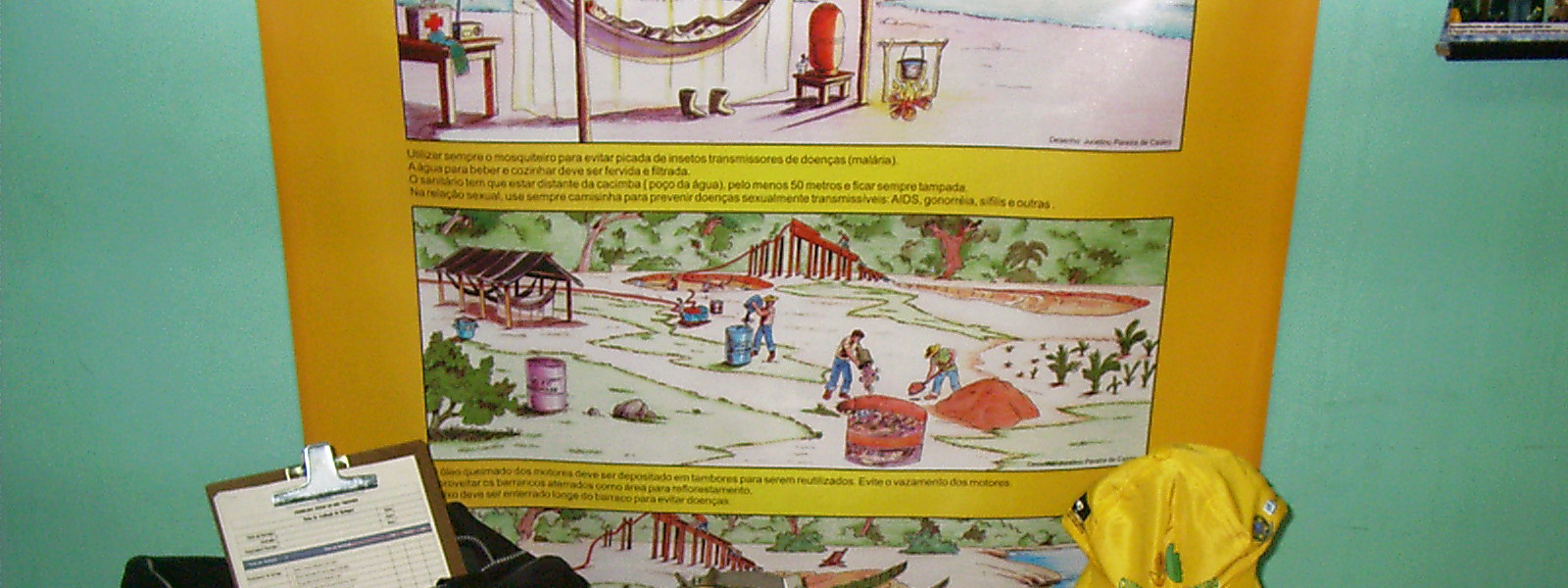

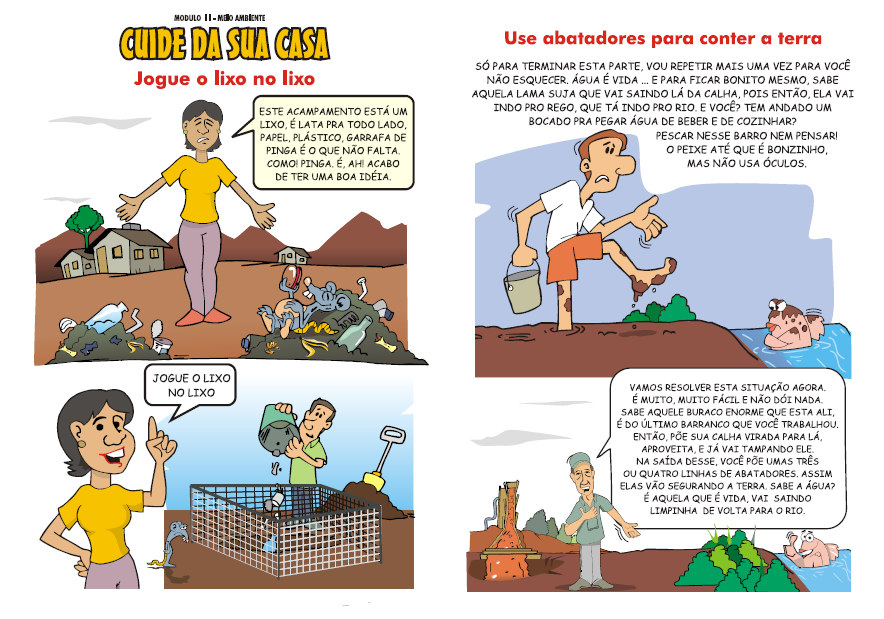

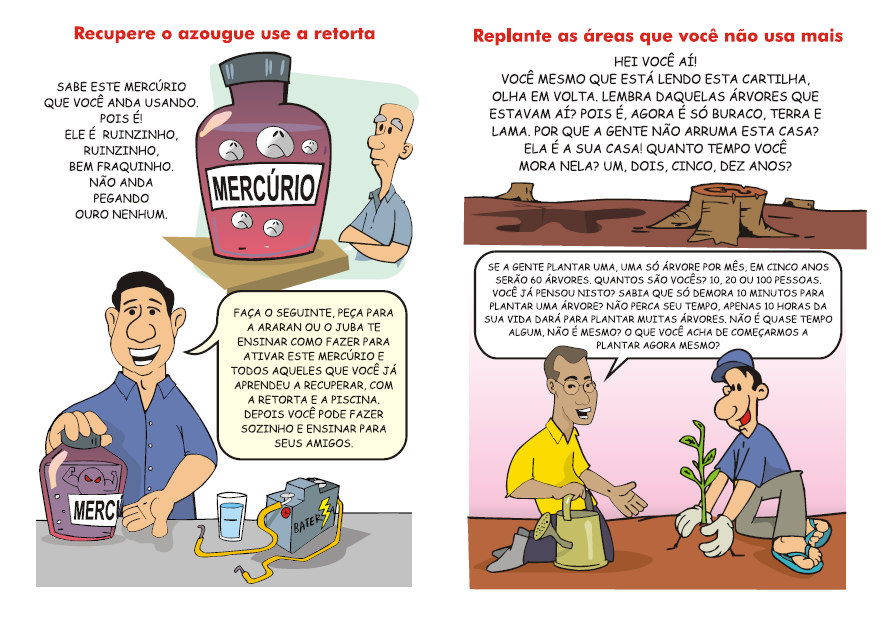

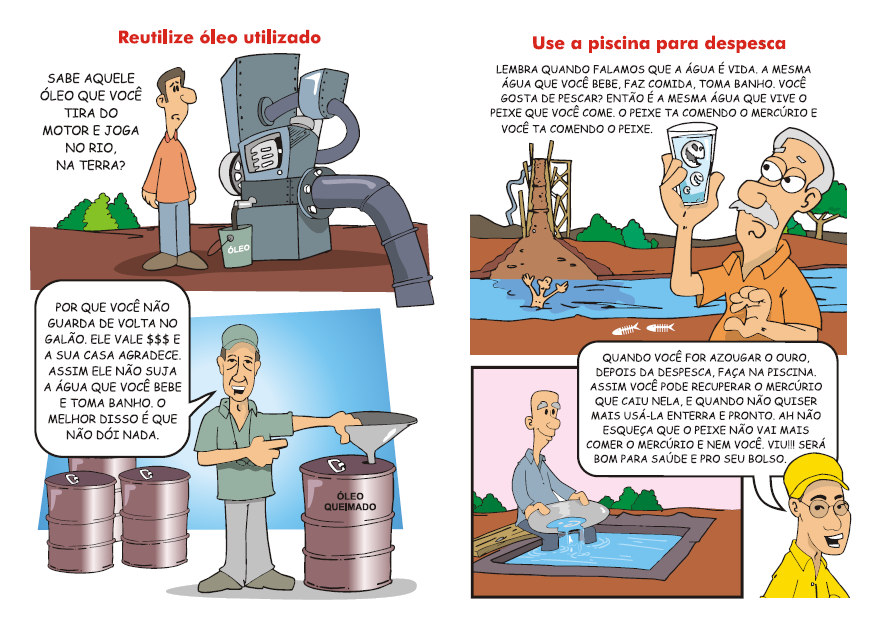

FIELD ACTIONS - TRAINING PROGRAM AND AWARENESS CAMPAIGN ............................... - 24 -

7.1 THE TRAINING PROGRAM IMPLEMENTATION ............................................................................................. - 25 -

7.2 GENERAL MATRIX OF EVALUATION ........................................................................................................... - 26 -

7.3 SELECTING PERFORMANCE INDICATORS .................................................................................................... - 28 -

7.4 EVALUATION OF EFFECTIVENESS .............................................................................................................. - 29 -

7.5 THE CRITICAL IMPORTANCE OF SELECTING CONSISTENT INDICATORS ....................................................... - 29 -

7.6 PERFORMANCE INDICATORS ..................................................................................................................... - 30 -

7.6.1

Legalization of mining sites ("garimpos") ..................................................................................... - 30 -

7.6.2

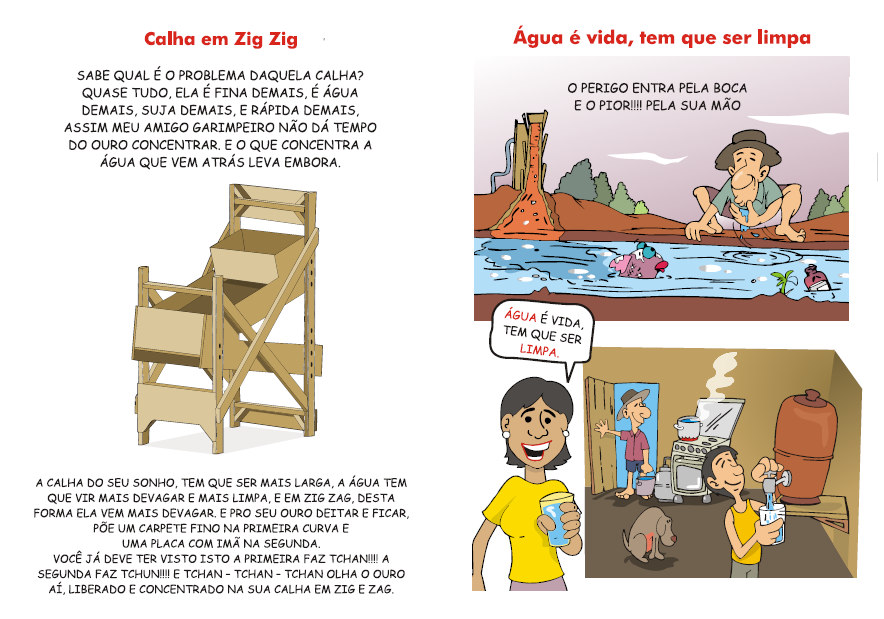

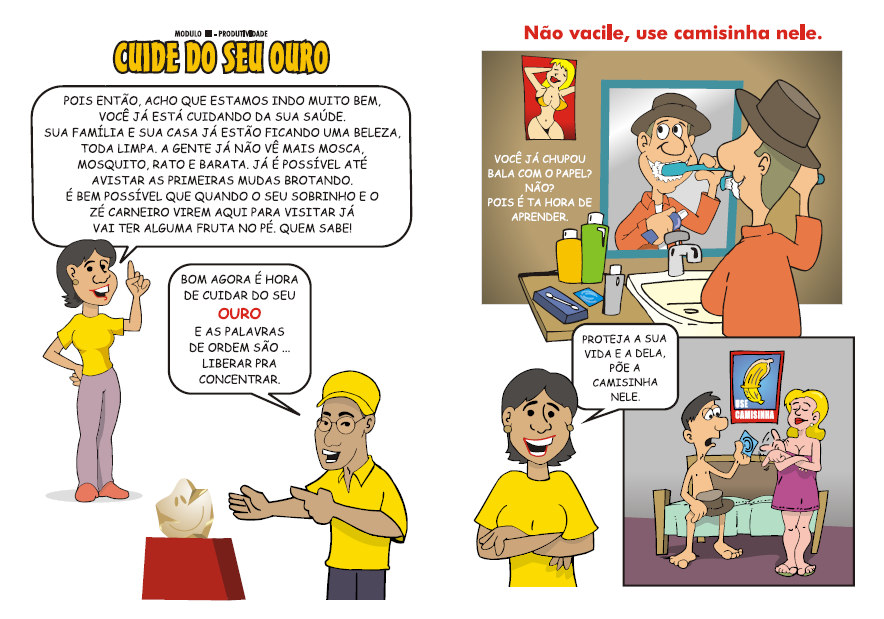

Techniques and processes to increase gold recovery ..................................................................... - 30 -

7.6.3

Protection of water and forest ........................................................................................................ - 31 -

7.6.4

Use of mercury ................................................................................................................................ - 32 -

7.6.5

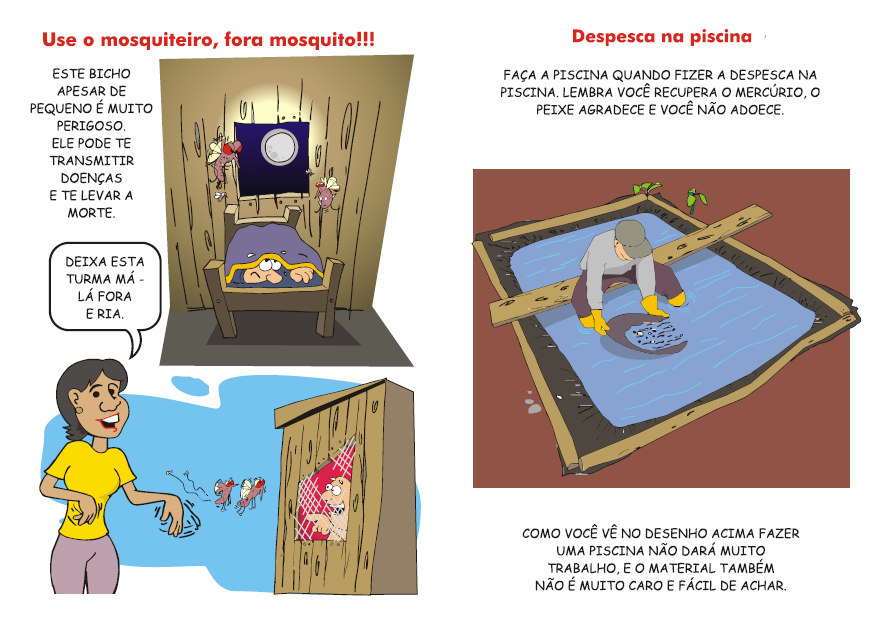

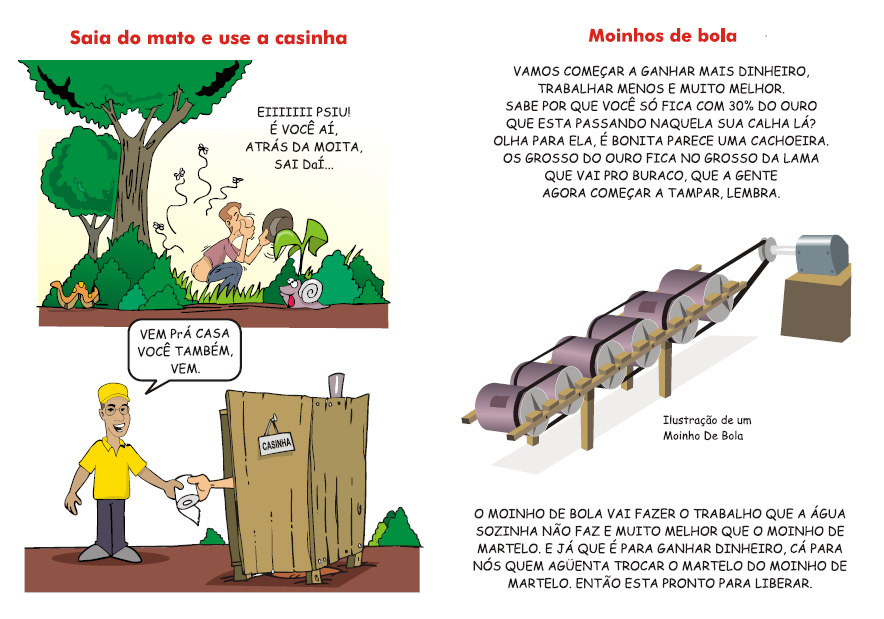

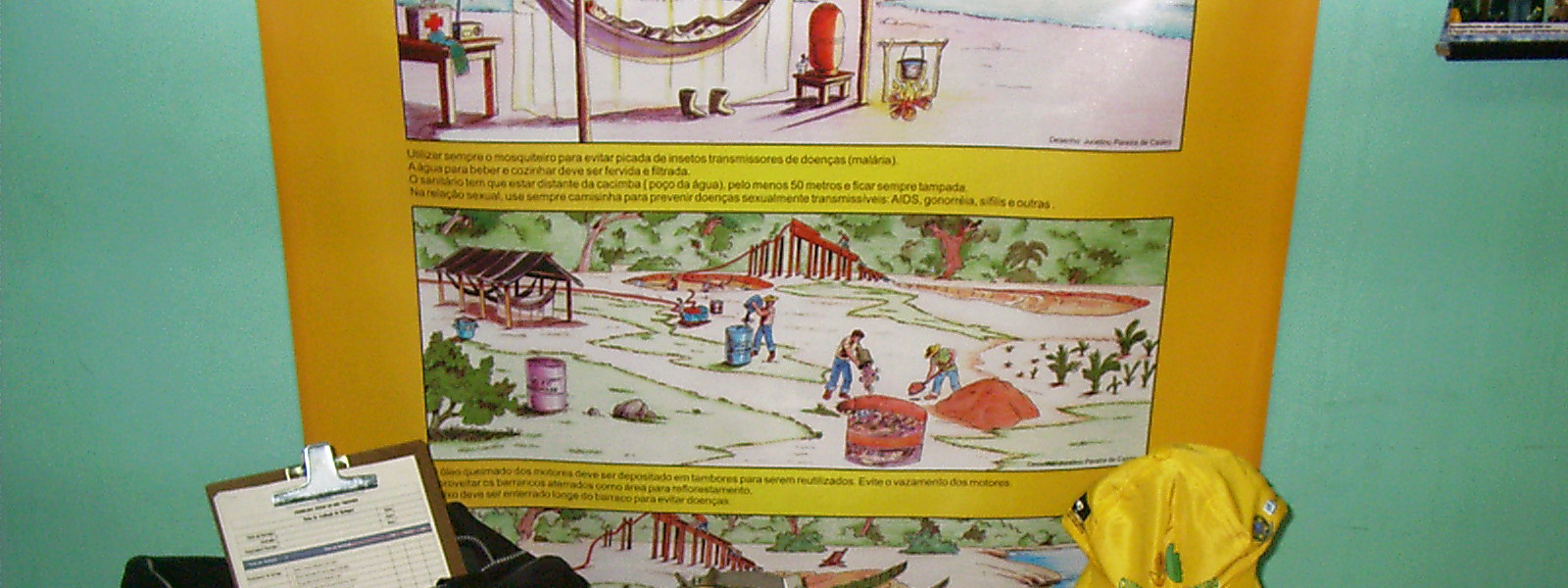

Health and sanitation...................................................................................................................... - 32 -

7.7 TECHNOLOGY, EQUIPMENT AND PILOT PLANT FOR TESTS AND TRAINING (TDU) ...................................... - 33 -

7.7.1

Ball mill for cyanidation tests ......................................................................................................... - 34 -

7.7.2

Falcon Centrifuges designed for artisanal mining ......................................................................... - 35 -

7.7.3

Fume hoods in gold shops in Itaituba ............................................................................................. - 35 -

7.7.4

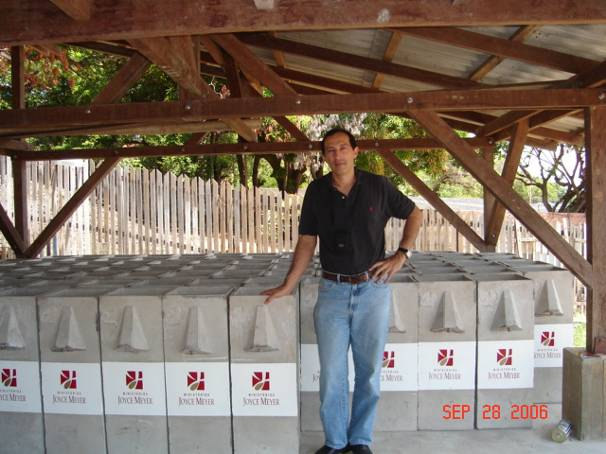

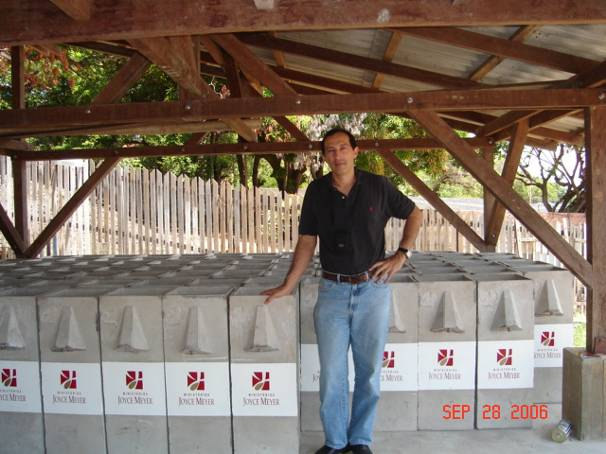

Biosand drinking water filters ........................................................................................................ - 36 -

8

PRACTICAL RESULTS OF GMP IN BRAZIL ..................................................................................... - 37 -

9

COSTS OF TRAINING, EQUIPMENT AND AWARENESS CAMPAIGN ........................................ - 42 -

10

ECONOMICAL ASPECTS IN ARTISANAL MINING IN TAPAJOS REGION ............................... - 43 -

11

ESTIMATED IMPACT ON MERCURY REDUCTION ........................................................................ - 45 -

12

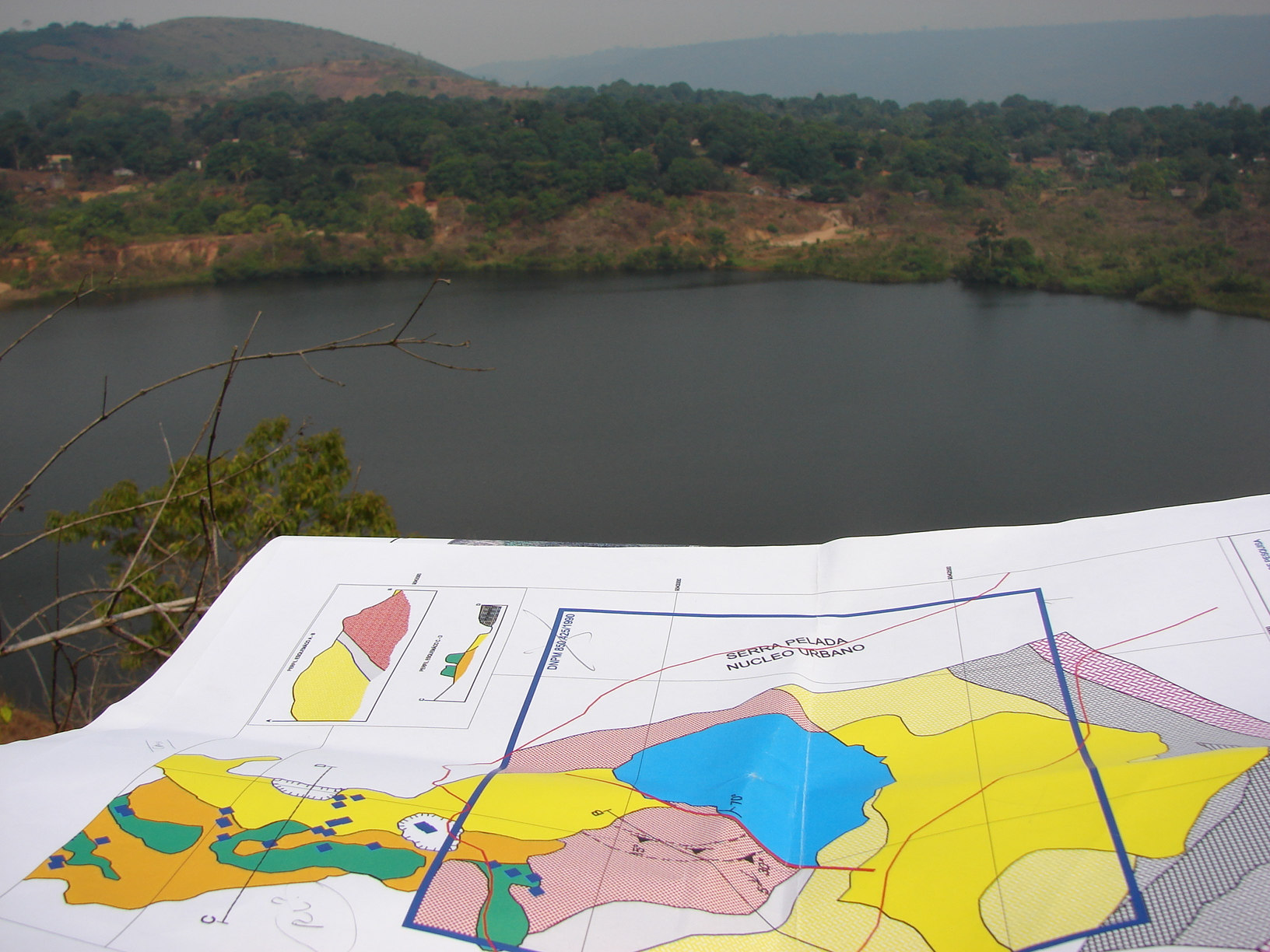

ASSESSMENT OF NEW POTENTIAL SITE FOR GMP2: SERRA PELADA .................................. - 46 -

13

SUMMARIZING THE MAIN ACCOMPLISHMENTS OF THE GMP IN BRAZIL ......................... - 47 -

- 3 -

14

LESSONS LEARNED AND CONCLUSIONS ........................................................................................ - 49 -

15

EXPECTATIONS FOR A POTENTIAL GMP II ................................................................................... - 50 -

16

FOLLOW UP .............................................................................................................................................. - 50 -

17

REFERENCES ............................................................................................................................................ - 51 -

LIST OF TABLES

TABLE 1: MINERS' GENERAL PROFILE ........................................................................................................................ - 12 -

TABLE 2: SWOT MATRIX FOR A MICROCREDIT PROGRAM FOR THE GMP IN BRAZIL ..................................................... - 22 -

TABLE 3: RELATIONSHIP BETWEEN OBJECTIVES, ACTIONS AND PERFORMANCE INDICATORS ....................................... - 28 -

TABLE 4: ABSOLUTE IMPROVEMENT (AI) AND DEGREE OF ACCOMPLISHMENT (DA) AFTER TRAINING.......................... - 38 -

TABLE 5: ABSOLUTE IMPROVEMENT AND DEGREE ACCOMPLISHMENT BY GENERAL OBJECTIVE ................................... - 40 -

TABLE 6: ACCOUNTING / COSTS OF TRAINING, EQUIPMENT AND AWARENESS CAMPAIGN ........................................ - 42 -

TABLE 7: EXAMPLE OF PRACTICAL FINANCE CONTROL FOR GARIMPO ..................................................................... - 44 -

TABLE 8: PROFITABILITY CALCULATED FOR A TYPICAL PIT ("BARRANCO") ............................................................ - 45 -

LIST OF FIGURES

FIGURE 1: LOCATION OF MINING SITES IN ITAITUBA BRAZIL. (RIBEIRO, 2006) .......................................................... - 9 -

FIGURE 2: RESULTS OF INDICATORS, SHOWING CONFORMITY BEFORE AND AFTER THE TRAINING ................................. - 39 -

FIGURE 3: RESULTS OF OBJECTIVES, SHOWING CONFORMITY BEFORE AND AFTER THE TRAINING ................................. - 40 -

FIGURE 4: DISTRIBUTION OF GARIMPOS PER CLASSES OF GRADES .............................................................................. - 41 -

- 4 -

Abstract

Artisanal small scale gold mining is the largest anthropogenic source of mercury release in

the environment. It is estimated at over 1000 tonnes of Hg/a are released. This activity involves

directly and indirectly over 100 millions people worldwide and almost 10% of this contingent is

located in the Amazon. Brazil produces 30 tonnes of gold a year (8 tonnes in the Tapajos river

basin region), and this process consumes 40 tonnes of mercury. Besides mercury contamination

the uncontrolled ASM also causes siltation of rivers and flora and fauna destruction.

In 2002 the UNIDO (United Nations for the Industrial Development Organization)

implemented the GMP (Global Mercury Project) in Brazil. This project aims to reduce mercury

emissions through the introduction of cheap and simple technologies, as well through health and

environmental awareness. In Brazil GMP has liaised with seven other local agencies and

performs its activities under the emblem "Take of your treasure more gold and less mercury".

During the diagnosis phase a series of studies were implemented in order to evaluate the

seriousness of mercury contamination as well to establish the magnitude of the peripheral

problems. A social economic study was conducted to analyze the history, characteristics and

dynamics of the chosen mining communities. A legal study was also conducted aiming to

identify the existent legal framework and regulation of the mining and related activities. An

environmental and health assessment was also conducted, generating instruments to evaluate the

problems under its political, social, health and environmental dimensions.

The environmental and health assessments showed levels of mercury in soil, sediments, fish,

blood, urine and hair far beyond the acceptable levels. The problems of mercury contamination

were amplified by the use of cyanidation. As the living conditions are very basic and the

population's way of living is very similar in the Tapajos basin river, the results obtained in the

selected sites of study can be assumed to represent a larger area. The main source of

contamination is Hg vapour inhalation during the amalgam burning and the ingestion of

contaminated fishes. The main symptoms of contamination included tremors, ataxia and

concentration problems.

The lessons learned from the studies in Sao Chico and Creporizinho indicated that rather

than only avoiding eating carnivorous fish, which are source of available vitamin and part of the

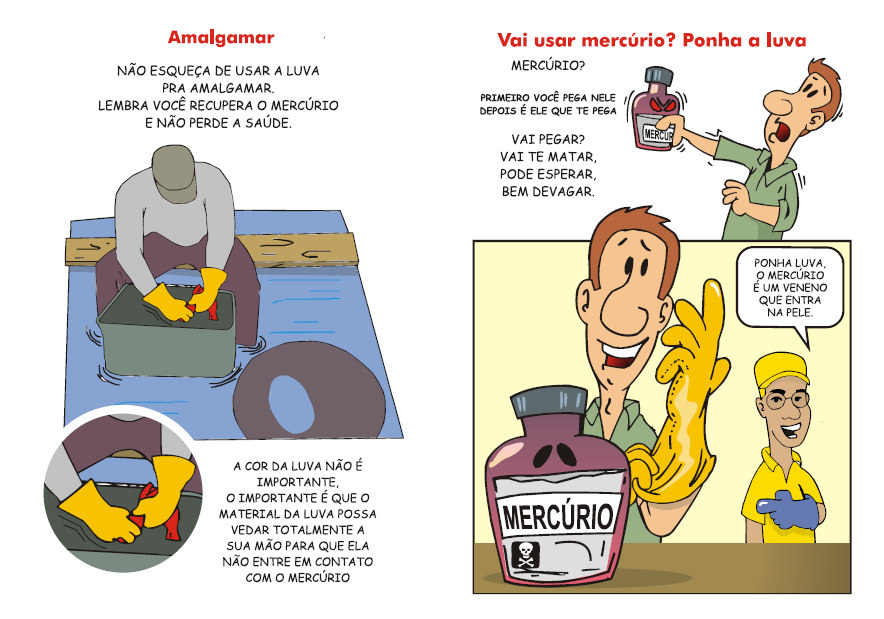

local eating habit, the focus should be the reduction of contamination. Practices such as the

amalgamation of the concentrate instead of the whole ore, the confinement of mercury in canvas

pools during the amalgamation, and the use of retorts, could drastically reduce the level of

contamination of soil, sediments, fish and miners.

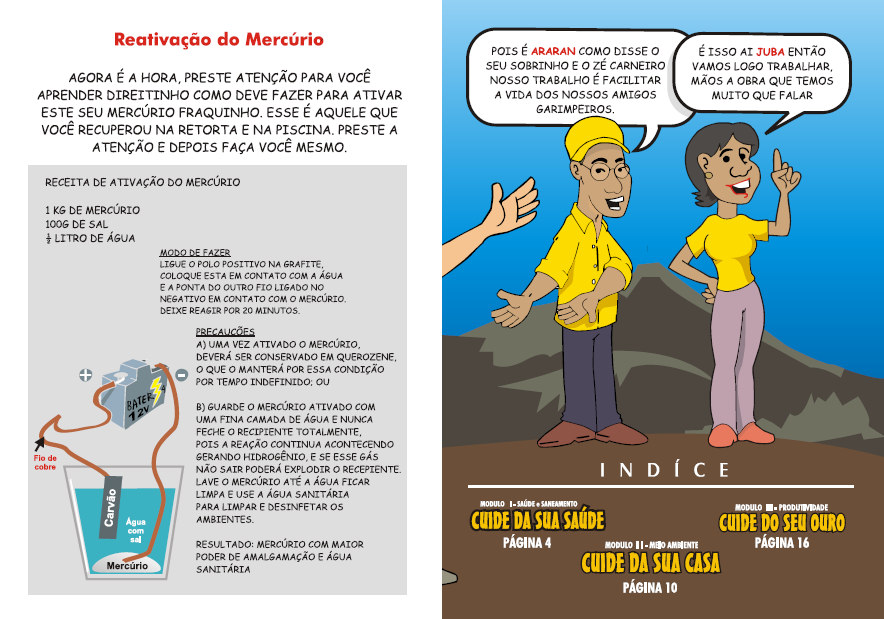

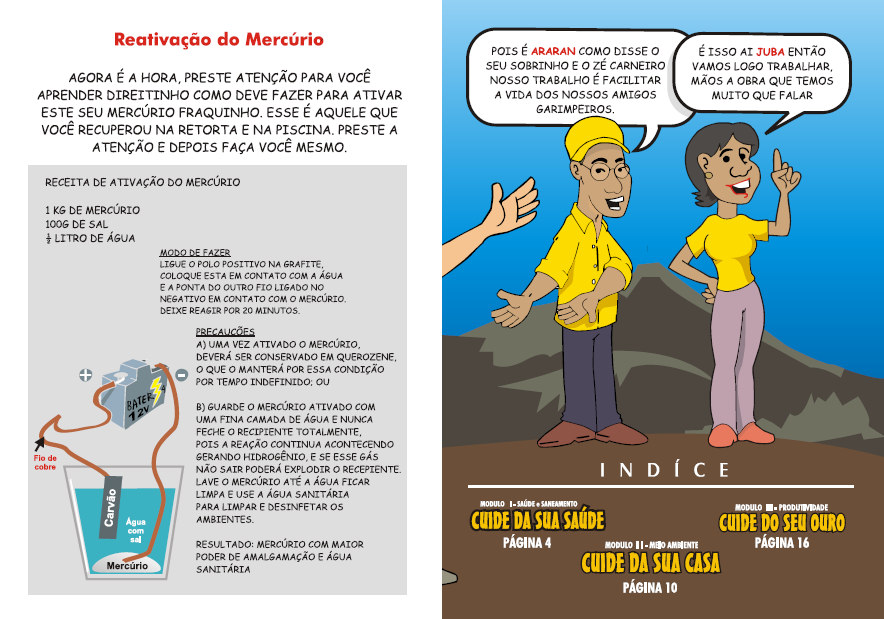

The program implemented in the Tapajos River in the Amazon basin resulted in the training

of 4,200 miners in 141 mining sites and communities in the municipality of Itaituba. Among

good practices implemented by the miners, the main highlights are: the processes of gold

concentration ("zig-zag" sluice boxes, centrifuge), process of amalgamation in canvas pool,

electrolytic activation of mercury for reduction of losses during amalgamation, equipments of

amalgamation of larger efficiency, introduction of low cost retorts for recycling and reducing

mercury consumption, refilling of old pits and rehabilitation of degraded areas and the

introduction of biological filters for filtering and disinfecting water. Through the establishment

of indicators of performance, the areas were evaluated both before and after the training

program, showing an overall improvement of 28.8%.

- 5 -

1

Introduction

Artisanal small scale gold mining (ASM), locally known as "garimpo" is the largest source

of mercury release in the environment from intentional use sources, estimated at over 1000

tonnes/a. According to UNIDO (United Nations for the Industrial Development Organization)

about 100 million people are directly or indirectly involved in the ASM worldwide and about

10% of this contingent is located in the Amazon (Veiga & Baker, 2004). Brazil produces 30

tonnes of gold a year (8 tonnes in the Tapajos river basin region), and it is estimated that this

process consumes 40 tonnes of mercury (DNPM, 2006). Besides the contamination of mercury

ASM also causes siltation of the rivers (sediments in suspension) and flora and fauna destruction.

In 2002 Brazil was chosen for the implementation of an UNIDO initiative titled GMP

(Global Mercury Project). This project aims to reduce mercury emission through the introduction

of simple technologies, education campaigns and environmental awareness. The selected

location in Brazil was the Tapajos river basin, where 40,000 miners work in the extraction of

alluvial and primary gold. According to SEMMA (Itaituba Environmental Agency) the area of

Tapajos is one of the largest concentrations of mines of the world, containing more than 2000

mines and estimated 432 landing strips (Feijão, 1992) (Silva, 2001).

Worldwide, environmental and health problems related to small-scale gold mining have not

received high priority from governments and agencies over the time, so the problem has grown

and reached proportions as never seen before. The general characteristics of the problem tend to

be similar in developing countries as they all face poverty. Therefore, fighting against pollution

requires a combination of coordinated actions that actually fight poverty.

The implementation of the GMP (Global Mercury Project) in 2002 represented a significant

contribution to mitigate the impacts resulting in uncontrolled small scale gold mining. Since

then, GMP has demonstrated ways of overcoming barriers to the adoption of consistent practices,

which include correct waste disposal practices, measures to prevent mercury pollution,

protection of water streams, protection of miners' health, and introduction of techniques to

increase gold recovery rates, consequently increasing miners' revenue.

GMP has supported the implementation of technologies that represent both economic and

environmental advances, such as the use of retorts and fume hoods, reactivation and recycling of

mercury, use of ball mills to liberate more gold, efficient sluice boxes to increase recovery.

Besides Brazil, GMP also operates in other developing countries, including Sudan, Tanzania,

Zimbabwe, Indonesia and Laos. These countries were chosen based on their importance in terms

of gold mining activities, the use of mercury, their location and the existence of important

transboundary river or lake basins. In addition to that, GMP supported the development of

regulatory mechanisms to enable local governments to assess and control environmental impacts

resulting from ASM activities. The strategies employed in these countries included the

preliminary investigations in order to evaluate ASM activities through social economic studies,

legal framework assessments, and the implementation of massive training programs.

The results reached in these countries are substantial, and it would be more difficult for local

governmental agencies and NGOs to finance the programs themselves, due to the complexity of

the problems and their lack of appropriate resources. The partnership between GMP and local

agencies has been proven to be the best mechanism to ensure the effective implementation of

- 6 -

such programs. In Brazil GMP has liaised with seven other local agencies and performs its

activities under the emblem "Take of your treasure more gold and less mercury".

2

Objectives of GMP

Overall, the ultimate goals of the GMP are (1) to reduce mercury pollution caused by

artisanal miners, thereby protecting human health and local water bodies; (2) to introduce cleaner

technologies for gold extraction and develop mechanisms to allow this technology to be supplied

locally; (3) to train local miners and develop community awareness about all environmental

impacts derived from artisanal mining; (4) to reduce informality by enhancing the legalization of

the mining activities; (5) help miners to improve their overall health and sanitation by providing

training of planning and control of their activities, multiplying the "best practices".

The term introduction of new technology does not necessarily mean to import a non-existent

technology to the mining sites. Due to lack of adequate communication, the existent best

practices are not properly accessed by all miners, and GMP's trainer team acts to "democratize"

existent best practices, extending them to remote areas.

3

The use of mercury in the artisanal small-scale gold mining (ASM)

Around 70% of the mercury used by ASM is lost in the aquatic system, and one of the main

reasons for this loss is the use of the copper plates for amalgamation of the whole ore. Around 20

to 30% of the mercury is lost to the atmosphere and measurements made in the local area have

proved the contamination of miners, their families and the neighboring communities (Veiga &

Baker, 2004).

The amalgamation of the whole ore using copper plates is responsible for the largest

mercury loss in the mines. Around 2 to 3 times more mercury is lost when the whole ore is

amalgamated, compared to only a small portion of concentrate that is amalgamated in the sluice

boxes or centrifuges (Veiga & Hinton, 2002). The contaminated tailings with 50 to 200 ppm Hg

that leave the cooper plates go into the water streams and are subject to the oxidation and

methylation of mercury, which can be transformed in a more poisonous form, methyl mercury

Meech et al., 1998). This is why in addition to developing environmental awareness it is crucial

to work towards the elimination of practices such as the amalgamation of the whole ore, instead

of only the concentrate. Simple and effective orientations developing these goals are part of the

GMP training programs.

Some miners use mercury contaminated tailings to remove part of the residual gold by

cyanidation. The sodium cyanide dissolves not only gold but also mercury, forming mercury

cyanide, which is either more bio-available to be methylated than metallic mercury. This fact has

been identified in different locations worldwide including Brazil, where GMP has already found

in Tapajos levels of Hg in fish as high as 22 ppm, whereas the permissible maximum level for

human consumption is 0.5 ppm total Hg

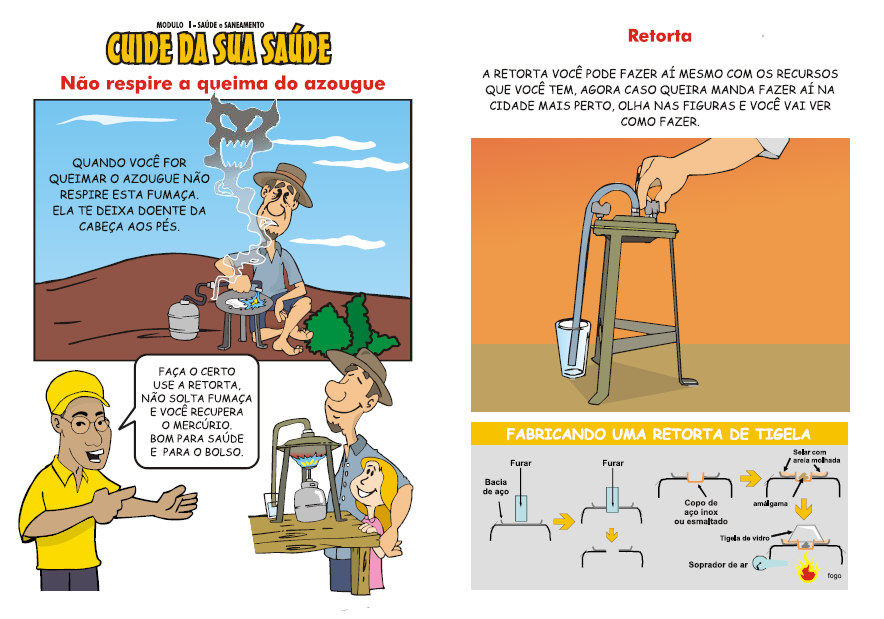

The roasting of amalgam in open air pots is another critical health problem faced by the

miners, their families and community around the mines. Mercury vapors are inhaled by the

miners and accumulate in their kidneys and brains. Several miners and community members of

- 7 -

Tapajos showed neurological symptoms of mercury intoxication from exposure to vapor. The

use of retorts can substantially reduce the emission of Hg to the atmosphere as well as

occupational exposure. It is unknown how far the mercury vapor can travel, however the use of

low cost retorts can reduce more than 95% of mercury vapor.

Once the mercury collects fine particles of gold from concentrates or from the whole ore,

miners squeeze the amalgam in order to remove excess mercury by filtration in a piece of fabric.

This result in an amalgam usually with 60% Au, 40% Hg. Depending on the manual strength

applied to the piece of fabric, this amalgam can have more or less mercury. When the amalgam

is centrifuged the amalgam can have only 20% Hg (Veiga, 1997). The roasting of amalgam in

open air pans with a blowtorch is the main process to separate mercury from gold and this is

another critical health problem faced by miners, their families and community living around the

mines. Mercury vapors are inhaled and accumulated in the kidneys and brains. Mercury

intoxication in ASM communities has been widely reported ((Malm et al, 1995; Malm, 1998;

Betancourt et al, 2005; Vieira, 2004; Limbong et al, 2003; Hinton et al, 2003; Akagi et al, 2000;

Drasch et al, 2001; Harada et al, 1999; Taylor et al, 2005; Drake et al, 2001; Rojas et al, 2005;

Maponga and Ngorima, 2003)

4

Site location: Tapajos river basin Itaituba Brazil

It is known that the Tapajos region in Brazil is the largest artisanal gold mining region in the

world. There are more than 2000 mine sites in the 98,000 km2 of the Tapajos basin and its sub-

basins (Silva, 2001). The GMP has selected and evaluated pilot sites of artisanal gold mining in

the Tapajos region (including São Chico, Creporizinho and Creporizão) to implement the

activities of environmental and health assessment and technology demonstration to gold miners.

These locations are an integral part of the municipality of Itaituba in the State of Para, in Brazil.

These mining communities are located around 300 to 500 km from Itaituba city. By 1980, with

the construction of the Transgarimpeira road, many mining communities were created due the

existence of this transportation route. Since then, other peaks have occurred fluctuating

according to the discovery of new gold deposits.

For the first phase of the GMP, the mining communities of São Chico and Creporizinho,

located 350 km distant from Itaituba, were selected,. These areas were already considered

prosperous in 1980 and again in 1990 when gold rich primary deposits were discovered. At that

time about three tons of gold were produced at the site at the beginning of the gold rush, with

double this amount of mercury being used. The population of these villages reached 5,000 and

10,000 people respectively (Rodrigues et al., 2004). The exploitation of alluvial gold ore is over

and even primary deposits are rare, and the few remaining miners survive from the reprocessing

of tailings. The most common practice was the direct amalgamation in mercury coated copper

plates, a practice through which most of the mercury was released to the environment. The plates

were scratched and the amalgam collected was burnt to evaporate the mercury, and the use of

retorts was uncommon. The processes currently used employ sluice boxes and amalgamation of

the gravity concentrate. In 2001 miners incorporated cyanide to amalgamate mercury

contaminated tailings and it might be responsible for increasing mercury mobility as well as the

high levels of mercury in fish.

- 8 -

The exploration of alluvial gold has been the main source of gold during the last decades,

however such reserves are becoming scarce, and miners have started the exploration of primary

ores. The usual practice for extracting gold from alluvial deposits consists in the use of hydraulic

monitors to break the soil and expose the gold deposit, creating slurry which is pumped to the

sluice box, where the gold is retained in carpets and the gravity concentrate is captured by

mercury. The exploitation of primary ore originated from open pits or shafts involves the

crushing of rocks in hammer mills, followed by the amalgamation in copper plates. As in most

cases, miners do not use retorts to burn the amalgam, the estimated ratio between gold (Au)

produced and mercury (Hg) lost can reach 1 to 2. It is also common to use cyanide to

amalgamate tailings contaminated with Hg, which can increase the availability of mercury in

water streams, elevating the level of possible fish contamination.

In order to successfully reduce the exposure of miners to mercury there is no single remedy,

but the strategy should encompass a combination of actions on different fronts, dealing with

technology, education, legislation, and awareness. None of theses separately could produce the

required results, as such a combination of strategies is necessary, for example mercury awareness

will only be successful in conjunction with a general health program including water quality,

safety risks, sexually transmitted diseases, AIDS, sanitation, and so on. Furthermore, not only

miners but also their families should be involved in the program in order to produce a

meaningful change in behavior.

Crepori River Basin

The Brazilian Amazon

Manaus

Belém

Itaituba

Amazon River

Tapajos River

Cuiabá

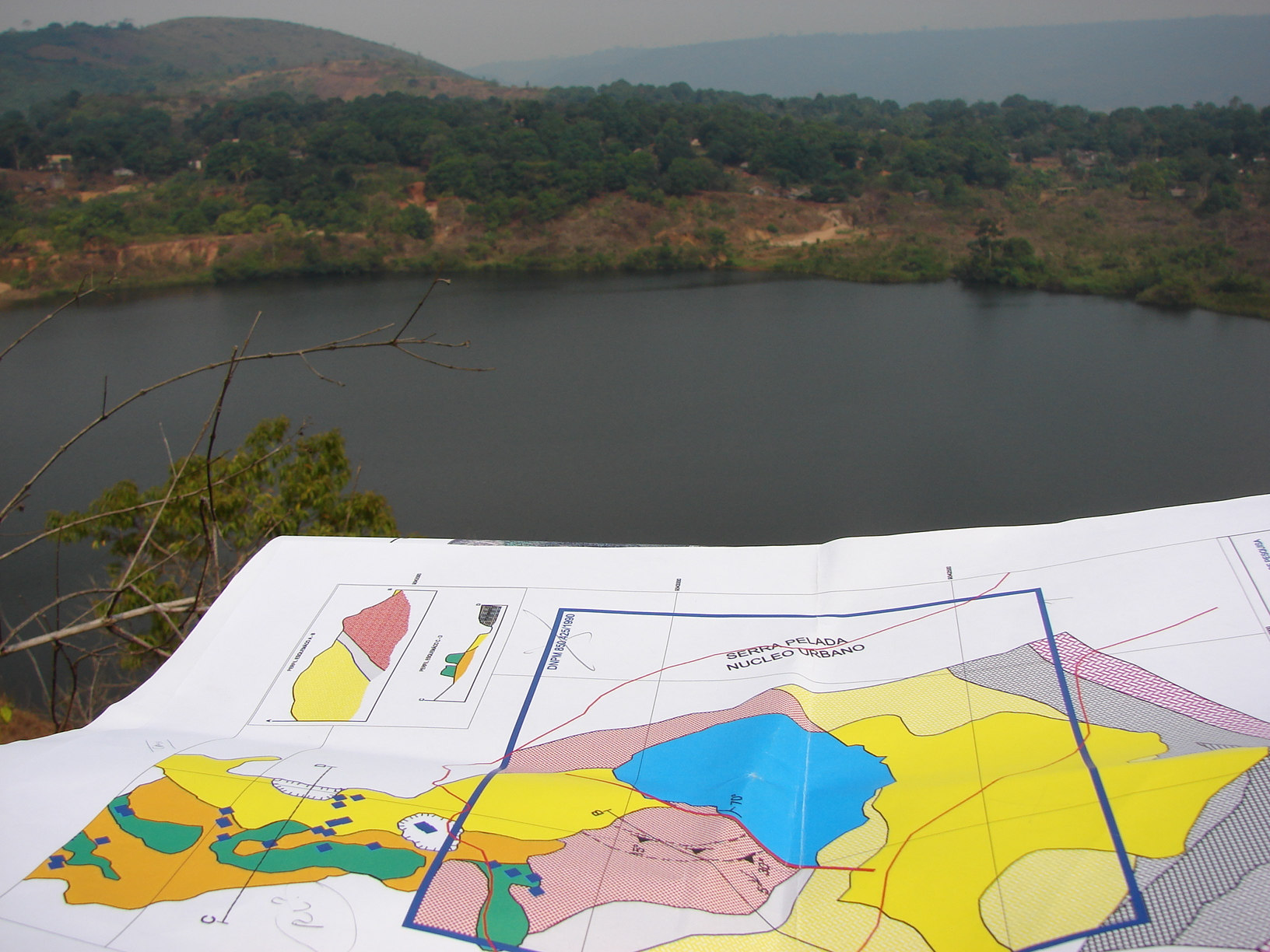

Figure 1: Location of Mining Sites in Itaituba Brazil. (Ribeiro, 2006)

- 9 -

5

The diagnostic phase Socio, environmental and health assessment

In order to address the problems and solutions for mercury pollution, a series of studies were

implemented to evaluate the seriousness of mercury contamination as well to establish the

magnitude of the problems. A social economic study was conducted in July 2003 to analyze the

history, the characteristics and dynamics of the selected mining communities. A legal study was

also conducted aiming to identify the existing legal framework, mining regulation and other

related activities. The environmental and health assessment provided a baseline to evaluate the

degree of the mercury impact on the targeted communities.

5.1 The Environmental assessment study

In order to address the problems and solutions for mercury pollution from artisanal gold

miners, a series of studies were previously conducted to evaluate the level of mercury

contamination as well to establish the magnitude of the problems at the GMP site in the Tapajós

region. A social economic study was conducted in July 2003 to analyze the history, the

characteristics and dynamics of the selected mining communities used as project sites (Mathis,

2003). A legal study was also conducted aiming to identify the existing legal framework, mining

regulation and other related activities (Guimaraes, 2004). An environmental and health

assessment revealed the degree of mercury impact on the aquatic environment and targeted

communities. Rodrigues et al. (2004), on behalf of the GMP, collected 658 samples from soils,

sediments and water in two Tapajos "garimpos", and found the worst scenario in a mine site

called São Chico. This site has witnessed a gold rush since the beginning of the 90s and about 3

tonnes of gold were produced with consequently release of 7.5 tonnes of mercury to the

environment. It was found that over 50,000 m² of soil is covered with Hg-contaminated tailings.

The mercury level in the tailings ranged from 4 to 300 ppm Hg (mg./kg), and river

sediments ranged from 7 to 14 ppm Hg. This study has shown extremely high levels of mercury

in soils and aquatic sediments and has demonstrated that Hg is already bioavailable since fish

samples have shown high concentration of mercury in muscles. This problem is exacerbated by

the fact that a few miners have extracted residual gold from Hg-contaminated tailings by

cyanidation using heap leaching process. The sodium cyanide dissolves not only gold but also

mercury, forming mercury cyanide. The residual mercury cyanide complex stays in the tailings

(in the heap) and it is mobilized by rain water reaching the water streams. It is expected that

water-soluble mercury cyanide is either more bioavailable or easier to be biomethylated than

metallic mercury. This is a new fact that deserves more investigation, but in fact it has been

identified in the Global Mercury Project sites in Indonesia, Zimbabwe and Brazil higher levels of

mercury in fish when mercury and cyanide are used together than when only amalgamation is

applied (UNIDO, 2006). In the monitoring program in a lagoon receiving effluents from a

cyanidation operation at the São Chico site, it was found an average level of Hg in 73 samples of

fish of 2.53±3.91 mg Hg /kg (Rodrigues et al. 2004). This is a very high level considering the

short length of the fish samples (18.75±14.42 cm). The average mercury level of 31 samples of

carnivorous fish was 4.16±5.42 mg Hg/kg and one sample analyzed 21.9 mg Hg/kg. The

permissible maximum level for human consumption according to the Brazilian legislation is 0.5

mg of total Hg/kg of fish (Ministry of Environment, 1999). Similar situation was found in the

Talawaan River in Indonesia. Artisanal gold miners in Talawaan, North Sulawesi extract residual

- 10 -

gold from Hg-contaminated tailings using cyanidation in agitated tanks. All tailings are released

to poorly engineered ponds and easily reach the river in the rainy season (Castilhos et al., 2006).

This study showed the extremely high mercury levels in soils, sediments and fish, and this

problem is exacerbated by the use of cyanidation of Hg-contaminated tailing. Considering that in

the Tapajos river basin most mining communities employ the same technology for extracting

gold as the villages used in the study, it can be assumed that equivalent levels of mercury

contamination can be found in different locations, thus justifying the choice of Tapajos river

basin for the implementation of training programs and awareness campaigns.

5.2 The health assessment study

The general working and living conditions at both mining sites Sao Chico and Creporizinho

were very basic, and the incidence of malaria, parasitosis and other diseases are very high. In Sao

Chico 246 volunteers were examined - of which 109 were miners according to the health

assessment protocols. The GMP team collected 234 blood samples, 235 urine samples and 137

hair samples. In Creporizinho 451 people were assessed of which 230 were miners and GMP

team collected 401 blood samples, 344 urine samples and 116 hair samples.

Several miners and community members of the Tapajos region showed neurological

symptoms of mercury intoxication from exposure to vapor. Typical symptoms included tremors,

poor balance, ataxia, and concentration problems. Occurrence of symptoms such as metallic

taste, excessive salivation, palpitations, and paraesthesia was more significant among miners

than among non-miners. Hepatomegaly, splenomegaly, and dyspepsia and arterial hypertension

were about 3 to 5 times higher in miners. Levels of Hg in urine of people directly involved with

amalgamation were as high as 78.5 µg Hg/g of creatinine (Rodrigues et al., 2004) (UNIDO,

2006) when the normal level supposes to be below 5 µg Hg/g creatinine (Veiga et al., 200). The

use of retorts can substantially reduce the emission of Hg to the atmosphere as well as

occupational exposure. It is unknown how far the mercury vapor can travel, however the use of

low cost retorts can reduce more than 95% of mercury vapor emissions (Diaz, 2000).

The main source of mercury contamination is through vapor inhalation during the amalgam

burning process. Since artisanal miners do not have habit of consuming fish regularly, the

mercury levels in hair of 136 people in São Chico averaged 3.16±2.63 ppm and 1.82±1.53 ppm

in 116 people in Creporizinho, in spite of the high concentrations of mercury in fish muscles

(Rodrigues et al., 2004).

The lessons learned from the studies in Sao Chico and Creporizinho indicated that rather

than only avoiding eating carnivorous fishes, which are source of available nourishment and part

of local eating habits, focus had to be placed on the reduction of Hg contamination. Practices

such as the amalgamation of the concentrate instead of the whole ore, the confinement of

mercury in canvas pools during the amalgamation, and the use of retorts, could drastically reduce

the levels of contamination in soil, fish and miners.

- 11 -

5.3 Socio-economic aspects

The number of miners varies substantially over the time. Such fluctuation is consequence of

the discovery of new gold veins or the economy as a whole. When opportunities in agriculture

decrease, small peasants can migrate to mining activities. A simplified survey to profile the

socio-economic conditions in the Tapajos region was applied by the GMP team to 376 miners

(Table 1), showing that the mining communities have the following characteristics:

Most miners are illegal. Little or no technology for primary gold processing

Few women are miners and all cooks are women

Miners' education varies from illiteracy to an elementary level

No child labor was identified in the area

Gold is the main source of revenue. Agriculture and cattle are very incipient

Deforestation occurs mainly due to fires

Fish is an important source of protein for the local communities

Main mean of transportation are airplanes and boats, at very high cost

Mercury locally costs US$200/kg and Gold is sold by US$25/g (Nov/2007)

Table 1: Miners' general profile

Evaluated item

Min

Max

Mean

Median

Age of miners (years)

16

75

32

28

Time in mining activity (years)

1

50

12

11

Family members

1

15

4

5

Hg consumed (g/ month.miner)

0

300

40

35

Production (g of gold/month.miner)

0

200

18

16

Revenue (US$ / month.miner)

0

4000

350

310

About 99% of miners are male, and women are only indirectly involved in the mining

activities, as cooks and clerks in the local commerce. The level of prostitution is also high. No

child labor (age below 14) was observed in the area, and the youngest miner found was 16 years

old. The level of illiteracy or basic reading and writing is around 60%. Although artisanal miners

in general do not establish roots into the place they work, most of them have been involved in

this activity for more than 10 years in the region. The mobility of miners is very high and they

move frequently from one mine site to another where they believe they will find "easier"

extractable gold. Almost 70% of miners live away from their families and their home town. The

most frequent migration occurs from the Brazilian Northeast States (Maranhão and Piauí) to the

North (State of Pará). This cause many social impacts, since families area left behind and women

have to raise their children alone.

The average gold production is about 18g/month.miner, which corresponds to a

US$350/month-income. This is basically twice the minimum legal salary in Brazil, but the cost

- 12 -

of living in mining sites area is far higher than the Brazilian average, due to difficulties of

transportation. To exemplify, a 2 liter bottle Coca-Coca costs US$1.50 in regular markets in

Itaituba city, and in some remote mining sites the price escalates to US$10.00. However, this

income is an average value, and not rarely miners spend months without any production. The

amount of mercury (Hg) consumed is about 40g/month.miner and the local price of mercury is

US$200 while the international price is around US$20/kg.

It is possible to classify the miners into 4 different groups according to their social condition:

1) Garimpo's owners: are those that own the land where they work, although there are issues

of documentation. They are estimated between 500 to 1,000 people in Tapajos region.

2) Garimpeiros: miners who work for garimpo's owners receiving commission. Their

relationship is recognized as partnership, and the group of miners split 25% of the gross

production. In general their manager receives extra 3% commission and the supervisor

receives extra 1%.

3) Independent miner: owns basic machinery (pump to excavate the pit and another pump to

feed the slurry in the sluice box). Do not own lands and work by permission or invasion

on other's lands. Most land are public but are occupied by someone who claimed the

ownership first.

4) Temporary "out-of-service" miners: those who are not mining currently but consider

themselves as miners as they can retake the activity at any time. Some are not mining for

years but they still keep ties with associations as they believe in future benefits. Example:

40,000 miners are members the Association in Serra Pelada, but only 2,000 live in the

Village.

6

Policy and regulations

The relationship with local authorities is a key point that determines the success of any

initiative of this nature. GMP has established important networks with the Brazilian government

at its federal, state and municipal levels. This relationship has been built through numerous

contacts, meetings and workshops. The key contacts involve the Ministry of Mines

(MME/DNPM), Ministry of Environment (MMA), Environmental State Agency

(SECTAM/SEICOM), municipal authority (SEMMA) and community leaders of garimpos.

During the workshops and meetings aspects of the environmental legislation were widely

discussed with the objective of facilitating the communication and understanding between the

different levels of governance. As a result of this communication, some responsibilities have

been delegated to the local level, which facilitate the implementation of programs like GMP

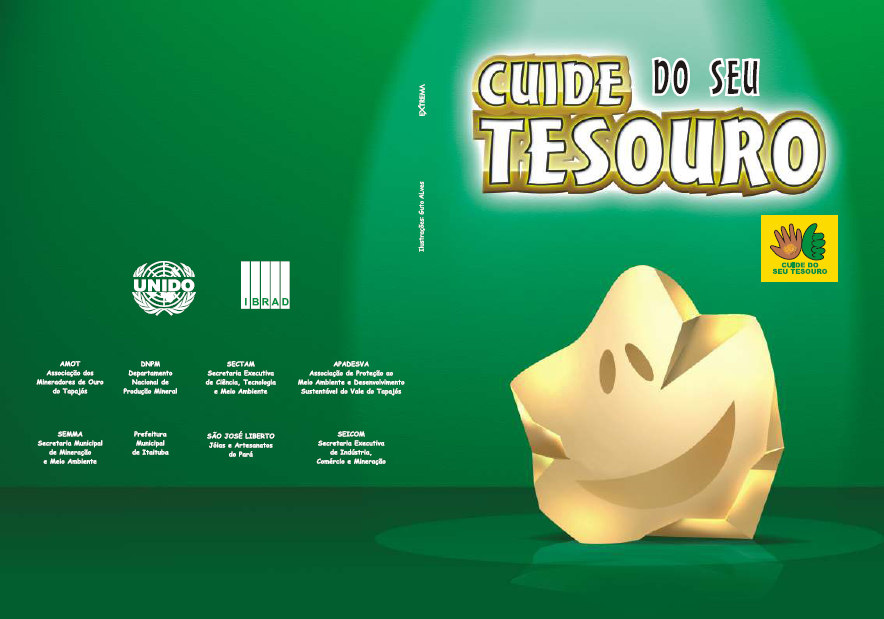

(locally know as "Cuide de seu Tesouro", or "Take care of your treasure"). In addition to that,

GMP has supported the study of a microcredit program in Brazil in order to develop resources

that miners can use to improve their technology. A very positive channel was open between

GMP and the Ministry of Mines to develop a project together.

Two main workshops took place in Brazil aiming to discuss the legal issues of the artisanal

mining activities and the results of GMP. A workshop in Brasilia (capital) on October/2006 put

together 40 people representing several ministries in the government. Another workshop in

Itaituba (GMP main site) was held on May/2007 and put together 90 people, including

government representatives, community and miners. The main debate during these workshops

- 13 -

was related to efficient ways to help miners to comply with legislation, and sometimes to

leverage proposes to make the law more realistic and more effective.

6.1 Study on the Environmental legislation addressing mining in protected areas

Specific report authored by the consultant Carlos Ribeiro (2006) addresses problems

concerning the environmental legislation in Brazil, in particular for the Amazon area. The report

is titled "Delineation of the Permanent Preservation Areas in the Tapajós River Basin: Toward

Environmental Compliance on Artisanal Gold Mining Areas". According to Ribeiro, Brazil has a

wide-ranging system of protected areas, which form part of the National Protected Areas System

(SNUC). The 1965 Brazilian Forest Code, law no 4771, defined two categories of protected

forests:

Legal Reserves, which require that every property keeps at least 20% of the land to be

covered with the natural vegetation (being it 35% for the savannas of the Legal Amazon, and

80% everywhere else in the Legal Amazon region), and

Permanent Preservation Areas, whose definitions are based on key geographic watershed

features such as divides, riparian areas, hilltops and steep hillsides.

While the forests that make up a legal reserve may be managed but never clear-cut for

timber production, on permanent preservation areas one precludes all direct economic uses of the

forested area. Violations to this law are defined as crimes against the environment subject to both

imprisonment and fine. Low levels of environmental compliance often result from inadequate

law enforcement by governmental agencies. This means nothing less than illegal appropriation of

public goods for the sole benefit of individuals or corporations. Seen as a cornerstone, the

Brazilian law 6938/1981, known as the National Environmental Protection Act, did much more

than establishes a contemporary environmental policy framework: it provided the regime of a

strict liability standard for environmental damages. This law defines as crime subject to

imprisonment all conducts that pose serious risk to human life or health or to the environment,

even when covered by a valid permit.

Subsequently the Brazilian Congress passed the law no 7347/1985, extending to non-

governmental organizations standing to sue in environmental affairs. Later, the Constitution of

1988 clearly denoted the Brazilian society's concerns on environmental protection. Recognizing

the increasing effectiveness and power of criminal law for the protection of human health and

ecosystems, in February 12, 1998 Brazil enacted law no 9605, introducing remarkable

innovations in crimes against the environment, such as the provision for corporate criminal

liability, "punishing with one to four years in jail and a fine anyone who causes pollution of any

nature at levels that result or may result in injury to human health or that cause animal death or

significant destruction of flora". The article 66 of this law instituted the punishment one to

three years of incarceration plus fine of any environmental official who makes false or

misleading statements, omits the truth, or does not disclose technical and scientific information

or data in applications for environmental permits or licensing. Among other legal penalties, the

offender is permanently precluded from signing contracts with the government, receiving tax

incentives or any kind of benefit and taking part in any public bids. Furthermore, its activities

can be partially or even totally suspended.

The technical challenges posed to the fulfillment of its constitutional duty to effectively

enforce environmental compliance on permanent preservation areas along with the increasing

international pressure for stopping deforestation in the Amazon rainforest led the Brazilian

- 14 -

government to create the National Protected Areas System in 2000, which was affiliated to the

Ministry of Environment and coordinated by the Brazilian Institute for the Environment and

Renewable Natural Resources (IBAMA). The law no 9.985 of July 18, 2000, has defined two

categories:

1) Strictly protected areas, which include national parks and biological reserves, and

2) protected areas of sustainable use, e.g. national forests and extractive reserves.

Encompassing the global environmental awareness, the Brazilian National Council for the

Environment enacts resolution no 303/2002, which has instituted the following types of

permanent preservation areas:

1. on hilltops, comprising the upper-third of hills and mountains;

2. along divides, encompassing the upper-third of the hillsides;

3. on upland catchments, so defined by the contributing area of any given spring;

4. on the margins of natural lakes and lagoons;

5. on riparian zones, whose widths depend on the extent of their floodplains;

6. on areas with slopes equal to or greater than 100%; and

7. on any area situated above 1.800m.

The broad category of permanent preservation areas still included provisions for protecting

environmentally sensitive sites such as those used for nesting or refuge by migratory birds,

beaches, mangroves, salt marshes (restingas), permanent swamp areas dominated by palm trees

(veredas), habitats of endangered species, and dunes. Conversely, the mapping of such protected

areas cannot be automated.

The historic lack of appropriate maps depicting the limits of permanent preservation areas

along with the shortage of infrastructure and personnel of governmental institutions to perform

inspections on remote regions made it virtually impossible to fully enforce this law over the

Brazilian Amazon. In contrast to the permanent preservation areas, the boundaries of protected

areas, as stated in the law no 9.985, are subjectively defined, being much easier to be mapped

and thus enforced. The study of Rylands and Brandon (2005) indicates the existence of 478

strictly protected areas spanning over 370,197 km2, and 436 sustainable-use ones covering

745,927 km2, created and enforced at both federal and state levels. These values comprise,

respectively, 4.3% and 8.8% of Brazil's territory (8,511,965 km2).

An endless polemic on the legality of interfering on permanent preservation areas was

recently settled by the Ministry of Environment of Brazil. In response to the insidious threat

posed by invading exotic species to biodiversity and to ecosystem services provided by riparian

vegetation, and in order to legalize the necessary actions aimed to eradicating, containing the

spread and controlling the numbers of invasive species, CONAMA (Environmental Council) has

enacted resolution no 369 which introduced regulatory exceptions into the Brazilian Forest Code.

This act came into effect on March 29, 2006, instituting a wide range of situations in which the

intervention or even the removal of vegetation on permanent preservation areas is imperative and

strictly in the interest or for the benefit of the general public.

Along with other innovations, this act regulates issues of paramount importance to the

mining sector. Among others activities, the prospecting and the exploration of mineral resources

located on those areas and granted by the proper authority were legally recognized by the

Brazilian government as of public utility (art. 2, 1st part, provision c). Concerning environmental

compliance, this represents the first tangible, unparalleled opportunity over the past 40 years to

- 15 -

insert artisanal gold mining into the formal economy and to have it properly included in local and

regional development plans.

Yet, there is a long way ahead before the permit for mining on protected areas is issued.

Article 3 of this resolution states the general conditions:

1. Nonexistence of technological and local alternatives for the proposed facilities, activities

or projects;

2. Compliance with the conditions and standards applicable to water bodies;

3. Notarized registration of the "legal reserve area";

4. Absence of risking aggravation of natural processes such as floods, soil erosion or rock

sliding.

A map depicting the limits of the permanent preservation areas will dictate if the applicant

must or not request the specific environmental license to operate.

Besides this complex scenario of laws, it is not clear the authority of federal, state and

municipal level to regulate each activity that may impact the environment. There are some

agreement between Federal and State level, and between State and Municipal levels. These

agreements, though, are not always valid in practical terms. One of the biggest advantages of

workshops and meeting with three level of government is to improve their communication, and

to allow that solution may be found to legalize artisanal miners. Currently, starting by the GMP

training sites, the Brazilian mining ministry (DNPM) is filing miners in order to assess their

situation and evaluate requirements to legalize them.

6.2 GMP influence on regional legislation

GMP has worked to influence its stakeholders and partners in order to promote the best

practices on Mercury use. For the federal and state level, GMP has organized workshops and

participated in numerous meeting with authorities to advocate for its principles and guidelines.

These guidelines are general recommendations generated by the team of experts of GMP.

However, it is more difficult to work in the federal and state levels as it involves a more complex

structure. It is easier, however, to work locally, at the municipal level. GMP has explored this

idea and promoted the transference of responsibilities from the federal and state level to the

municipal.

A practical example of this is the transference of responsibility to issue environmental

license from the State of Para to Itaituba Municipality. Through a formal agreement, the

Secretary of Environment and Mining of Itaituba (SEMMA) can currently establish criteria and

issue environmental license for many activities undertaken in Itaituba limits. Environmental

licensing for mining activities is under negotiation and has progressed well. It is expected that in

2008 SEMMA will start to evaluate and issue environmental licenses for garimpos. SEMMA's

criteria are based on the 5 objectives and 20 performance indicators suggested by GMP. A

mining site will be granted an environmental license based on the degree of conformity of it

practices, evaluated by SEMMA team.

Another practical example of success is the recent municipal bill that demands that every

gold shop in town has a fume hood installed by the end of 2008. GMP has worked in partnership

with USEPA (US Environmental Protection Agency) and SEMMA (Mining and Environmental

Secretary of Itaituba Municipality) to promote fume hoods in gold shops. This promotion stands

- 16 -

for testing new prototypes, implementing solutions, monitoring new and existent systems, train

locals on the use and cleaning of these filters, awareness campaigns about the importance of

hoods and discussion with Itaituba authorities on proposed legislation addressing the

obligatoriness of hoods.

6.3 Micro Credit Initiative

GMP hired the local consultant Lygia Lobo to study alternatives of micro credit for

garimpeiros, to discuss these alternatives with government representatives and GMP team, to

identify potential partners and to propose strategies for GMP to facilitate the implementation of

such program. The following paragraphs were extracted from Mrs. Lobo findings (Lobo, 2006).

There is a consensus in Brazil among Government Authorities, economists and the Brazilian

Civil Society that Brazil still lacks a set of well founded comprehensive public policies that

support productive credit to small entrepreneurial activities. The need for such policies and

programs has continuously been recognized and addressed by several multilateral agencies

including the World Bank, the Interamerican Development Bank, the International Labor

Organization among others, in an attempt to reduce poverty, improve social welfare, and

promote sustainable development and economic growth.

The Brazilian Market holds over 13 million small enterprises, representing over 60% of total

employment and 8% of GDP. Despite these figures and the numerous government initiatives to

address this issue, small enterprises access to productive credit is still limited and presents

prohibitive costs. This stems from their limited capability to show ability to pay back due to

either informality, inability to show adequate income or other similar reasons.

Restricted access to credit by this group obstructs the Brazilian Government's objective of

boosting employment. Overcoming this problem has become a challenge to the Brazilian

Government and entails the development of strategic programs and instruments to increase credit

opportunities to small and micro enterprises. In a recent attempt do address this issue, the

Brazilian Government has through the Ministry of Labor and Employment, developed the

National Program for Oriented Productive Micro-credit (PNMPO), launched in April 2005. Its

goal is to motivate generation of jobs among micro-entrepreneurs through assisted credit to the

lower income population.

The PNMPO Program is funded through partnerships with several credit institutions

including development banks and funds from the Ministry of Labor and Employment itself.

Partners for the PMNPO include the World Bank and Banco do Nordeste, The Brazilian National

Economic Development Bank (BNDES) in partnership with the Interamerican Development

Bank (IABD), Banco do Brasil, Caixa Econômica and others, whose programs will be briefly

described below.

Within this scenario, since the creation of the PMNPO many associated small credit

programs have been successfully created. One such program is the Credit for Family Agriculture,

which will be described below. Another is the ICC Blu-Sol, a program created in partnership

worth the BNDES in 2003 and expanded in 2005 to include the PMNPO, also described below.

- 17 -

The implementation of the technology introduced by the GMP (Global Mercury Project)

involves (i) capacity building to enable miners to use the technology and (ii) the introduction of a

micro-financing program to enable miners to purchase the necessary equipment to use this new

technology. GMP studies include the assessment and evaluation of the existing potential micro-

credit sources and programs in Brazil and abroad that can support the artisanal miners.

6.3.1 Micro financing in Brazil

Early milestones in the Brazilian micro-credit history can be summarized as follows:

1973 Creation of the first micro-credit program in Brazil, developed in the Northeast, by

the Northeast Union for Assistance to Small Organizations (UNO), which disappeared in

1991 due to the lack of rules and practices that would guarantee the program's self

sustainability.

1987 Creation of the Support Center for Small Enterprises (CEAPE/RS) in Porto Alegre,

RS, which was the first formal micro-credit program in the country. The Program was

funded by the IABD and the Interamerican Foundation (IAF). In the 90s, CEAPE was

expanded to 12 other states of the Union.

1989 Initiation of a micro-credit program in Bahia Bank for Women supported by the

IABD and UNICEF. Today the Bank for Women is also present in the states of Paraná, Rio

Grande do Sul, Amazonas, Minas Gerais and Rio de Janeiro.

1995 Creation of the Community Credit Institution PORTOSOL, by the City of Porto

Alegre (RS), in partnership with entities from the Civil Society. In addition to the

municipality of Porto Alegre, the administration of the State of Rio Grande do Sul other

national and International institutions also contributed in funding the Project, for example

SEBRAE/RS, BNDES, the German Society for Technical Cooperation (GTZ) and the

Interamerican Foundation (IAF).

1996 The VivaCred, located in the Rocinha Shantytown in Rio de Janeiro, was created in

1996 as an initiative of the Viva Rio NGO movement. It currenly has four agencies located

in the shantytonws of Rocinha, Maré, Rios das Pedras as well as in the South Zone of Rio de

Janeiro. VivaCred obtained financial support from (loans) BNDES and Fininvest, and has

institutional and technical support from SEBRAE.

1998 The World Bank and Banco do Nordeste launched the CrediAmigo Program in 1998

to finance small entrepreneurial initiatives. Today, CrediAmigo is the largest micro-credit

program in Brazil with over 2.48 million operations funding over R$ 2.07 billion. By

December 2005 its portfolio had reached R$136 million with 195 active clients.

Brazil seems to have the perfect conditions to develop solid microfinance program for many

reasons: (i) it has the highest concentration of income in South America; (ii) sixty million

Brazilians (or 33% of the total population) live on less than US$1 dollar per day; (iii) only 54

million people have checking or savings accounts; (iv) the country has a well developed financial

market in terms of retail banking. However, the micro credit sector in Brazil has not reached a

relevant level of growth. Thus, the sector has failed to take off.

Today, there are 171 institutions performing traditional micro-credit in Brazil. Most of them

are non-governmental organizations (NGOs) and small programs with an average of 1,300

clients per institution. The total number of active clients is 230,000 and the total portfolio is

approximately US$60 million.

- 18 -

Credit is accessed based on the traditional mechanism of requiring formal proof of income.

However, most new applicants cannot present proof of personal income, an account balance

sheet, or any formal kind of credit guarantee. Furthermore, the current trend in the Brazilian

labor market is towards a decrease in formal employment (registered job), and an increase in the

number of micro enterprises. Data from the Brazilian federal government indicates that the

population without formal employment registration increased from 38% of the active economic

population in 1991 to 51% in 2004. The Central Bank has estimated that 16 million of micro

enterprises exist. Of those 16 million, 80% do not have formal legal constitution, 46% do not

have any accounting or financial statement and 85% have no access to the traditional banking

credit. Despite this increasing demand, there is not enough of a supply of credit to meet the real

demands of low-income entrepreneurs. In such a context, micro-credit plays an extremely

relevant role.

The main difficulty faced by micro credit suppliers in Brazil is developing a credit model

that can be applied on a larger scale. The clients of this segment present some characteristics that

make it difficult to apply statistical or mathematical models. First, the personal and professional

issues in terms of finance do not have a clear borderline, which makes it difficult to understand

the destination of the credit after the disbursement. Second, most of these clients cannot formally

prove their sources of income. While Brazilian banks and department retailers are offering credit

to the low-income segment, this mechanism only functions properly when the client can formally

prove their source of income. For this reason, the development of a process of credit offer based

on personal contacts is a great advance, and is a fundamental step to building credit models on a

larger scale. Banks could develop a profitable model to reach the growing class of low income

entrepreneurs.

Only one Brazilian private bank currently offers micro-credit services: Unibanco, which

operates jointly with the International Finance Corporation of the World Bank (IFC-World Bank)

to offer micro-credit in poor communities in Rio de Janeiro, Sao Paulo and Porto Alegre.

Unibanco is the third largest bank in Brazil, with 17 million clients, and operations throughout

the country.

The case of Unibanco raises a simple question: why has Unibanco leapt into a market that

most retail bankers consider too risky and too expensive - especially when it could offer other,

more profitable credit products? The answer lies in the type of credit offered to low income

entrepreneurs in Brazil. Despite the small size of the micro-credit sector, low income people

have gained access to financial services, particularly credit. For example, retail and department

stores provide a tremendous amount of credit to the low-income segment of the population to

finance the acquisition of durable goods, like televisions and refrigerators. Seventy million store

cards have been issued by retailers, while only 45 million people hold traditional credit cards

(MasterCard, Visa and Amex) and checking accounts. Furthermore, 40% of the people that have

store cards in Brazil live on less US$3 dollars per day. While some retailers offer credit, others

have joined mainstream financial institutions. For example, two important low income retailers,

Ponto Frio and Magazine Luiza, have joined Unibanco in offering services to five million clients.

Unibanco is meeting this demand by offering credit to small entrepreneurs that do not have

formal proof of income. The most significant difference between these services and the

traditional model of credit is in the process. This is not done through the traditional methods of

modeling and credit scoring, but instead relies on the loan officer. The loan officer visits the

- 19 -

entrepreneur's business and collects key information about the business activity and the

entrepreneur. This information helps establish the sustainability of the business and real risks of

default. Under this system, clients with similar characteristics are receiving loans that are four

times larger through the micro-credit offering, with a lower default-rate. "For the first time I have

found the right credit at the right moment and it was through micro-credit. I have finally started

to get loans that were really positive for the development of my small business" said Vera Alves,

a Unibanco micro-credit client who makes and sells cakes and candies in a very poor community

in Rio de Janeiro. Thus, the micro-credit process is meeting entrepreneurs' demands more

effectively, and better controlling the risk of the client as well.

The goal of Unibanco, that already has experience and largely operates with the low income

segment, is to be the pioneer in fully meeting the demands of the micro-credit market. This

would be a breakthrough in portfolio growth in the increasingly competitive Brazilian financial

market. To reach this goal, a fully developed micro-credit operation is essential. No other private

retail bank in Brazil has done this before, but Unibanco and the IFC-World Bank believe that this

is possible and relevant for the country's economic development.

Given the potential market for microfinance services, the high interest rates paid to informal

lenders and the lack of penetration by the formal financial sector, there are several microfinance

programs operating in Brazil. The Brazilian programs can be divided into two categories: (i)

VivaCredi of Rio de Janeiro, and PortoSol of Porto Alegre, focused on their local markets; (ii)

CrediAmigo (a program of Banco do Nordeste) and FENAPE, regional or national. None of the

programs is leveraged with funds from deposit accounts or private bank loans, though several

receive subsidized loans from the BNDES.

6.3.2 Institutional Framework and Regulation

The Brazilian Government has recently attempted to regulate microfinance activities and to

attract a larger participation from the private sector. To this end, the Brazilian legislation has

established two basic formats for the constitution and qualification of institutions for microcredit:

The non-profit Public Interest Civil Society Organizations (Organizações da Sociedade Civil

de Interesse Público (OSCIP)), regulated by Law n.º 9.790/99. These are legally recognized

by the Ministry of Justice as public interest entities.

The Credit Societies to the Micro Entrepreneur (Sociedades de Crédito ao

Microempreendedor (SCM)), whose constitution was authorized by Law nº. 10.194/01 of

Feb 14th, 2001, and regulated by the National Monetary Council (Conselho Monetário

Nacional (CMN)), through Resolution n.º 2874 from the Brazilian Central Bank. This

Resolution defines its constitution as closed firms per the terms established by the Law n.º

6.404 (Anonymous Societies) or as a partnership by quotas with limited responsibility

(Ltda.), in this case allowing profit.

Funding granted by micro-credit institutions abide by the following rules:

i. Micro-credit aims at financing small entrepreneurs productive activities and rarely will

finance consumption.

ii. The amount financed is compatible with business needs and payback capabilities. In credit

renewal amounts may increase.

iii. Interest rates are generally the market rates.

iv. The guarantees requested by the micro credit institutions are very simple, and abide by the

conditions presented by the borrowers. Thus, requests for real collateral (property, for

- 20 -

instance) are rare. The request for a co-signer is more common, and the latter is usually an

acquaintance of the borrower.

v. Payment terms are usually short periods of time and are usually linked to the object of the

financing as well as to the activity's cash flow. For instance, in the case of investments in

machinery payback periods can be longer and dependent on the return on investment (ROI)

capabilities.

vi. Release of resources by the financing institutions is usually pretty quick, but varies from

institution to institution. However, it is usually fast enough so that the borrower does not

lose his business opportunity.

6.3.3 Recommendations on the GMP Micro Credit Program for Brazil

Before analyzing and making recommendations for the development of a micro credit plan

for the GMP in Brazil it is necessary to take a look at the SWOT Matrix presented ahead, which

summarizes what has been accomplished so far, and what one might expect in the future.

- 21 -

Table 2: SWOT matrix for a microcredit program for the GMP in Brazil

STRENGTHS

WEAKNESSES

· Program contemplates all of the UN · Brazilian Government too slow to act

Millennium Development Goals

· No specific potential actions identified by the

· Program aims at reducing negative

Brazilian government yet

environmental impact due to mercury use · No specific structure or format for a micro

· Program aims at reducing health risks for

credit program for artisanal miners identified

artisanal

miners

de

to

mercury

by the Brazilian Government as of yet

intoxication

· Upper bound on existing microfinance

· Program aims at increasing efficiency of

programs too low (R$ 1,000 to R$ 2,000), to

gold extraction using mercury

little for the proposed technologies

· Program develops new technologies to · Due to the difficulties above, no specific

accomplish the above goals

technology chosen yet, despite choices

· Program fosters to disseminate the use of

presented by UNIDO

best practices to support all items above · High informality and mobility among potential

through a capacity building and training

beneficiaries

program

· Very little or non-existing education among

· Program aims to establish a micro credit

potential beneficiaries, which makes it difficult

program to finance the use of the

for them to understand benefits of the program,

aforementioned technologies

leading to little motivation from potential

· Strong Brazilian government Support

beneficiaries to adopt whichever proposed

· Existing legal and institutional framework

measures

for microfinance in Brazil

· Lack of organization of potential end users

· Existing funding from local development

(artisanal

miners

themselves).

Existing

banks for other microfinance programs

associations belong to mine owners and not to

· Existing

funding from multilateral

artisanal miners. Ex: AMOT

agencies for other microfinance programs · Little

interaction

between

Brazilian

in Brazil

Government

Authorities

and

Miners's

· Brazilian government willing to develop

representatives

public policies to address ASM

OPPORTUNITIES

THREATS

· Introduction of new technologies to · Slow government action and follow up, thus

minimize environmental impact and

possibility to stall the program

health risks

· No motivation for miners to implement best

· Introduction and dissemination of best

practices & technologies

practices to achieve this goal through · No continuity of program among local users

capacity building and training

· Use of micro credit money for other purposes

· Increase in income for the artisanal miner · Default by end user (artisanal miners)

through more efficient technologies in · Appropriation of resources by other entities

gold extraction

(mine owners, other associations, politicians,

· Implementation in Brazil of public

etc.)

policies accompanied by a well structured · No follow up and thus, no satisfactory reports

microfinance program to increase the

on improvements of social and project

feasibility of achievement of these goals

indicators

· Improvement in overall welfare

- 22 -

Given this scenario, we can conclude a few facts. First, on the positive side, one can observe

that there is a favorable environment in Brazil for the creation and implementation of a micro

credit program to support for the Artisanal Mining in the country as part of the GMP.

To this end, all necessary ingredients are present, and these include the reduction of a

negative environmental impact, contemplation of all MDGs, the potential improvement of health

conditions, dissemination and implementation of best practices, an increase in income due to

more efficient extraction technologies, and consequently the improvement of overall sector

welfare. On the institutional side there are signals from the Brazilian Government Authorities

that there is a willingness to cooperate, evidenced through changes in the legislation such as the

acceptance of mercury usage for gold extraction in some specific cases, the introduction of

public policies to address artisanal mining issues, and extending existing microfinance programs

in other areas to this sector. Furthermore, there is already in the Brazil a legal framework

established for other micro credit programs that can be easily adapted to the artisanal mining,

once certain issues are addressed, and which will be commented below.

One problem found was that the Brazilian Government Authorities have been slow to act

and interact with the UNIDO parties involved in this project. In a first moment there was a strong

interest expressed in this interaction, given that the Program was brought to Brazil from abroad

by a multilateral agency and was to be implemented in Brazilian territory, therefore, it had to be

implemented under the Brazilian Government supervision. However, the Program had to adapt

its pace to other Government priorities. Given that UNIDO, UNDP and the Brazilian

Government Authorities needed to work hand in hand in a cooperative atmosphere. Some

recommendations are presented herein, and their implementation is expected for an eventual

second phase of the project.

The general Government recommendations will move along three lines. First, follow the

format adopted by PRONAF, the family micro credit agricultural program in place in the

country, which presents very low interest rates and caters to strong social interests. With this

regard the micro credit portion of the GMP in Brazil is still in its embryo stage and a lot still

needs to be done. Second, Government Authorities are aware that a line of micro credit needs to

be developed to micro and small firms, and although they are working closely with BNDES, they

still have not come up with an objective solution or recommendation with this regard. Third, the

Government Authorities are trying to come up with a solution to the problem presented by the

lack of guarantees presented by the borrowers, given that without collateral it becomes very

difficult for financial institutions to become involved in such Program.

To finalize, we can make a few recommendations to be discussed in the future with the

Brazilian Government Authorities as this Program enters its next stage. They include the

following:

1) Beneficiary: given the difficulty to get the micro credit to the end user, be it due to the

fact that most artisanal miners are informal workers with no fixed address, ID or social security

identification, or be it due to the fact that usually it is the mine owner who controls the whole

mining operation, two questions arise: (i) how can this program motivate the migration of

artisanal miners to formality? (ii) How can one we guarantee that the micro credit will indeed go

to the miner and not to the mine owner or a mine owner association? One solution is to develop

- 23 -

a micro credit program to be administered by an OSCIP as described above, who would register

all miners in the working site, ensure that they would be fully documented by aiding each

individual in the process of obtaining an ID card and a social security number (Brazilian CPF),

manage the funds, ensure that each miner obtained the funds.

2) Appropriate use of funds: once each miner is registered within the OSCIP, this entity

could ensure that the funds are used to purchase the piece of equipment, in this way making sure

that the funds will not be deviated to other purposes. One way of doing this would be to have the

miner apply for a specific piece of equipment directly with the OSCIP, who would receive the

cash from the financial agents, purchase and distribute the equipments to the miners, and would

also give the guarantees to the banks. It would be the OSCIP's responsibility to receive the

funds, purchase the equipment, give it to the miner, provide the guarantees to the Banks, pay

back the loans, follow up and report back the results. This, of course, would need to be closely

monitored by the Government Authorities, financial institutions and the multilateral agencies

involved.

In sum, the main advantage of having an OSCIP manage the micro credit funds for the GMP

artisanal mining project, aside the fact that there is already in place the legal framework

regulating their participation in this kind of activity, is the fact that they can ensure that the

beneficiary is the end user, i.e., the miner and not the mine owner, they can also ensure that the

money will be spent appropriately, i.e., for the purchase of equipment, and that their participation

reduces substantially the risk of default.

The elaboration of a funding program with the Brazilian Development Bank, BNDES, other

government and private banks (Banco do Brasil, Banco da Amazonia, Banco do Nordeste, etc.),

other multilateral agencies (IABD, World Bank, etc.) needs to be carefully studied and

implemented with the Brazilian government, and will be pursued as a future endeavor.

7

Field actions - Training program and awareness campaign

In each participant country UNIDO has hired contractors for the implementation of GMP

actions. In Brazil the first contractor was CETEM (Center of Mineral Technology), which was

later substituted by the NGO IBRAD (Brazilian Institute of Development). Although CETEM

had also worked with awareness and training, its participation was more focused in the

diagnostic phase. IBRAD has wide experience in conducting environmental education programs

and was selected to drive the field actions in Tapajos. By the analysis of opportunities phase,

several partnerships were established, and GMP initiated a larger partnership entitled "Takes care

of your Treasury more gold and less mercury". Under this motto the project incorporated the

following partners' efforts: GMP - Global Mercury Project / IBRAD, SEMMA (Itaituba City

Hall), AMOT/COOPA (Miners Associations), SEICOM / São José Liberto / SECTAM

(Government of the State of Pará), General office of Geology / DNPM. At the same time a

strong relationship was also built with USEPA (United States Environmental Protection

Agency).

Concepts of ISO - Quality Management Systems (ISO, 1999), as mentioned by Tricker

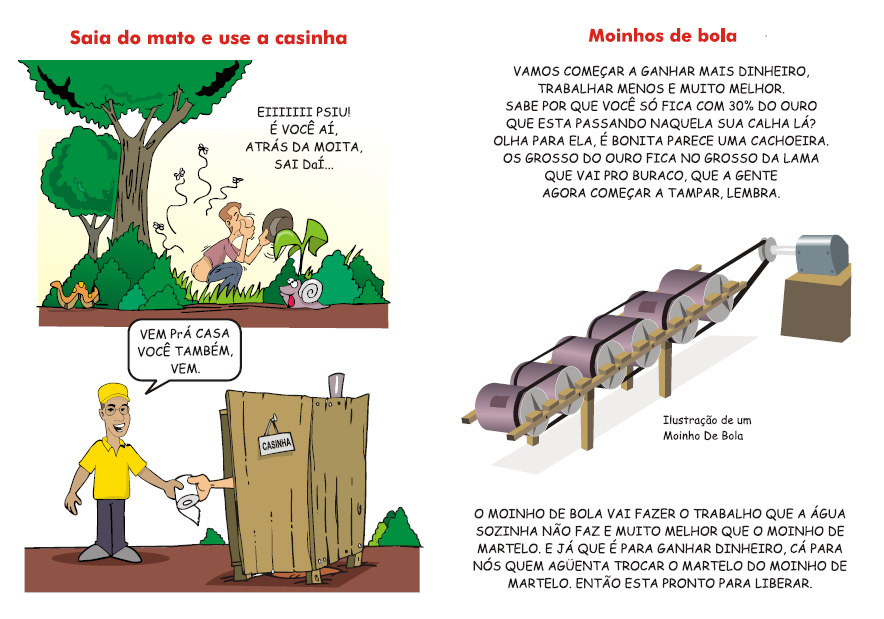

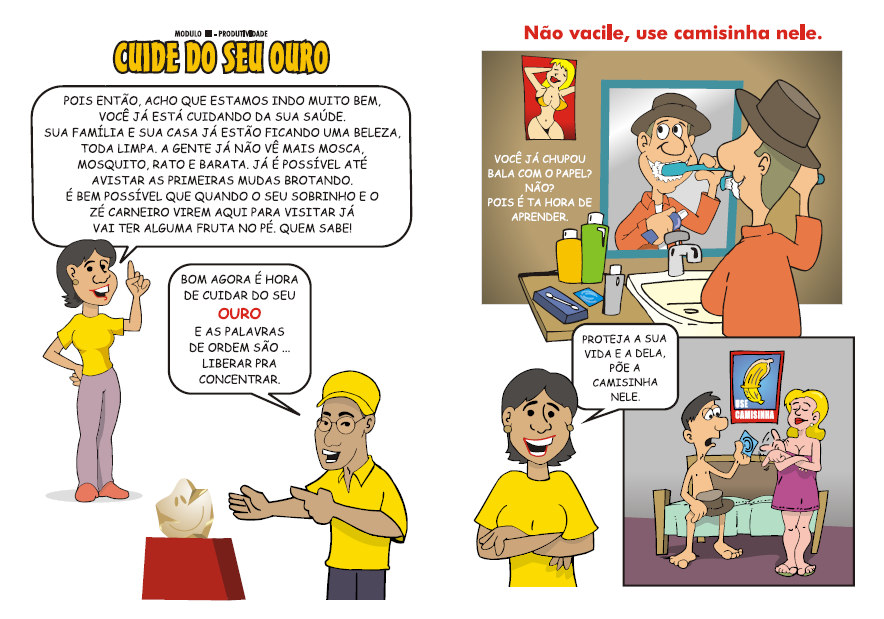

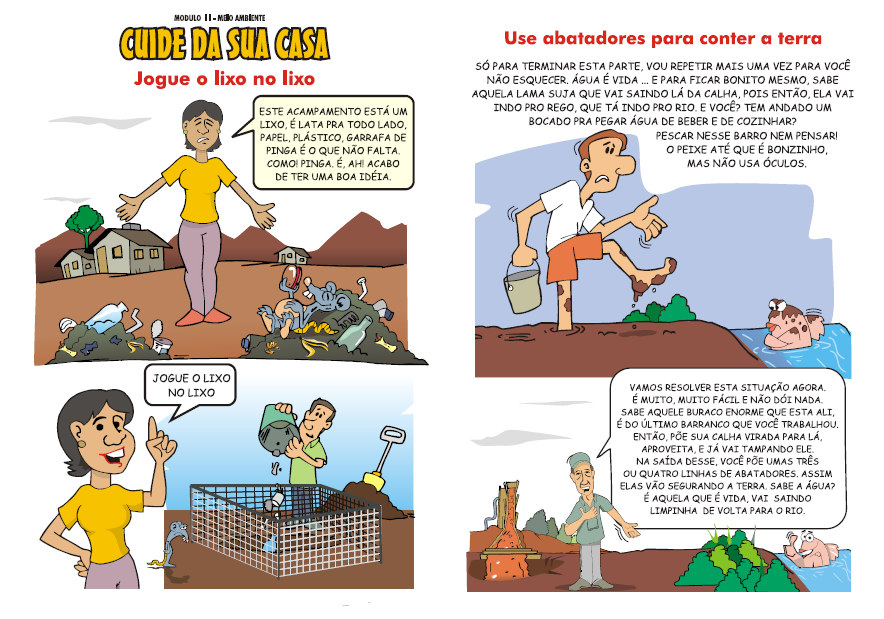

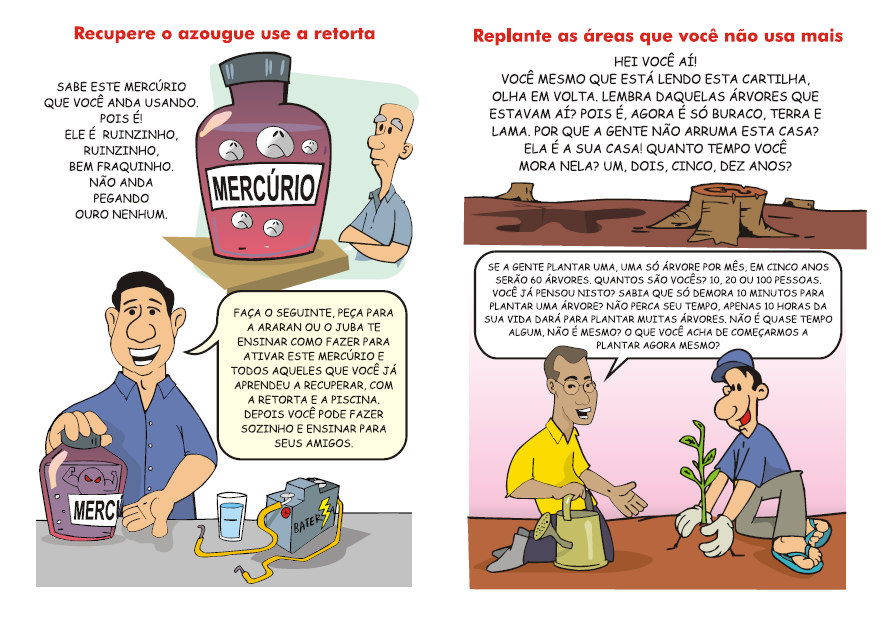

(2000), have been employed with the purpose of assuring effectiveness of the training process.

The GMP strategic plan involved the capacity building and preparation of a team of trainers.