E2150

v6

Public Disclosure Authorized

ENVIRONMENTAL IMPACT ASSESSMENT ON

GEF SHANGHAI AGRICULTURAL AND

NON-POINT POLLUTION Reduction PROJECT

Public Disclosure Authorized

Public Disclosure Authorized

Public Disclosure Authorized

EAST CHINA NORMAL UNIVERSITY

AUGUST 20, 2009

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

CONTENTS

1 INTRODUCTION .........................................................................................................................1

1.1 Project

Background.......................................................................................................1

1.2

Consistency with Governmental Plans..........................................................................1

1.3 Purpose and Scope of Assessment ......................................................................................2

1.4 Basis of the EIA ..................................................................................................................3

1.4.1 EA Documents and FSRs of Related Components ..................................................3

1.4.2 Laws of the PRC for Environmental Protection.......................................................3

1.4.3 Shanghai's Rules for Environmental Protection ......................................................4

1.4.4 World Bank's Safeguard Policies ............................................................................4

1.4.5 Technical Documents for Assessment .....................................................................5

1.5 Standards of Assessment .....................................................................................................5

1.5.1 Standard of Environment Quality Assessment.........................................................5

1.5.2 Pollutants Discharge Standard..................................................................................8

1.6 Grade of Assessment.........................................................................................................12

1.7 Range of Assessment ........................................................................................................12

1.7.1 Water Environment ................................................................................................12

1.7.2 Ambient Air............................................................................................................13

1.7.3 Acoustic Environment............................................................................................13

1.8 Environment Protection Objective....................................................................................13

1.8.1 Water Environment Protection Objective...............................................................13

1.8.2 Ambient Air Protection Objective..........................................................................13

1.8.3 Acoustic Environment Protection Objective..........................................................13

1.8.4 Environmental Sensitive Objectives ......................................................................13

1.9 Organization of the EA Report .........................................................................................14

2 OVERVIEW OF PROJECT.........................................................................................................16

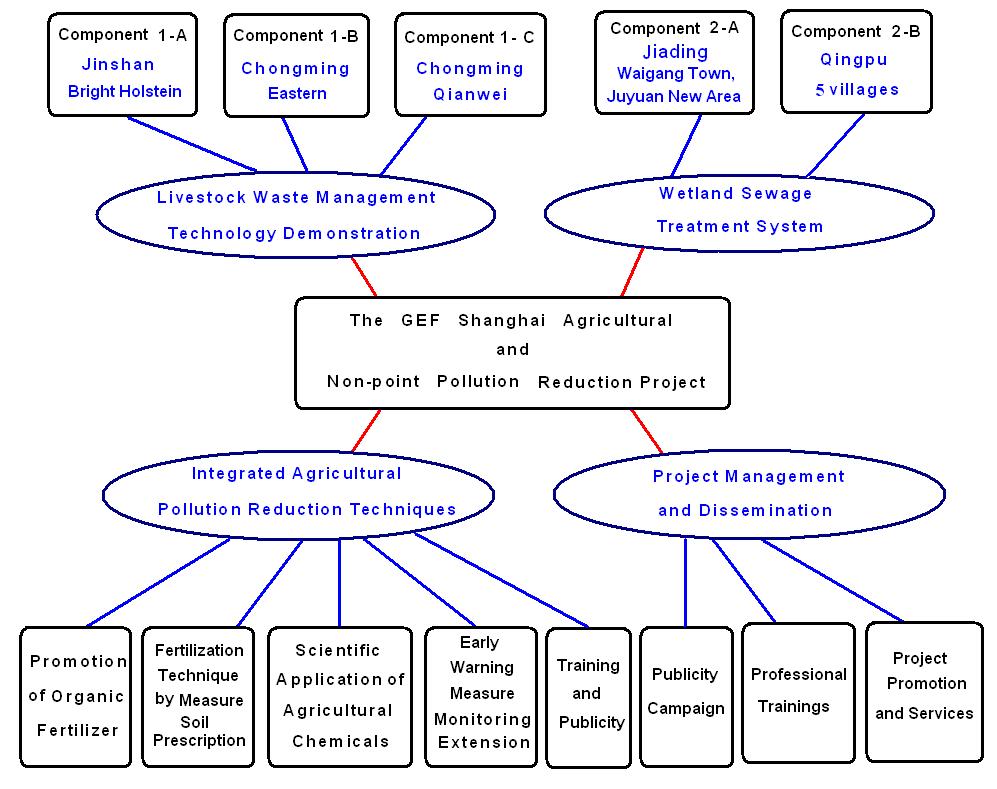

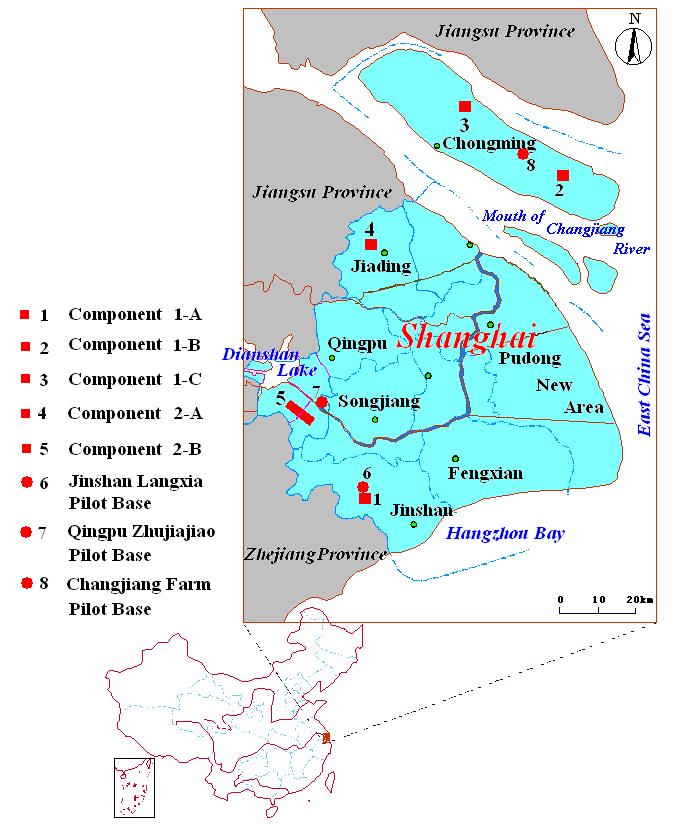

2.1 Project Framework............................................................................................................16

2.2 Description of Livestock Waste Management Technology Demonstration ......................17

2.2.1 Livestock Waste Management on Large Farm (Jinshan Dairy Farm)Component

1-A ..............................................................................................................................18

2.2.2 Livestock Waste Management on Medium Farm (Chongming Dairy Farm)

Component 1-B .......................................................................................................21

2.2.3 Integrated Livestock and Agricultural Waste Management (Qianwei Village)

Component 1-C .......................................................................................................23

2.3 Description of Wetland Demonstration for Pollution Reduction ......................................29

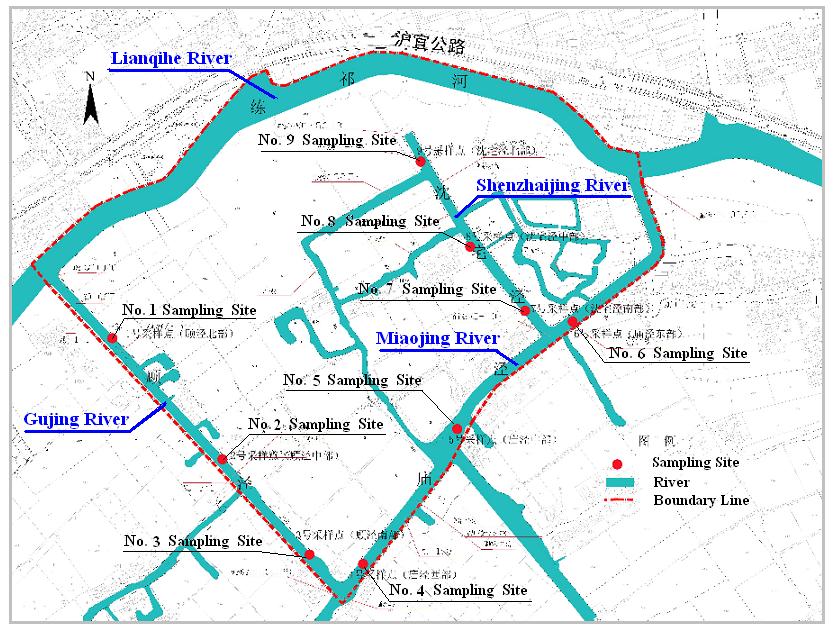

2.3.1 Jiading Town River-network Wetland DemonstrationComponent 2-A..........29

2.3.2 Qingpu Village Wetland Sewage Treatment SystemComponent 2-B ............33

2.4 Investment Estimation.......................................................................................................35

i

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

3 OVERVIEW OF LOCAL ENVIRONMENT ..............................................................................36

3.1 Physical Environment .......................................................................................................36

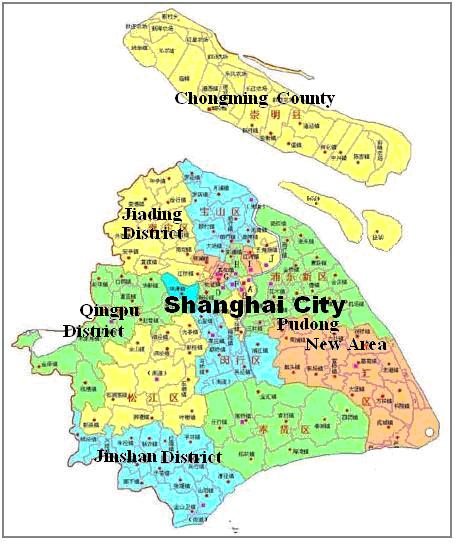

3.1.1 Locations of the Project .........................................................................................36

3.1.2 Geology and Terrain Features ................................................................................37

3.1.3 Climate ...................................................................................................................37

3.1.4 Surface Water.........................................................................................................37

3.1.5 Groundwater...........................................................................................................39

3.1.6 Surface Temperature ..............................................................................................39

3.1.7 Natural Calamity ....................................................................................................39

3.2 Water Quality ....................................................................................................................39

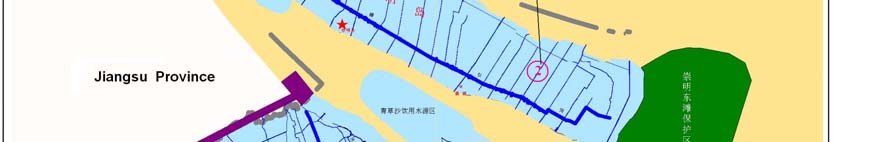

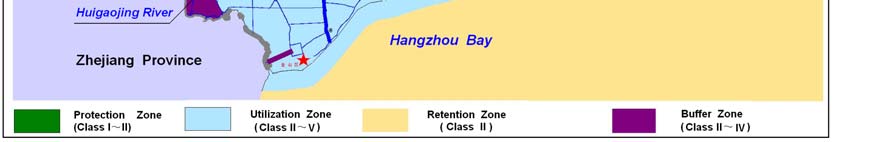

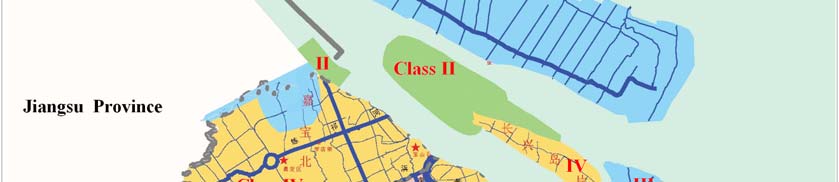

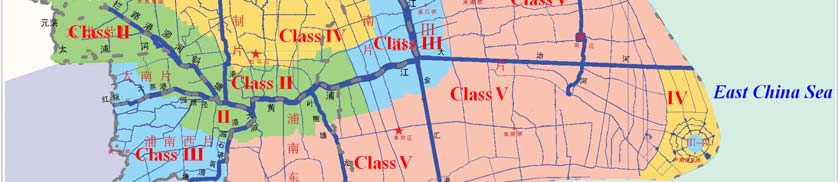

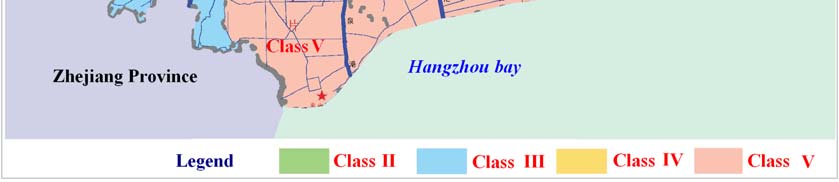

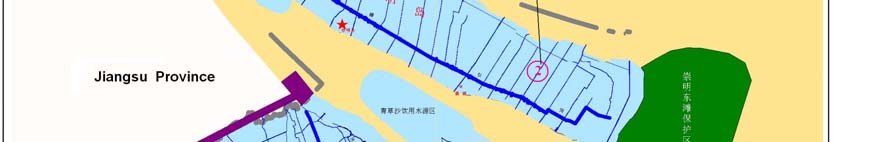

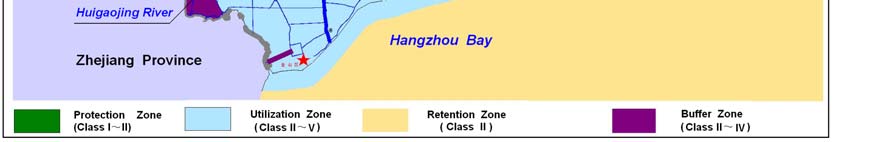

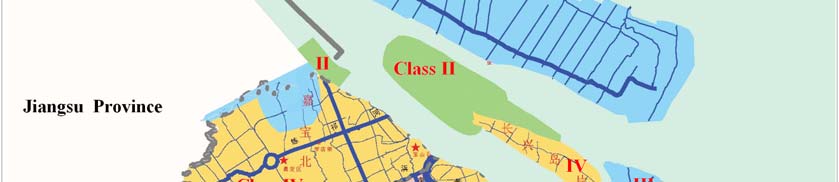

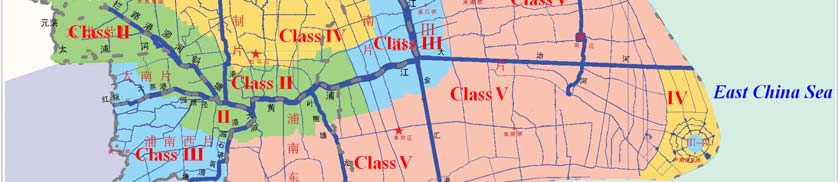

3.2.1 Zoning of Surface Water Quality in Shanghai .......................................................39

3.2.2 Water Quality in Shanghai Area.............................................................................40

3.3 Quality of Ambient Air .....................................................................................................42

3.4 Ambient noise ...................................................................................................................43

3.5 Ecological Environment....................................................................................................43

3.5.1 Jinze Town and Liantang TownQingpu District.................................................43

3.5.2 Langxia Town, Jinshan District..............................................................................43

3.5.3 Shuxin Town and Zhongxing Town, Chongming County......................................43

3.5.4 Waigang Town and Juyuan New Area, Jiading District .........................................44

3.6. Social and Economic Conditions .....................................................................................44

3.6.1 Population and Land ..............................................................................................44

3.6.2 Social Economy Condition ....................................................................................44

4 PROJECT ALTERNATIVE ........................................................................................................46

4.1 With and Without Projects................................................................................................46

4.1.1 With and Without the Livestock Waste Management Technology Demonstration

Project .............................................................................................................................46

4.1.2 With and Without the Wetland Demonstration for Pollution Reduction................46

4.2 Alternative Locations........................................................................................................47

4.2.1 Alternative Locations for the Livestock Waste Management Technology

Demonstration Project.....................................................................................................47

4.2.2 Determination of Wetland Demonstration for Pollution Reduction Site................48

4.3 Alternative Technical Process...........................................................................................59

4.3.1 Livestock Waste Management Technology Demonstration ...................................59

4.3.2 Wetland Demonstration for Pollution Reduction ...................................................63

5 IMPACT ASSESSMENT AND MITIGATION MEASURES.....................................................70

5.1 Analysis of Pollution Source.............................................................................................70

5.1.1 Livestock Waste Management Technology Demonstration...................................70

5.1.2 Wetland Demonstration for Pollution Reduction ...................................................84

5.2 Measures to Reduce Environmental Impact in the Project Construction Period ..............88

5.2.1 Livestock Waste Management Technology Demonstration ...................................88

5.2.2 Wetland Demonstration for Pollution Reduction ...................................................96

5.3 Measures to Reduce Environmental Impact in the Project Operation Period .................101

ii

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

5.3.1 Livestock Waste Management Technology Demonstration .................................101

5.3.2 Wetland Demonstration for Pollution Reduction .................................................117

5.4 Risks and Hidden Danger................................................................................................119

5.4.1 Explosion and Deflagration..................................................................................119

5.4.2 Disastrous weather ...............................................................................................119

5.4.3 Analysis on Environmental Risks ........................................................................119

6 PROJECT BENEFITS ...............................................................................................................124

6.1 Expected Benefits of Component 1-A ............................................................................124

6.1.1 Social Benefits .....................................................................................................124

6.1.2 Environmental Benefits........................................................................................124

6.1.3 Economic Benefits ...............................................................................................126

6.2 Expected Benefits of Component 1-B.............................................................................126

6.2.1 Social Benefits .....................................................................................................126

6.2.2 Environmental Benefits........................................................................................126

6.2.3 Economic Benefits ...............................................................................................127

6.3 Expected Benefits of Component 1-C.............................................................................128

6.3.1 Social Benefits .....................................................................................................128

6.3.2 Environmental Benefits........................................................................................128

6.3.3 Economic Benefits ...............................................................................................129

6.4 Expected Benefits of Component 2-A ............................................................................129

6.4.1 Social Benefits .....................................................................................................129

6.4.2 Environmental Benefits........................................................................................130

6.4.3 Economic Benefits ...............................................................................................131

6.5 Expected Benefits of Component 2-B.............................................................................131

6.5.1 Social Benefits .....................................................................................................131

6.5.2 Environmental Benefits........................................................................................131

6.6 Expected Benefits for Integrated Agricultural Pollution Reduction Techniques.............132

6.7 Summary for Environmental Benefits.............................................................................133

7 PUBLIC CONSULTATION & INFORMATION DISCLOSURE ...........................................134

7.1 Information Disclosure ...................................................................................................134

7.2 Public Participation .........................................................................................................134

7.2.1 Results of Public Participation in Internet Survey ...............................................134

7.2.2 Results of Public Participation in Questionnaire Survey .....................................135

7.2.4 Main Conclusion for the public participates ........................................................137

8 DESCRIPTION AND EMP FOR INTEGRATED AGRICULTURAL POLLUTION

REDUCTION TECHNIQUES......................................................................................................139

8.1 Description of Integrated Agricultural Pollution Reduction Techniques ........................139

8.1.1 Project Base and Objective ..................................................................................139

8.1.2 Project Location ...................................................................................................140

8.1.3 Project Description...............................................................................................140

8.1.4 Training and Publicity..........................................................................................142

iii

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

8.1.5 Project Demonstration and Promotion Plan .........................................................142

8.1.6 Project Schedule...................................................................................................142

8.2 Environmental Monitoring Plan......................................................................................143

8.2.1 Environmental Monitoring Plan for Integrated Agricultural Pollution Reduction

Techniques ....................................................................................................................143

8.2.2 Environmental Investigating Plan for Integrated Agricultural Pollution Reduction

Techniques ....................................................................................................................143

8.3 Environmental Management Plan ...................................................................................145

9 ENVIRONMENTAL MANAGEMENT PLANEMPAND MONITORING PLAN .........148

9.1 Objectives of EMP ..........................................................................................................148

9.2 Role of EMP....................................................................................................................148

9.3 Contractual Management ................................................................................................148

9.3.1 Execute the Contract ............................................................................................148

9.3.2 Obligations of contractors ....................................................................................148

9.4 Entities implementing EMP ............................................................................................149

9.5 Environmental Management Cost Estimation.................................................................150

9.6 Monitoring Program for Components.............................................................................152

9.6.1 Monitoring Program for Component 1-A ............................................................152

9.6.2 Monitoring Program for Component 1-B.............................................................154

9.6.3 Monitoring Program for Component 1-C.............................................................156

9.6.4 Monitoring Program for Component 2-A ............................................................158

9.6.5 Monitoring Program for Component 2-B.............................................................160

9.7 EMP Summary for Components ...................................................................................162

9.7.1 Environmental Management Plan for Component 1-A........................................162

9.7.2 Environmental Management Plan for Component 1-B........................................169

9.7.3 Environmental Management Plan for Component 1-C........................................174

9.7.4 Environmental Management Plan for Component 2-A........................................180

9.7.5 Environmental Management Plan for Component 2-B........................................184

10 CONCLUSIONS......................................................................................................................189

iv

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

1 INTRODUCTION

1.1 Project Background

Shanghai is the most economically developed and the most populated city in China. At the

end of 2007, Shanghai had a population of 18 million across its 6340.5 km2 of land. The

suburban area beyond the outer ring is an important production base for agriculture and

industry of Shanghai. N, P and organic matters discharged to water bodies in suburban area

account for 60-70%, mainly from agriculture and animal husbandry, agricultural chemicals

and surface runoffs including rain runoff and farmland irrigation water drainage, livestock

and poultry manure and untreated industrial and domestic wastewater are the major causes

for eutrophication of water bodies. Non-point pollution has become a major form of pollution

for the water environment of Shanghai. Contaminated surface waters draining into Huangpu

River and Yangtze River impose an adverse impact on the two rivers that we cannot afford to

neglect. As the municipal drinking water source protection area upstream Huangpu River

suffers from increasingly heavier contamination of water in recent years, the development of

the higher-quality new Qingcaosha municipal drinking water source has to be accelerated. To

reduce land-based pollution of offshore waters of Yangtze River Estuary, improve natural

and ecological environment of Shanghai, and eliminate the conflicts between agricultural and

non-point pollution in Shanghai and its objective of becoming an environment-friendly city,

Shanghai Municipal Government cooperates with the World Bank, the PIU of GEF, to seek a

feasible new approach to pollution reduction in relation to the non-point pollution in

suburban areas where the economy experience ongoing growth, and to find solutions for

difficulties in regional economic growth and urbanization.

In November 2007, GEF approved the Shanghai Agricultural and Non-Point Pollution

Reduction Project (SANPRP). The Ministry of Finance of China entered into the Shanghai

GEF Project Preparation Grant (PPG) Agreement on June 24, 2008. The project is invested in

jointly by Shanghai Municipal Government and GEF and implemented by Shanghai

Municipal Government. The project consists of a series of environmental protection

demonstration components aiming at mitigating agricultural and non-point pollution,

reducing pollutants discharged via runoffs into Huangpu River and Yangtze River, and

protecting and improving water environment.

1.2 Consistency with Governmental Plans

The Eleventh Five-year Plan for Shanghai's National Economy and Social Development

implemented since 2006 is a strategic overall plan that provides a framework for economic

and social development of Shanghai during the 11th Five-year Plan. According to the plan,

Shanghai will develop cyclic eco-agriculture, reduce use of chemical fertilizers, pesticides

and mulch plastic films, promote integrated use of crop straws and livestock and poultry

manure, and increase the use of commodity organic fertilizers; improve the quality of water

environment; accelerate watercourse regulation in suburban areas, and further improve water

1

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

quality of suburban watercourses; boost development of modern agricultural parks, with

focus on the three islands in Chongming County, Huangpu River upstream area, northern

bank of Hangzhou Bay and the wedge-shaped agricultural zone at urban fringe.

The Eleventh Five-year Plan for Shanghai's Marine Economy Development sets out that, in

respect of marine ecological environment, Shanghai should protect the marine environment

and strictly control new pollution, and the major land-derived pollutants discharged into sea

will decrease by 15% from 2005 by 2010.

The Three-year Action Plan for Shanghai's Environmental Protection in 2006-2008 sets out

that, in respect of compliance of livestock and poultry farms and comprehensive use of

livestock and poultry manure, Shanghai should enhance law enforcement regulation over

livestock and poultry farms and further establish and improve facilities turning livestock and

poultry manure into useful resources, and, in respect of agricultural and non-point pollution

control, the city should promote the use of organic fertilizers, reduce use of chemical

fertilizers, effectively reduce agricultural and non-point pollution and improve the ecological

environment of farmland. Therefore, the Project is consistent with the municipal

government's plan for environmental protection and pollution control.

1.3 Purpose and Scope of Assessment

According to the laws and regulations of the People's Republic of China and World Bank

Operational Policies 4.01 and 4.09 in relation to environmental impact assessment, and based

on the type, location, sensitivity, sizes of Component s and as well as the nature and extent of

possible environmental impact of the Project, the environmental impact assessment of the

Project falls into Class B and has been carried out. An environment management plan has

been prepared as an operational basis and assurance for environmental impact mitigation in

construction and operation of the Project.

According to the Circular on Enhancing Management of Environmental Impact Assessment

on Projects Financed by International Financial Institutions and World Bank assurance

policies issued by PRC on Jun. 21, 1993, Shanghai Project Management Office (PMO) and

the project owner has commissioned Shanghai University to prepare the Environmental

Impact Report on Integrated Use of Bio-Agricultural Wastes in Qianwei Village, Shuxin

Town, Chongming County ("Component 1-C") and the Environmental Impact Report on

Straw Gasification-based Power Generation and Biomass Briquetting in Qianwei Village,

Shuxin Town, Chongming County ("Component 1-C"), commissioned Shanghai Normal

University to prepare the Environmental Impact Report on Livestock and Poultry Manure

Treatment Center in East Chongming County ("Component 1-B"), and commissioned

Shanghai Academy of Environmental Sciences to prepare the Environmental Impact Report

on Biogas Power Generation at Shanghai Bright Holstein Jinshan Dairy Farm ("Component

1-A").

2

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

1.4 Basis of the EIA

1.4.1 EA Documents and FSRs of Related Components

The GEF SANPRP environmental impact assessment documents for the Report are based on

the following environmental impact assessment documents and feasibility study reports:

(1) Environmental Impact Report on Integrated Utilization of Bio-Agricultural Wastes in

Qianwei Village, Shuxin Town, Chongming County, June 2006, Shanghai University;

(2) Environmental Impact Report on Straw Gasification-based Power Generation and

Biomass Briquetting in Qianwei Village, Shuxin Town, Chongming County, June 2006,

Shanghai University;

(3) Environmental Impact Report on Livestock and Poultry Manure Treatment Center in East

Chongming County, November 2007, Shanghai Normal University;

(4) Environmental Impact Report on Cow Manure-to-Biogas Generation at Jinshan Dairy

Farm, June 2009, Shanghai Academy of Environmental Sciences;

(5) Feasibility Study Report on Cow Manure-to-Biogas Generation at Jinshan Dairy Farm,

March 2009, Shanghai Environmental Sanitation Engineering Design Institute;

(6) Feasibility Study Report on Livestock and Poultry Manure Treatment Center in East

Chongming County, July 2008, Shanghai Shenye Dairy Farm;

(7) Feasibility Study Report on Integrated Utilization of Bio-Agricultural Wastes in Qianwei

Village, Shuxin Town, Chongming County, July 2008, Biomass Energy Research Center

of Tongji University;

(8) River Network Wetland Demonstration Project in Waigang Town and Juyuan New Area,

Jiading District, April 2009, Shanghai Investment Consulting Co., LTD.

(9) Feasibility Study Report on Qingpu District Rural Domestic Wastewater Treatment Phase

I Project, February, 2009, Shanghai Municipal Engineering Design General Institute;

1.4.2 Laws of the PRC for Environmental Protection

(1) Law of Environmental Protection of the PRC, December, 1989;

(2) Law of Environment Impact Assessment of the PRC, October, 2002;

(3) Law of Air Pollution Prevention and Control of the PRC, April, 2000;

3

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

(4) Law of Water Pollution Prevention and Control of the PRC, February, 2008;

(5) Law of Environmental Noise Pollution Prevention and Control of the PRC, October,

1996

(6) Management Regulations on Environmental Protection for Construction Projects, People

Republic of China State Council No.253 order, November. 1998;

(7) Law of Solid Waste Pollution Prevention and Control of the PRC, December, 2004.

(8) Law of Cleaning Production Promotion of the PRC, June, 2002;

(9) Law of the People's Republic of China on Regenerated Energy, February, 2005;

(10) Management Regulations for Electricity Generation from Renewable Energy, National

Development and Reform Commission, January, 2006;

1.4.3 Shanghai's Rules for Environmental Protection

(1) Regulations of Shanghai Municipality on Environmental Protection, May, 2006;

(2) Functional Division of Shanghai Water Environment, December, 2004;

(3) Functional Division of Shanghai Ambient Atmospheric Quality, July, 2004;

(4) Functional Division of Shanghai urban noise Environment, June, 2008;

(5) Eleventh Five Year Plan of Shanghai National Economic and Social Development;

February, 2006;

(6) Shanghai Wastewater Plan (2005-2020);

(7) Shanghai Three-Year Environment Protection, Construction and Action Plan for

2006-2008;

1.4.4 World Bank's Safeguard Policies

(1) The World Bank's OP/BP4.01, Environmental Assessment;

(2) The World Bank's OP4.09, Pest Management;

(3) The World Bank's OP/BP4.12, Involuntary Resettlement;

(4) The World Bank's OP/BP 4.36, Forests;

(5) The World Bank's OP/BP 4.37, Safety of Dams;

4

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

(6) The World Bank's OP/BP7.50 , International Waterways;

(7) The World Bank's /BP7.60, Projects in Disputed Areas;

(8) The World Bank's OP/BP4.11, Physical Cultural Resources;

(9) The World Bank's OP/BP4.10, Indigenous Peoples;

(10) The World Bank's OP/BP 4.04, Natural Habitats;

1.4.5 Technical Documents for Assessment

(1) Professional Standard, The Technology Guiding of Environment Impact Assessment

the Principle, HJ/T2.1-93;

(2) Professional Standard, The Technology Guiding of Environment Impact Assessment

Environment air, HJ/T2. 2-93;

(3) Professional Standard, The Technology Guiding of Environment Impact Assessment

Surface Water Environment, HJ/T2. 3-9;

(4) Professional Standard, Technology Guiding of Environment Impact Assessment Sound

Environment, HJ/T2. 4-1995;

(5) Professional Standard, Technology Guiding of Environment Impact Assessment

Ecological Environment of Nature Resource Development, HJ/T19-1997;

1.5 Standards of Assessment

The following assessment standards are employed in line with the location of the Project and

Shanghai Municipal Government's zoning water environment, ambient air and noise and

applicable laws and regulations.

1.5.1 Standard of Environment Quality Assessment

(1) Environmental Quality Standard for Surface Water

According to the Shanghai Water Environment Zoning, Component 2-B is located within the

municipal drinking water source protection area upstream Huangpu River and subject to

Class II standard defined in the Environmental Quality Standards for Surface Water;

Components 1-B and 1-C are seated in Chongming Island and subject to Class III standard;

Component 1-A is situated in Langxia Town, Jinshan District and subject to Class V standard,

falling into Class V area; Component 2-A is located in Waigang Town and Juyuan New Area,

5

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Jiading District, subject to Class IV standard. Table 1.1 lists selected indicators for the

environmental quality standards for surface water.

Table 1.1 Environment Quality Standard for Surface Water (GB3838-2002)

mg/Lexcept pH

No. Parameter

Class II

Class III

Class IV

Class V

1 pH

69 69 69 69

2

DO

6 5

3

2

3 CODCr 15

20

30

40

4 BOD5 3

4

6

10

5 NH3-N 0.5

1.0

1.5

2.0

6

TP 0.1

0.2 0.3 0.4

(2) Environmental Quality Standard for Noise

According to the Shanghai Environmental Noise Zoning, Components 1-B, 1-C and

2-B are within Class 1 zone and subject to Class 1 standard defined in Standard of

Environmental Noise of Urban Area; Components 1-A and 2-A fall into Class 2 zone and is

subject to Class 2 standard. Table 1.2 lists the standard values of environmental noise of

urban area.

Table1.2 Environmental Quality Standard for Noise (GB3096-2008) Leq(A):dB

Standard Value

Standard Value

Grade

Grade

Daytime Nighttime

Daytime Nighttime

0 50 40 3 65 55

1 55 45 4 70 55

2 60 50

(3) Ambient Air Quality Standard

According to the Zoning of Ambient Air Quality in Shanghai, Components 1-B and 1-C are

within Class I Zone and subject to Class I standard. Component 2-B consists of two parts.

The Sun Island nature protected area and Dianshan landscape and water body protection area

are within Class 1 Zone and subject to Class I standard, and the remaining areas are subject

to Class II standard. Components 1-A and 2-A are subject to Class II standard. Table 1.3 lists

the standard values of Ambient Air Quality (GB3095-1996).

6

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Table 1.3 Ambient Air Quality StandardGB3095-1996 mg/m3

Grade Sampling

Time TSP PM10 SO2 NO2

Annual average

0.08 0.04 0.02 0.04

1st

Daily

average 0.12 0.05 0.05 0.08

Standard

Hourly average

0.15 0.12

Annual average

0.20 0.10 0.06 0.08

2nd

Daily

average 0.30 0.15 0.15 0.12

Standard

Hourly average

0.50 0.24

(4) Standard of Assessment for Sediment

The Class II standard defined in Environmental Quality Standard for Soils (GB156181995)

is used for assessment on river sediment removal involved in the Project, see Table 1.4.

Table1.4 Executive Standard of Assessment for Sediment

Environmental

Standard

Pollutant

Unit Standard

Value

Factor

Reference

Parameter

Copper mg/kg 100

Environmental

Lead mg/kg 350

quality standard for

Chromium mg/kg

250

soils GB15618

Soil

Zinc mg/kg 300

1995

Cadmium mg/kg

0.60

Grade II

Arsenic mg/kg

30

Mercury mg/kg

1.0

The analysis on heavy metal content of removed bottom sediments of watercourses is as per

the Solid Waste - Extraction Procedure for Leaching Toxicity (HJ/T299-2007).

If any hazardous component of the leaching solution of a solid waste prepared as per

HJ/T299 exceeds the concentration limit specified in the table Table1.5, such solid waste is

considered hazardous waste with leaching toxicity characteristics.

Table1.5 Standard Values for Determination of Leaching Toxicity (HJ/T299-2007)

S/N

Hazardous Component

Concentration Limit of

Analysis Method

Hazardous Component in

Leaching Solution(mg/L)

1

Lead(total lead)

5

ICP-AES, ICP-MS, etc.

2

Cadmium(total cadmium)

1

ICP-AES, ICP-MS, etc.

3

Copper (total copper)

100

ICP-AES, ICP-MS, etc.

4

Zinc(total zinc)

100

ICP-AES, ICP-MS, etc.

5 Mercury(total

mercury)

0.1

ICP-MS

7

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

1.5.2 Pollutants Discharge Standard

(1) Wastewater Discharge Standard

Wastewater discharge is subject to Shanghai Integrated Wastewater Discharge Standard

(DB31/1991997) and the standard for pollutant discharge by urban wastewater treatment

plants. Component 2-B is located within the municipal drinking water source protection area

upstream Huangpu River, and its wastewater treatment plant is subject to Class1B standard

defined in GB18918-2002; Components 1-B and 1-C fall into Class III water quality area and

are subject to Class I standard for discharge; Component 1-A is within Class V water quality

area and Component 2-A within Class IV water quality area, both subject to Class II standard

for discharge. After expansion of capacity, the wastewater treatment facilities of Component

1-A shall suffice to treat the liquid fraction from bio-digester and other wastewater produced

in the Project, with pollutants contained in the effluent to comply with the Discharge

Standard for Municipal Sewerage System(DB31/425-2009). Table 1.6 lists selected

indicators for the Shanghai Integrated Wastewater Discharge Standard (DB31/1991997),

Table 1.7 lists selected indicators for the Discharge Standard of Pollutants for Municippal

Wastewater Treatment Plant (GB18918-2002) and Table 1.8 lists selected indicators for the

Discharge Standard for Municipal Sewerage System(DB31/425-2009).

Table1.6 Shanghai Integrated Wastewater Discharge Standard (DB31/199-1997)

mg/L

Standard

Maximum allowable concentration of Class II

pollutants discharged

Parameter

Class I

Class II

BOD5 20

30

CODcr 100

100

Petroleum

5 10

NH3-N 10

15

SS 70

150

Vegetable and animal oils

10

15

Table1.7 Discharge Standard of Pollutants for Municippal Wastewater Treatment Plant

(GB18918-2002)

(mg/L)

Standard

Grade I

Grade II

Grade III

A

B

BOD5 10

20

30

60

CODcr 50

60

100

120

Petroleum 1

3

5

15

NH3-N 58 8(15) 25(30) -

TN 15

20

-

-

8

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

SS 10

20

30

50

Vegetable and animal oils

1

3

5

20

TP 0.5

1

3

5

Table 1.8 Discharge Standard for Municipal Sewerage SystemDB31/425-2009

Maximum allowable concentration of

S/N

Parameter

pollutants discharged

1 pH

69

2 CODCrmg/L 500

3 BOD5 mg/L 300

4

SS mg/L 400

5

TN mg/L 60

6

NH3-N mg/L 40

7

TP mg/L 8

(2) Integrated Emission Standards for Air Pollutants

According to the State Environmental Protection Administration and the National

Development and Reform Commission jointly issued the Circular on Strengthening

Management of Environmental Impact Assessment on Biomass-Fueled Power Generation

Projects (HF [2006] No. 82), the flue gas emission in biogas-based power generation projects

is subject to the maximum allowable emission concentration for air pollutants emitted by

gas-fired boilers defined in the Emission Standard for Air Pollutants from Boilers

(DB31/387-2007), see Table 1.9 Unorganized emission of malodorous pollutants is subject to

Class II standards for plant boundary defined in the Emission Standards for Odor Pollutants.

Table 1.9 Emission Standard for Air Pollutants from Boilers (DB31/387-2007)

Maximum allowable emission concentration

No.

Pollutants

Unit

for air pollutants emitted by gas-fired boilers

1

SO2

mg/m3

50

2

NOx

mg/m3

200

3

Smoke

mg/m3

30

Nitrogen oxide contained in exhaust gas of generator units shall meet the Stage II limit (7.0

g/kW.h) provided in Limits and measurement methods for exhaust pollutants from positive

ignition (P.I.) engines of vehicles and vehicles equipped with P.I. engines GB14762-2002,

sulfur dioxide to meet Class II standard defined in Integrated Emission Standard of Air

Pollutants GB16297-1996, and these Standards are listed in Table 1.10 and Table 1.11.

9

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Table1.10 Limits and measurement methods for exhaust pollutants from positive

ignition (P.I.) engines of vehicles and vehicles equipped with P.I. engines

GB14762-2002

Pollutant

Limits for Exhaust Pollutants from Positive Ignition NG Engine g/(kw·h)

NOx 7

Table1.11 Integrated Emission Standard of Air PollutantsGB16297-1996

Rate of Maximum Allowable Emission (kg/h)

Concentration of Maximum

Pollutant

Allowable Emission (mg/m3)

Height of Exhaust Stackm

Class II

15 3.0

SO2 1200

20 5.1

In Components 1-B, the cow production size meets the intensive farm requirements, and the

livestock and poultry manure treatment works are within the dairy farm. Therefore, the

Discharge Standard of Pollutants for Livestock and Poultry Breeding (GB18596-2001) is

applicable to discharge of odor pollutants( see Table1.12). Component 1-A and the

wastewater treatment plant of Component 2-B are subject to class II plant boundary standard

defined in the Plant Boundary Standard for Odor Pollutants(GB14554-93), while Component

1-C subject to Class I plant boundary standard, see Table 1.13.

Table 1.12 Discharge Standard of Pollutant for Livestock and Poultry Breeding

(GB18596-2001)

Discharge Pollutant

Limited Value

Odor concentrationNo unit 70

Table 1.13 Plants Boundary Standard Value of Odor Pollutants (GB14554-93)

Class II

Discharge Pollutants

Class I

New build or

Before June 8, 1994

rebuild

NH3-N (mg/m3) 1.0

1.5

2.0

H2S (mg/m3) 0.03

0.06

0.10

Odor concentrationNo unit 10

20

30

(2) Emission standards for noise

According to the Emission Standard for Industrial Enterprises Noise at Boundary

10

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

(GB12348-2008), Components 1-B, 1-C and 2-B fall into Class 1 area, where the noise at

plant boundary must meet Class 1 standard. Component 2-A falls into Class 2 area, where the

noise at plant boundary must meet Class 2 standard. Component 1-A must meet Class 3

standard of noise at boundary. These standards are listed in Table 1.14.

Table 1.14 Emission Standard for Industrial Enterprises Noise at Boundary

(GB12348-2008),

Leq(A)dB

Standard Value

Standard Value

Grade

Grade

Daytime Nighttime

Daytime Nighttime

0 50 40 3 65 55

1 55 45 4 70 55

2 60 50

4Discharge Standard for Sediment

In addition to the environmental quality standard for soils, the Control Standard for Pollutants in Sludge

from Agricultural Use is also used for river sediment removal to control disposal and discharge of sludge

from river sediment removal (details see Table 1.15).

Table1.15 Control Standards of Pollutants in Sludge for Agricultural Use (GB 4284-84)

Standard Limited Value(mg/kg dried sludge)

Standard

Pollutant

Parameter

Reference

Acidic Soil

Neutral and Basic Soil

(pH<6.5)

(pH6.5)

Cadmium and

5 20

its compounds

Mercury and its

5 15

compounds

Lead and its

300 1000

Control

compounds

Standards of

Chromium and

Pollutants in

600 1000

its compounds

Sediment Sludge for

Arsenic and its

Agricultural

75 75

compounds

Use (GB

4284-84)

Copper and its

250 500

compounds

Zinc and its

500 1000

compounds

Nickel and its

100 200

compounds

11

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

1.6 Grade of Assessment

Base on Technology Guiding of Environment Impact Assessment (HJ/T2.12.3-93

HJ/T2.4-1995HJ/T19-1997, The grade of assessment could be defined as follows:

(1) Waste Water

In Component 1-A, the liquid fraction from bio-digester will be discharged into the

municipal sewer network after treatment at the wastewater treatment station reconstructed. In

Components 1-B and 1-C, harmless liquid (liquid fraction from bio-digester) from anaerobic

fermentation of livestock and poultry manure will be directly used for farmland and not

directly discharged into surface water. Component 2-B is subject to treatment at wastewater

treatment plants and constructed wetland, with a small quantity of tail water (less than 500

m3/day station) that meets Class IB standard, water environment assessment falling into

Class III.

(2) Noise

The noise is temporary in construction period, low-noise equipments are used, and the noise

increment value is very low [<3 dB(A)]. Therefore, the acoustic environment assessment

falls into Class III.

(3) Ambient Air

The impact on ambient air is mainly from fugitive dusts in the construction period, while

from odor of livestock and poultry manure in the operation period. Malodorous gases,

typically H2S and NH3, are unorganized discharge. The malodorous pollutants generated in

the Project are not discharged in a huge quantity, and can meet relevant standards after

proper treatment. Air pollutants from boilers, i.e. SO2, NOx and Smoke, have an equivalent

standard emission level of less than 2.5*108m3/h, thus the ambient air assessment falls into

Class III.

1.7 Range of Assessment

1.7.1 Water Environment

For Components 2-A and 2-B, the assessment covers watercourses receiving tail water from

constructed wetland. For Component 1-A, the assessment covers Hongqiao Port adjacent to

the dairy farm. For Components 1-B and 1-C, the assessment covers adjacent water systems

and, of course, effect on the East China Sea.

12

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

1.7.2 Ambient Air

The assessment covers the project area and 2500 m beyond the project boundary.

1.7.3 Acoustic Environment

The assessment covers the project area and 100 m beyond the project boundary.

1.8 Environment Protection Objective

1.8.1 Water Environment Protection Objective

For Components 1-B and 1-C, the water environment protection objective is that the water

quality should meet Class III standard defined in the Environmental Quality Standards for

Surface Water (GB3838-2002). For Component 1-A, the water quality in Hongqiao water

quality should meet Class V standard defined in the Environmental Quality Standards for

Surface Water (GB3838-2002). For Components 2-A, the water environment protection

objective is that the water quality should meet Class IV standard defined in the

Environmental Quality Standards for Surface Water (GB3838-2002). For Component 2-B,

the water quality in Hongqiao water quality should meet Class II standard defined in the

Environmental Quality Standards for Surface Water (GB3838-2002).

1.8.2 Ambient Air Protection Objective

For Components 1-B and 1-C, the ambient air quality should meet Class I defined in the

Ambient Air Quality Standard (GB3095-1996); for the part of Component 2-B within the Sun

Island nature protected area and Dianshan water body protection area, the ambient air quality

should meet Class I standard defined in the Ambient Air Quality Standard (GB3095-1996),

and the remaining part should meet Class II standard.

1.8.3 Acoustic Environment Protection Objective

For Components 1-B, 1-C and 2-B, the acoustic environment protection objective should

meet Class I standard defined in the Standard of Environmental Noise of Urban

Area(GB3096-2008). Components 1-A and 2-A should meet Class II standard.

1.8.4 Environmental Sensitive Objectives

13

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

The sites of Components 1-B and 1-C are far away from villages, without any sensitive

residential area around; there are villages residing within the 300 m protection area of

Component 1-A; residential houses are situated south of the constructed wetland of

Component 2-A; residential houses are found adjacent to the constructed wetland and

wastewater treatment plant of Component 2-B. Table1.16 lists the Position of the

Environmental Sensitive Objectives.

Table1.16 Position of the Environmental Sensitive Objectives

No.

Components

Sensitive objectives

Position

Distancem

1

Component

Yonggan village

Southeast

About 200

2

1-A

Nantang village

North

About 200

3

Component

Zhujiazhai village

North

About 15

2-A

4 No.34,Jintian

village North

About

10

5

No.82,Qianwan village

West

About 10

6 No.167,Beiwangbang

village

South

About

10

Component2-B

7

No.289,the South of Beiwangbang village

North

About 10

8

No.76,the West of Xiezhuang village

North

About 10

9

The East of Xiezhuang village

North

About 10

1.9 Organization of the EA Report

The chapters of this report deal with the following topics:

Chapter 1 Introduction

Based on EA documents of Components, this chapter provides an overview of project

background; purpose, scope and basis of preparation of EA reports; discharge standards,

assessment classes, assessment scope and environmental protection objectives; and at last

provides a summary of all chapters of the Report.

Chapter 2 Overview of Project

Briefly introduce composition of the Project and Components

Chapter 3 Overview of Local Environment

Briefly introduce natural environment, environmental quality and social environment of the

project area.

Chapter 4 Project Alternatives

14

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Analysis will be made on whether or not to implement the alternative site selection or

technological process solutions for the Project and its Component s.

Chapter 5 Impact Assessment and Mitigation Measures

This chapter analyzes and predicts environmental impact of Components during their

implementation and operation and provides mitigation actions against negative impacts.

Chapter 6 Expected Benefits of Project

This chapter analyzes positive effects of the Project in respect of social, environmental and

economic benefits.

Chapter 7 Public Participation

This chapter provides an overview of information disclosure and public participation

methods of the Project and comments and suggestions on the Project.

Chapter 8 Description and EMP for Integrated Agricultural Pollution Reduction

Techniques

This chapter briefly introduces the comprehensive agricultural and non-point pollution

control technology demo project, and propose the environment management plan for

comprehensive agricultural and non-point pollution control technology demo project. As the

use and management of pesticides are involved, the pest management plan will be developed

separately.

Chapter 9 Environmental Management Plan and Monitoring Plan

This chapter briefly describes the purpose, role, organization and budget of environment

management plan, and the environment management plan and monitoring plan of

Components.

Chapter 10 Conclusions

This chapter briefly summaries the main conclusions on the EA report.

15

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

2 OVERVIEW OF PROJECT

The Project focuses on the most serious and the most urgent agricultural and

non-point pollution problems in suburban and rural areas of Shanghai. These

pollutants are mainly livestock and poultry manure, agricultural chemicals (chemical

fertilizers and pesticides), agricultural wastes and crop straws. The Project is

consistent with the overall work of the government and included into the 4th

three-year action plan for environment protection (2009-2011).

2.1 Project Framework

In general, the Project is intended to play a demonstration role by implementing

integrated management of livestock and poultry manure and agricultural wastes, rural

wetland wastewater treatment system and comprehensive agricultural pollution

reduction technology. Some sites will be selected in suburban and rural areas of

Shanghai to implement effective and innovative pollution reduction project and

finally reduce contamination of water bodies of Yangtze River Estuary and the East

China Sea arising from agricultural pollution.

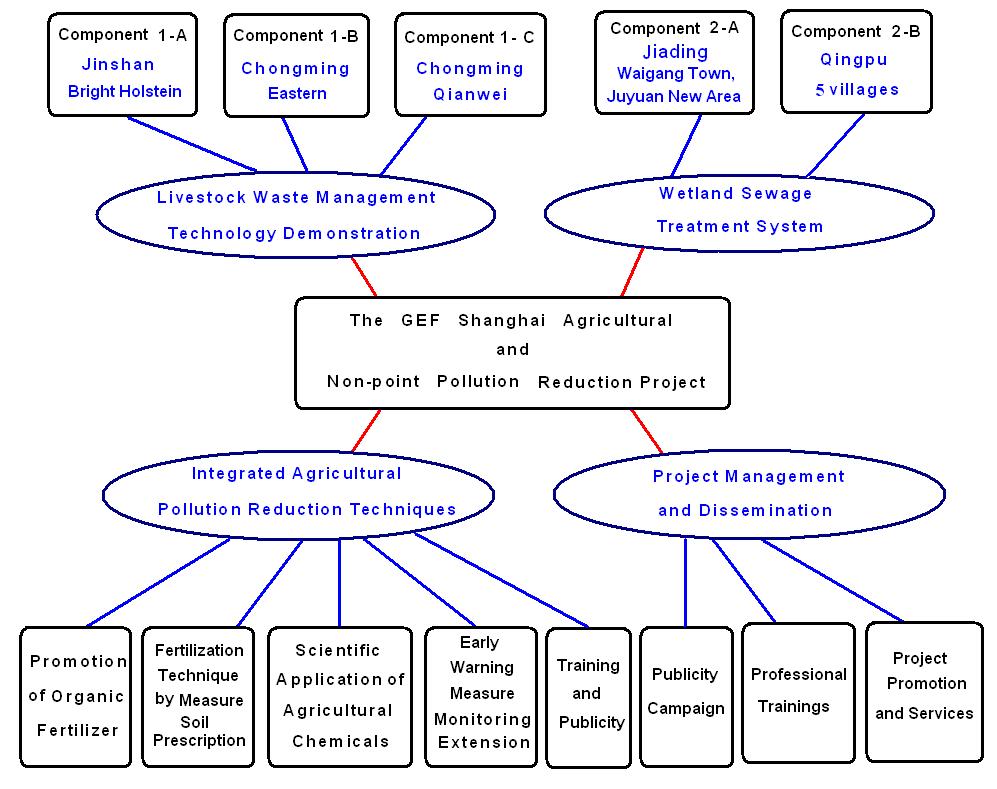

Figure2.1 Project Framework of the GEF Shanghai Agricultural and Non-point

Pollution Reduction Project

In the foregoing Components, environmental impact assessment (EA) and the

environment management plan (EMP) will be made for livestock and poultry wastes

16

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

integrated management technology demonstration and wetland wastewater treatment

technology. Therefore, this chapter will provide a brief introduction. According to the

Environmental Impact Assessment Law of the People's Republic of China, the

environmental impact assessment will not be made for the comprehensive agricultural

pollution reduction technology demonstration of Components, but a separate chapter

will be provided to briefly describe the environmental impact, and a separate EMP

will be developed. The following chapters will no longer involve the fourth

component (project management and promotion) of GEF SANPRP.

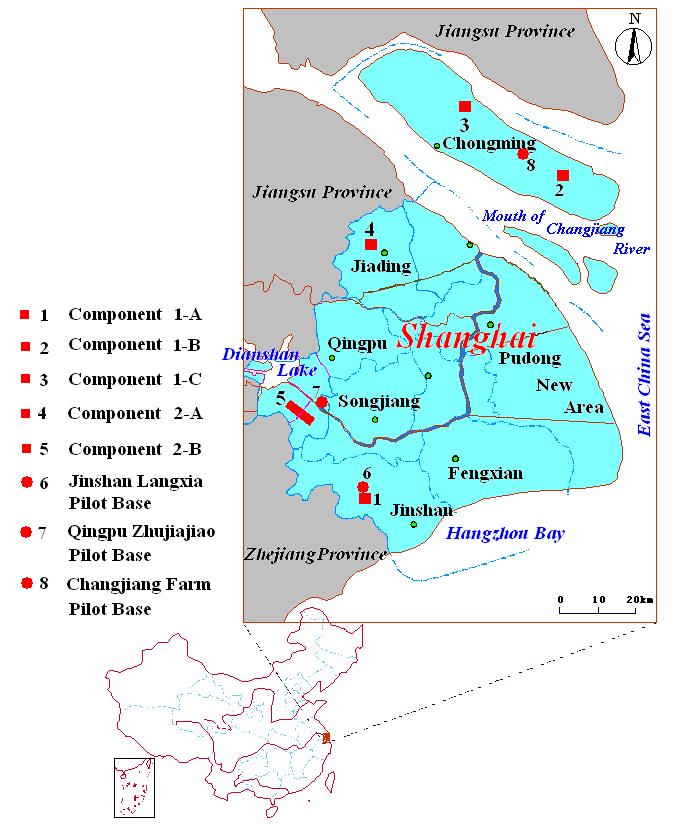

Fig.2.2 Locations of GEF Shanghai Agricultural and Non-point Pollution

Reduction Project

2.2 Description of Livestock Waste Management Technology

Demonstration

The Livestock Waste Management Technology Demonstration Project consists of

three Components. Details are provided as follows:

17

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

2.2.1 Livestock Waste Management on Large Farm (Jinshan Dairy

Farm)Component 1-A

(1).Owner

Shanghai Bright Holstan Co., Ltd.

(2) Project Location and Description

The project is located at the existing site of Shanghai Bright Holstein Dairy Farm in

the Jinshan Modern Agricultural Park, Langxia Town, Jinshan District, Shanghai.

The project will produce biogas through pre-treatment and anaerobic digestion of cow

wastes, silage leachate and wastewater from milking stall rinsing and cooling

sprinklers generated each day by 5,000 cows in the dairy farm, and use the purified

biogas to generate electricity with the cogeneration units fueled by biogas; the

residual heat from cogeneration units is used for heating anaerobic feeds; the liquid

fraction from bio-digester will be discharged into the municipal sewer network after

treatment at the wastewater treatment station reconstructed to the discharge standard

of Jinshan Langxia Wastewater Treatment Plant, and the sludge is shipped to organic

fertilizer plant and turned into organic fertilizer for sale.

The project mainly consists of civil works and plant works. The civil works include

anaerobic reactor, biogas storage tank, power generation building, storage tank for

liquid fraction from biodigester and reconstructing wastewater treatment station. The

plant works include power generation units, grid connection system and pipework

(3) Discharge System

Adopt the system of separate sewer and stormwater. The stormwater will be

discharged into the epidemic prevention river (moat) after sedimentation.

(4) Economical Technical Index

The main economical technical indexes of Component 1-A are shown in Table 2.1.

Table 2.1 The Main Economical Technical Indexes of Component 1-A

No. Item

Unit

Economical

Technical

Index

1

Total covered area

m2 2460

2

Total floor area of new buildings

m2 820

3

Total covered area of structures

m2 740

4 Road

m2 400

5 Greening

m2 500

6 Treatment

capacity

t/d

270

18

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

7 Construction

phase

month 17

8

Total works investment

Million RMB

36.0002

9

Total cost unit price

RMB /t

37.77

10

Operating cost unit price

RMB /t

14.27

5Integrated Waste Treatment Process

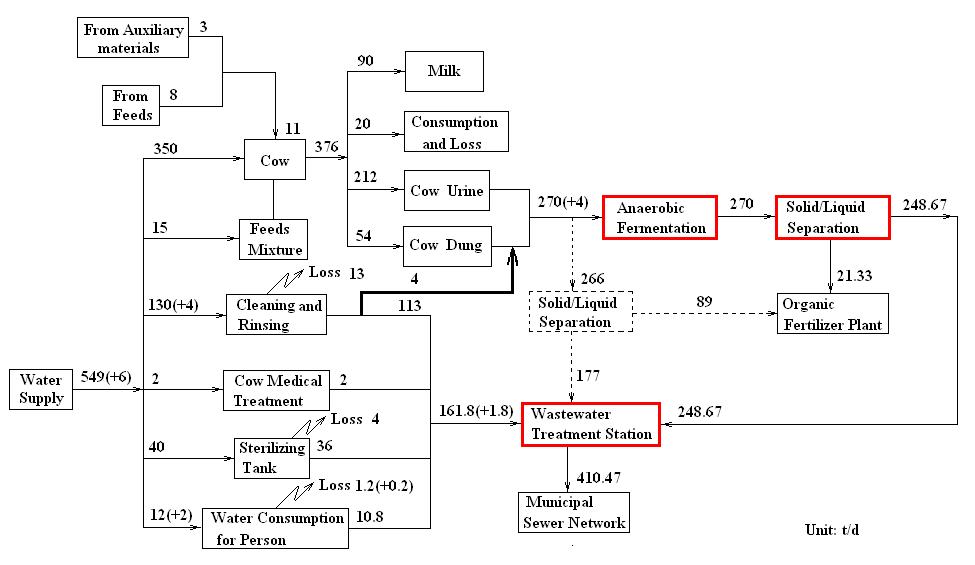

For the process flow diagram of integrated waste treatment of the project, see Fig. 2.3.

Fig. 2.3: Integrated Waste Treatment Process Flow Diagram

6Process flow of wastewater treatment station

For the process flow diagram of wastewater treatment station, see Fig. 2.4.

Fig. 2.4: Process Flow Diagram of the Wastewater Treatment Station

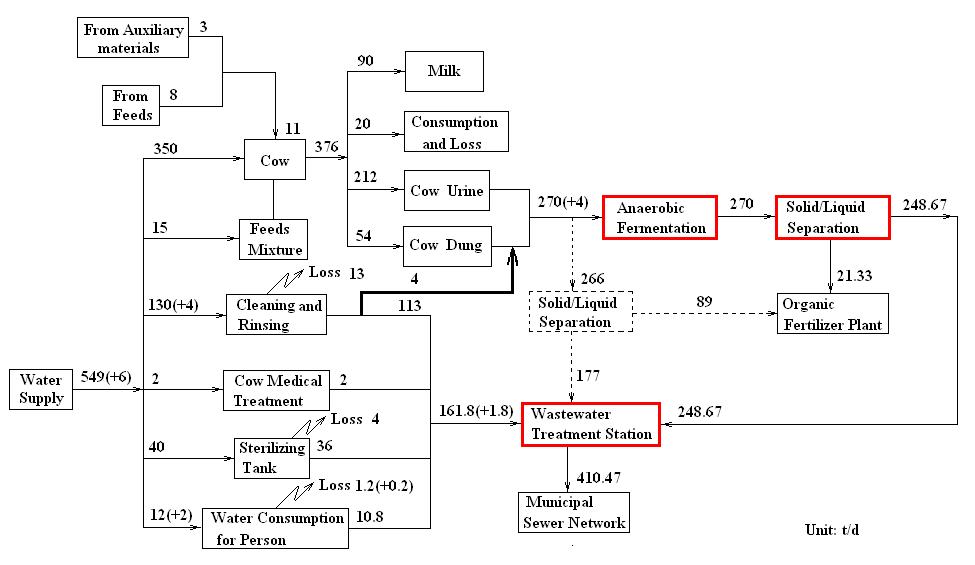

7Water Balance

For water balance of the project, see Fig. 2.5.

19

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Remarks:

The additional water consumption in this Project is 6 t/d (indicating in positive figure).

Dry feed moisture content is estimated as 10%.

The part enclosed with dotted line will be cancelled after the completion of this Project.

The moisture content in the solid part after solid/liquid separation is 80% in the original

process, v. but 75% in the new process.

In the figure, the part in red boxes is the newly-built or modified works in this Project.

Fig. 2.5: Water balance in the whole plant after implementation of this Project

8Process flow of biogas-fueled power generation

For the process flow of biogas-fueled power generation, see Fig. 2.6.

Grid connection

Biogas

Hot water tank

Generator

purification

Residual heat

Hot water for cow farm

Pretreatment

Anaerobic

Cow wastes

Solid/liquid

digester

collection truck

separation

Storage tank for

Wastewater treatment

liquid fraction

station

from bio-digester

Processed at organic

fertilizer plant and

Solid organic

sold

fertilizer

Fig. 2.6: Process Flow Diagram of Biogas-fueled Power Generation

20

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

After pretreatment and anaerobic digestion, the cow dung and urine of the project

produce biogas, which is then purified and generate electricity with the biogas-fueled

co-generation units; the residual heat from the biogas-fueled co-generation units are

used to heat anaerobic feedstock; the liquid fraction from bio-digester will be

discharged into the municipal sewer network after treatment at the wastewater

treatment station reconstructed to the discharge standard of Jinshan Langxia

Wastewater Treatment Plant, while the sludge is shipped to organic fertilizer plant and

made into organic fertilizer for sale.

2.2.2 Livestock Waste Management on Medium Farm (Chongming

Dairy Farm)Component 1-B

(1) Owner

Shanghai Shenye Dairy Cooperative

(2) Project location and description

The project is located at Chongming Dairy Farm, Beiliuyao Section, Chongming

Modern Agricultural Park. The park is included into Chongming overall development

plan. The project covers a total land area of 18,750 m2. The farm now has a stock of

1,600 cows.

The project plans to build the Eastern Chongming Livestock Waste Treatment Center

that produces 6,000t solid organic fertilizers and 10,500t liquid organic fertilizers (the

center to be under management of Shanghai Shenye Dairy Farm). The project mainly

includes the dry livestock waste treatment system and the livestock farm livestock

wastewater treatment and transfer system.

In the project, the total floor area of new buildings is 7,075 m2, with volume of

structures being 2,130 m3, fermentation workshop being 4,000 m2 and on-farm slurry

transfer pipeline being 3,000 m. Specifically:

A. The 7,075 m2 new buildings consist of 2,000 m2 storage shed, 2,000 m2

fermentation workshop, 300 m2 fertilizer workshop, 2,400 m2 storehouse, 125 m2

office space, 100 m2 of living space and 150 auxiliary spaces.

B. The 2,130 m3 new structures of the wastewater treatment and transfer system

consist of 900 m3 fermentation tank, 1,230m3 pre-sedimentation tank and 3,000

on-farm liquid fertilizer transfer pipeline.

(3) Economical Technical Index

The main economical technical indexes of Component 1-B are shown in Table 2.2.

21

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Table 2.2 The Main Economical Technical Indexes of Component 1-B

Economical

No. Item

Unit

Technical index

1 Total covered area

m2 18750

2 Total floor area of new buildings

m2 7075

3 Volume of structures

m3 2130

4 Road and paved surface

m2 2500

5 Greening

m2 1600

6 Dispose of Wet dung

t/d

49.3

7 Construction

phase

month

9

8 Total works investment

Million RMB

6.449

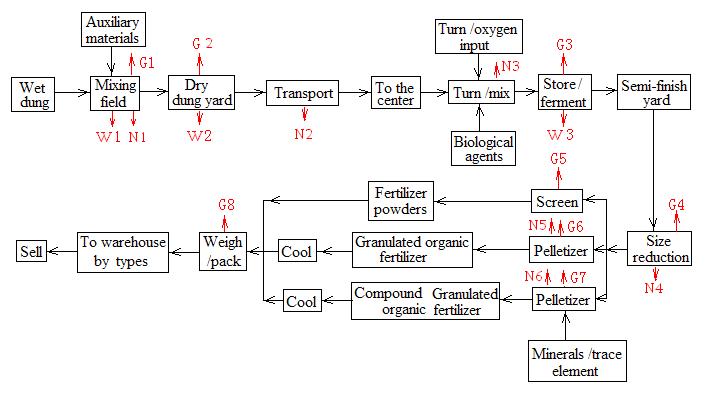

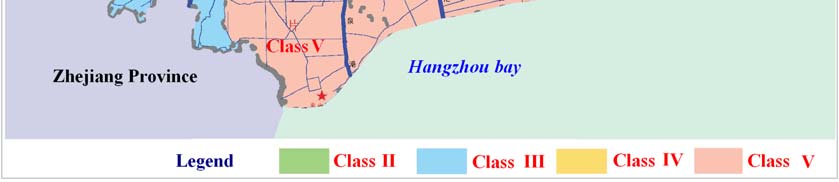

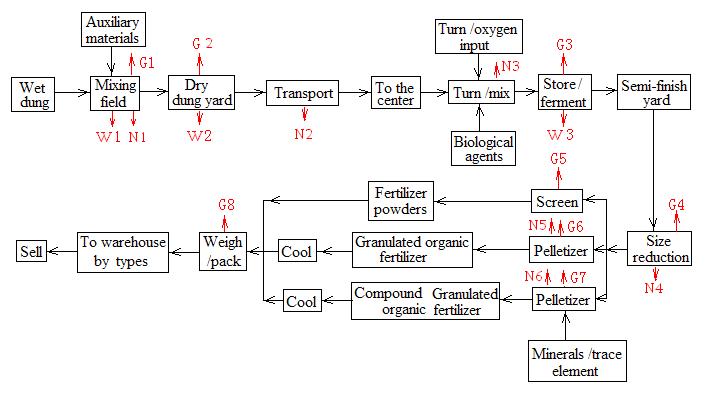

(4) Process Technology

The separate dry manure and urine wastewater treatment process is adopted.

A. Dry Livestock Waste Treatment

The dry livestock wastes, after collected from farms, are transferred to the

fermentation workshop, where automatic oxygen input occurs during turning by

turners. Then, after addition of biological agents, automatic cutting of straws

(auxiliary materials) and mixing, they enter the high-efficiency composting stage

(secondary fermentation). The materials after removal of disease-causing bacteria and

pest eggs are sent to the deep processing system where they are made into

high-quality organic fertilizers in power or pellet form.

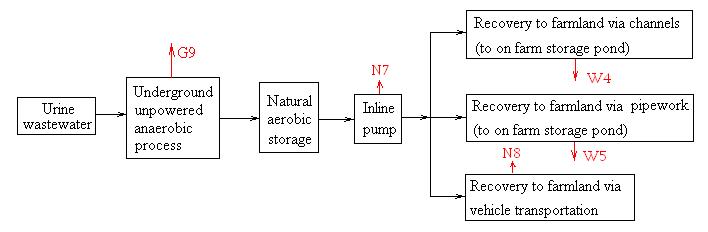

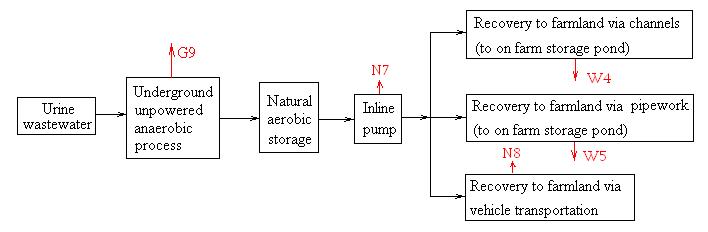

B. Livestock Wastewater Treatment

Livestock wastewater is collected and transferred into the underground unpowered

anaerobic and aerobic digestion systems. The wastewater, after anaerobic and aerobic

digestion, is made into high-quality organic fertilizers and conveyed to crop fields via

channels and pipelines, thereby being recovered to farmlands harmlessly.

5Technological Process

For the process flow of livestock wastewater, see Fig. 2.7 and the process flow of the

dry livestock wastes, see Fig. 2.8.

Fig. 2.7: Liquid Fertilizer Production Process Flow Diagram

22

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Remarks: There is only one set of pelletizer, operated alternately for the two types of fertilizers.

Fig. 2.8: Process Flow Diagram of Solid Organic Fertilizers from Livestock

Wastes

2.2.3 Integrated Livestock and Agricultural Waste Management

(Qianwei Village)Component 1-C

(1) Project Owner

Chongming ShuxinTown Qianwei Village Committee

(2) Project Location

The project is located at Eco-farming Demonstration Zone, Qianwei Ecological

Village, to the north of the east-west axis of the village, between Jing'er Road and

Jingsi Road, and to the north of Wei'er Road. The project covers a total area of 6,900

m2 or 10.3 Mu.

The land for the project is in the possession of Qianwei Ecological Village and

currently used as fish ponds, breeding farms and crop fields. There are ditches drained

23

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

to river course, 150 m2 brick-laid single-floor buildings, a 3 m wide unpaved road

connected to a 4 m gravel road that allows access by farm tractors. No water or power

supply facilities are available. To the south of the land lot is the hog breeding base of

Qianwei Village that has a hog stock of 4,000 and produces 10,000 hogs a year.

(3) Project Description

The project consists of two independent sub-systems: the multiple agricultural

wastes-based biogas-fueled power generation and nutrients recovery sub-system, and

the straw gasification-based power generation and biomass briquetting sub-system.

The two sub-systems are inter-adjusted in operation to ensure stability of energy

supply.

The project coves a land area of 6,900 m2 (90m×60m+50m×30m), including 5,400 m2

for the multiple agricultural wastesbased biogas-fueled power generation and

nutrients recovery sub-system (90m×60m), and 1,500 m2 for the straw

gasification-based power generation and biomass briquetting sub-system (50m×30m).

There are over 2,550 m2 structures for the multiple agricultural wastesbased

biogas-fueled power generation and nutrients recovery sub-system, including 1,190

m2 greenhouse structures, over 650 m2 workshops and auxiliary buildings, 11,000 m

long slurry pipes in fields, and over 1,200 m3 slurry holding ponds in fields.

The straw gasification-based power generation and biomass briquetting sub-system

consists of over 280 m2 buildings, 50 m3 structures and over 500 m2 greenhouse

structures.

After the Project is completed, the 600 m3 biogas plant completed in 1993 with

investment of RMB2.66 million Yuans and having an annual output of 150 m3 biogas

will be removed. Residuals in the biogas digester will be used as raw materials of

organic fertilizers, construction wastes will be disposed of according to requirements

of the Construction Wastes Management Office, and the original site will be prepared

and afforested.

4Economical Technical Index

The main economical technical indexes of Component 1-C are shown in Table 2.3.

Table 2.3 The Main Economical Technical Indexes of Component 1-C

Economical

No. Item

Unit

Technical index

1

Total covered area

m2 6900

2

Buildings covered area

m2 2620

3

Volume of structures

m3 2600

4

Power generation capacity

kwh

940000

5 Biogas

m3/d 2138

24

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

6

Output of solid organic fertilizer

t/a

1801

7

Output of liquid organic fertilizers

t/a

11093

8 Construction

phase

month

8

9

Total works investment

Million RMB

20.72

10

Annual profit

Million RMB/a

1.06

11

Phase of return on investment

year

20

5Process Technology

A.Technological Process

The project consists of two independent sub-systems: the multiple agricultural

wastesbased biogas-fueled power generation and nutrients recovery sub-system, and

the straw gasification-based power generation and biomass briquetting sub-system.

The two sub-systems are inter-adjusted in operation to ensure stability of energy

supply (See Fig. 2.9). In the multiple agricultural wastesbased biogas-fueled power

generation and nutrients recovery sub-system, different raw materials are separately

treated and digested in anaerobic digestion to avoid difficult feeding and discharge

due to mixed raw materials.

Fig. 2.9: Overall Process Flow Diagram

25

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

B. Anaerobic Digestion Process of Livestock Wastes and Wastewater

The dung and wastewater from livestock farms are mixed and then digested on a fully

mixed. The liquid generated from digestion and the acid solution from acid crop straw

combine to further deepen digestion, which in turn provides nitrogen and phosphorus

for acid solution. For the process flow of anaerobic digestion process of livestock

wastes and wastewater, see Fig. 2.10.

Fig. 2.10: Anaerobic Digestion Process Flow Diagram for Livestock Wastes and

Wastewater

C. Anaerobic Digestion Process of Organic Domestic Wastes

The domestic wastes are first pre-treated separately and then hydrolyzed. The

hydrolytic liquid of wastes is mixed with dung and wastewater from livestock farms

and then digested on a fully mixed. The liquid generated from digestion and the acid

solution from acid crop straw combine to further deepen digestion, which in turn

provides nitrogen and phosphorus nutrients for acid solution. For the process flow of

anaerobic digestion process of organic domestic wastes, see Fig. 2.11.

26

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Fig. 2.11: Anaerobic Digestion Process of Organic Domestic Wastes

D Anaerobic Digestion Process of Crop Straw

This project adopts the moderate temperature internal circulation acid generation gas

co-generation and two-stage anaerobic digestion process developed by the Biomass

Energy Research Center of Tongji University (hereinafter the "BERC Process"). The

BERC process, through special process management, controls the acid generation

phase and separate the acid and gas generation phases so that the acid generation

phase is in semi-open digestion while the gas generation phase is in closed digestion,

which simplifies the intensity of feeding/discharge and improves the reaction

efficiency of the system. For the process flow of anaerobic digestion process of crop

straw, see Fig. 2.12.

27

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

Fig. 2.12: Anaerobic Digestion Process Flow Diagram of Crop Straw

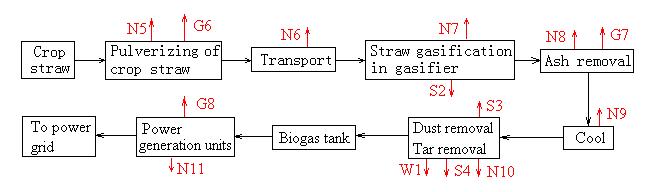

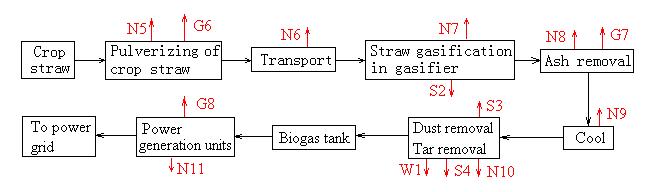

E. Straw Gasification Process

After pulverizing of crop straw, the down-draft fixed bed gasifier is used to produce

forced air discharge through the two-stage gasifier in the feeding section. On the one

hand, that gasifier is simple and easy to start; on the other hand, the water and

hydrocarbon from the raw materials reduced under high temperature are used to

increase the proportion of hydrogen and methane in the gas and improve gas quality.

For the process flow of straw gasification process, see Fig. 2.13.

Fig. 2.13: Straw Gasification Process Flow Diagram

28

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

F. Biomass Briquetting Process

The ring mill type briquetting equipment is used for rice chaff biomass briquetting,

which consumes less energy and produces pellets of suitable sizes. For the process

flow of biomass briquetting process, see Fig. 2.14.

Fig. 2.14: Biomass Briquetting Process Flow Diagram

2.3 Description of Wetland Demonstration for Pollution Reduction

2.3.1 Jiading Town River-network Wetland Demonstration

Component 2-A

(1) Project Owner

Shanghai International Automobile City Newanting United Development Co.,

Ltd.

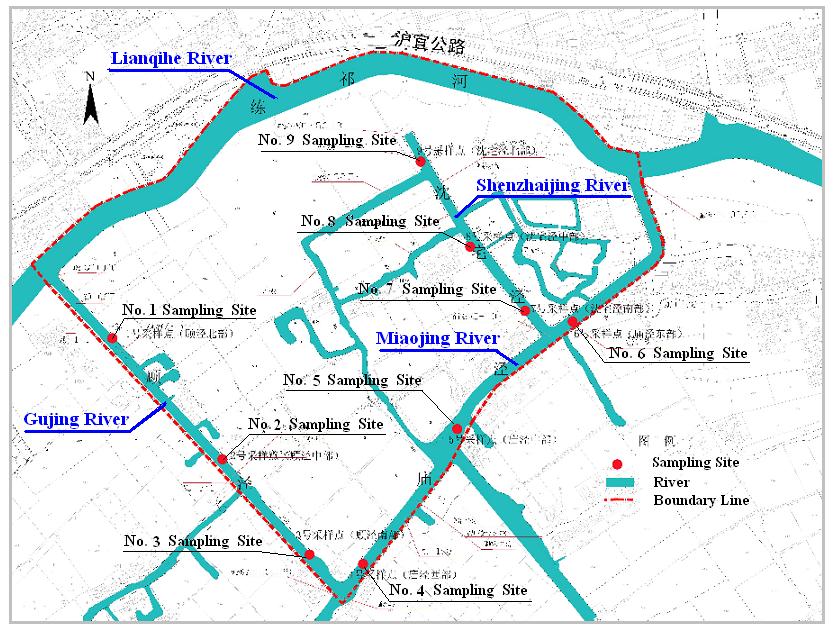

(2) Project Location

The River Network Wetland Demonstration Area is situated northwest of the planned

North Suburban Wetland, encompassing the area confined by Lianqihe, Gujing and

Miaojing, sized around 667407.34 m2. The location of River Network Wetland

Demonstration Area is shown on the Fig.2.15.

Location of the Demonstration Area Monitoring Point of Pengmen

Fig.2.15 Location and Scope of the Demonstration Area

29

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

3Situation of the Rivers Dredging

A. River Dredging and Its Function

In the range of the dredging project there are main rivers, like Miaojing River, Gujing

River and Shenzhaijing River, as well as some natural creeks, all of which are

governed by the Town. These rivers have now the principal functions of flood control

and drainage, and provision of agricultural and fisheries water. In the future after the

completion of the river regulation, apart from the current functions, new functions

will be added such as wetland and landscape, thus becoming a model project of

river-network and wetland construction. Table 2.4 lists the present situation of the

rivers.

Table 2.4 the Present Situation of the Rivers.

Length

Wide

Area of the Rivers

River

Beginning and End

m

m

ha

Miaojing Gujing

Lianqi

river

1104

1015

1.7

Gujing

Lianqi river - Miaojing

783

813

1

Shenzhaijing

Miaojing - Lianqi river

487

811

0.54

Natural creeks

2405

7-15

3

Total

6.24

B. Present situation of river bed material

According to the heavy metal content sampling analysis and the sediment toxic

leaching test done on the bottom sludge dredged from Miaojing River, Shenzhaijing

River and Gujing River (The monitoring results of heavy metal content test are shown

in Table 5.19, the results of the toxicity characteristic leaching test are shown in Table

5.20.), the contents of heavy metals do not exceed the requirements in "Control

standards for pollutants in sludge from agricultural use" GB4284-84, and the

concentration of leach solution are not exceeded the concentration limits of hazardous

components (Identification standard hazardous wastes- leaching toxicity

identification GB5085.3-2007), therefore, these bottom sludge dredged are not

hazardous wastes and can be used for agricultural use or forestry purposes.

C. Purpose of River Dredging

In consideration of the following reasons:

the water from the Yangtze River estuary has a high content of SS, which is easy

to settle down as the flow slows down in inland rivers;

surface runoff resulting from rainstorm often carries out large amount of sediment

into rivers, causing deposition; and

falling leaves from the trees and other plants along rivers, and water discharged

from farmland come to river courses, so that sediment with large quantity of

30

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

organic matters settle down to deposition;

therefore, the river courses in rural area have to be regulated every few years

(clean-up work included). Otherwise, they would be silted up, seriously affecting the

basic functions of the river courses, such as flood control and drainage, irrigation of

farmland and others. Meanwhile, river mud dredged is a good organic fertilizer. In the

Chinese countryside, there is a fine tradition that every winter there is usually a period

of time arranged for irrigation work, including dredging of small and medium rivers

in the rural area. In so doing, on one hand, the river courses are dredged through, and

on the other hand, the dredged mud can be used for agricultural purpose. For example,

the river mud is often used in winter wheat field, to be dried in cold weather to cover

wheat seedling, thus protecting the seedling and improving the farmland soil. In

addition, the dredged mud serves as an outer layer of isolation for outdoor livestock

manure and green manure anaerobic compositing. Therefore, this river dredging

project fundamentally aims to enlarge wetted cross-section of river courses for

smooth flow, increase the water storage capacity, and enhance the basic functions of

river, such as flood control and drainage, irrigation of farmland, etc, as well as some

help for improvement of river water quality.

(4) Project Description

The project consists of the following two aspects:

A. To form river network wetland by means of eco-restoration to restore functions of

river network wetland.

This part includes 3 aspects: base repair, construction of vegetation buffer zone and

connection of river system.

Basement Repair

Base repair mainly refer to dredge exist rivers. This project of river dredging and

widening is to achieve the following objectives:

- to maintain the wetland function of the original river courses as far as possible,

including reeds;

- to strengthen river dikes, improve soil and water conservation capacity of river

bank, so as to conform with the requirements of stability of river side slope, and

decrease silting-up resulting from collapse;

- to build a various-wide bed configuration structure as appropriate with deep

pools and shallow beaches, instead of a unification of river bed configuration,

so as to provide a variety of ecological environment for zoobenthos.

The design standard of the river substrate restoration works are as follows:

Ratio of River to Slope

According to geological data and based on the overall stability of the slope of the river,

the ratio of river to slope is set to 1:2.0. Because rivers on the site are relatively small

31

Environmental Impact Assessment on GEF Shanghai Agricultural and Non-point Pollution Reduction Project

ones, construction will generally be carried out under water cut-off.

Standard of Flood Drainage: